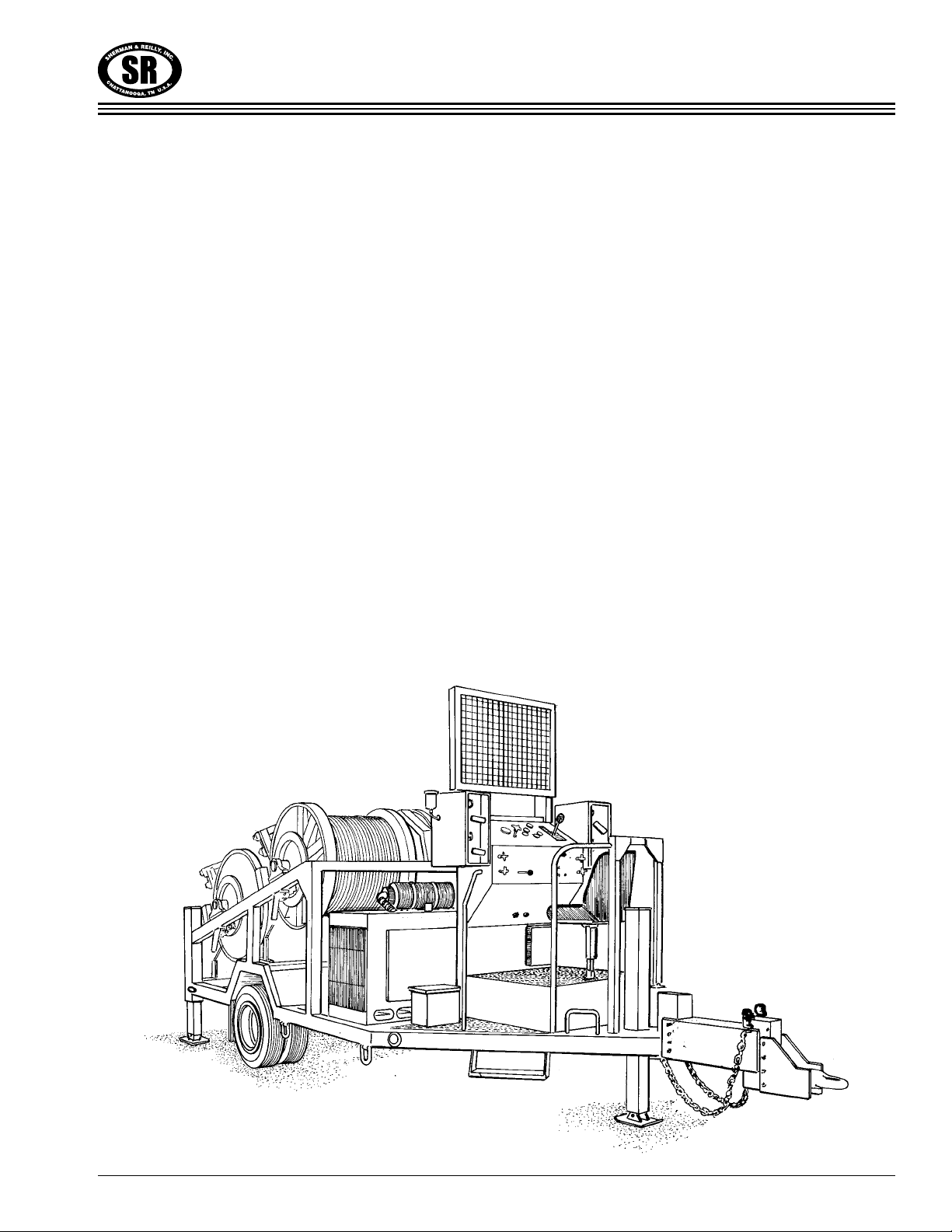

Sherman + Reilly PLW-250-4-T Guide

Pilot Line/

Drum Puller

• Operation

• Service

• Parts

SHERMAN & REILLY, INC.

P.O. Box 11267 •400 West 33rd Street

Chattanooga, TN 37401 USA

Phone 423•756•5300

Fax No. 423•756•2948

Toll-Free 800•251•7780

Web Site www.sherman-reilly.com

© Copyright December 2, 2010 Sherman & Reilly, Inc.

I

TABLE OF CONTENTS

Section 1 • INTRODUCTION

Important Information . . . . . . . . . . . . . . . 1.1

Specifications .....................1.2

Section 2 • SAFETY

WarningTerms ....................2.1

Operator Safety Precautions . . . . . . . . . . 2.1

Employer Safety Requirements . . . . . . . . 2.3

Section 3 • OPERATION

Description of Operating Controls . . . . . 3.1

Terms You Need To Know. . . . . . . . . . . . 3.5

Pre-Operation Inspection . . . . . . . . . . . . 3.7

Towing.......................... 3.8

Reel Drive Coupling Shifter. . . . . . . . . . . 3.9

Filling the Pulling Reel . . . . . . . . . . . . . . 3.9

Emergency/Parking Brake . . . . . . . . . . . 3.10

Emergency While Pulling . . . . . . . . . . . 3.10

Payout Overspin Brake . . . . . . . . . . . . . 3.10

Pulling..........................3.11

LevelWinding....................3.14

JumpStarting.....................3.15

Section 4 • SERVICE

eneralService....................4.1

Important Information . . . . . . . . . . . . . . . 4.1

Safety Precautions . . . . . . . . . . . . . . . . . . 4.2

Hydraulic System . . . . . . . . . . . . . . . . . . 4.3

Engine...........................4.3

Service Requirements

Daily.........................4.4

Weekly .......................4.4

Semi-Annual ...................4.5

Reel and Pillow Block Bearings. . . . . . . . 4.5

PayoutBrake......................4.5

Chain and Sprocket. . . . . . . . . . . . . . . . . 4.5

Section 5 • TROUBLESHOOTING

Engine Will Not Start or Run. . . . . . . . . . 5.1

Reel Will Not Turn. . . . . . . . . . . . . . . . . . 5.1

Reel Does Not Stop When Control

Lever is Shifted To Neutral . . . . . . . . . 5.1

Front Jack Creeps Down . . . . . . . . . . . . . 5.1

Unit Will Not Build Maximum

Hydraulic System Pressure. . . . . . . . . 5.1

Hydraulic Fluid Temperature is High. . . . 5.1

Engine Electrical Schematic (Diesel) . . . . 5.2

Air Plumbing Diagram (ABS Air Brakes) . 5.3

ABS Air Brakes Wiring Diagram . . . . . . . 5.4

Trailer Wiring Diagram . . . . . . . . . . . . . . 5.5

Hydraulic Hoses & Fittings Schematic. . . 5.6

Section 6 • PARTS

Operator’s Seat & Miscellaneous. . . . . . . 6.1

Trailer Components. . . . . . . . . . . . . . . . . 6.2

Pump Assembly. . . . . . . . . . . . . . . . . . . . 6.4

Hydraulic Tank . . . . . . . . . . . . . . . . . . . . 6.5

Controls. . . . . . . . . . . . . . . . . . . . . . . . . . 6.6

Operating Controls . . . . . . . . . . . . . . . . . 6.7

Cross Relief Valve Assembly Controls . . . 6.8

Hydraulic Jack Assembly (Optional) . . . . 6.9

Engine and Components . . . . . . . . . . . . 6.10

Drive Assembly . . . . . . . . . . . . . . . . . . . 6.11

Reef Shaft Assembly . . . . . . . . . . . . . . . 6.12

Shifter/Braker Assembly. . . . . . . . . . . . . 6.13

Levelwind Assembly (Current). . . . . . . . 6.14

Miscellaneous . . . . . . . . . . . . . . . . . . . . 6.16

Trailer Lighting . . . . . . . . . . . . . . . . . . . 6.17

Axle............................6.18

Wheel Hub Assembly . . . . . . . . . . . . . . 6.19

Air Brake Assembly . . . . . . . . . . . . . . . . 6.20

Shifter/Brake Asesmbly (Older Models) . 6.21

Levelwind Assembly (Older Models). . . 6.22

Reel Shaft Assembly (Older Models) . . . 6.24

December 2, 2010

II

TABLE OF CONTENTS

1.1

Section 1 • INTRODUCTION

IMPORTANT INFORMATION

It is very important to all of us at Sherman &

Reilly that every machine is operated in a safe

manner. We have taken every precaution to

guard against the possibility of an accident. To

properly, safely operate this machine, it is neces-

sary and important that operators and service

people read and understand the information in

this and the engine manufacturer’s manual.

