Shenglu SL1.2KuSC-B User manual

1

1.2m Offset VSAT antenna

For Ku band

TYPE: SL1.2KuSC-B

Installation, Operation and

Maintenance Manual

Guangdong Shenglu Telecommunication Tech. Co., Ltd.

NO.4 Jinye 2nd Road, Sanshui, Foshan, Guangdong, China www.shenglu.com

528100

Contents

1. Summary

2

2. Specification of the antenna

3. Installation, operation and maintenance of the antenna

4. The structural figures

1. Summary

The 1.2 m off-set satellite communication antenna is the leading production of

my corporation, which adopts of totally molding production, advanced

3

technology, superior manufacture, and with ascendant performance index. This

production has spacious market demand all the world. The antenna is mostly

composed of the pedestal mount, reflector, back support strut, elevation

adjusting lead screw, feed strut, feed bracket, feed OMT and so on. ( refer to

the figure ).

1.1 Pedestal mount

The antenna adopt the kingpost structure, which is composed of kingpost (φ76

steel tube), rib plate (used to fix the foundation),supporting parts in the

middle and basement in the top. The pedestal can be unloaded, installed simply

and carried conveniently.

Azimuth adjusting mechanism adopt double half- rotation and lock

structure .The center of the top of the pedestal mount is fixed by anchor

bolts ,which would be adjusted conveniently, locked reliably, and have strong

capability of wind-loading.

Elevation adjusting mechanism and locking mechanism are special and proper.

The locking mould is press into arc. In any elevation angle, the anchor nut can

stick flexibility to the locking mould ,which make it have the high adjusting and

locking character.

Compare with similar production, our pedestal mount has the high intensity,

stability, wind loading and adjusting capability.

1.2 The reflector of the antenna.

Main reflector with high precision ( σ≤0.4mm) adopt the high quality

anti-rust alloy aluminum which is stretch-formed once .The edge of the reflector

is rolled repetitious ,which enhances the strength of reflector ;The main

reflector adopting the square tube structure is fixed onto the rolling position

with the 2 pieces feed struts, which bears the accuracy of position and

convenience of installation, and can guarantee the electric capability completely.

To guarantee the strength of the whole reflector , the supporting

struts(adjustable up and down ) are install between the feed strut and

kingpost .Compare with the similar product ,the reflector bears high strength

4

and surface precision character.

1.3 Surface coating of antenna

The antenna as one unit using outdoor, the environmental condition is severe,

so the surface must be dealt with electrostatic spraying. The steel structure

dealing with dacromet bears anti-rust and long lifetime.

2. The specification of antenna

C-Band Ku-Band

◆R.F SPECIFICATIONS RECEIVE TRANSMIT RECEIVE TRANSMIT

1. Frequency(GHz) 3.625-4.2 5.85-6.425 12.25-12.75 14-14.5

3.4-4.2 ★5.85-6.725 ★10.95-12.75 ★13.75-14.5 ★

2. Typical Gain(dBi) 32.03 at

F=3.8GHz

35.68 at

F=6.0GHz

42.05 at

F=12.5GHz

42.84 at

F=14.25GHz

3. VSWR 1.25:1 1.25:1 1.25:1 1.25:1

4. Beamwidth (-3dB) 4.11° 2.70° 1.30° 1.18°

5. Antenna Noise Temperature(°K) 2Port Feed 2Port Feed

10°Elevation 38K 44K

20°Elevation 31K 39K

40°Elevation 25K 35K

6. Typical G/T at 20°EL 13.8dB/K (4.0GHz,30K LNA) 20.4dB/K (11.725GHz, 70K LNA)

7. Power Handling Capability 5KW/Port 1KW/Port

8. Feed Interface CPR-229 CPR-137 WR-75 WR-75

9. Feed Insertion Loss 0.2dB 0.15dB 0.25dB 0.2dB

10. Tx to Rx Isolation ≥85dB ≥85dB

11. Cross Pol Isolation

On Axis ≥35dB ≥35dB

12. Sidelobes CCIR.580-5 CCIR.580-5

◆MECHANICAL SPECIFICATION ENVIRONMENTAL SPECIFICATION◆

1. Antenna Type Offset 1. Wind Loading, Operational (Maintain

Precision) 45 mph(72km/h)

