SHG TEGERNSEE User manual

Operating manual:

Mobile speciality pump Tegernsee

SHG SPECHTENHAUSER HOCHWASSER-

UND GEWÄSSERSCHUTZ GMBH

Gewerbestraße 3, D-86875 Waal, Germany

Operating manual: Mobile speciality pump TEGERNSEE

SHG SPECHTENHAUSER HOCHWASSER-UND GEWÄSSERSCHUTZ GMBH

Gewerbestraße 3, D-86875 Waal, Germany www.spechtenhauser.de

Tel.: +49 (0)8246.9695-20 shg@spechtenhauser.de

Fax: +49 (0)8246.9695-24 418BATSE003

1

Table of contents

1General information ______________________________________________________________________ 2

1.1 Version ______________________________________________________________________________ 2

1.2 The operating instructions ____________________________________________________________ 2

2Safety instructions _______________________________________________________________________ 4

2.1 Qualifications of personnel____________________________________________________________ 4

2.2 Hazards in the event of non-compliance with the safety instructions______________________ 4

2.3 Safety regulations for owner/operator __________________________________________________ 4

2.4 Safety instructions relevant for operation_______________________________________________ 4

2.5 Safety instructions relevant for maintenance, inspection and assembly work______________ 5

2.6 Unauthorized modes of operation______________________________________________________ 5

3Technical data____________________________________________________________________________ 6

3.1 Electrical and technical data___________________________________________________________ 6

3.2 Performance _________________________________________________________________________ 6

3.3 Capacity-head table___________________________________________________________________ 6

3.4 Materials_____________________________________________________________________________ 7

3.5 Wiring diagram _______________________________________________________________________ 7

3.6 Dimensions __________________________________________________________________________ 8

4Operating the pump ______________________________________________________________________ 9

4.1 Motor protection switch ______________________________________________________________ 10

4.2 Operating the pump _________________________________________________________________ 10

4.3 Low-level pumping __________________________________________________________________ 11

4.4 Low-level pumping at low water level__________________________________________________ 12

4.5 Use of the pump with pluggable float switch ___________________________________________ 12

4.6 Operation with emergency power generator ___________________________________________ 13

5Accessory ______________________________________________________________________________ 14

6Service and Maintenance_________________________________________________________________ 15

6.1 Pump cleaning and maintenance _____________________________________________________ 15

6.2 Maintenance intervals________________________________________________________________ 15

6.3 Dismantling the impeller _____________________________________________________________ 15

6.4 Assembling the impeller _____________________________________________________________ 17

6.5 Network cable and motor protection switch____________________________________________ 19

6.6 Motor_______________________________________________________________________________ 19

7Malfunctions; causes and rectification ____________________________________________________ 20

Operating manual: Mobile speciality pump TEGERNSEE

SHG SPECHTENHAUSER HOCHWASSER-UND GEWÄSSERSCHUTZ GMBH

Gewerbestraße 3, D-86875 Waal, Germany www.spechtenhauser.de

Tel.: +49 (0)8246.9695-20 shg@spechtenhauser.de

Fax: +49 (0)8246.9695-24 116BATSD001

2

1 General information

Dear Customer,

Thank you for your decision to purchase and install this top quality product. Please follow

these operating instructions, especially those concerning safety. They are there for your

safety, will save you trouble and guard from loss of guarantee.

One important point first:

If the failure of this submersible pump (power failure, technical defect) can lead to major

material or non-material damage, you may have to take precautions by installing a second

pump with dual pump control, alarm systems (independent of the mains), emergency gen-

erators and other equipment. For information please contact our customer service depart-

ment.

1.1 Version Pump including carrying handle, motor protection switch with IP67 shock-proof plug, 20 m

heavy-duty power cable, B-Storz coupling on outlet side, pump base with integrated low

level pumping device

1.1.1 Marking of the pumps

Each TEGERNSEE pump is marked by a nameplate. The nameplate gives information

about:

Field 1: Manufacturer Field 6: Electrical input Field 11: Nominal rotation speed

Field 2: Type designation Field 7: Operating voltage Field 12: Rated current consumption

Field 3: Year of manufacture Field 8: Frequency Field 13: Max. capacity

Field 4: Serial number Field 9: Max. head Field 14: Max. liquid temperature

Field 5: Max immersion depth Field 10: Protection class

1.1.2 Application

The mobile submersible pump TEGERNSEE is designed for soiled waste water or sewage

including solids or long fibers in case of flood control, flooding, pipe bursts or water level

reduction. The pump is designed for temporary mobile use. For permanent fixed installation

the use of sewage pumps made of cast iron is recommended. The pump may not be used

in explosive areas.

1.1.3 Pumped medium

The pumped medium may not exceed a maximum density of 1.1 kg/l. Dangerous pumped

media (e.g. explosive, toxic, hot > 60°C) may only be pumped within the scope of the use

conditions named in these operating instructions. The pump can pump solids up to a parti-

cle size of 40 mm. The pH value of the pumped medium must lie within the range between

5 and 8. No guarantee can be given for safe operation of the pump if the pH value of the

medium exceeds or is lower than the given value. In case of borderline pH values, the

material resistance must be additionally tested before using the pump.

1.2 The operating instructions

These operating instructions contain information and instructions so that you can work

safely, properly and economically with the pump. Only if the contents of the operating in-

structions are understood and followed can

Field 12

Field 6

Field 10

Field 7

Field 11

Field 3

Field 1

Field 5

Field 13

Field 9

Field 8

Field 4

Field 2

Field 14

Operating manual: Mobile speciality pump TEGERNSEE

SHG SPECHTENHAUSER HOCHWASSER-UND GEWÄSSERSCHUTZ GMBH

Gewerbestraße 3, D-86875 Waal, Germany www.spechtenhauser.de

Tel.: +49 (0)8246.9695-20 shg@spechtenhauser.de

Fax: +49 (0)8246.9695-24 418BATSE003

3

•hazards be avoided and

•the reliability and life of the pump be increased.

With the issue of these operating instructions, regulations and standards not named in them

are not rescinded.

1.2.1 Definition of terms

Several important terms are used in these operating instructions, which are defined as

follows:

Owner/operator: The owner/operator is any natural or legal

person, who uses the pump or on whose be-

half the pump is used.

Pump: A pump is the complete submersible pump.

1.2.2 Marking of information and instructions

Safety instructions given in the operating manual, the non-observance of which could

cause danger to life have been specifically highlighted with the general danger symbol.

The presence of dangerous voltage is identified with the safety symbol.

Other safety points in these instructions, the non-observance of which may endanger ma-

chinery or its operation, are marked as follows.