ANYONE working around the machine should

read the safety precautions in the manuals. Be

aware each warning and precaution is to help

protect against needless injury. Taking unneces-

sary risks and ignoring warnings is the primary

cause of personal injury and fatal accidents in

the work place. If you have any questions regard-

ing operation or safety of a procedure or situa-

tion, contact the Sherman & Reilly Customer

Service Manager at 1-800-251-7780.

The Sherman & Reilly Model PLW-250/300 Pilot

Line/Drum Puller is a gas or diesel engine pow-

ered, hydraulically operated trailer or skid

mounted machine. It is designed to pull one, two

three or four conductors simultaneously. Each

reel has infinitely variable speed and line tension

control. This manual was prepared to help the

operator use and service the machine in a safe

manner. Responsibility for safety during opera-

tion and service rests with the person(s) doing the

work. Be alert, observe, and practice all safety

measures, including OSHA requirements and

ANSI standards, to help prevent the possibility of

an accident.

This manual is of no value if the operator does

not read and understand the instructions and

precautions (before starting and trying to operate

the machine). The operator must be

aware of the machine’s capacities

and limitations. It is the operator’s

responsibility to watch for

situations and conditions which

could affect the normal

performance of the machine and safety in the

work area.

Publication of this manual and the safety pre-

cautions in it does not in any way represent an

all inclusive list. It is the operator’s responsibility

to make sure the machine is operated in accor-

dance with all state and local safety require-

ments and codes, including all applicable OSHA

(Occupational Safety and Health Act) and ANSI

(American National Standards Institute) regulations.

Should a problem or unsafe condition arise,

shut the machine down using the normal shut-

down procedure. In the event of an emergency,

use the emergency stop procedure. Turn igni-

tion key off, then apply emergency/parking

brake. Notify the proper authority or follow your

employer’s prescribed procedure for an emer-

gency situation.

Sherman & Reilly strongly recommends that only

persons literate and understanding the English lan-

guage be considered as operators or service per-

sonnel for the Sherman & Reilly Model PLW-

250/300 Pilot Line/Drum Puller.

1.2

Section 1 • INTRODUCTION

GENERAL SPECIFICATIONS MODEL PLW-250-4-T DRUM PULLER*

Maximum Pulling Capacity (each reel). . . . . . . . . . . . . . . 48,500 In. Lbs. of Torque (2,500 lbs. on Top of Reel

MaximumSpeed ....................................................4MPH(Avg.toFillReel)

Reel Capacity . . . . . . . . . . . . . . . . . . . . . . . Rope Diameter .5" – 11,000 Ft.; Rope Diameter .625" – 7,000 Ft.

Engine ............................................................KubotaDiesel(Standard)

DriveSystem...................................................Hydraulic/ChainandSprocket

Hydraulic System Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Dexron Quality Transmission Fluid

HydraulicReservoir ......................................................35 allonCapacity

Emergency/Parking Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Spring Applied/Hydraulic Pressure Released

Payout (Overspin) Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Caliper/Disc (Hydraulic)

LevelWind.......................................................FourHydraulic(1perReel)

Construction........................................................RectangularSteelTubing

Reel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38.5" Flange x 12.75" Core x 29" Inside Width

Net Weight (without rope) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Approximately 10,250 lbs.

OverallLength .....................................................Approximately17ft.8in.

OverallWidth...........................................................Approximately8ft.

Height to Top of Control Panel (guard down) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Approximately 7 ft. 6 in.

Maximum ross Vehicle Weight Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16,000 lbs.

Axle.............................................................................Single

Suspension.....................................................................LeafType

Tires...............................................................8.25x15Dual(14Ply)

TrailerBrakes.....................................................................Electric

FuelCapacity ..................................................................27 allon

ElectricSystem....................................................................12Volt

Jacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Front: Hydraulic; Rear: Drop Leg and Pin

Towing...............................................................AdjustablePintleEye

SafetyChains/Hooks..................................................................Two

Lights(Tail,Turn,Stop,andClearance)..................................................12Volt

Paint...............................................................SafetyOrangeStandard

GENERAL SPECIFICATIONS MODEL PLW-300-T PILOT LINE WINDER*

Maximum Pulling Capacity (each reel). . . . . . . . . . . . . . . 60,000 In. Lbs. of Torque (3,000 lbs. on Top of Reel

MaximumSpeed...................................................3.5MPH(Avg.toFillReel)

Reel Capacity . . . . . . . . . . . . . . . . . . . . . . . Rope Diameter .5" – 11,000 Ft.; Rope Diameter .625" – 7,000 Ft.

Engine...........................................................................Diesel

DriveSystem...................................................Hydraulic/ChainandSprocket

Emergency/Parking Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Spring Applied/Hydraulic Pressure Released

LevelWind.......................................................FourHydraulic(1perReel)

Net Weight (without rope) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Approximately 12,390 lbs.

OverallLength .........................................................Approximately19ft.

OverallWidth..........................................................Approximately 8ft.

Height to Top of Control Panel (guard down) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Approximately 7 ft. 6 in.

rossVehicleWeightRating......................................................16,700lbs.

rossAxleWeightRating ........................................................15,500lbs.

Suspension.....................................................................LeafType

Tires.................................................................Dual215/75R17.5-H

Trailer Brakes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.25x5, Electric Brake; Optional 12.25x5 Air Brake

Jacks.................................................Front:Hydraulic;Rear:DropLegandPin

SafetyChains/Hooks..................................................................Two

Towing...............................................................AdjustablePintleEye

Lights(Tail,Turn,Stop,andClearance)................................................Standard

Paint...............................................................SafetyOrangeStandard

* Dimensions, weights, capacities are approximate. Manufacturer’s specifications subject to change without notice.

2.1

Section 2 • SAFETY

WARNING TERMS

Signal words in this manual call the operator’s

attention to safety concerns.

The word DANGER indicates the information

relates to a specific immediate hazard which, if

disregarded, will result in severe personal injury

or death.

The word WARNING indicates the information

relates to a specific immediate hazard or unsafe

practice which, if disregarded, could result in

personal injury or death.

The word CAUTION indicates the information

pertains to a potential hazard or unsafe practice

which, if disregarded, may result in minor per-

sonal injury or equipment damage.

The word NOTE indicates the information is

important to the correct operation or mainte-

nance of the machine.

DANGER

WARNING

CAUTION

NOTE

Do not place any part of the body into a poten-

tial pinch point. The machine must be turned

off and locked out in accordance with OSHA

re ulations before attemptin to correct a prob-

lem, workin on the machine, or performin

re ularly scheduled service.

Do not attempt to operate

Sherman & Reilly

equipment without

proper instruction,

including reading and

understanding the manual.

Obey and enforce all warnings including OSHA

requirements and ANSI standards.

Never allow anyone to ride on the unit while it is

being towed.

Always wear proper safety equip-

ment as required by employer.

Never bypass safety switches or

operate equipment with faulty

safety devices.

Be sure all guards and access

covers are secure in place when the machine is

being operated.

Be aware of people in the work area who may be

at risk during operation.

Know all emergency

shutdown procedures.

Do not obstruct controls or

fire extinguisher.