2. Drive Type Manual 2. Wind Loading, Operational (Decrease

Precision) 60 mph(97km/h)

3. AZ Travel 0 to 360° 3. Wind Loading, Survival (Fixed

Heavenward)

125

mph(200km/h)

4. EL Travel 10° to 90° 4. Ambient Temperature -40°C to 60°C

5. POL Travel ±90° 5. Rain 100mm/h

6. Reflector Material Precision formed

aluminum 6. Relative Humidity 0 to 100%

5

7. Relfector Segments 1 7. Solar Radiation 360 BTU/h/ft2 (1000Kcal/h/m2)

8. Mount Type Pole mount 8. Ice 25mm on all surface or 13mm on all

surface with 130km/h wind gusts

9. Surface Accuracy 0.5mm(R.M.S) 9. Shock and

Vibration

As encountered during shipment by

commercial air, sea or truck

10. Seismic(Survival) 0.3G’s horizontal, 0.15G‘s vertical

Design and specifications subject to change without notice.

3. Operation and maintenance of antenna

3.1 Loosening the connecting bolts of feed clip slightly, adjust the feed

focus and polarization angle to the proper angle .

3.2 Loosening clip bolts of the half of the kingpost , rotate the bolts of elevation

lead screw up and down , elongate and shorten the length of elevation

lead screw to the angle coincident with the satellite’s , then, rotate the clip

bolts of half of kingpost .

3.3. Loosening the fastening bolts of bracket and kingpost, rotate azimuth to

the angle of the satellite needed.

3.4. According to the singles, re-adjust the azimuth, the elevation angle, the

position of feed and polarization angle continuously to gain the best signals.

At this time, pointing the satellite is successful , then , fasten all the loosen

bolts .

3.5. The antenna should be inspected and maintenance periodically after using,

which can guarantee the operation capability and prolong the lifetime.

3.6. Fastener should be inspected per 2 to 3 month in normal condition, Replace

promptly the fastener with the same specification if damaged or brush off.

Especially, before and after severe weather .

3.7. Surface coating should be inspected periodically , re-paint the damage

position promptly

3.8. After the severe weather, clear the accumulation of the antenna surface

( such as sand , dust , snow and so on )

4. The structural figures

6

13

111

12

13

14

15

16

1

1

1

1

10

1

4

10

2

2

1

1

1

1

1

1

9

8

7

6

5

4

3

2

1

1100

12

14

15

16

8

9

7

6

5

4

11

3

2

1

17

17

Components and accessories

S eri al No Title Qty Re mark Se ria l N o Ti tle Qt y Rem ark

Kin gpo st

Half

Rib pl ate

Azi mut h B rac ket

Elevation lead screw

Panel

Ea rin g

Feed strut

F eed st rut

Pedestal mount strut

Fe ed bra cke t

Fee d c lip

feed

OMT

f oun dat ion

Fi ne ad ju st ing m ec han is m

fas ten er

Ma nua l

Cer tif icat ion of qua lit y

1s et

1s et

1b ag

1c opy

1c opy

according to user's foundation condition

B ack su ppo rt

Structure figure of antenna

7

Pedestal mount installation

A-A

(connect half and

kingpost and kingpost

strut)

M8×25bolt、nut

flat washer、lock washer

pedestalmounttube

1. Re quir ement of t he g round fou ndati on : the a ntenn a ne ed to be insta llati on o n a o pen groun d not les s tha n 22 squar e me ters

,i n th e cen ter of wh ich i s th e fou ndat ion o f ant enna faci ng t oward s th e sky with out any o bstr uctio n . The fou ndati on of

ant enna shou ld b e con firme d ac cordi ng t o use r's f ield situ atio n . If the a nten na is ins talle d on the groun d ,a conc rete

fou ndat ion n ot l ess t han 6 0sho uld b e ca st fo r the ant enna . If t he an tenna is insta lled on t he to p of buil ding s or the

cem ent groun d ,t hat i nstal lati on mu st b e ver y fir m .

2. F aste ner t he fo ur p ieces of rib p late s in the h omol ogous pos ition of k ingp ost w ith M8× 95 b olts ,nuts fla t was her ,and

spr ing washe r .