Symbols directly on the pump itself, e.g.

•Direction of rotation

•Type plate

must be carefully observed and must be maintained in legible condition.

1.2.3 Explanation of symbols

CE symbol: With the CE marking the manufacturer, dis-

tributor or authorised EU representative de-

clares in accordance with EU Regulation

765/2008, that “the product is in conformity

with the applicable requirements set out in

Community harmonisation legislation provid-

ing for its affixing”.

Symbol for hot surfaces: Warning sign "Hot surface" according to

safety sign ASR A1.3:2013 and EN ISO

7010.

Sign for risk of injury and burns caused byhot

surfaces.

Symbol for hand injuries: Warning sign "Hand injuries” according to

BGV A8, ASR A1.3:2013 and DIN

4844. Sign for risks caused by a machine,

these areas can lead to hand injuries

Operating manual: Mobile speciality pump TEGERNSEE

SHG SPECHTENHAUSER HOCHWASSER-UND GEWÄSSERSCHUTZ GMBH

Gewerbestraße 3, D-86875 Waal, Germany www.spechtenhauser.de

Tel.: +49 (0)8246.9695-20 shg@spechtenhauser.de

Fax: +49 (0)8246.9695-24 418BATSE003

4

2 Safety instructions

(General safety instructions as per VDMA 24292)

This operation manual gives basic instructions that should be followed carefully during in-

stallation, operation and maintenance. It is essential that this manual is carefully read by

the responsible personnel/operator before assembly and commissioning. It is always to be

kept available at the installation/usage site of the pump.

2.1 Qualifications of personnel

An authorized (certified) electrician and mechanic shall carry out all work. Scope of respon-

sibility and supervision of the personnel must be exactly defined by the operator. If the staff

does not have the necessary knowledge, they must be trained and instructed, which may

be performed by the manufacturer or supplier on behalf of the operator, moreover, the

operator is to make sure that the contents of the operating manual are fully understood by

the personnel.

Minimum requirements for the operating personnel:

•Legal age

•Firefighter training in accordance with the fire service regulation 2 and additional

instruction of the trained machinist or "Technical Assistance" course in accordance

with fire service regulation 2 or

•basic training Level I (German THW) as a rescue worker

Minimum requirements for the maintenance and inspection personnel:

•Legal age

•Qualified electrician

2.2 Hazards in the event of non-compliance with the safety instructions

Non-compliance with the safety instructions may produce a risk to the personnel as well as

to the environment and the machine and results in a loss of any right to claim damages or

compensation. For example, non-compliance may involve the following hazards:

•Failure of important functions of the pump

•Failure of specified procedures of maintenance and repair

•Exposure of people to electrical, mechanical and chemical hazards

•Endangering the environment owing to hazardous substances being released

2.3 Safety regulations for owner/operator

All safety instructions contained in this manual, all relevant national and local health and

safety codes and any other service and safety instructions issued by the owner shall be

complied with.

2.4 Safety instructions relevant for operation

Always follow these safety instructions before using the pump:

Danger of electric shock:

•Protect plug-and-socket connections against moisture and increasing water levels in

flood areas.

•When using the pump in swimming pools or ponds and the surrounding area DIN/VDE

0100 must be complied with.

•Hazards resulting from electricity are to be prevented (see for example, the national-

specifications or the regulations of your local electricity supply company)

General danger

•In dry-well installation respectively in case of low level pumping (in case of low water

level) the motor housing heats up after a lengthy operating period. You must therefore

only use the carrying handle to transport the pump and avoid direct contact with the

motor housing. Always wear protective gloves too.

Operating manual: Mobile speciality pump TEGERNSEE

SHG SPECHTENHAUSER HOCHWASSER-UND GEWÄSSERSCHUTZ GMBH

Gewerbestraße 3, D-86875 Waal, Germany www.spechtenhauser.de

Tel.: +49 (0)8246.9695-20 shg@spechtenhauser.de

Fax: +49 (0)8246.9695-24 418BATSE003

5

•When pumping hot fluids the pump always becomes as hot as the pumped fluid. In this

case you must only touch the pump if you are wearing suitable protective gloves.

•In pumping mode strong suction is produced at the intake area of the pump. It is there-

fore necessary to ensure that while the pump is running you never allow your hands,

feet, loose clothing (e.g. ties) or jewelry (e.g. chains) to get into the area of the pump

intake (suction side) or pump discharge (pressure side). There is risk of shearing inju-

ries or getting tangled.

•The protection against contact (pump base) for moving parts (impeller) may not be

removed if the machines are in operation. The pump itself maynot be operated without

the appropriate protection against contact.

•Any leakage of hazardous (e.g. explosive, toxic, hot) fluids (e.g. from the shaft seal)

must be drained away so as to prevent any risk to persons or the environment. Statu-

tory regulations are to be complied with.

Damage of the pump due to inappropriate use:

•Store the pump in dry rooms only. If kept dry and clean the pump can be stored down

to a minimum temperature of –20°C. Highly super cooled pumps must be allowed to

thaw to above 0 °C before being used, to prevent the formation of ice on immersion in

the fluid to be pumped.

•Ensure that the place in which the pump is used is protected against frost.

•Always use the carrying handles to transport the pump.

•Only use the notch at the carrying handle to lower the pump using ropes. Never lower

the pump by its power cable or a hose connected to the pump.

2.5 Safety instructions relevant for maintenance, inspection and assembly work

It shall be the user’s responsibility to ensure that all maintenance, inspection and assembly

work is performed by authorized and qualified personnel who have adequately familiarized

themselves with the subject matter by studying this manual in detail. Any work on the ma-

chine shall only be performed when it is at stand-still, it is being imperative that the proce-

dure for shutting down the machine described in this manual be followed (see chapter 4).

Pumps and pump units which convey hazardous media must be decontaminated. All waste

emissions such as used oil must be appropriately disposed of, oil spills must be cleaned

up and emissions to the environment must be reported.

On completion of work all safety and protective facilities must be reinstalled and made

operative again. Before restarting the points listed in chapter 4 must be noted and followed.

Any modification may be made to the pump only after consultation with the manufacturer.

Using spare parts and accessories authorized by the manufacturer is in interest of safety.

Use of other parts may exempt the manufacturer from any warranty or compensation

claims.

2.6 Unauthorized modes of operation

The reliability of the pump delivered will be only guaranteed if it is used in the manner

intended, in accordance with this manual. The limit values specified in the data sheet must

under no circumstances be exceeded. These installation and operation instructions do not

supersede or exclude generally valid regulation and standards.