Make sure fire extinguisher

is fully charged.

DANGER

OPERATOR SAFETY PRECAUTIONS

2.2

Section 2 • SAFETY

Never operate equipment while under the influ-

ence of any substance which could impair oper-

ator ability or judgement. This presents a safety

hazard in the work place.

Always use employer approved grounding pro-

cedures when operating the machine.

Do not operate equipment if work ability is

impaired by fatigue, illness, or other causes.

Never operate machine with engine cover

removed.

Never use hands to check for hydraulic system

leaks. Hydraulic fluid escaping under pressure

can cause personal injury.

Avoid contact with pumps, cylinders, hoses,

engine components, and exhaust system.

Do not refuel unit while the engine is running or

hot.

Do not jump start with cable ground connection

directly on the battery.

Keep all body parts, head, and limbs away from

all moving parts.

Refer to the engine manufacturers’ manual for all

safety precautions which relate to engine opera-

tion and service.

Know location and function of all controls,

gauges, instruments, and protective devices.

Never use unit to tow or winch another vehicle.

Never use controls or hoses for hand holds.

Do not climb on machine – use the operation

platform.

Do not exceed unit

specifications and

limitations for weight.

Know where to get help

in the event of an

emergency or injury.

Maximum towing speed is 60 miles per hour for

the PLW-250/300 Pilot Line/Drum Puller Towing

speed may be slower in certain conditions.

Do not make physical contact with rope or cable

as it enters or leaves machine or reel.

To prevent the possibility of electrocution, do

not enter or leave the unit while it is operating

or allow anyone to touch or lean on the

machine when in use.

2.3

Section 2 • SAFETY

This guideline is intended to assist owners/

employers to ensure equipment is serviced and

operated in a safe manner. Each job site may

have additional situations and conditions which

need consideration.

Monitor the operators to be sure they observe

and practice safety procedures and operate the

support equipment as outlined in this manual.

Establish a regular inspection program which

includes malfunction reports, inspection, and

service records. This inspection should cover the

machine condition, adjustment, and ensure all

safeguards are in place and functional.

Make sure that any malfunction or breakdown

that will affect the safe operation of the equip-

ment is properly corrected or repaired before

returning machine to service.

The employer shall provide training and instruc-

tion in safe methods of work before assigning

workers to operate, service, or repair the equip-

ment. A record of training dates, employee

names, and level of training should be main-

tained. Only persons literate and understanding

the English language should be considered to

operate the PLW-250/300.

Employer shall utilize a lock-out/tag-out proce-

dure which complies with part 1910.147 of Title

29 of the Code of Federal Regulations (OSHA).

The procedure will include control of all keys.

The employer will specifically inspect all safety

equipment and protective devices on the equip-

ment to ensure they are not bypassed or dis-

abled. Operation of the equipment will not be

permitted unless all safety devices are functional

and in place. The employer shall meet the appro-

priate protection requirements for the workers.

