Sherman + Reilly PTR-7230 User manual

PTR-7230(S)/7240(S)

Puller Tensioner Reconductorer

Operators Manual

Rev. 0D\ 2015

S+R Revolution Series PTR-7230(S) / PTR-7240(S) Puller Tensioner Reconductorer 2

Table of Contents

6

Section 1: Introduction

6 Liability

7Terms of Use

8

Section 2: Specifications

8 PTR-7230 General Overview and Key Features

9 PTR-7230 Specification Details

10 PTR-7230S General Overview and Key Features

11 PTR-7230S Specification Details

12 PTR-7240 General Overview and Key Features

13 PTR-7240 Specification Details

14 PTR-7240S General Overview and Key Features

15 PTR-7240S Specification Details

16

Section 3: Safety

16 Hazard Overview

16 Safety Warning Terms

17 General Warnings

18 Operator Safety Precautions

19 Employer Safety Precautions

20 Chemical Safety

22

Section 4: Operation

22 Terms You Need to Know- Long Models

24 Terms You Need to Know- Split Models

26 Under the Hood- PTR-7230/7230S

28 Under the Hood- PTR-7240/7240S

30 Safety Zone Cab

32 Operator Controls- [Operator Console]

34 Master Power Key Switch

34 Engine Power Switch

34 Engine Start Button

34 Emergency Stop Button

35 Pull Mode Selection Button

35 Joystick Control

35 Winter/Summer Mode Switch

35 Maintain Speed/”Cruise” Control Button

S+R Revolution Series PTR-7230(S) / PTR-7240(S) Puller Tensioner Reconductorer 3

36 ATS/Tension Mode Selection Button

36 Bullwheel Potentiometer

36 Reel Stand Potentiometer

37 System Control Panel

38 Upper Indicator Bar

39 Lower Control Bar

39 Input Overload Settings Screen

41 Meter Counter Reset Button

41 Error Indicator and Function Screen

42 Information Screen

43 Settings Screen/Button

43 Time Settings Screen/Button

44 Data Settings Screen/Button

45 Data Recording Screen

46 Recording Intervals Screen/Button

47 Additional Settings Screen/Button

47 Service Menu

47 Client Menu

48 Input Cable/Rope Diameter Screen

50 USB Interface

53 Exterior Work Lighting Power Switch

53 Engine Diagnostics Port

53 Windshield Wiper Control Knob

53 Interior Dome Light

54 Hydraulic Control Switches

54 Enable Jacks Switch

54 Jack Controls

56 Drum Roller Control

57 Levelwind

58 Integral Reel Stand/RC3000X

60 Reel Stand Hydraulics

61 External Reel Stand

63 Quick Start Guide

66 Overhead Pulling Swivels and Cable Connections

67 Towing and Road Safety

69 Positioning the Machine

70 Start-Up/Set-Up Procedure

77 Pull Mode

81 Tension Mode

83 Shutdown Procedure

84 Emergency Stop Procedure

86

Section 5: Troubleshooting

86 Quick Tips

87 General Faults

S+R Revolution Series PTR-7230(S) / PTR-7240(S) Puller Tensioner Reconductorer 4

87 Engine Error Codes

89 Machine Control Error Codes

92

Section 6: Maintenance

92 Safety and Reliability Disclaimer

93

Safety

93 Safety Warning Terms

94 General Care and Inspections Instructions

94 Cleaning

94 Fault and Malfunction Detection

95 Hydraulic System

96 Hydraulic System/Hose Inspection

97 Checking Hydraulic Fluid

97 Adding Hydraulic Fluid

98 Replacing Hydraulic Fluid and Filter

100 Hydraulic Hose Replacement

101 Drive Assembly

101 Drive Motors

102 Bullwheels

102 Checking/Adding Bullwheel Gear Oil

104 Changing Bullwheel Gear Oil

104 Greasing Bullwheel Bearings

105 Integral Reel Stand/RC3000X

105 Greasing Reel Shaft Bearings

105 Greasing Reel Shaft Gear

105 Lubricating the Levelwind

106 Checking/Adding Reel Stand Gear Oil

106 Changing Reel Stand Gear Oil

107 Greasing Manual Reel Brake Crank Bearing

107 RC3000X Hydraulic Power Pack

108 Hydraulic Power Engine

109 Arctic Kit

110 Safe-Zone Cab™

110 Inspection of Operators Chair

110 Climate Control System

111 Trailer Assembly

111 Brakes

111 Towing

112 Tires

112 Wheels

113 Axle Drum Oil

114 Trailer Lighting

115 Lighting Replacement

116 Electrical Equipment

117 Pre-Operation Inspection Checklist

S+R Revolution Series PTR-7230(S) / PTR-7240(S) Puller Tensioner Reconductorer 5

120 Post-Operation Inspection Checklist

122 Preventive Maintenance Schedule

125 Torque Ratings for Machine Fasteners

127 Lubrication Chart

128

Section 7: Service & Repair

128 Equipment Information

128 Major Fault Issues

128 When to send for Service or Repair?

130

Section 8: Parts

130 Sherman + Reilly Accessories

130 Miscellaneous Replacement Parts

Appendix A: Manufacturer Manuals

DEUTZ TCD 2013 L06 2V Engine Manual

Caterpillar C9 Engine Manual

Webasto Arctic Kit Timer

Appendix B: Manufacturer Manuals

Honda GX390 Engine Manual

Trailer Axle Manual

Ridewell Trailer Suspension Manual

S+R Revolution Series PTR-7230(S) / PTR-7240(S) Puller Tensioner Reconductorer 6

1

Introduction

Liability

Publication of this manual and the safety precautions in it does not in any way represent an all-

inclusive list. It is the operator’s responsibility to make sure the machine is operated in

accordance with all state and local safety requirements and codes, including all applicable

OSHA- (Occupational Safety and Health Administration) and EPA- (Environmental Protection

Agency) regulations, as well as ANSI- (American National Standards Institute) accredited

standards.