Operating manual: Mobile speciality pump TEGERNSEE

SHG SPECHTENHAUSER HOCHWASSER-UND GEWÄSSERSCHUTZ GMBH

Gewerbestraße 3, D-86875 Waal, Germany www.spechtenhauser.de

Tel.: +49 (0)8246.9695-20 shg@spechtenhauser.de

Fax: +49 (0)8246.9695-24 418BATSE003

6

3 Technical data

3.1 Electrical and technical data

TEGERNSEE

Coupling size

B-Storz/2”

Max. solid passage

Ø 40 mm

Fluid temperature

0° - 60°C submersed

0° - 40°C in dry conditions

Weight including cable

25 kg

Cable length

20 m

Cable type

H07RN8-F

Sound emission in 1 m

< 70 dB(A)

Operating voltage

230 V

Frequency

50 Hz

Protection class

IP 68

Nominal current

8,0 A

Electrical power input P1

1,8 kW

pH-value

5 - 8

Density pumping medium

≤ 1,1 kg/l

3.2 Performance

Head H [bar]

0

0,2

0,4

0,6

0,8

1,0

1,2

1,4

Capacity Q [l/min]

800

740

660

580

500

420

340

260

3.3 Capacity-head table

Operating manual: Mobile speciality pump TEGERNSEE

SHG SPECHTENHAUSER HOCHWASSER-UND GEWÄSSERSCHUTZ GMBH

Gewerbestraße 3, D-86875 Waal, Germany www.spechtenhauser.de

Tel.: +49 (0)8246.9695-20 shg@spechtenhauser.de

Fax: +49 (0)8246.9695-24 418BATSE003

7

3.4 Materials

•All housing parts made of saltwater-proof aluminum alloy G-AlSi10Mg

•All screw connections made of stainless steel 1.4301

•Impeller made of corrosion-free, wear-resistant and self-cleaning aluminium bronze

G-CuAl10Ni

•Dry and endurance run suitable double mechanical seal made of SiC/SiC and SiC/car-

bon

•Carrying handle made of Nylon-PA6

•Pump base made of PE

3.5 Wiring diagram

Operating manual: Mobile speciality pump TEGERNSEE

SHG SPECHTENHAUSER HOCHWASSER-UND GEWÄSSERSCHUTZ GMBH

Gewerbestraße 3, D-86875 Waal, Germany www.spechtenhauser.de

Tel.: +49 (0)8246.9695-20 shg@spechtenhauser.de

Fax: +49 (0)8246.9695-24 418BATSE003

8

3.6 Dimensions

Operating manual: Mobile speciality pump TEGERNSEE

SHG SPECHTENHAUSER HOCHWASSER-UND GEWÄSSERSCHUTZ GMBH

Gewerbestraße 3, D-86875 Waal, Germany www.spechtenhauser.de

Tel.: +49 (0)8246.9695-20 shg@spechtenhauser.de

Fax: +49 (0)8246.9695-24 418BATSE003

9

4 Operating the pump

Caution:

The pump may only be operated in compliance with the instructions and information of this

operating manual.

Caution:

The pump is fitted with a thermal protection switch. Once the maximum operating temper-

ature is exceeded, the thermal protection switch automatically shuts down the pump. If the

temperature falls below the maximum operating temperature again, the pump starts up

again immediately.

Caution:

Work is only to be carried out on the pump when the pump is switched off at the motor

protection switch by pressing the green rocker switch and the network plug is unplugged.

In addition, appropriate measures are to be taken to secure the pump against accidental

restart.

Note:

Before starting the pump, check that the supplied voltage and frequency matches the in-

formation on the nameplate.

Danger from electric shock:

Bring electrical plug connections to a flood-proof area to protect them from water. Watch

out for rising water levels in flood areas!

Caution:

For outdoor use, the provisions of EN EN 60204-1 must be observed.

Danger from electric shock:

No-one should be present inside the pumping medium when the pump is in operation. The

pump may only be operated over residual current devices (RCD) with rated residual current

of not more than 30 mA.

Caution:

The operating personnel must ensure that no third parties (e.g. spectators during demon-

strations, residents affected byfloods, voluntary helpers, curious onlookers, etc.) can stand

in the pumped fluid and can never get into the area of the pump intake (suction side) or

pump outlet (pressure side)

Caution:

In dry-well installation and/or in case of low level pumping (in case of low water level) the

motor housing heats up after a lengthy operating period. You must therefore only use the

carrying handle to transport the pump and avoid direct contact with the motor housing.

Always wear protective gloves too.

Caution:

The intake ports and the hoses must always be connected with coupling keys. The pump

may only be started up if the discharge hose and one intake port or one intake hose are

connected.

Caution:

The suction on the intake side can cause long-fibre substances to be drawn in. Do not

remove these during operation. Switch off the pump, secure it against accidental switching

on and then remove the objects.

