1

CONTENTS

PRODUCT.......................................................................................................................................2

1 MODELS LIST ....................................................................................................................2

2 NOMENCLATURE .............................................................................................................2

3 FUNCTION ..........................................................................................................................3

4 PRODUCT DATA ................................................................................................................4

4.1 Product Data at Rated Condition.................................................................................4

4.2 Operation Range..........................................................................................................5

4.3 Electric Data................................................................................................................5

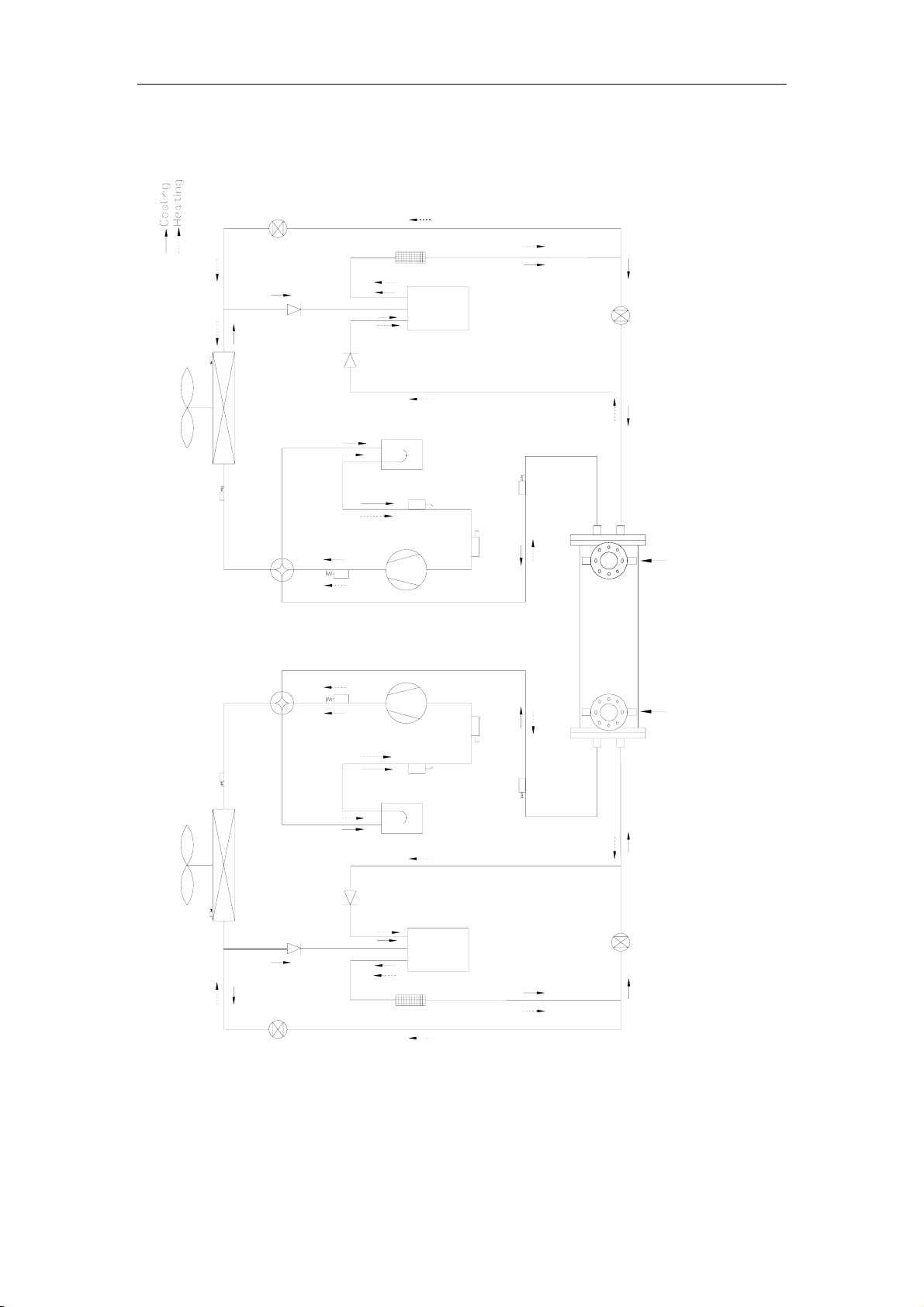

5 PIPING DIAGRAM.............................................................................................................6

5.1 Cooling Only...............................................................................................................6

5.2 Heat Pump...................................................................................................................7

CONTROL ......................................................................................................................................9

1 OPERATION FLOWCHART ............................................................................................9

1.1 Cooling Operation.......................................................................................................9

1.2 Heating Operation .....................................................................................................10

2 MAIN LOGIC ....................................................................................................................11

2.1 Cooling Mode............................................................................................................11

2.2 Heating Mode(Defrosting/ Auxiliary Electric Heater(E-heater)).........................12

2.3 Antifreezing Protection Control ................................................................................14

2.4 Control of 4-Way Valve.............................................................................................14

2.5 Control of Water Pump..............................................................................................14

3 WIRED REMOTE CONTROLLER................................................................................14

3.1 Function ....................................................................................................................14

3.2 Operation View .........................................................................................................14

3.3 Display View.............................................................................................................16

3.4 Menu Structure of Controller ....................................................................................17

3.5 Sketch map of DIP switch.........................................................................................18

INSTALLATION...........................................................................................................................20

1 BEFORE INSTALLATION ..............................................................................................20

2 INSTALLATION SITE......................................................................................................20

3 CAUTIONS FOR INSTALLATION ................................................................................20

4 MACHINE FOOTPRINT .................................................................................................20

5 DIMENSION DATA ..........................................................................................................22

6 INSTALLATION CLEARANCE DATA..........................................................................22

7 TYPICAL WATER PIPING DIAGRAM .........................................................................23

8 ANTIFREEZE....................................................................................................................24

9 ELECTRIC WIRING WORK ..........................................................................................24

9.1 Wiring Principle ........................................................................................................24

9.2 Electric Wiring Design..............................................................................................26

9.3 Wiring Diagram.........................................................................................................28

MAINTENANCE ..........................................................................................................................32