Should a problem or unsafe condition arise, shut the machine down using the normal shut-

down procedure. In the event of an emergency, use the emergency stop procedure described

on page 84 of this manual, and then notify the proper authorities or follow your employer’s

prescribed procedure for an emergency situation.

Sherman+Reilly strongly recommends that only persons who have a full understanding of the

provided manual and who are competent in the use of overhead line pulling and tensioning

machines; to include all applicable laws, regulations, and safety standards, be allowed to

operate this machine. There are significant hazards inherent to the use of this machine;

therefore, all operators should be educated on all functions, procedures, and safety measures

outlined in this manual prior to their use or maintenance of this machine.

S+R Revolution Series PTR-7230(S) / PTR-7240(S) Puller Tensioner Reconductorer 7

Introduction

Terms of Use

It is very important to all of us at Sherman+Reilly that every machine is operated in a safe

manner. We have taken every precaution to guard against the possibility of an accident. To

properly and safely operate this machine, it is necessary that operators and maintenance

personnel read and understand the information in this manual, to include appendixes and

other provided materials.

Anyone working around the machine should also, at a minimum, read the safety precautions

listed in this manual. Be aware of each warning and precaution, as they are designed to help

protect against injury. Taking unnecessary risks and ignoring warnings is usually the primary

cause of personal injury and fatal accidents in the workplace. If you have questions regarding

any operational steps or the safety of a procedure listed in this manual, contact Sherman+Reilly

at 1-800-251-7780 or by email at [email protected].

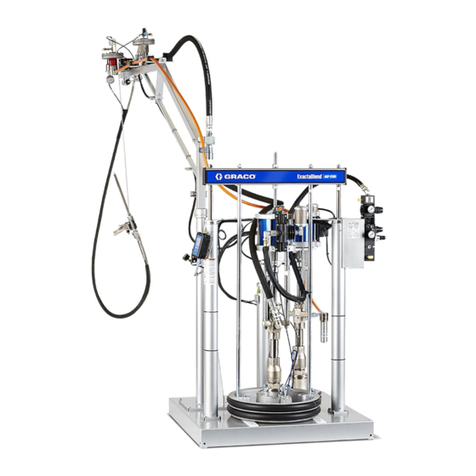

The Sherman+Reilly PTR-Series Puller/Tensioner/Reconductorer are diesel engine powered,

hydraulically actuated machines. This machine has variable speed and line tension controls;

however, if pulling multiple conductors using a running board, the total line tension applied

from all conductors must not exceed the pulling capacity of the machine.

This manual was prepared to help the operator use and service the machine in a safe manner.

Responsibility for safety during operation and service rests with the person(s) performing the

work. Being alert of surroundings and observing all safety precautions, including OSHA, EPA,

and all rating requirements and standards is a must to help reduce the possibility of an

accident. This manual is of no value if the operator does not read and understand the

instructions and precautions- before starting or trying to operate the machine. The operator

must be aware of the machine’s capacities and limitations. It is the operator’s responsibility to

watch for situations and conditions which could affect the normal performance of the machine

and the safety of the operating/work environment.

S+R Revolution Series PTR-7230(S) / PTR-7240(S) Puller Tensioner Reconductorer 8

2

Specifications

PTR-7230

General Overview

The Sherman+Reilly™ Revolution Series PTR-7230 is a puller/tensioner/reconductorer in a single unit

deliv-ering 30,000 lbs. of pulling force and tensions up to 25,000 lbs. With a maximum speed of 4

mph, the 72 inch bullwheels provide constant tension and can handle transmission-class conductors.

The PTR-7230 features a fully electronic, integrated control system for precision application of force to

conductors, and an integrated drum for steel hardline; no separate reel trailer is required.

This machine also allows for synchronized integration of external reel stands. The PTR-7230’s heavy-

duty 5th wheel trailer off ers excellent ground clearance for tackling very rugged terrain. The addition

of a pow-erful 7.1 liter, 268 HP, 6-cylinder diesel engine supplies plenty of power for the large and long

pulls. The operator controls employ PLC machine control with CAN-bus technology, and uses a

removable/replace-able memory card to store all relevant stringing data. The onboard computer

system allows for self-diag-nostics of all hydraulic circuits with results shown on a large color display.

The PTR-7230 features a Safe-Zone™ Cab providing ultimate safety and comfort for the operator. The

Safe-Zone™ Cab employs a poly carbonate front window for maximum visibility while providing

superior protection against impact. The cab includes climate control, a fully adjustable ergonomic

seat, and all required electronic controls and gauges. The Safe-Zone™ Cab is designed to reduce

operator fatigue, and provide an “off -ground” envelope for greatly reducing the risk of “touch

potential” in energized environ-ments.

Key Features

Fully Hydraulic/Direct Drive System

Puller/Tensioner/Reconductor in a single unit.