EMPLOYER SAFETY REQUIREMENTS

2.4

Section 2 • SAFETY

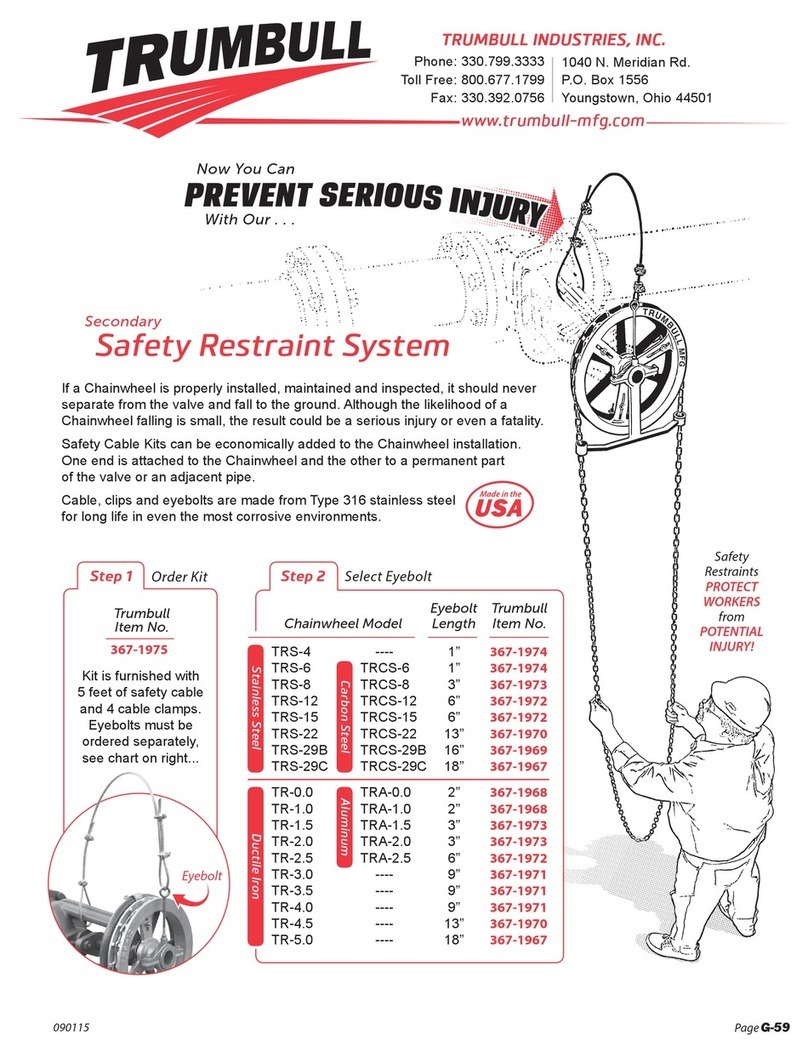

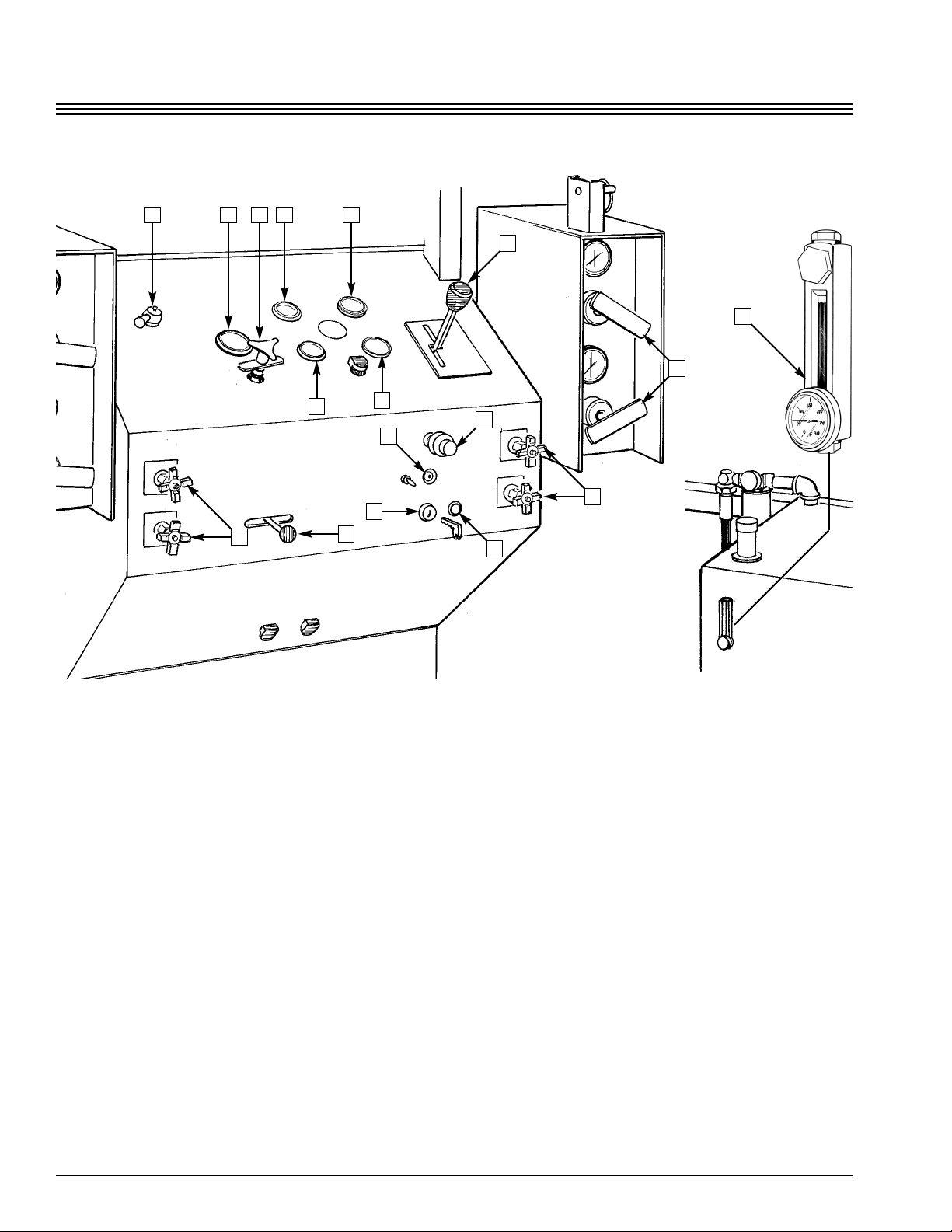

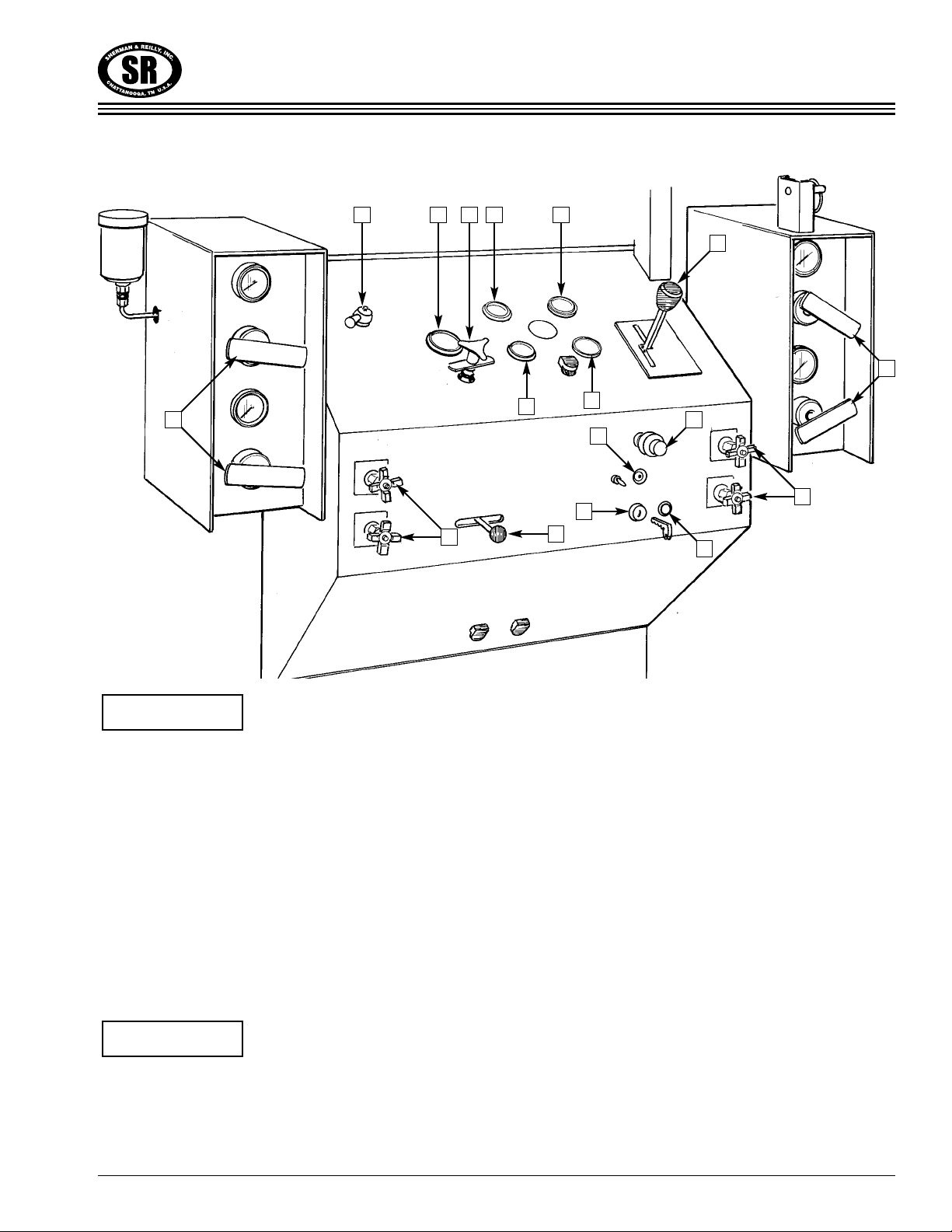

1) Emergency Parking Brake

This two-position control is used to stop the reel

in an emergency situation and for holding the

reel when necessary. The brake must be released

or “off” for the reel to operate. The brake is spring

applied and hydraulic pressure released. The

brake engages automatically when hydraulic

pressure is lost. Parking brake should be applied

when operations have stopped.

Emer ency brake does not function when drive

clutch is disen a ed (each reel has a drive clutch).

2) Glow Lamp

This lamp indicates the preheat level of the glow

plugs.

3) Drive System Pressure Gauge

This 0 to 3000 PSI variable control gauge indi-

cates the existing hydraulic system pressure set-

ting.

4) System Pressure Control (Decrease/Increase

This variable-position control increases and

decreases the hydraulic motor torque. This con-

trol determines how much tension is on the line.

Clockwise rotation increases hydraulic pressure.

Counter-clockwise rotation decreases pressure.

Always leave pressure control knob approxi-

mately three inches counter-clockwise (left) from

panel when the machine is not in use.

CAUTION

3.1

Section 3 • OPERATION

DESCRIPTION OF OPERATING CONTROLS

8

1 3 4 14 13

11 12

5

8

7

10

16

15

76

2

3.2

Section 3 • OPERATION

5) Reel Speed and Direction Control

This control lever determines the direction the

reel will rotate and at what speed from slow to

maximum speed. The farther the lever is moved

from neutral position, the faster the reel turns.

6) Level Wind Control Left/Right/Neutral

This three position lever controls the side move-

ment of the telescoping hydraulic level wind. The

control returns to neutral and movement stops

when the lever is released.

7) Level Wind Speed Control

(Increase/Decrease)

There are four control knobs, one for each Reel/

Level Wind. Each level wind movement speed

is individually set with the specified control.

Turn knobs counter-clockwise (left) to increase

speed and clockwise (right) to decrease speed.

8) Payout Brake Control (Decrease/Increase)

There are four control handles with gauges. Each

reel payout brake can be individually set to the

amount of tension or drag desired. The gauge

indicates the brake pressure in pounds per

square inch (PSI). Rotate handle counter-clock-

wise (left) to decrease pressure/drag and clock-

wise (right) to increase pressure/drag.

9) Hydraulic Oil Level/Temperature Gauge

This gauge displays the fluid level of the

hydraulic tank. It also has a temperature gauge to

indicate oil temperature.

10) Throttle Control

The throttle control is used to set the engine

speed. The red release button must be pushed to

move the control. Pull out to increase speed,

push in to decrease speed.