3. Wa rp t he do uble half on t he b ody o f ki ngpos t, pu t on the clam ping bolt M10× 25( keep ing s crew not tight en t empor aril y ),

and ins tall anot her s ide o f do uble half over the pede stal moun t str ut w ith t he M8 ×2 0 bol ts .

4. Wr ap t he br acket on the k ingp ost , fast en th e cla mpin g bol t M8 ×20 and fast en th e ce nter of b racke t wit h th e M8× 25 bolt s .

5. In sert elev ation adj ustin g le ad sc rew in th e slo tted hole ; f asten resp ecti vely up a nd do wn wi th a M16 nut and f lat

was her .

6. Cl ip t he ha lf of azi muth fine adju stme nt (t wo ha lves ) on the pede stal moun t Usi ng M 8×2 5 bo lts, besid e , conne ct t he

lea d sc rew o f fi ne ad justm ent with base ment and t he h alf o f az imuth fin e adj ustme nt.

7. Li ftin g the king post aim at t he ri b pl ate h ole a nd f ounda tion bolt ,fas ten with bolt s ,fl at wa sher ,and spr ing w asher to

mak e su re th e ki ngpos t be fixe d ver tica lly .

M8×20bolt,nut

flat washer、lock washer

M10×25bolt、nut

flat washer、lock washer

kingpost strut

half

kingpost

kingpost

fine adjusting mechanism

azimuth bracket

elevation lead screw

arc washer

M16bolt

M8×25bolt

flat washer、lock washer

Half

rib plate

A

A

8

Antenna installation

fee d cli p

feedbracket

feed strut

panel

M8×20bolt

flatwasher、lockwasher

Fe ed s tru t

M 10× 6 0bo lt

nu t、 fl at wa sh er、 l oc k w as her

M6×12bolt

was he r

fee d str ut

M6 × 12 bol t

washer

1.In the two sides of the reflector radial beam , connect the connecting earing with M6×45 bolt to the radial

beam .

2.Connect the reflector and kingpost .Connect the connecting earing and bracket with M10×25 bolts ,connect the

elevation lead screw and radial beam with M10×60 bolts .

3.Connect one head of feed strut to the panel and radial beam with M8×16 bolts ,and the head to the feed clip

with M8×10 bolts .

4.Connect one head both of the two feed strut of the feed to the radial beam in the two sides of the reflector

with M6×12 bolts ,and the other head to the two sides of feed bracket with M8×10 bolts.

5.Move the double half to the right position ,connect kingpost strut to the radial beam with M8×60 bolt, and

fasten double half of the kingpost with the clamping M10×25 bolt 。

co nne ct in g p la te

(c onn ec t the f eed s tru t and b ac k s up por t and

r efl ec to r s up por t)

bac k su ppo rt

f eed s tru t

M6× 4 0b olt

nu t、 f lat e was he r、 lo ck wa sh er

back support

reflectorsupport

9

A- A

1:2

feed installation

feed

fe ed cl ip

M8×20bolt

f lat w as her 、 loc k was he r

f eed b rac ke t

(connect the feed strut and feed bracket and

feed clip and feed)

1.Install the feed and OMT as the fig ure ,and using feed clip to fasten the feed with

M8×20 bolts .