Safe-Zone™ Cab- Fully Enclosed, w/Climate

Control

72” Bullwheels- Hydraulically Driven

84 in. Rope Reel with Optional 25,000 ft.

(Max)

Unitrex

™

Synthetic Rope

Horizontal Automatic Levelwind/Fairlead

Centralized Engine Controls- CAN-bus

technology

Digital Controls and Self Diagnostics

S+R Revolution Series PTR-7230(S) / PTR-7240(S) Puller Tensioner Reconductorer 9

Specifications

Specifications Details: PTR-7230

(Dimensions, weights, and capacities listed are approximate. All specifications are subject to change without notice.)

Maximum Pulling Capacity 30,000 lbs.

Maximum Tensioning Capacity 25,000 lbs.

Maximum Line Speed Pulling: 4 mph. @ 16,000 lbs. / 2.3 mph @ 30,000 lbs.

Maximum Reconductor Reel Size 112 in. Diameter / 60 in. Width / Contact S+R for Total Weight w/Conductor

Rope Reel Dimensions 84 in. Diameter / 60 in. Width / 3,832 lbs. Weight (Empty)

(Opt.) 112 in. Diameter / 60 in. Width / 5,173 lbs. Weight (Empty)

Rope Reel Capacities .84 in. dia. Unitrex™ / 25,000 ft. on 84 in. Reel / 5,750 lbs. Rope Weight

Hardline Capacity (Maximum) 20 mm. dia. Anti-Twist Steel Cable / 24,250 ft. on 84 in. Reel / 29,102 lbs Total Weight

Bullwheels (2) 72 in. / 8 Groove

Bullwheel Linings 1 3⁄16 in. Groove Radius / Molded Neoprene / Replaceable

Drive System Direct Drive: hydraulic motor, bullwheel

Drive System Engine Turbocharged, diesel, 268 HP, water-cooled

Fuel Capacity 35 U.S. gallon

Hydraulic Fluid ISO Grade 32

Hydraulic Reservoir 20 U.S. gallon

Hydraulic Fluid Filtration (3) 25 microns, two in tank return lters, one pump lter

Tensioning Brake Hydraulic-applied, automatically controlled- per operator settings

Fail-Safe Brake Spring-applied- released by hydraulic pressure

Fairlead Rollers / Levelwind Single, hydraulically driven, automatically controlled, remotely adjustable

Levelwind Hydraulically driven, automatically controlled

Operator’s Safety Enclosure Safe-Zone™ Cab, fully enclosed, dual door, climate controlled

Frame Construction Steel, continuous-weld

Length (Overall, Nom.) 48 ft.

Width (Overall, Nom.) 8 ft., 6 in.

Height (Overall, Nom.) 12 ft., 2 in.

Weight (With Rope, Nom.) Contact S+R

GVWR 63,391 lbs.

Suspension Air Ride

Axle Con guration Tandem

Wheel Con guration and Tires Dual 275/70R 22.5

Brakes (Trailer) Air

Towing Attachment 5th Wheel, 2 in. king pin

Rear (R/L) Jacks (2) Hydraulic, with shoe

Front/Nose Jack (2) Hydraulic, vertical cylinder type, with shoe

Electrical System Split 12/24 VDC

Battery (2) 12 V, 720 CCA, BCI group 93

Lights / Navigation 12 V, LED, U.S. DOT-approved

Tie Downs (2) 1 in. dia. steel D-Rings

Rope Tie-O s (2) 1 in. dia. steel D-Rings

Grounding (6) ¾ in. dia. copper-clad steel loops

Wheel Chocks Standard

Fire Extinguisher ABC

Color S+R White

S+R Revolution Series PTR-7230(S) / PTR-7240(S) Puller Tensioner Reconductorer 10

Specifications

PTR-7230S [Split Model]

General Overview

The Sherman+Reilly™ Revolution Series PTR-7230S- (Split Model) is a bullwheel puller/tensioner/

reconductorer in a paired unit, delivering up to 30,000 lbs. of pulling force and tensions up to 25,000

lbs. With a maximum speed of 4 mph, this Revolution Series PTR’s 72 inch bullwheels provide

constant tension and can handle transmission-class conductors.

The PTR-7230S features a fully-electronic, integrated control system for precision application of force

to con-ductors. This split model PTR comes with a separated reel carrying trailer that includes a

pulling drum designed for synthetic rope or steel hardline. Having a separate reel carrying trailer

provides a reduced equipment foot-print for storage purposes, as well as minimizing operating space

in the fi eld. The PTR is also equipped with an automatic levelwind and an optional reconductoring

reel that can be used in place of the provided rope drum. Additionally, the usage of the reel carrying

trailer can be bypassed altogether for use of external conductor reel stands - all under system control.

The PTR-7230S offers either a heavy-duty 5th wheel king pin hitch or a pintle eye hitch option for

maximum vehicle towing compatibility, providing excellent ground clearance that can handle very

rugged terrain. Also included are a powerful 7.1 liter, 268 HP 6-cylinder diesel engine, PLC machine

control with CAN-bus technol-ogy, a removable/replaceable USB memory card interface for recording

and storage of all relevant stringing data, and complete system self-diagnostics for all hydraulic

circuits shown on the large color display.

The PTR-7230S features a Safe-Zone™ Cab providing ultimate safety and comfort for the operator. The

Safe-Zone™ Cab employs a polycarbonate front window for maximum visibility while providing

superior protection against impact. The cab includes climate control, a fully adjustable ergonomic

seat, and all required electronic controls and gauges. The Safe-Zone™ Cab is designed to reduce

operator fatigue, and provide an “off -ground” envelope for greatly reducing the risk of “touch

potential” in energized environments.