1 3 4 14 13

11 12

5

8

7

10

16

15

76

2

9

3.3

Section 3 • OPERATION

This is a fine speed adjustment knob. Rotate

clockwise to decrease en ine speed, counter-

clockwise to increase en ine speed.

*Fuel Gauge

This gauge displays the amount of fuel remaining

in the fuel tank (on fuel tank).

*Emergency Cut-Out Button Tattletale Reset

If the engine oil pressure falls too low or coolant

temperature gets too high, the engine will auto-

matically shut down.

The button must be depressed and held until the

en ine oil pressure reaches operatin pressure

when startin .

11) Oil Pressure Gauge

This gauge displays the engine oil lubricating sys-

tem pressure in pounds per square inch (PSI). It

should be checked frequently to ensure the system

is functioning and there is adequate oil in the

engine for lubrication. Should the pressure fluctu-

ate or drop, stop the engine, determine the cause,

and make the necessary repairs. Do not operate

the engine with lower than normal oil pressure.

Doing so could result in engine damage.

12) Engine Temperature Gauge

The temperature gauge registers the engine

coolant temperature. Operating the engine at

the correct temperature will extend service life,

ensure maximum power, and provide better fuel

economy.

13) Voltmeter

The voltmeter measures the charging voltage

with the engine running.

NOTE

NOTE

8

1 3 4 14 13

11 12

5

8

7

10

16

15

76

2

3.4

Section 3 • OPERATION

14) Hourmeter

This gauge registers the number of hours the

engine runs and is useful in keeping accurate ser-

vice records.

15) Ignition Switch Pre-Heat/Off/On/Start

Key operated four-position switch. Used to pre-

heat, start, operation and shut down the engine.

The key can only be removed when the switch

is in the “off” position.

16) Engine Running Light

This light comes on when the key switch is in the

“on” position.

NOTE

8

1 3 4 14 13

11 12

5

8

7

10

16

15

76

2

3.5

Section 3 • OPERATION

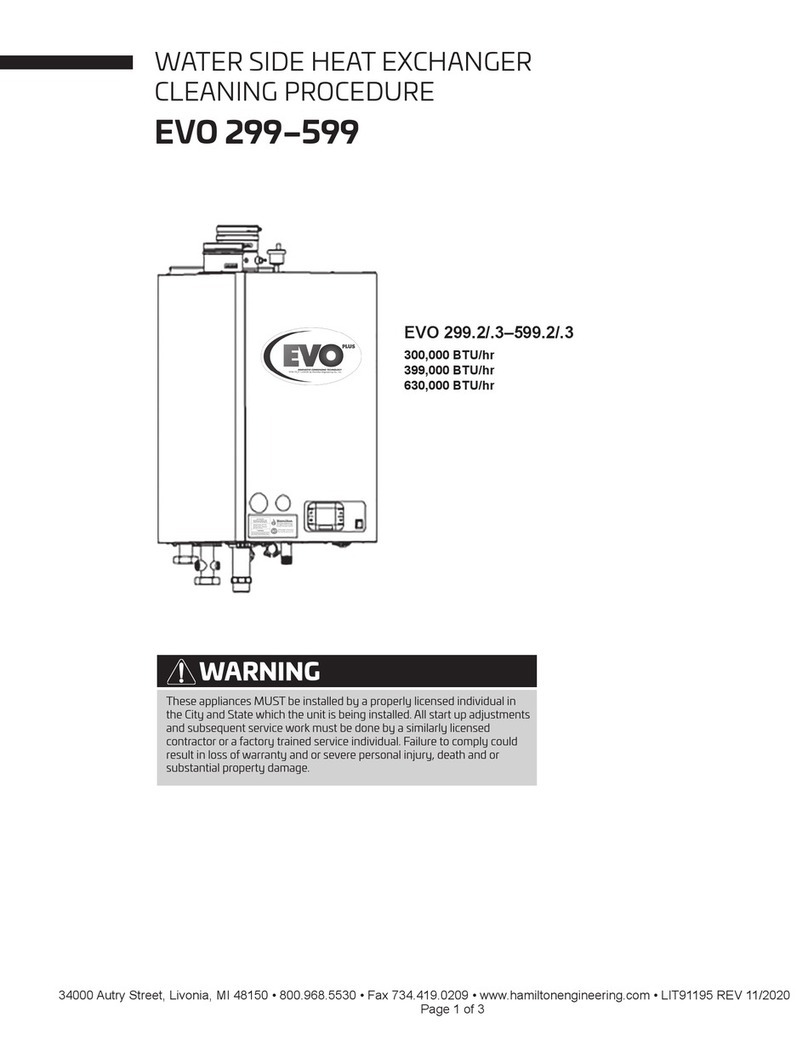

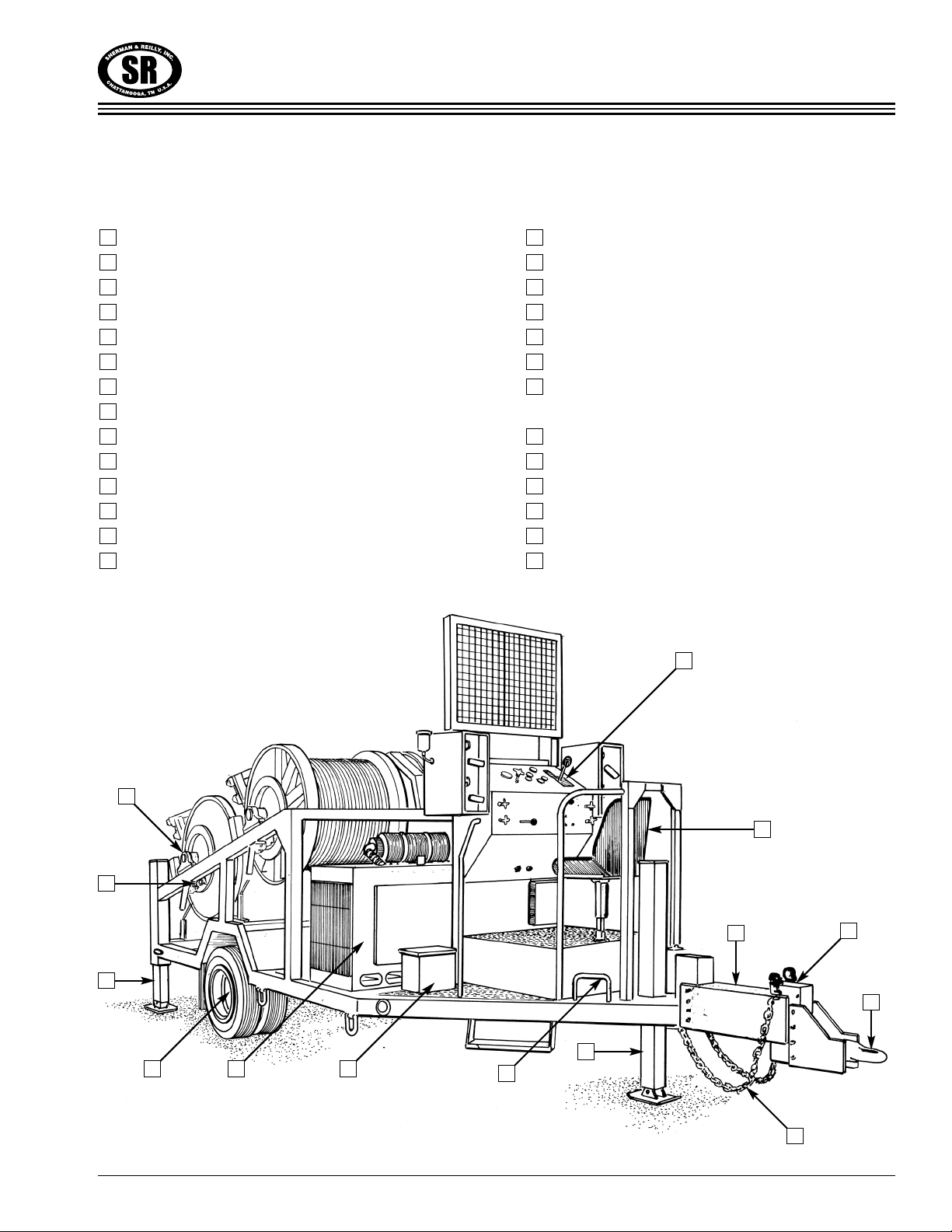

TERMS YOU NEED TO KNOW

Adjustable Pintle Eye

Safety Chains

Breakaway Safety Switch

Rear Hydraulic Jacks

Front Hydraulic Jack

rounding Loop (4 Locations)