Operating manual: Mobile speciality pump TEGERNSEE

SHG SPECHTENHAUSER HOCHWASSER-UND GEWÄSSERSCHUTZ GMBH

Gewerbestraße 3, D-86875 Waal, Germany www.spechtenhauser.de

Tel.: +49 (0)8246.9695-20 shg@spechtenhauser.de

Fax: +49 (0)8246.9695-24 418BATSE003

10

4.1 Motor protection switch

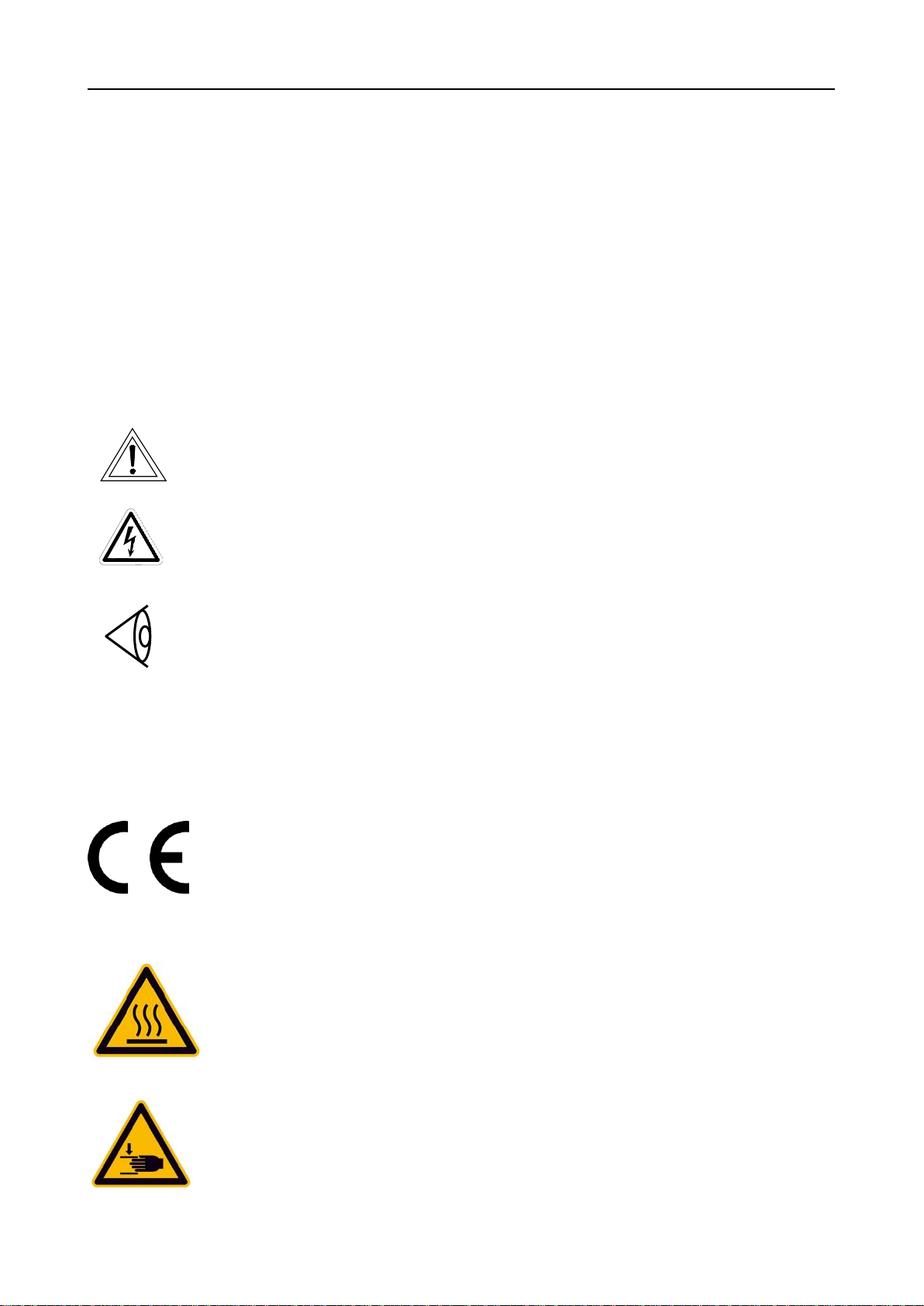

The pumps are fitted with motor protection switch (see image

1).

Before the power plug for pump operation is inserted into a

power socket, it is to be ensured that the green rocker switch

on the motor protection switch is pressed at position 0, in or-

der to rule out accidental starting of the pump.

To start the pump, the green rocker switch is to be set from

position 0 to 1. To switch off the pump, the green rocker

switch is to be set from position 1 to 0.

4.2 Operating the pump

For safe working on and with the pump, the wearing of safety

shoes and safety gloves is recommended, in order to prevent

injury from crushing or cutting.

Each time when using the pump, also ensure the following

points:

1. Before using the pump, it must be checked for damage to

the plug, cable and motor protection housing.

2. Transport the pump to the place of use.

Caution:

Always transport the pump with the handles provided for

this purpose only.

Danger:

The PE pump base on the inlet side is used to protect the

impeller from contact. The pump itself may not be operated

without the appropriate contact protection.

3. Mount a dimensionally stable spiral pressure hose with B-

Storz coupling to the outlet side of the pump. A suitable

fire hose can now be connected to this spiral hose. Lay

this at a suitable drain or collection tank. The end of the pressure hose must be ade-

quately secured against impact. The fire hose should be laid without kinks where pos-

sible to achieve an optimum pumping power. It is strongly recommended that you use

the optional dimensionally stable spiral pressure hose for the first 3 m.

Danger:

Ensure that the pressure hose end is adequately secured and

fixed. Otherwise, there is the risk of the hose end being hit

when switching on the pump.

