SHENZHEN LANDO TECHNICAL INDUSTRIAL LD-0.5HP Mounting instructions

Compression-type Water Chiller Use Manual

Dear Customer:

Product Specification

1.Energy conservation, adopt the most efficient compressor cooling system.

2.Unique design of casing heat exchanger efficiency heat transfer, high

cooling efficiency.

3.Pure titanium cooling water circulation system, corrosion resistance,

fresh water, sea water can be used.

4. Intelligent temperature control system, with a variety of control and

protection functions, convenient operation, accurate temperature.

5. Bass design, machine is running, from 1.5 meter outside almost no noise.

SHENZHEN LANDO TECHNICAL INDUSTRIAL CO.,LTD

Technology Parameter

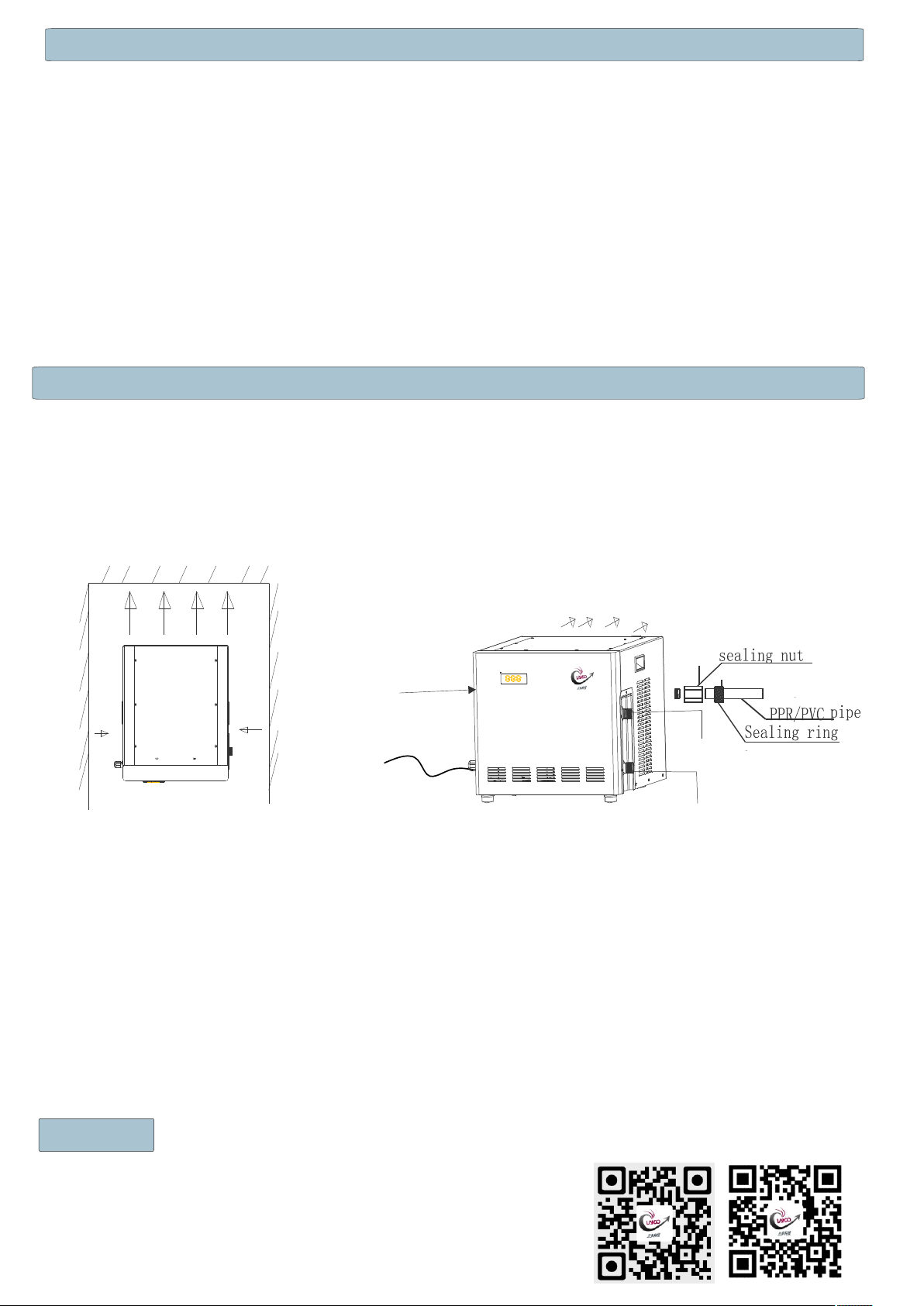

1. The installation of the chiller must comply with the safety precautions and warnings .The unit must be used with a

circulating system and a filtering system . As outlined bellow

Aquarium or reservoir – filtering systems or filter – water pump – inlet or chiller / warmer – outlet of chiller / warmer –

aquarium / reservoir .

Installation Operation

2. The ground or frame of the chiller must be firm and flat, free from uneven or sloping surfaces.

3. Power ground and leakage switch, the power plug must be clean without water, can not be fixed in wet places.

VOLT- #2

CURRENT

HEATING CAPACITY

WEIGHT

POWER

REFRIGERANT

RECOMMENDED TANK SIZE

OUTLET/INLET SIZE

MODEL

COOLING CAPACITY

WATER FLOW

1

Note: The Test Condition---Ambient Temperature/ Water Inlet Temperature----Winter 20 ℃/15 ℃, Summer 35 ℃/32 ℃

Environmentally Friendly Refrigerant:R134A R407C R410A ;The Power Supply is 110-120V/60Hz,220-240V/50Hz.

Thanks for using our product compression

chiller. Please read the manual before using

the product. If you have some questions,

Please contact the dealer or us.