Fuel Tank with auge

Operator Seat (Adjustable)

Engine and Cover

Hydraulic Fluid Reservoir

Hydraulic Fluid Level & Temperature auge

Operator Control Console

Reel

Reel Drive Coupling Shifter (4)

Pillow Block Housing

Payout Brake (Disc)

Fire Extinguisher

Drive Chain/Sprockets

Hydraulic Pump

Battery/Case

Hydraulic Drive Motor and

ear Box with Brake

Reel Locking Pins (4)

Axle Hub

Hydraulic Telescoping Level Wind

Suction Filter with auge

Return Filter with auge

Optional Hitch Extension

2714

26

25

24

23

22

21

20

19

18

17

16

15

13

12

11

10

9

8

7

6

5

4

3

2

1

823 20

4

22

15

6

5

7

3

12

1

27

2

3.6

Section 3 • OPERATION

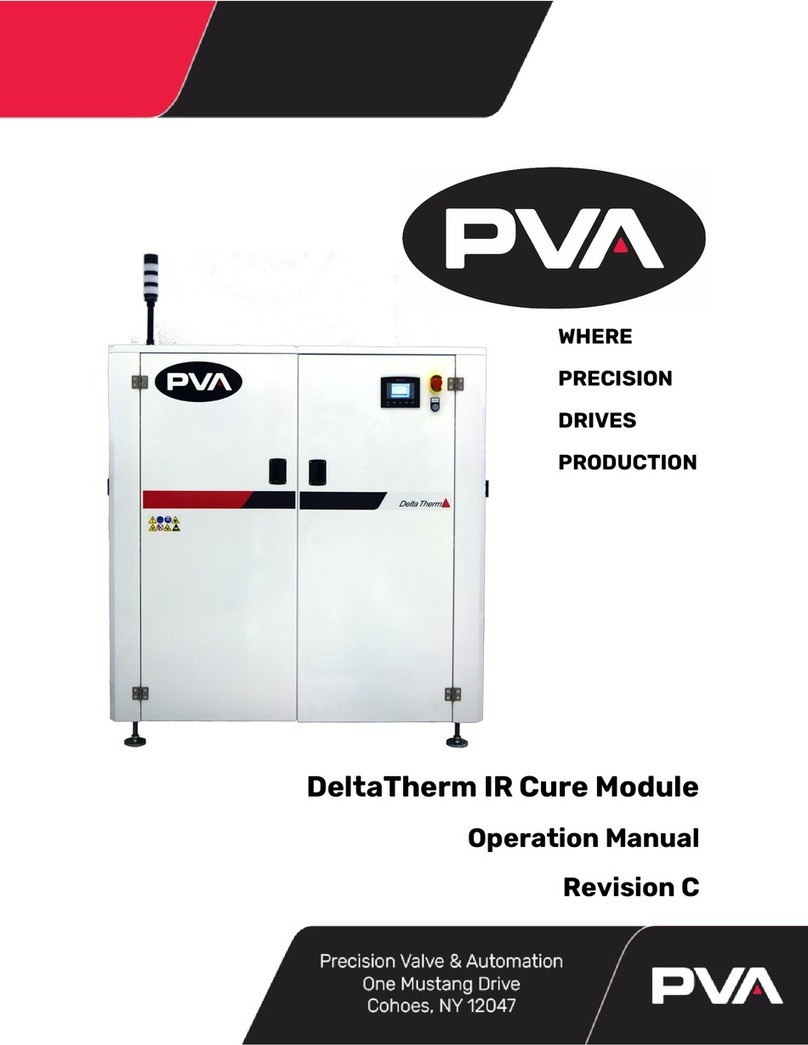

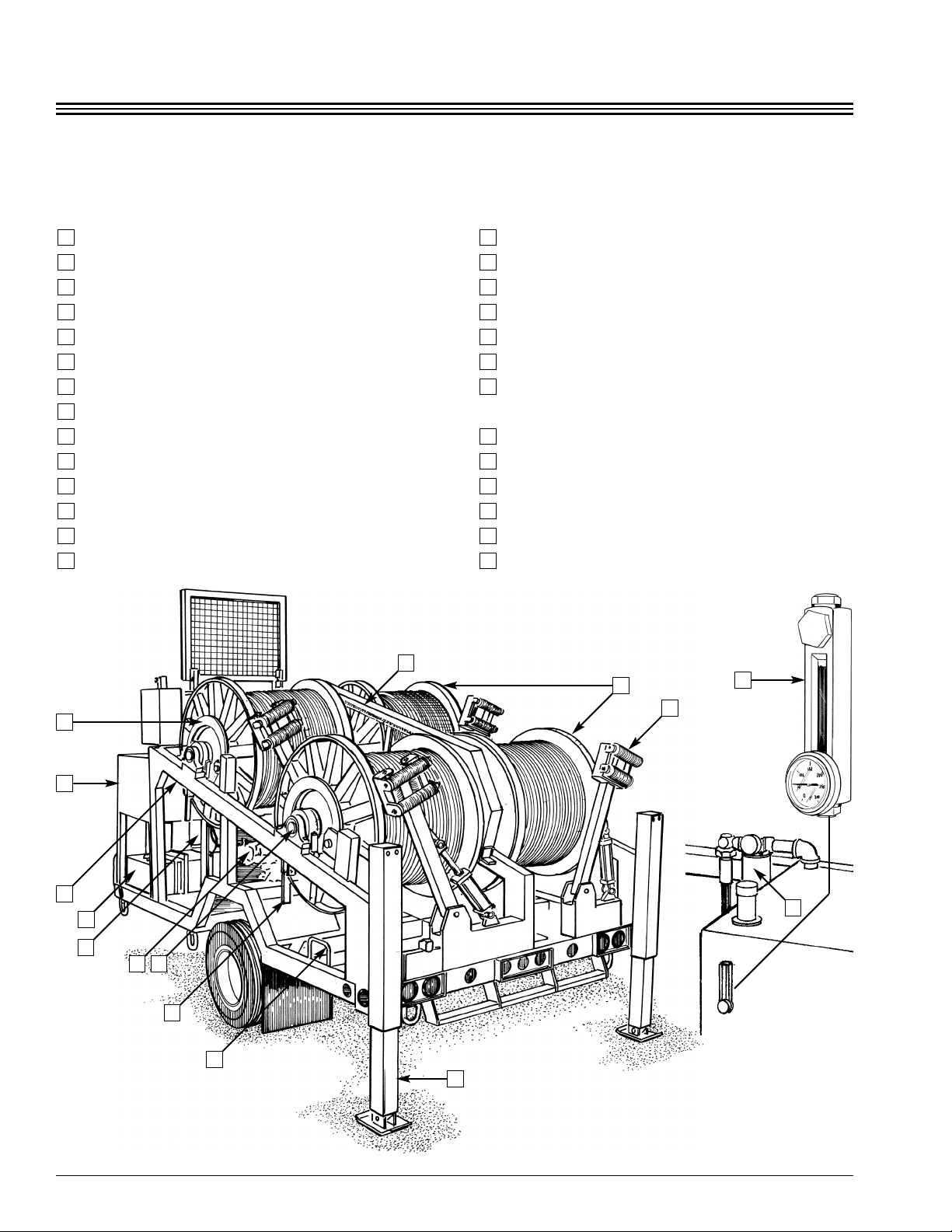

TERMS YOU NEED TO KNOW

Adjustable Pintle Eye

Safety Chains

Breakaway Safety Switch

Rear Hydraulic Jacks

Front Hydraulic Jack

rounding Loop (4 Locations)