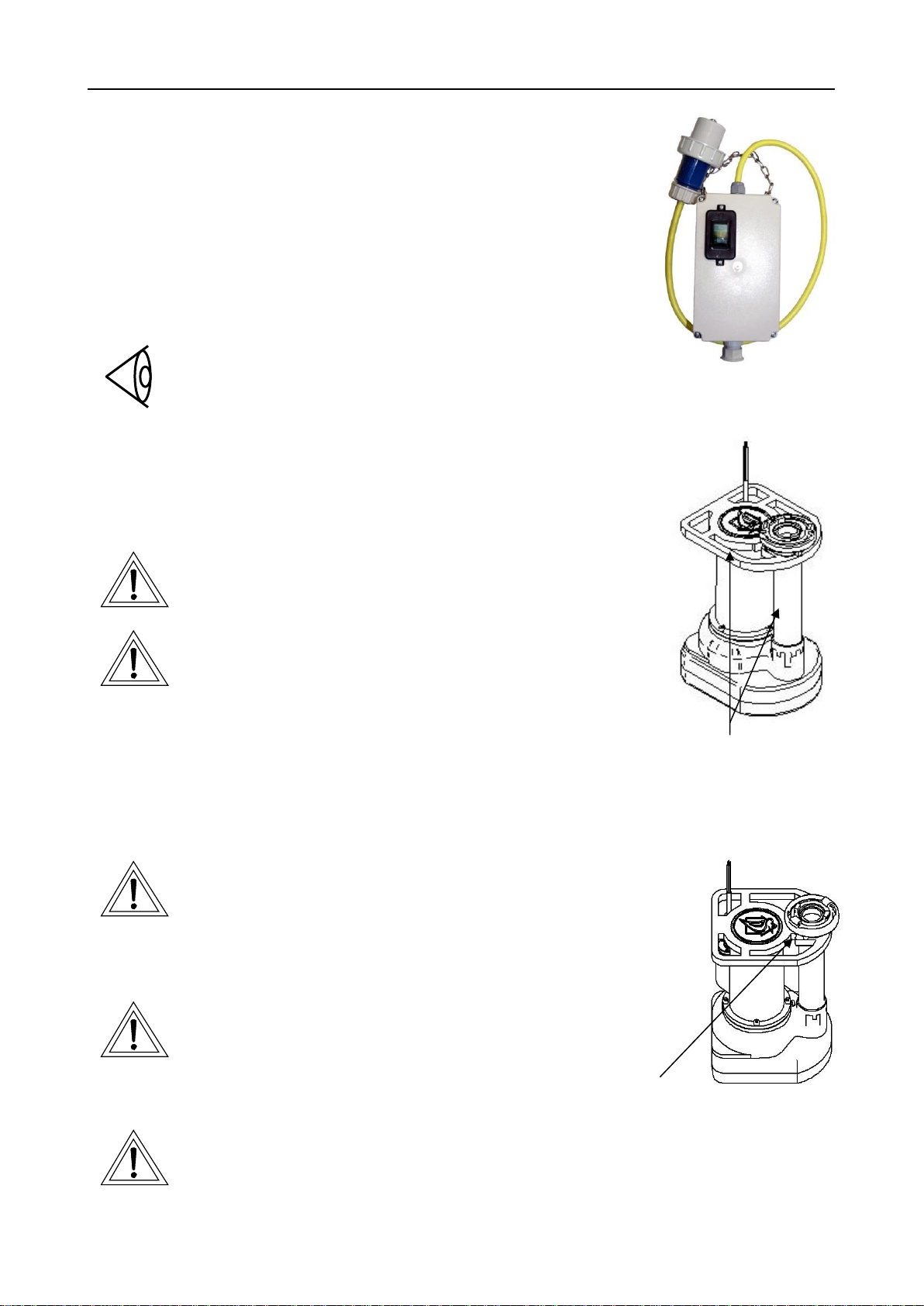

4. If the pump is to be lowered into a shaft, attach a suitable

length of rope to the notch at the carrying handle.

Caution:

To lower the pump only the designated abseiling notch is used.

Under no circumstances should the pump be lowered to the

mains cable or the connected hoses.

5. Lower the pump on this rope into the liquid.

Danger from suspended loads:

When lowering the pump, ensure that no-one is under the pump in the shaft.

Image 2: Tegernsee carrying

handles

Image 3: Abseiling notch

Image 1: Motor protection switch

Operating manual: Mobile speciality pump TEGERNSEE

SHG SPECHTENHAUSER HOCHWASSER-UND GEWÄSSERSCHUTZ GMBH

Gewerbestraße 3, D-86875 Waal, Germany www.spechtenhauser.de

Tel.: +49 (0)8246.9695-20 shg@spechtenhauser.de

Fax: +49 (0)8246.9695-24 418BATSE003

11

6. Make sure that the pump is standing safely.

7. Ensure that the pump is switched off. To do this, the green rocker switch on the motor

protection switch has to be pressed to position 0. Plug the motor protection plug into

a socket that is fused via a residual current device (RCD) with a rated residual current

of no more than 30 mA. Each plug-in connection (socket, generator, etc..) must be

fused with an overcurrent protective device with 16 ampere. The overcurrent protec-

tive device must at least have tripping characteristic B, characteristic C is recom-

mended.

Danger from electrical shock:

Ensure that the network socket at the network socket connection is dry. Never carry

out changes on the socket! The power socket is to be protected by a residual current

device (RCD) with rated residual current of not more than 30 mA.

8. Switch the pump on by pressing the green rocker switch to position 1. The pump

should now pump with the defined pumping performance.

Caution:

The plug and the motor protection switch must be easy to access during operation of

the pump. They must always be supervised, so that they cannot be plugged in or

unplugged or acknowledged, erroneously or accidentally.

9. Switch the pump off again by pressing the green rocker switch to position 0 as soon

as the water level has sunk so far that the pump is taking in air. If low-level pumping

is to be carried out, only lower the liquid down to the minimum water level for low level

pumping (upper edge of the spiral housing, see chapter 4.3).

10. Clean the pump with clear water after each use, particularly after using it with muddy

liquid. In addition, let the pump run for about 10 minutes in a basin with clean water.

The pump is to then be completely emptied.

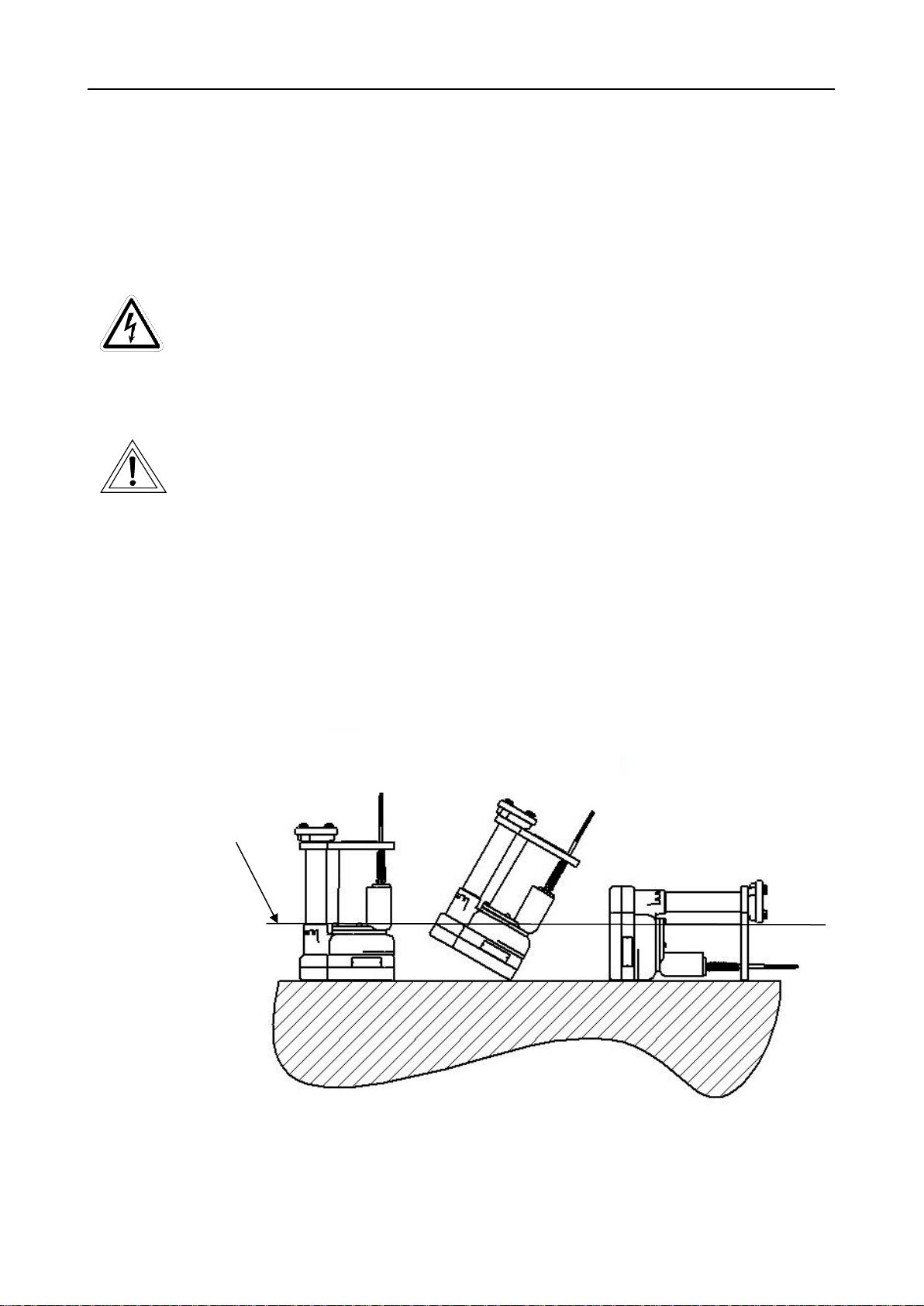

4.3 Low-level pumping

If low-level pumping is to be carried out, the fluid is lowered down to the upper edge of the

spiral housing. Now switch the pump off and turn it by 90° to pump the fluid up to a residual

water level of a few millimeters.