The compression chiller is for fish tank/aquarium,

hydroponic tank,cool equipment, laser cooler, liquid cooling system etc.

VOLT-1#

CURRENT

UNIT SIZE

220-240V/50Hz

0.5HP(550W)

R22/R410A

500L-700L

32kg

2.2A-2.5A

Φ25

LD-0.5HP

1600W

>2500L/H

1800W

110-120V/60Hz

4.4 5A- .5A

49X38X39CM

220-240V/50Hz

1.0 8HP( 50W)

R22/R410A

800L-1100L

3 kg6

4.2 4 7A- . A

Φ32

LD-1.0HP

2600W

>3500L/H

2800W

110-120V/60Hz

8.2 9 5A- . A

54X38X41CM

220-240V/50Hz

1 12.5HP( 50W)

R22/R410A

1200L-1600L

45kg

5.2 5A- .5A

Φ32

LD-1.5HP

3600W

>4000L/H

3800W

110-120V/60Hz

10.0 11 2A- . A

52X54X47CM

Circuit Diagram

Chiller Separate Configuration Pumps,

Pump Head Must Be Controlled Within 8 M.

Installation of the chiller must comply with all

safety precautions and warnings.

Unit must be used with a filtering system and

circulating pump as shown:

Line Control Panel

outlet

inlet

water pump

filtering system / filter

Dimensions diagram:

1 2 3 4 5 6 7 8 9 10 1 1 1 2

TE M PER A TUR E C ONT R OLL E R

FAN

CO MP R E S SO R

CAPACITOR

M

CAPACITOR

SW I TC H

POWE R P LUG

COOLING WIRING DIAGRAM

AC CONTACTOR

1 2 3 4 5 6 7 8 9 10 1 1 1 2

TE M PER A TUR E C O NT R O LL E R

FAN

CO M PR ESS OR

CA PA C IT OR

M

CA PA CI T O R

POWE R P LUG

AC CON T A C TO R

wat e r

sensor

wa t e r

se n s o r

Frost

sensor

VA L VE CO IL

蓝蓝

蓝

蓝

蓝

蓝

红红

红

黑黑

红

白

蓝蓝

蓝

蓝

蓝

蓝

蓝

红

红

红

红

白

黑黑蓝

红

SWITCH

CO OLI NG /HE AT ING

WI RIN G DI AGR AM

cooling control panel

SET

UP KE Y

DOW N K E Y

Def r o st ke y

cool/warm control panel

2

WATER TEMPERATURE

SET W A T ER TE M P ERA T U RE

UP KE Y

DOW N K E Y

RESERVOIR/AQUARIUM

WL

H

22

LENGTH

HEIGHT

MODEL

WIDTH

382

370

LD-0.5HP/0.75HP

492

382

413

LD-1.0HP

542

518

470

LD-1.5HP

542

Long distance control mode,

Line length can be set.