Fuel Tank with auge

Operator Seat (Adjustable)

Engine and Cover

Hydraulic Fluid Reservoir

Hydraulic Fluid Level & Temperature auge

Operator Control Console

Reel

Reel Drive Coupling Shifter (4)

Pillow Block Housing

Payout Brake (Disc)

Fire Extinguisher

Drive Chain/Sprockets

Hydraulic Pump

Battery/Case

Hydraulic Drive Motor and

ear Box with Brake

Reel Locking Pins (4)

Axle Hub

Hydraulic Telescoping Level Wind

Suction Filter with auge

Return Filter with auge

Optional Hitch Extension

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

13

4

16

10

7

6

24

11

18

14

15

19

25

22

26

3.7

Section 3 • OPERATION

PRE-OPERATION INSPECTION

It is recommended pre-operation inspection be

done before leavin the yard or ara e.

Check fuel level on tank gauge.

Check engine oil and radiator coolant levels.

It is necessary to remove the en ine cover to

make these checks. Be sure they are replaced

and latched in position properly.

Check hydraulic fluid level in reservoir.

As you continue the inspection, look for struc-

tural dama e, bent or broken parts, cracked or

broken welds, missin pins and retainers.

Inspect pump and hoses for loose fittings,

leaking fluid, damaged hoses.

Inspect drive motor/gear box and brake.

Inspect drive chain for proper lubrication and

excessive wear.

Check chain tension and make sure the chain

guard is secure.

Inspect pillow block bearings on reel shafts (6

locations).

Inspect disc brake assemblies (4 locations).

Check reel locks for damage (4 locations).

Inspect level wind. Make sure the rollers move

freely. Check cylinders and hoses for fluid

leaks. Check for hose damage.

Make sure locking couplings operate correctly

and are not damaged (4 locations).

Start the engine

Start-Up Procedure

•Make sure all controls are in neutral and

parking brake is on.

•Start the engine.

•Refer to en ine manufacturer’s manual for

complete startin instructions.

•

•Never add ETHER to fuel to start cold en ine.

Ether WILL dama e small diesel en ines.

•Check engine oil pressure and ammeter to

be sure everything is working properly.

•Check hydraulic filter indicators (2) to be

sure the filter is serviceable.

•With the engine running, move each control

lever to make sure the lever moves easily

and the function operates correctly.

Shut the engine down.

CAUTION

NOTE

NOTE

NOTE

NOTE

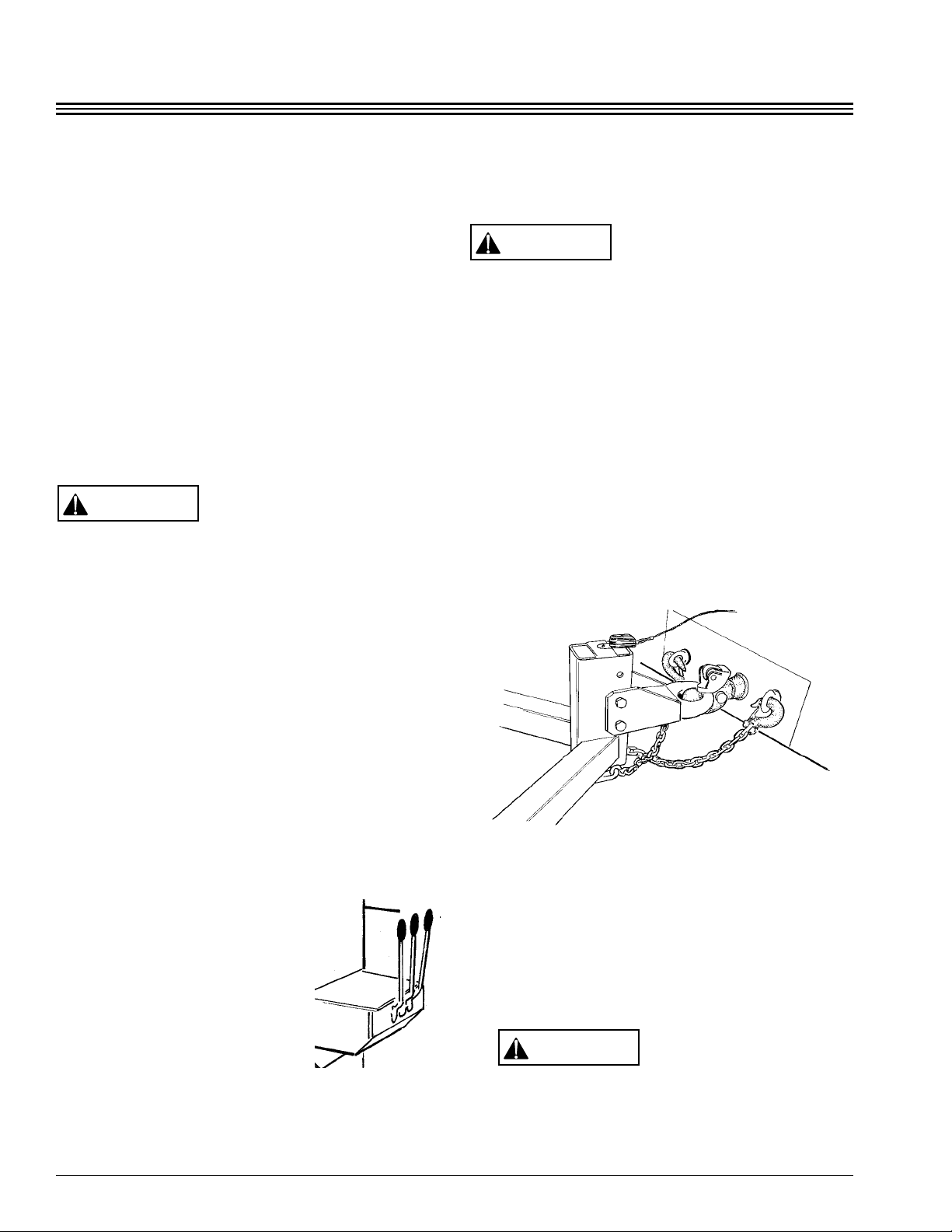

TOWING (Trailer Units Only)

Connecting to the tow vehicle:

Make certain tow vehicle has the capacity and

rating to tow safely.

Inspect pintle eye and safety chains for exces-

sive wear, corrosion, cracked welds or struc-

tural damage.

Inspect tow vehicle hitch and ensure hitch is

serviceable.

Make sure trailer road brakes (air or electric)

are operable.

Do not attempt to tow if there is any question

about the service condition of the safety chains,

hitch or trailer brakes.

Make sure the unit is safe for towing with tires

in good condition and properly inflated.

Make sure reel locks are in lock position (4

locations).

Make sure engine covers securely closed.

Make sure there are no tools, objects, or refuse

which could fall off during transport.

Make sure level wind cylinder rods are retract-

ed (4 locations).

Make sure rear leveling jacks are fully retract-

ed and secured with pins and retainers.

Chock or block wheels on both sides of the

machine.

Start the engine using the

prescribed start-up proce-

dure.

Use the hydraulic jack to

raise or lower the pintle eye

to the correct height for the

tow vehicle hitch.

Open the tow vehicle hitch

and back unit into position under the pintle

eye. Set tow vehicle parking brake.

Close and secure the hitch.

The hitch coupler is a pinch point. Keep hands

and fin ers clear.