Key Features

Fully Hydraulic/Direct Drive System

Puller/Tensioner/Reconductor in a single unit.

Safe-Zone™ Cab- Fully Enclosed, w/Climate Control

72” Bullwheels- Hydraulically Driven

84 in. Rope Reel with Optional 25,000 ft.

(Max)

Unitrex

™

Synthetic Rope

Horizontal Automatic Levelwind/Fairlead

Centralized Engine Controls- CAN-bus technology

Digital Controls and Self Diagnostics

S+R Revolution Series PTR-7230(S) / PTR-7240(S) Puller Tensioner Reconductorer 11

Specifications

Specifications Details: PTR-7230S [Split Model]

(Dimensions, weights, and capacities listed are approximate. All specifications are subject to change without notice.)

Maximum Pulling Capacity 30,000 lbs.

Maximum Tensioning Capacity 25,000 lbs.

Maximum Line Speed Pulling: 4 mph. @ 16,000 lbs. / 2.3 mph @ 30,000 lbs.

Maximum Reconductor Reel

Size

112 in. Diameter / 60 in. Width / Contact S+R for Total Weight w/Conductor

Rope Reel Dimensions 84 in. Diameter / 60 in. Width / 3,882 lbs. Weight (Empty)

(Opt.) 112 in. Diameter / 60 in. Width / 5,224 lbs. Weight (Empty)

Rope Reel Capacities .84 in. dia. Unitrex™ / 25,000 ft. on 84 in. Reel / 5,750 lbs. Rope Weight

Hardline Capacity (Maximum) 20 mm. dia. Anti-Twist Steel Cable / 24,250 ft. on 84 in. Reel / 29,102 lbs Total Weight

Bullwheels (2) 72 in. / 8 Groove

Bullwheel Linings 1 3⁄16 in. Groove Radius / Molded Neoprene / Replaceable

Drive System Direct Drive: hydraulic motor, bullwheel

Drive System Engine Turbocharged, diesel, 268 HP, water-cooled

Fuel Capacity 35 U.S. gallon

Hydraulic Fluid ISO Grade 32

Hydraulic Reservoir 20 U.S. gallon

Hydraulic Fluid Filtration (3) 25 microns, two in tank return lters, one pump lter

Tensioning Brake Hydraulic-applied, automatically controlled- per operator settings

Fail-Safe Brake Spring-applied- released by hydraulic pressure

Fairlead Rollers / Levelwind Single, hydraulically driven, automatically controlled, remotely adjustable

Levelwind Hydraulically driven, automatically controlled

Operator’s Safety Enclosure Safe-Zone™ Cab, fully enclosed, dual door, climate controlled

Rear (R/L) Jacks (2) Hydraulic, with shoe

Front/Nose Jack (4) Hydraulic, vertical cylinder type, with shoe

Electrical System Split 12/24 VDC

Battery (2) 12 V, 720 CCA, BCI group 93

Lights / Navigation 12 V, LED, U.S. DOT-approved

Wheel Chocks (4) Standard, 2 per trailer

Fire Extinguisher (2) ABC, one per trailer

Color S+R White

Frame Construction Steel, continuous-weld

Reel Trailer Jack Power 13 HP Engine, hydraulic pump/reservoir

PTR-7230S 5th Wheel PTR-7230S Pintle Eye RC3000X Reel Trailer RC2500X Reel Trailer

Length (Overall, Nom.) 34 ft., 6 in. 30 ft., 9 in. 23 ft. 21 ft., 10 in.

Width (Overall, Nom.) 8 ft., 6 in. 8 ft., 6 in. 8 ft., 6 in. 8 ft., 6 in.

Height (Overall, Nom.) 12 ft., 4 in. 11 ft. 9 ft., 10 in. 12 ft., 4 in.

Weight (Nom.) Contact S+R Contact S+R Contact S+R (With Rope) Contact S+R

GVWR Contact S+R 40,000 lbs. 58,527 lbs. 40,000 lbs.

Suspension Air Ride Air Ride Air Ride Air Ride

Axle Con guration Tandem Tandem Tandem Tandem

Wheel Con guration and Tires Dual 275/70R 22.5 Dual 275/70R 22.5 Dual 275/70R 22.5 Dual 275/70R 22.5

Brakes (Trailer) Air Air Air Air

Towing Attachment*5th Wheel 2 in. king pin 3 in. pintle eye 5th Wheel, 2 in. king pin 3 in. pintle eye

Tie Downs (4) (2) 1 in. dia. steel D-Rings (2) 1 in. dia. steel D-Rings (2) 1 in. dia. steel D-Rings (2) 1 in. dia. steel D-Rings

Rope Tie-O s (5) (2) 1 in. dia. steel D-Rings (2) 1 in. dia. steel D-Rings (3) 1 in. dia. steel D-Rings (2) 1 in. dia. steel D-Rings

Grounding (8) (4) ¾ in. dia. copper-clad

steel loops

(4) ¾ in. dia. copper-clad

steel loops

(4) ¾ in. dia. copper-clad

steel loops

(4) ¾ in. dia. copper-clad

steel loops

*Speci cations may alter for pintle eye trailer confi gurations. Contact Sherman + Reilly for more information.