Operational Control

Intelligent temperature controller with more perfect control system,

control the time delay of compressor, fan and on/off, defrosting

temperature into the Settings, defrosting quit. the temperature of the

cooling and heating operation process by time and temperature of double

protection self-checking overheat detection, sensor self-inspection (E1

said sensor fault line), the operation is simple, powerful.

After the machine power on, open the switch, panel auto-matically detect

probe the relationship between temperature and set temperature, etermine

the machine cooling or heating mode (the machine is only cooling, and

standby mode).

When the water temperature is greater than the set temper-ature more

than 2 °C/°F, the machine start delay cooling mode operation after three

minutes. When the water temperature is less than the set temperature

below 2 °C/°F, the machine start delay heating mode operation after three

minutes. When the water temperature and set temperature within 2 °C/°F,

standby the machine.

Temperature once set, the parameters are stored, if not reset, the machine

has been operating and stop to set temperature.

The chiller has power failure memory function. Call again after the

blackout, still in accordance with the mode of the original machine.

The chiller has the compressor delay start protection function. Stop after

restarting, if the downtime is less than 3 minutes, automatic control system

delay to meet 3 minutes after the restart.

See illustration on the control panel 1~2.

Press and hold the SET into the function of temperature setting,

adjusted by “▲”key or “▼”key until conform to the requirements of the

owner.

Stop the operation (don't press any keys) for 10 seconds, automatically

converted to digital tube display temperature, set up effective.

3

1. In order to ensure safety, please place the machine in aquatic animals or other liquid

does not splash into place, in order to avoid leakage of dangerous.

2. Please place the machine where the children not easy contact, lest the children play and

accidental damage.

3. The operation of the machine need ventilation cooling. Machines placed must keep

enough space, therefore, generally The direction of the wind at no less than 30 cm and The

direction of the exhaust air of not less than 50 cm.

4. In order to prevent the machine from the water circulation pipeline jam, please on the

inlet side of the machine assembly filtering device or series filter barrels outside the

cylinder.

5. Please use hard hose or tube wall thickness, not easy to winding soft hose as machines

in and out of the water pipe, In order to prevent the water pipe is blocked and the

refrigerating capacity of the machine impact or not refrigeration.

6. Please check whether the power supply voltage before starting the conform to the

requirements of the machine parameters, Open the water cycle system, and make sure the

normal operation of water flow.

7. Please regular cleaning machine(Generally should not be more than a month),Ensure

machine ventilation cooling, prevent the dust adhesion caused by leakage phenomenon.

8. If you don't use machine for a long time, please empty your machine internal moisture,

and clean, Placed in ventilated dry place, make sure the next can normal use.

Email: sales@cnlando.com

Web: www.lando-chillers.com www.cnlando.com

Mobile: 0086-15814051508

Contacts

1. Machine normal use for a long time, If it is found that the capacity

significantly less or without refrigeration, should consider whether or not

the refrigerant quantity is not enough, Please sent to professional

maintenance and repair, and infuse the right amount of the same

refrigerant(R22 or R410a).

2.Use for a long time, if the air temperature or water temperature is too high,

poor ventilation dust accumulation make machines could cause compressor

protective stop working, At this time should be cut off power supply, clean

machine and strengthen the ventilation and heat dissipation, which can be

restored to normal work.

Maintenance

Common Faults Scheduling

4

dist a n c e i n to the w i n d >3 0 c m

dist a n c e o f t he blo w >5 0 c m

water inlet

water outlet

Air switch

≥50cm

≥30cm

≥30cm

≥30cm

This manual suits for next models

2

Popular Chiller manuals by other brands

Carrier

Carrier 30AJ Installation, operation and maintenance manual

CIAT

CIAT LJ 65/75 manual

S&A

S&A CWFL-3000 user manual

Carrier

Carrier 19DG Start up & operation manual

AERMEC

AERMEC NRV 0550 Installation and maintenance manual

lancer

lancer Hi-Carb Superchiller S2H Installation, operation & service manual