Attach the break-away switch cable to the tow

vehicle.

Connect glad hands for air brakes (when

applicable).

Properly connect the safety chains. The safety

chains should be crossed and short enough to

prevent the tongue from digging into the

ground, should the unit unintentionally

become disconnected. The chains should be

no longer than necessary to allow slack for

turning – crossing the chains provides direc-

tional control.

Completely retract front jack, stop engine, and

remove key.

Connect the electrical plug to the tow vehicle

and check:

clearance lights.

brake lights.

turn signals.

brakes.

Do not tow the trailer unless all lights and

brakes are working correctly.

Remove the wheel chocks or blocks.

CAUTION

CAUTION

WARNING

3.8

Section 3 • OPERATION

3.9

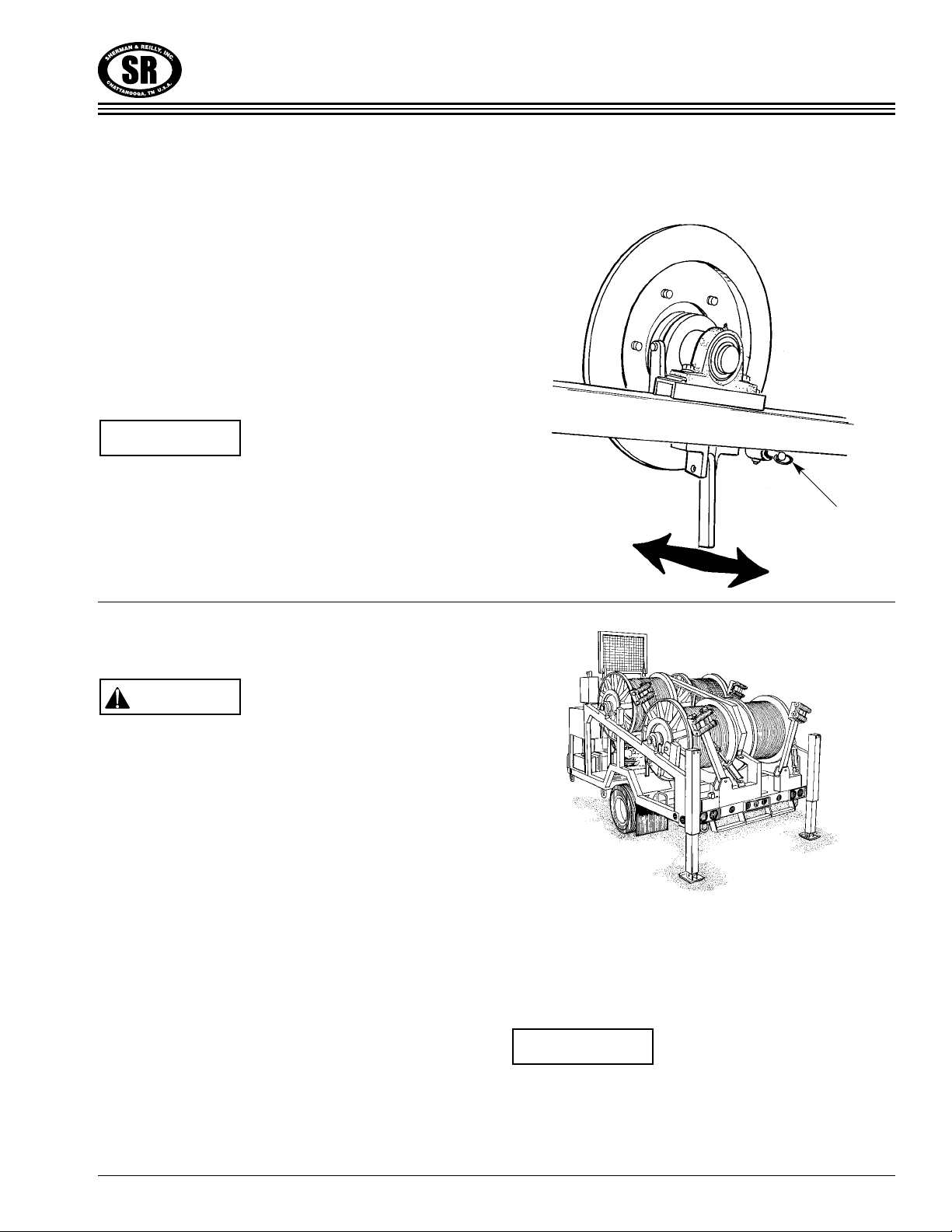

Section 3 • OPERATION

Each reel has a coupling shifter to engage and

disengage the reel. The shifter is located on the

outside of the machine near the payout brake

disc. Each lever is secured by a spring loaded

locking pin. Pull up on the locking pin to release.

For pulling, position the coupling shifter in to

engage; For pay out or free turn, position the

coupling shifter out to disengage.

There is a reel lockin pin which must be

unlatched before the reel will turn in either

direction.

NOTE

FILLING THE PULLING REEL

This unit is desi ned for a MAXIMUM rope

wei ht (not includin the reel) of 1,500 lbs. per

reel. If this wei ht is exceeded there could be

dama e to the shafts, bearin s and frame. The

machine is desi ned for SYNTHETIC PULLING

ROPES and the use of steel pullin lines may

overload the machine. Only synthetic ropes

with low elon ation such as Uniline or Sarlex

braided rope should be used. Ropes with hi h

elon ation or hi h elasticity, such as nylon, may

cause dama e to the pullin reel and should not

be used.

If the pulling reel is filled properly and the

machine is set up and leveled correctly, the

pulling rope will tend to level wind itself.

The unit is designed for overwind reeving; that

is, for the rope to wind on and off the top of the

reel.

Facing the pulling reel with your back to the first

structure, the right hand lay rope should attach to

the right hand reel flange. The left hand lay rope

should attach to the left flange the same way as

the right.

The initial fillin of the reel should be done with

the rope under li ht tension. Care should be

taken to ensure that the rope is initially level

wound on the reel.

NOTE

CAUTION

REEL DRIVE COUPLING SHIFTER

Reel Drive

Coupling Shifter

Reel Locking Pin

EMERGENCY/PARKING BRAKE

The brake is spring applied and released by

hydraulic pressure. The brake holds the gear-

box input shaft which is common to all reels

through the gearbox, chain, sprockets and reel

shafts. The drive coupling for a given reel must

be engaged for the brake to be effective for

that reel.

The brake is operated by the control valve

located on the left side of the control panel.

Push the control lever in to apply the brake

and pull out to release the brake.

Should you lose hydraulic pressure, the brake

will engage automatically.

IF YOU HAVE AN EMERGENCY

WHILE PULLING

Rotate the Emergency Brake Control lever and

simultaneously push the Reel Speed/Dir-

ection Control lever to the “Neutral” (center)

position.

3.10

Section 3 • OPERATION

PAYOUT OVERSPIN BRAKE

Each reel is equipped with a hydraulic operated

disc brake to prevent overspinning when pulling

out the rope. The brakes are mounted on the

trailer frame at the end of each reel. Rotating the

handle on the control panel clockwise increases

the braking force and counterclockwise rotation

decreases the braking force.

Pullin out the line without disen a in the

drive couplin will dama e both the earbox

and hydraulic motor.

CAUTION

Payout Brake Control

Emergency Brake Lever

This manual suits for next models

1

Table of contents

Other Sherman + Reilly Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

SCHUNK

SCHUNK ROTA THWplus Assembly and operating manual

Global

Global SV 550 operating manual

HEIDENHAIN

HEIDENHAIN ND 2100G operating instructions

WEIGH RIGHT

WEIGH RIGHT PMB-801C instruction manual

Endura

Endura 3911A02 Installation, use & care manual

HYDAC FILTER SYSTEMS

HYDAC FILTER SYSTEMS OFU-ATEX Operating and maintenance instructions