S+R Revolution Series PTR-7230(S) / PTR-7240(S) Puller Tensioner Reconductorer 12

Specifications

PTR-7240 General Overview

The Sherman+Reilly™ Revolution Series PTR-7240 is a puller/tensioner/reconductorer in a single unit

deliv-ering 40,000 lbs. of pulling force and tensions up to 25,000 lbs. With a maximum speed of 4 mph,

the 72” bullwheels provide constant tension and handles transmission-class conductors. The PTR-7240

features a fully electronic, integrated control system for precision application of force to conductors, and

an integrat-ed drum for steel hardline; no separate reel trailer is required.

This machine also allows for synchronized integration of external reel stands. The PTR-7240’s heavy-

duty 5th wheel trailer off ers excellent ground clearance for tackling very rugged terrain. The addition of

a powerful Caterpillar C9 industrial diesel engine supplies plenty of power for the large and long pulls.

The op-erator controls employ PLC machine control with CAN-bus technology, and uses a removable/

replaceable memory card to store all relevant stringing data. The onboard computer system allows for

self-diagnostics of all hydraulic circuits with results shown on a large color display.

The PTR-7240 features a Safe-Zone™ Cab providing ultimate safety and comfort for the operator. The

Safe-Zone™ Cab employs a polycarbonate front window for maximum visibility while providing superior

protection against impact. The cab includes climate control, a fully adjustable ergonomic seat, and all

required electronic controls and gauges. The Safe-Zone™ Cab is designed to reduce operator fatigue,

and provide an “off -ground” envelope for greatly reducing the risk of “touch potential” in energized

environ-ments.

Key Features

Fully Hydraulic/Direct Drive System

Puller/Tensioner/Reconductor in a single unit.

Safe-Zone™ Cab- Fully Enclosed, w/Climate Control

72” Bullwheels- Hydraulically Driven

112 in. Rope Reel with Optional 30,000 ft.

(Max)

Unitrex

™

Synthetic Rope

Horizontal Automatic Levelwind/Fairlead

Centralized Engine Controls- CAN-bus technology

Digital Controls and Self Diagnostics

S+R Revolution Series PTR-7230(S) / PTR-7240(S) Puller Tensioner Reconductorer 13

Specifications

Specifications Details: PTR-7240

(Dimensions, weights, and capacities listed are approximate. All specifications are subject to change without notice.)

Maximum Pulling Capacity 40,000 lbs.

Maximum Tensioning Capacity 25,000 lbs.

Maximum Line Speed Pulling: 4 mph. @ 16,000 lbs. / 2.3 mph @ 30,000 lbs.

Maximum Reconductor Reel Size 112 in. Diameter / 60 in. Width / Contact S+R for Total Weight w/Conductor

Rope Reel Dimensions 112 in. Diameter / 60 in. Width / 5,224 lbs. Weight (Empty)

Rope Reel Capacities 1.15 in. dia. Unitrex™ / 30,000 ft. on 112 in. Reel / 11,880 lbs. Rope Weight

Hardline Capacity (Maximum) 24 mm. dia. Anti-Twist Steel Cable / 20,646 ft. on 112 in. Reel / 29,999 lbs Total Weight

Bullwheels (2) 72 in. / 8 Groove

Bullwheel Linings 1 ⁄ in. Groove Radius / Molded Neoprene / Replaceable

Drive System Direct Drive: hydraulic motor, bullwheel

Drive System Engine Turbocharged, diesel, 268 HP, water-cooled

Fuel Capacity 35 U.S. gallon

Hydraulic Fluid ISO Grade 32

Hydraulic Reservoir 20 U.S. gallon

Hydraulic Fluid Filtration (3) 25 microns, two in tank return lters, one pump lter

Tensioning Brake Hydraulic-applied, automatically controlled- per operator settings

Fail-Safe Brake Spring-applied- released by hydraulic pressure

Fairlead Rollers / Levelwind Single, hydraulically driven, automatically controlled, remotely adjustable

Levelwind Hydraulically driven, automatically controlled

Operator’s Safety Enclosure Safe-Zone™ Cab, fully enclosed, dual door, climate controlled

Frame Construction Steel, continuous-weld

Length (Overall, Nom.) 48 ft.

Width (Overall, Nom.) 8 ft., 6 in.

Height (Overall, Nom.) 12 ft., 2 in.

Weight (With Rope, Nom.) Contact S+R

GVWR Contact S+R

Suspension Air Ride

Axle Conguration Tandem

Wheel Conguration and Tires Dual 275/70R 22.5

Brakes (Trailer) Air

Towing Attachment 5th Wheel, 2 in. king pin

Rear (R/L) Jacks (2) Hydraulic, with shoe

Front/Nose Jack (2) Hydraulic, vertical cylinder type, with shoe

Electrical System Split 12/24 VDC

Battery (2) 12 V, 720 CCA, BCI group 93

Lights / Navigation 12 V, LED, U.S. DOT-approved

Tie Downs (2) 1 in. dia. steel D-Rings

Rope Tie-Os (2) 1 in. dia. steel D-Rings

Grounding (6) ¾ in. dia. copper-clad steel loops

Wheel Chocks Standard

Fire Extinguisher ABC

Color S+R White

S+R Revolution Series PTR-7230(S) / PTR-7240(S) Puller Tensioner Reconductorer 14

Specifications

PTR-7240S [Split Model]

General Overview

The Sherman+Reilly™ Revolution Series PTR-7240S- (Split Model) is a bullwheel puller/tensioner/

reconductorer in a paired unit, delivering up to 40,000 lbs. of pulling force and tensions up to 25,000 lbs.