Minimum water level

Basic position

90° turning

Low level pumping

Operating manual: Mobile speciality pump TEGERNSEE

SHG SPECHTENHAUSER HOCHWASSER-UND GEWÄSSERSCHUTZ GMBH

Gewerbestraße 3, D-86875 Waal, Germany www.spechtenhauser.de

Tel.: +49 (0)8246.9695-20 shg@spechtenhauser.de

Fax: +49 (0)8246.9695-24 418BATSE003

12

If low-level pumping is to be carried out, the following points are to be observed:

1. Pump the medium according to section 4.2 of this user manual until the spiral housing

becomes visible. (approx. 15 cm residual water level).

2. Switch the pump off and remove the network plug. Secure the pump against accidental

restarting.

Danger from electric shock:

Only carry out work on the pump when the pump is disconnected from the network by

removing the network plug from the power supply. Prevent accidental restart of the

5pump by taking appropriate measures.

3. Turn the pump so that the intake openings face downwards.

4. Insert the network plug into the power socket and restart the pump.

5. If the intake openings get stuck on solids, first turn off the pump, then pull the power

plug and remove the solids from the intake openings.

6. Pump the liquid until the pump intakes air. Switch the pump off again.

4.4 Low-level pumping at low water level

In case of low water level (< 10-15 cm) there is not enough water inside the spiral hous-

ing to do low-level pumping. For this first the pump has to be filled. Therefor the following

points are to be observed:

1. Bring the pump into low-level pumping

position (see section 4.3).

2. Mount a 90° elbow with B-Storz cou-

plings on both sides to the outlet side of

the pump. (see image 4)

3. Fill the pump with water until water

drains off the inlet openings of the pump.

Now the pump is sufficiently filled with

water in order to start low-level pumping.

4. Mount a suitable pressure hose to the 90°elbow on the suction side of the pump and

start the start pump as described in section 4.2 and 4.3 of this manual. It takes about

10-15 seconds until the pumps achieves its normal capacity.

4.5 Use of the pump with pluggable float switch

To operate the pump with pluggable float switch (see image 5), first insert the pluggable

switch into a socket which is protected by a residual current device (RCD) with rated resid-

ual current of not more than 30 mA and then connect the motor protection plug to the

pluggable float switch. When operating the pump with float switch, also note the points

listed under section "4.2 Use of the Pump". The following is also to be observed:

1. Mount the float switch on the cable lug in such a way that it cannot be sucked by the

pump.

2. The float switch must only hang in the medium to the extent that it switches off shortly

before the pump sucks air at the latest.

3. The position of the float weight on the network cable of the float switch may not be

changed.

Image 4: Tegernsee with 90° elbow

Operating manual: Mobile speciality pump TEGERNSEE

SHG SPECHTENHAUSER HOCHWASSER-UND GEWÄSSERSCHUTZ GMBH

Gewerbestraße 3, D-86875 Waal, Germany www.spechtenhauser.de

Tel.: +49 (0)8246.9695-20 shg@spechtenhauser.de

Fax: +49 (0)8246.9695-24 418BATSE003

13

4.6 Operation with emergency power generator

All Tegernsee pumps can be operated with 3 kVA DIN power generators. In the case of

3 kVA units wherever possible the pump should be connected to the unit directly (i.e. with-

out an extension cable), as otherwise there is a risk of the unit stalling on switching on the

pump.

With generators with higher power, extension cables can be used without restriction. The

used extension cable must have a wire cross-section of at least 2.5 mm² or larger to keep

the voltage drop in the cable as low as possible.

Operating manual: Mobile speciality pump TEGERNSEE

SHG SPECHTENHAUSER HOCHWASSER-UND GEWÄSSERSCHUTZ GMBH

Gewerbestraße 3, D-86875 Waal, Germany www.spechtenhauser.de

Tel.: +49 (0)8246.9695-20 shg@spechtenhauser.de

Fax: +49 (0)8246.9695-24 418BATSE003

14

5 Accessory

The following accessories are available for the mobile speciality pump Tegernsee:

•PVC spiral hoses

•PRCD safety switch

•Pluggable float switch

•90°elbow with B-Storz couplings in both sides

In case of further questions please contact your local retailer.

Operating manual: Mobile speciality pump TEGERNSEE

SHG SPECHTENHAUSER HOCHWASSER-UND GEWÄSSERSCHUTZ GMBH

Gewerbestraße 3, D-86875 Waal, Germany www.spechtenhauser.de

Tel.: +49 (0)8246.9695-20 shg@spechtenhauser.de

Fax: +49 (0)8246.9695-24 418BATSE003

15

6 Service and Maintenance

It shall be the user’s responsibility to ensure that all maintenance, inspection and assembly work is performed

by authorized and qualified personnel who have adequately familiarized themselves with the subject matter by

studying this manual in detail.

Any work on the machine shall only be performed when it is at stand-still, it is being imperative that the proce-

dure for shutting down the machine described in this manual is be followed.

Pumps and pump units which convey hazardous media must be decontaminated. All waste emissions such

as used oil must be appropriately disposed of, oil spills must be cleaned up and emissions to the environment

must be reported. On completion of work all safety and protective facilities must be reinstalled and made

operative again.

6.1 Pump cleaning and maintenance

Clean the pump with clear water after each use, particularly after using it with muddy liquid. In addition, let the

pump run for about 10 minutes in a basin with clean water. The pump is to then be completely emptied.

6.2 Maintenance intervals

The pumps are completely maintenance-free. All components requiring lubrication are lifetime-lubricated. Dur-

ing the annual electrical test in accordance with DIN VDE 0701-0702 a trial run must also be performed to

check the functional capability of the pump. In case of vibrations, eccentric pump running or grinding noises a

customer service must be carried out in the factory. Also check the seals of the pump base for wear.