OMT

Feedclip

f eed

fe ed b rac ke t

Table of contents

Popular Satellite TV System manuals by other brands

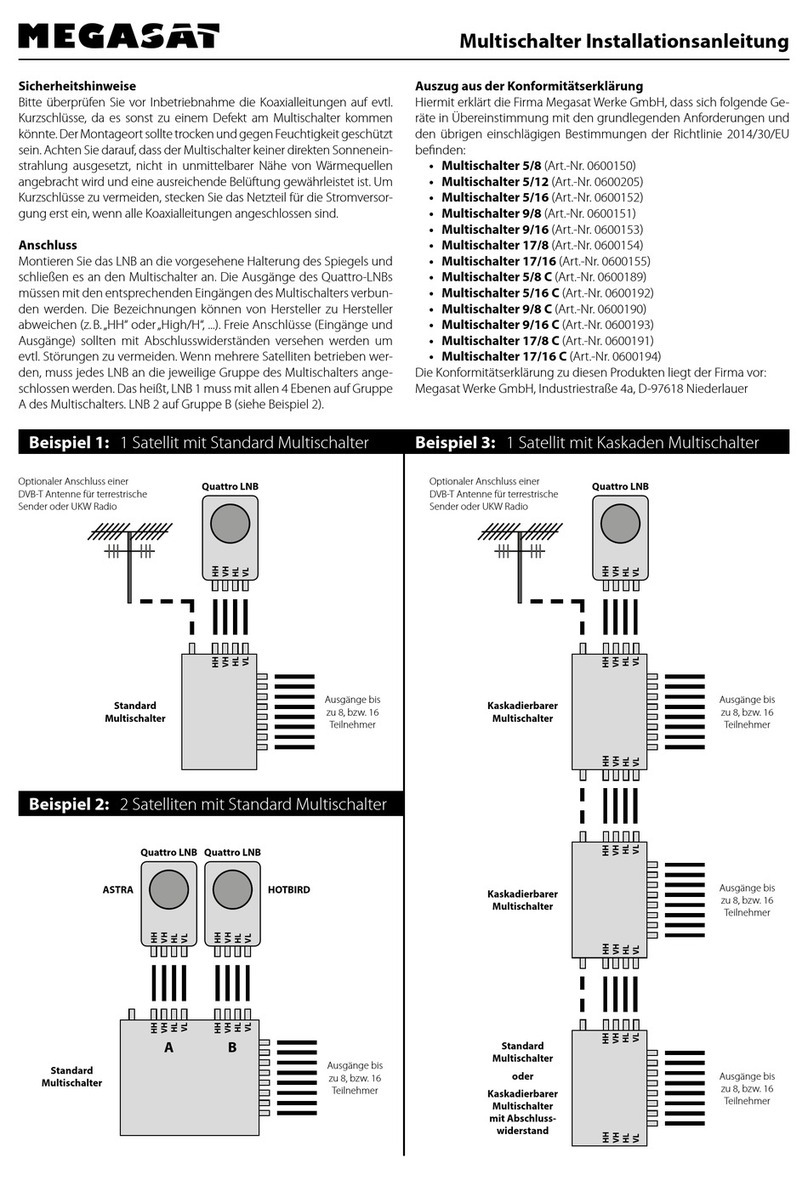

Megasat

Megasat Multiswitch Series Installation instruction

Philips

Philips STU 904 Instructions for use

Dish TV

Dish TV DVB-S6800PLUS Operation manual

Avermedia

Avermedia AVer3D R889 quick guide

Kathrein

Kathrein MobiSet 2 Digital CAP 600 Installation and operating manual

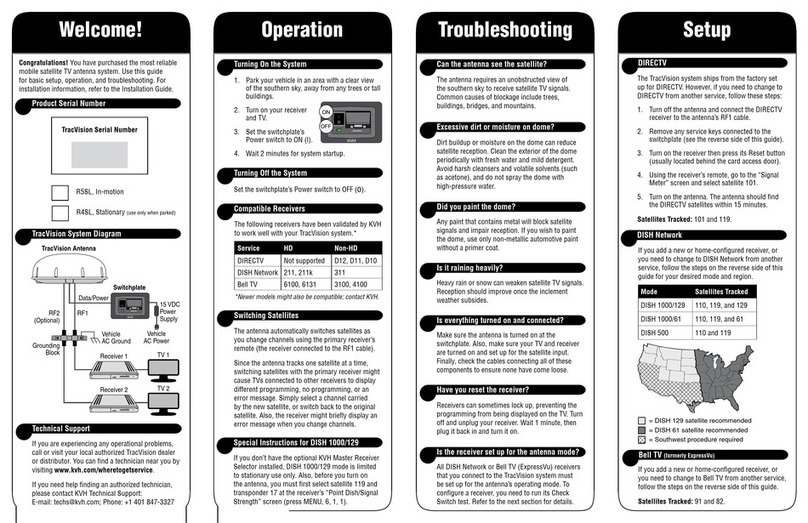

KVH Industries

KVH Industries TracVision R5SL user guide