With a maximum speed of 4 mph, this Revolution Series PTR’s 72” bullwheels provide constant tension

and can handle transmis-sion class conductors.

The PTR-7240S features a fully-electronic, integrated control system for precision application of force to

con-ductors. This split model PTR comes with a separated reel carrying trailer that includes a pulling

drum designed for synthetic rope or steel hardline. Having a separate reel carrying trailer provides a

reduced equipment foot-print for storage purposes, as well as minimizing operating space in the fi eld.

The PTR is also equipped with an automatic levelwind and an optional reconductoring reel that can be

used in place of the provided rope drum. Additionally, the usage of the reel carrying trailer can be

bypassed altogether for use of external conductor reel stands - all under system control.

The PTR-7240S is mounted on a heavy-duty 5th wheel trailer, off ering excellent ground clearance that

can handle very rugged terrain. Also included are a powerful Caterpillar C9 industrial diesel engine, PLC

machine control with CAN-bus technology, a removable/replaceable USB memory card interface for

recording and stor-age of all relevant stringing data, and complete system self-diagnostics for all

hydraulic circuits shown on the large color display.

The PTR-7240S features a Safe-Zone™ Cab providing ultimate safety and comfort for the operator. The

Safe-Zone™ Cab employs a polycarbonate front window for maximum visibility while providing superior

protection against impact. The cab includes climate control, a fully adjustable ergonomic seat, and all

required electronic controls and gauges. The Safe-Zone™ Cab is designed to reduce operator fatigue,

and provide an “off -ground” envelope for greatly reducing the risk of “touch potential” in energized

environments.

Key Features

Fully Hydraulic/Direct Drive System

Puller/Tensioner/Reconductor in a Split Unit

Safe-Zone™ Cab- Fully Enclosed, w/Climate Control

72” Bullwheels- Hydraulically Driven

112 in. Rope Reel with Optional 30,000 ft.

(Max)

Unitrex

™

Synthetic Rope

Horizontal Automatic Levelwind/Fairlead

Centralized Engine Controls- CAN-bus technology

Digital Controls and Self Diagnostics

S+R Revolution Series PTR-7230(S) / PTR-7240(S) Puller Tensioner Reconductorer 15

Specifications

Specifications Details: PTR-7240S [Split Model]

(Dimensions, weights, and capacities listed are approximate. All specifications are subject to change without notice.)

Maximum Pulling Capacity 40,000 lbs.

Maximum Tensioning Capacity 25,000 lbs.

Maximum Line Speed Pulling: 4 mph. @ 16,000 lbs. / 2.3 mph @ 30,000 lbs.

Maximum Reconductor Reel Size 112 in. Diameter / 60 in. Width / Contact S+R for Total Weight w/Conductor

Rope Reel Dimensions 112 in. Diameter / 60 in. Width / 5,224 lbs. Weight (Empty)

Rope Reel Capacities 1.15 in. dia. Unitrex™ / 30,000 ft. on 112 in. Reel / 11,880 lbs. Rope Weight

Hardline Capacity (Maximum) 24 mm. dia. Anti-Twist Steel Cable / 20,646 ft. on 112 in. Reel / 29,999 lbs Total Weight

Bullwheels (2) 72 in. / 8 Groove

Bullwheel Linings 1 / in. Groove Radius / Molded Neoprene / Replaceable

Drive System Direct Drive: hydraulic motor, bullwheel

Drive System Engine Turbocharged, diesel, 268 HP, water-cooled

Fuel Capacity 35 U.S. gallon

Hydraulic Fluid ISO Grade 32

Hydraulic Reservoir 20 U.S. gallon

Hydraulic Fluid Filtration (3) 25 microns, two in tank return lters, one pump lter

Tensioning Brake Hydraulic-applied, automatically controlled- per operator settings

Fail-Safe Brake Spring-applied- released by hydraulic pressure

Fairlead Rollers / Levelwind Single, hydraulically driven, automatically controlled, remotely adjustable

Levelwind Hydraulically driven, automatically controlled

Operator’s Safety Enclosure Safe-Zone™ Cab, fully enclosed, dual door, climate controlled

Rear (R/L) Jacks (2) Hydraulic, with shoe

Front/Nose Jack (4) Hydraulic, vertical cylinder type, with shoe

Electrical System Split 12/24 VDC

Battery (2) 12 V, 720 CCA, BCI group 93

Lights / Navigation 12 V, LED, U.S. DOT-approved

Wheel Chocks (4) Standard, 2 per trailer

Fire Extinguisher (2) ABC, one per trailer

Color S+R White

Frame Construction Steel, continuous-weld

Reel Trailer Jack Power 13 HP Engine, hydraulic pump/reservoir

PTR-7240 Split Trailer RC3000X Reel Trailer

Length (Overall, Nom.) 34 ft., 6 in. 23 ft.

Width (Overall, Nom.) 8 ft., 6 in. 8 ft., 6 in.

Height (Overall, Nom.) 12 ft., 4 in. 9 ft., 10 in.

Weight (Nom.) Contact S+R Contact S+R (With Rope)

GVWR Contact S+R 58,527 lbs.