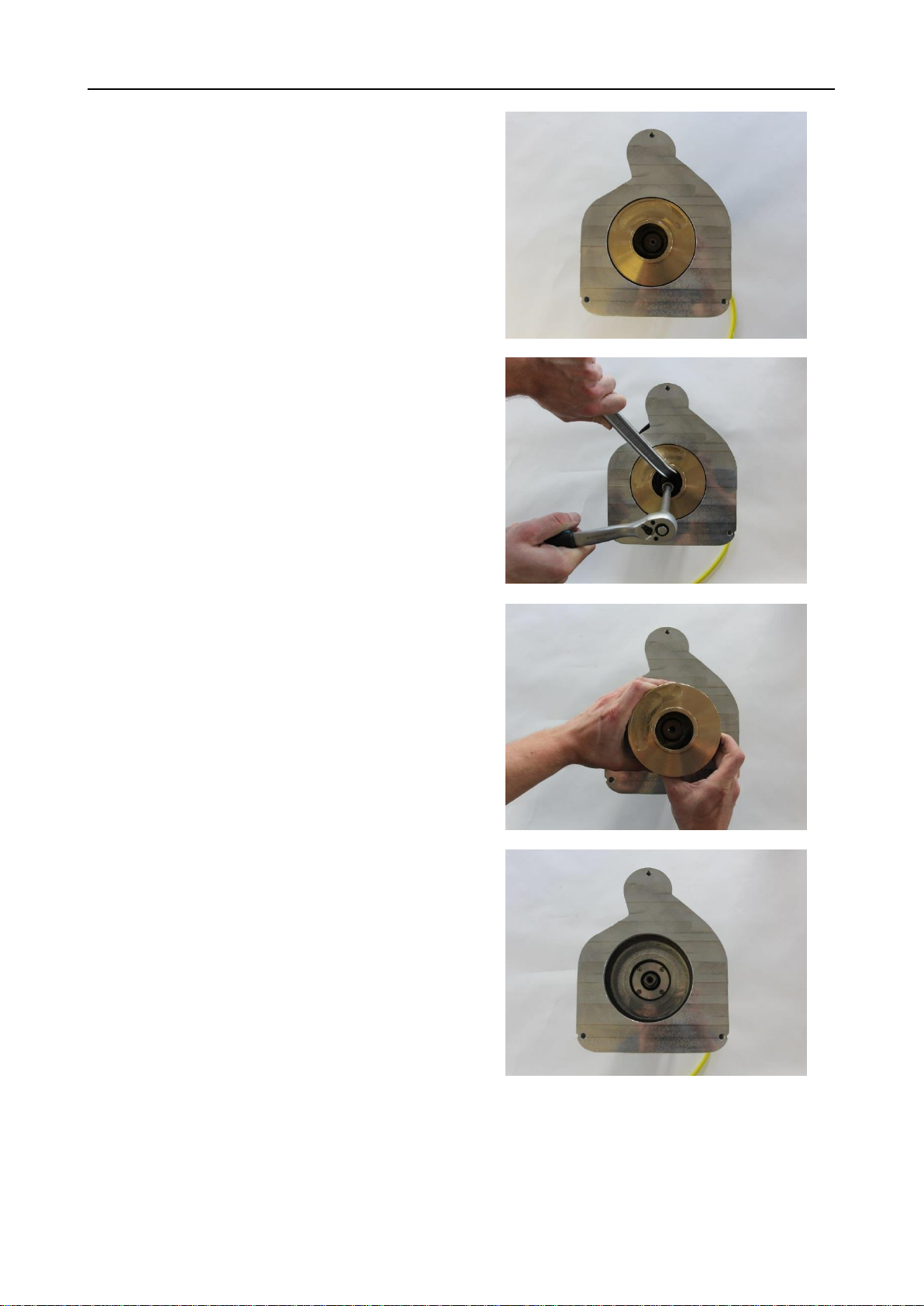

6.3 Dismantling the impeller

If stubborn blockages form in the spiral housing, the spiral housing and the impeller can be dismantled via the

following steps:

1. Unscrew the four cylindrical screws with hexagon

socket (M6) with which the PE pump base is

screwed together. Now remove the lower part of

the pump base.

2. Remove the three cylindrical screws with hexagon

socket (M8) which connect the upper pump base

with the spiral housing.

Operating manual: Mobile speciality pump TEGERNSEE

SHG SPECHTENHAUSER HOCHWASSER-UND GEWÄSSERSCHUTZ GMBH

Gewerbestraße 3, D-86875 Waal, Germany www.spechtenhauser.de

Tel.: +49 (0)8246.9695-20 shg@spechtenhauser.de

Fax: +49 (0)8246.9695-24 418BATSE003

16

3. Remove the upper pump base from the spiral

housing.

4. Remove the cylindrical screw with hexagon sock-

ets (M8) from the impeller using an assembly

lever.

5. Remove the impeller from the shaft. If it cannot be

removed easily screw a commercially available

M10 screw in the impeller in order to pull the im-

peller off the shaft. Clean the polygon connection

(impeller and shaft) and check it for damages.

6. Remove the blockage cause from the spiral hous-

ing and the impeller.

Operating manual: Mobile speciality pump TEGERNSEE

SHG SPECHTENHAUSER HOCHWASSER-UND GEWÄSSERSCHUTZ GMBH

Gewerbestraße 3, D-86875 Waal, Germany www.spechtenhauser.de

Tel.: +49 (0)8246.9695-20 shg@spechtenhauser.de

Fax: +49 (0)8246.9695-24 418BATSE003

17

6.4 Assembling the impeller

When assembling the impeller, the following steps are to be taken:

1. Ensure the polygon connection (impeller and shaft)

have been cleaned. Also clean the opening of the

spiral housing in order to ensure a smooth mount-

ing of the pump base including impeller counter

plate.

2. Evenly place the impeller on the motor shaft and

push it down until it stops.

3. Screw the impeller with the motor shaft using the

cylindrical screw with hexagon sockets (M8). To

fasten the screws, medium-strength screw locking

(Loctite) is to be used. Please refer to Table 6.4.1

Screw tightening torque for the correct screw tight-

ening torque.

4. Attach the O-Ring which is available as a spare

part to the upper pump base (the impeller counter

plate serves as guidance).

