370B369B407BTable of Contents

328B327B349B Introduction...........................................................................................................5

329B328B366B PVA Contact Information ........................................................................................................5

330B329B367B Document History.....................................................................................................................5

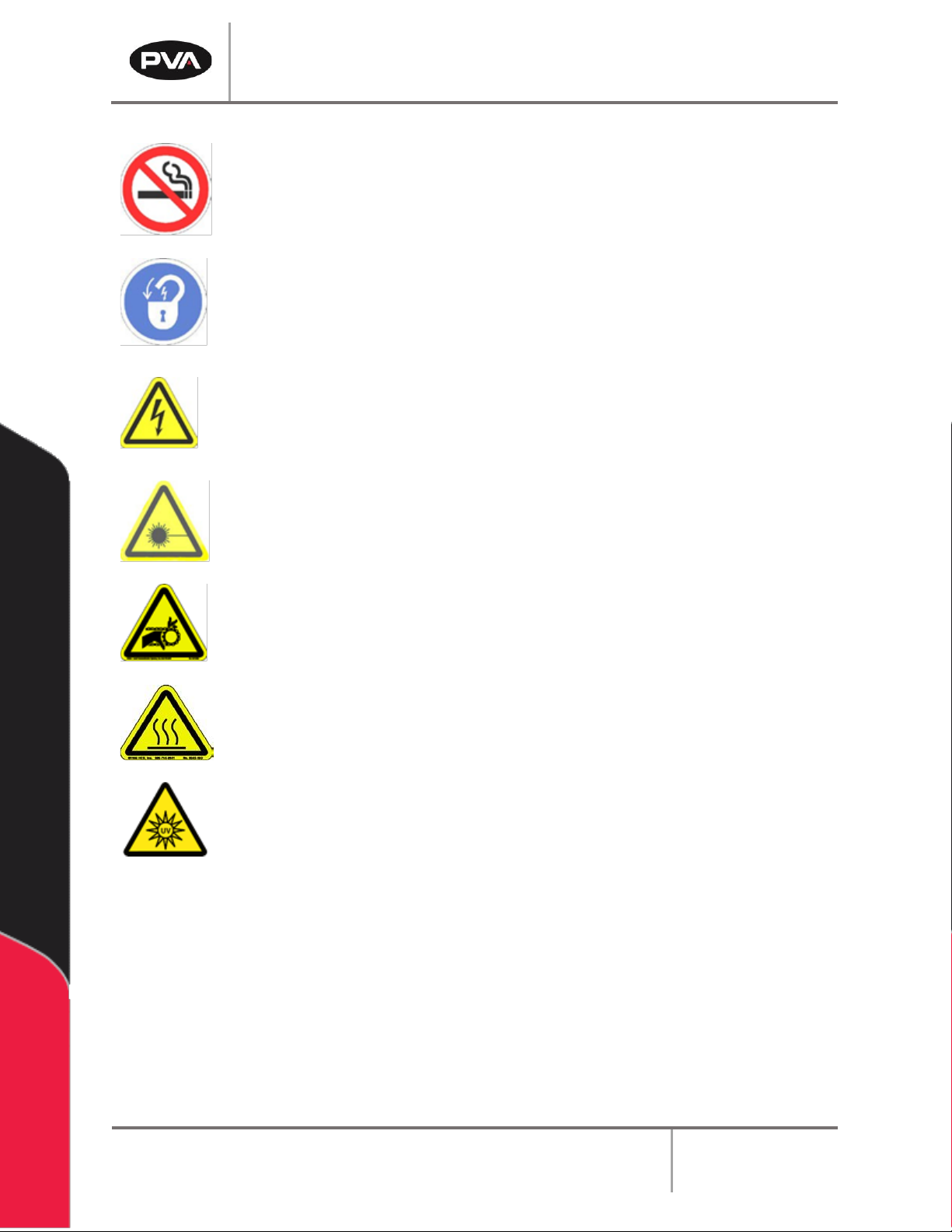

331B330B368B Safety ..........................................................................................................................................6

332B331B369B Theory of Operation ................................................................................................................ 8

333B332B370B Personal Protective Equipment............................................................................................ 8

334B333B371B Waste Disposal.......................................................................................................................... 8

335B334B372B Hazards Due to Contact ......................................................................................................... 8

350B Operating, Handling, Transportation, and Storage .........................................9

336B335B373B Dust and Debris.........................................................................................................................9

337B336B374B Temperature and Humidity.....................................................................................................9

338B337B375B Location ......................................................................................................................................9

351B SMEMA .................................................................................................................. 10

352B Installation and Setup .........................................................................................11

339B338B376B Installation.................................................................................................................................11

353B Operating Safety................................................................................................. 12

340B339B377B Notices and Warnings ............................................................................................................12

341B340B378B Safety Devices and Guarding...............................................................................................12

367B366B404B Safety Circuit ...................................................................................................................12

368B367B405B Doors..................................................................................................................................12

342B341B379B Exhaust Requirements ..........................................................................................................13

369B368B406B Air Velocity Test Point....................................................................................................13

354B Operation.............................................................................................................. 14

343B342B380B Startup Procedure ..................................................................................................................14

344B343B381B Light Tower Operation ...........................................................................................................15

345B344B382B Machine Safety Check ...........................................................................................................16

346B345B383B Shutdown Procedure.............................................................................................................16

347B346B384B Cycle Stop................................................................................................................................. 17

355B Auto Cycle ............................................................................................................ 18