Suspension Air Ride Air Ride

Axle Conguration Tandem Tandem

Wheel Conguration and Tires Dual 275/70R 22.5 Dual 275/70R 22.5

Brakes (Trailer) Air Air

Towing Attachment 5th Wheel, 2 in. king pin 5th Wheel, 2 in. king pin

Tie Downs (4) (2) 1 in. dia. steel D-Rings (2) 1 in. dia. steel D-Rings

Rope Tie-Os (5) (2) 1 in. dia. steel D-Rings (3) 1 in. dia. steel D-Rings

Grounding (8) (4) ¾ in. dia. copper-clad steel loops (4) ¾ in. dia. copper-clad steel loops

S+R Revolution Series PTR-7230(S) / PTR-7240(S) Puller Tensioner Reconductorer 16

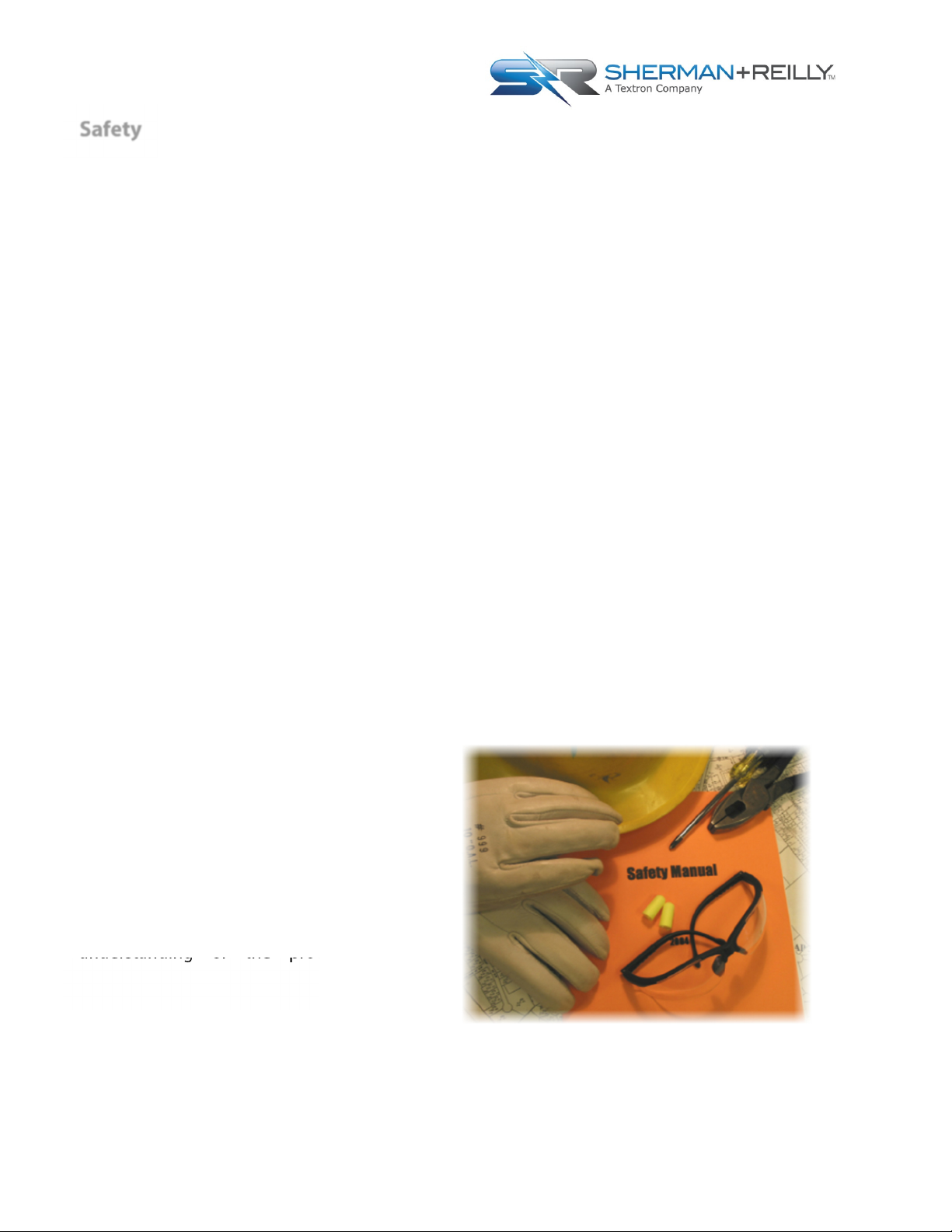

3

Safety

Hazard Overview

Please pay attention to all safety warning labels and information placards posted on the machine,

components, and trailer assembly. These labels and placards are provided to assist in identifying

areas containing potential hazards while also providing information regarding equipment

specification and limitations. Please see below for examples:

Warning Terms:

Are signal words in this manual that call the operator’s attention to safety concerns.

The word

DANGER

indicates the

information relates to a specific

immediate hazard which, if disregarded,

will result in severe personal injury or

death.

The word

WARNING

indicates the

information relates to a specific

immediate hazard or unsafe practice

which, if disregarded, could result in

personal injur

y

or death.

The word

CAUTION

indicates the

information pertains to a potential

hazard or unsafe practice which, if

disregarded, may result in minor

personal injury or equipment damage.

The word

NOTE

indicates the

information is important to the correct

operation or maintenance of the

machine.

S+R Revolution Series PTR-7230(S) / PTR-7240(S) Puller Tensioner Reconductorer 17

Safety

General Warnings

WARNING:

Ear protection should be

worn when operating machines with

operator ear noise levels above 85dB.