Operating manual: Mobile speciality pump TEGERNSEE

SHG SPECHTENHAUSER HOCHWASSER-UND GEWÄSSERSCHUTZ GMBH

Gewerbestraße 3, D-86875 Waal, Germany www.spechtenhauser.de

Tel.: +49 (0)8246.9695-20 shg@spechtenhauser.de

Fax: +49 (0)8246.9695-24 418BATSE003

18

5. Now insert the impeller counter plate including up-

per pump base in the opening of the spiral housing

until it stops. Screw the upper pump base with the

spiral housing using the three cylindrical screws

with hexagon socket (M8). To fasten the screws,

medium-strength screw locking (Loctite) is to be

used. Please refer to Table 6.4.1 Screw tightening

torque for the correct screw tightening torque.

6. Make sure that the sealing cord is positioned cor-

rectly in the recess.

7. Place the lower pump base on the already

mounted upper pump base and screw them to-

gether using the four cylindrical screws with hexa-

gon socket (M6). To fasten the screws, medium-

strength screw locking (Loctite) is to be used.

Please refer to Table 6.4.1 Screw tightening

torque for the correct screw tightening torque.

8. Make sure that the pump base including all parts

is fixed correctly.

6.4.1 Screw tightening torques

Screw

Screw connection

Tightening torque

M8

Impeller / shaft

18 Nm

M8

Upper pump base / spiral housing

34 Nm

M6

Upper pump base / lower pump base

12 Nm

Operating manual: Mobile speciality pump TEGERNSEE

SHG SPECHTENHAUSER HOCHWASSER-UND GEWÄSSERSCHUTZ GMBH

Gewerbestraße 3, D-86875 Waal, Germany www.spechtenhauser.de

Tel.: +49 (0)8246.9695-20 shg@spechtenhauser.de

Fax: +49 (0)8246.9695-24 418BATSE003

19

6.5 Network cable and motor protection switch

The network cable may only be replaced by the manufacturer, its technical service or similar qualified person-

nel. Replace the O-ring on each opening of the cable screw connection.

In the event of a cable defect, the damaged cable can be replaced by a Spechtenhauser network cable in a

few steps.

6.5.1 Dismantling of network cable

1. Remove the three cylindrical screws with the hex-

agon sockets (M5) from the housing.

2. Unplug the cable screw connection including plug

and coupling from the housing. Open the connec-

tion cable plug and unplug the cable from the cou-

pling.

6.5.2 Assembling the network cable

Assembly of the network cable is carried out in the reverse order of disassembly. Take care that the O-ring is

replaced on each opening of the cable screw connection.

6.6 Motor

With all pumps, opening of the engine is not permitted. Repairs and maintenance on the motor may only be

carried out by Spechtenhauser Customer Service or at the plant. In case of infringement, all claims for warranty

and damages are lost.

Other manuals for TEGERNSEE

1

Table of contents

Other SHG Water Pump manuals

Popular Water Pump manuals by other brands

Dolomite

Dolomite Mitos Programming instructions

Xylem

Xylem Goulds AquaBoost Advanced instruction manual

EBARA

EBARA ETM Operating and maintenance manual

Bosworth

Bosworth Guzzler G2-0501N Operator's manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 02D3-X2 3P Installation, operation, and maintenance manual with parts list

BUSCH

BUSCH COBRA BC 1001 G instruction manual

Conel

Conel FLOW TPF Installation and operation instruction

Grundfos

Grundfos SPK Series Installation and operating instructions

Samoa

Samoa LARIUS MINIPEGASO Operating and maintenance manual

Teral

Teral LPWE-GS instruction manual

Whale

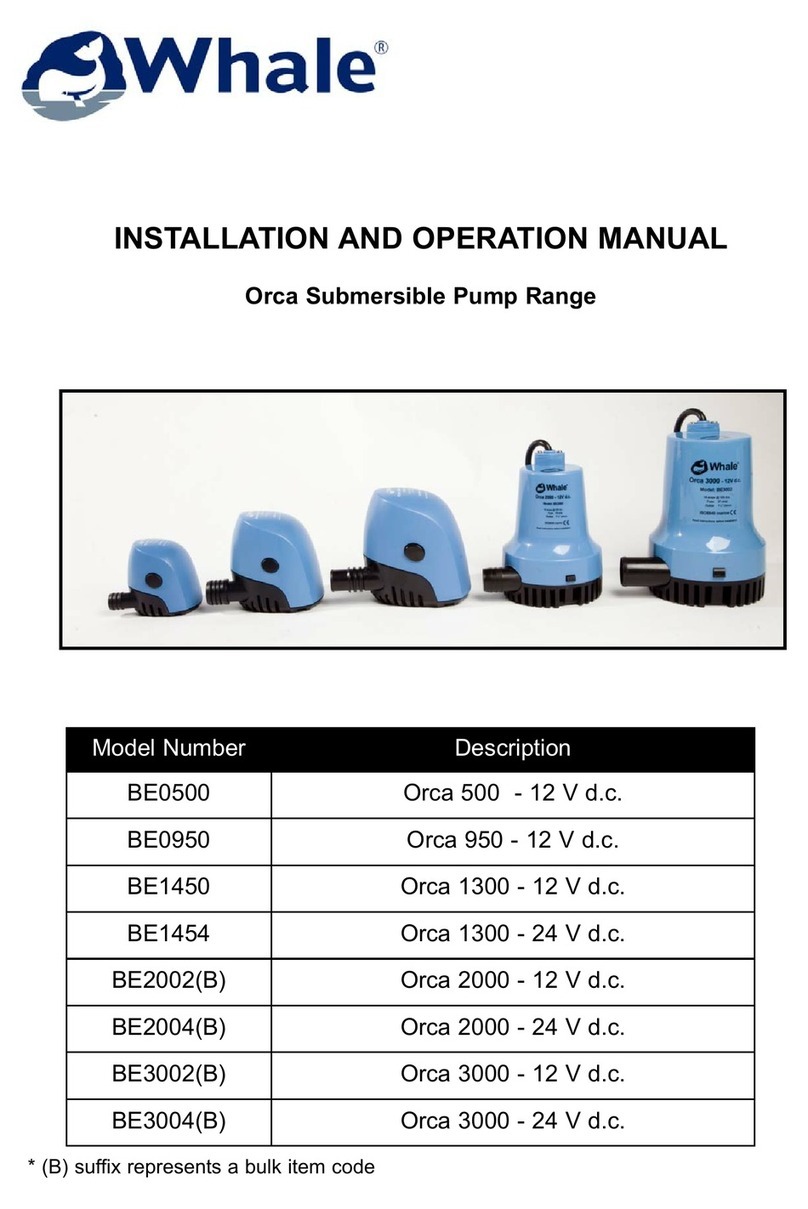

Whale Orca 500 Installation and operation manual

Nitecore

Nitecore AP10 user manual