WARNING:

California Proposition 65:

Engine exhaust, some of its elements, and

certain vehicle components contain or

emit chemicals known to the State of

California to cause cancer and birth

defects or other reproductive harm.

WARNING:

To prevent serious injury

from hot and high pressure oil, never use

your hands to check for oil leaks; use

paper or cardboard. Hydraulic fluid

escaping under pressure can have

sufficient force to penetrate skin. If fluid

is injected into the skin, it must be

surgically removed within a few hours by

a doctor familiar with this form of injury,

otherwise gangrene may develop.

WARNING:

Batteries produce explosive

gases, contain corrosive acid, and supply

levels of electrical current high enough to

cause burns.

WARNING:

This machine must not be

used as a winch for pulling another

vehicle. For trailer models: this trailer

must not be modified to allow towing of

another trailer behind and in tandem

with this trailer.

S+R Revolution Series PTR-7230(S) / PTR-7240(S) Puller Tensioner Reconductorer 18

Safety

Operator Safety Precautions

Do not place any part of the body into a

potential pinch point. The machine must be

turned off and locked out in accordance with

OSHA regulations before attempting to correct a

problem, work on the machine, or perform

preventive maintenance.

Do not attempt to operate any Sherman+Reilly

equipment without proper instruction,

including reading and understanding the

provided manual.

Obey and enforce all warnings including OSHA

requirements and ANSI standards.

Never allow anyone to ride on the unit while it is

being towed.

Always wear proper safety equipment as

required by employer.

Never bypass safety switches or operate

equipment with faulty safety devices.

Be sure all guards and access covers are in place

and secured when the machine is being

operated.

Be aware of people in the work area who may be

at risk during operation.

Know all emergency shutdown procedures.

Do not obstruct controls or fire extinguisher and

make sure fire extinguisher is fully charged.

Never operate equipment while under the

influence of any substance which could impair

ability or judgment.

Do not operate equipment if work ability is

impaired by fatigue, illness, or other causes.

Always use employer approved grounding

procedures when operating the machine.

Never use hands to check for hydraulic system

leaks. Hydraulic fluid escaping under pressure

can cause personal injury.

Avoid contact with pumps, cylinders, hoses,

engine components, and exhaust system.

Do not refuel unit while the engine is running or

hot.

Keep all body parts, to include head and limbs,

away from all moving parts.

Refer to engine manufacturer’s manual for all

additional safety precautions which relate to

engine operation and service.

Know location and function of all controls,

gauges, instruments, and protective devices.

Never use unit to tow or winch another vehicle.

Never use controls or hoses for hand holds.

Do not exceed unit specifications and

limitations, to include weight.

Know where to get

help in the event of an

emergency or injury.

When towing this machine/unit trailer, the driver

should use caution and adjust speed based on

road, weather, and terrain conditions, as well as

applicable laws and speed limits.

Do not make physical contact with rope or cable

as it enters or leaves the machine or drum.

To prevent the possibility of electrocution, do

not enter or leave the unit while it is operating or

allow anyone to touch or lean on the machine

when in use.

S+R Revolution Series PTR-7230(S) / PTR-7240(S) Puller Tensioner Reconductorer 19

Safety

Employer Safety Precautions

This guideline is intended to assist

owners/employers to ensure equipment is

serviced and operated in a safe manner. Each

job site may have additional situations and

conditions which need consideration.

Monitor the operators to be sure they observe

and practice safety procedures and operate the

support equipment as outlined in this manual.

Establish a regular inspection program which

includes malfunction reports, inspection, and

service records. This inspection should cover

the machine condition, adjustment, and ensure

all safeguards are in place and functional.

Additionally, all pre/post-operation

inspections should be conducted at prescribed

intervals.

Make sure that any malfunction or breakdown

affecting the safe operation of the equipment

is properly corrected or repaired before

returning the machine to service.

The employer shall provide training and

instruction in chemical safety and safe

methods of work before assigning workers to

operate, service, or repair the machine and

equipment. A record of training dates,

employee names, and level of training shall be

maintained. Only persons who have a full

understanding of the provided manual-

(provided in English only)

, and who are competent in

the use of overhead pulling and tensioning

machines; to include all applicable laws,

regulations, and safety standards, should be

allowed to operate this machine. There are

significant hazards inherent to the use of this

machine, therefore all operators should be

educated on all functions, procedures, and

safety measures outlined in this manual- prior

to their use or maintenance of this machine.

Employer shall utilize a lock-out/tag-out

procedure which complies with OSHA

Standard, Part 1910.147, Title 29 of the Code of

Federal Regulations. This procedure must

include control of all keys.

The employer will specifically inspect all safety

equipment and protective devices on the

equipment to ensure they are not bypassed or

disabled. Operation of equipment will not be

permitted unless all safety devices are in place

and functional. The employer shall meet all

appropriate information dissemination and

protection requirements for the workers.

This manual suits for next models

3

Table of contents

Other Sherman + Reilly Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Dongguan Xin Bao Instrument

Dongguan Xin Bao Instrument Transport Simulation Vibration Table Operation manual

GIGAIPC

GIGAIPC QBiX-Pro-BYTA1900HD-A1 quick start guide

BIRD

BIRD TERMALINE 8400 SERIES Instruction book

Calder Brothers

Calder Brothers Mauldin Precision Spray Owner/Operator & Parts Manual

eao

eao BR04 Assembly instruction

Siemens

Siemens Sivacon S8 operating instructions