Shield SD-DVH5 User manual

112 www.shieldglobal.com

pass check valve and restriction orice from the

system supply side to the top chamber, so that

supply pressure in the top chamber act across the

diaphragm operated clapper which holds the seat

against the inlet supply pressure because of the

differential pressure design. On detection of re the

top chamber is vented to atmosphere through the

outlet port via opened actuation devices.

The top chamber pressure cannot be replenished

through the restricted inlet port, and the upward

force of the supply pressure lifts the clapper allow-

ing the water ow to the system piping network and

alarm devices.

TRIM DESCRIPTION

The trims are functionally termed as Dry Pilot Trim,

Wet Pilot Trim, Electric Trim and Test and Alarm

Trim as per the method of actuation of the deluge

valve. The functionality of these trims is described

below.

a) DRY PILOT TRIM (PNEUMATIC RELEASE)

Dry pilot operation uses a pilot line of closed Sprin-

kles/QB detectors containing air under pressure,

located in the area to be protected. It requires reg-

ulated dry air supply with main supply point through

restricted orice. The air pressure to be maintained

as specied in the catalogue of Dry Pilot Actuator.

The pilot line is connected to air inlet side of actua-

tor. The top chamber of the deluge valve is con-

nected to water inlet side of actuator.

When there is an air pressure drop, or due to re-

lease of any of the release device on detection of

re, the diaphragm of actuator is lifted and allows

the water to drain. This releases the water pressure

DESCRIPTION

Deluge Valve is known as a system control valve in a deluge sys-

tem, used for fast application of water in a spray system. Deluge

valve protects areas such as power transformer installation, stor-

age tank, conveyor protection and other industrial application etc.

With the addition of foaming agent deluge valve can be used to

protect aircraft hanger and inammable liquid re.

VALVE OPERATION

SHIELD Deluge valve is a quick release, hydraulically operated

diaphragm valve. It has three chambers, isolated from each other

by the diaphragm operated clapper and seat seal. While in SET

position, water pressure is transmitted through an external by-

DELUGE VALVE

MODEL: SD-DVH5

TECHNICAL DATA

NORMAL SIZE 200,150,100, 80, 50 NB

MATERIAL Nickel Aluminium Bronze

SEVICE PRESSURE 1.4 to 17.5 Bar

(20 to 250 PSI)

THREADED OPENING BSPT

MOUNTING Vertical or Horizontal

FACTORY HYDOSTATIC 35 Kg/sq.cm. (500 PSI)

TEST PRESSURE

FLANGE CONNECTION ANSI B 16.5 # 150 FF

WET PILOT SPRINKLER As per graph in the catalogue

HEIGHT LIMITATION

NET WEIGHT 200 NB - 154 Kg

WIHTOUT TRIM 150 NB - 82 Kg

100 NB - 55 Kg

80 NB - 36 Kg

50 NB - 31 Kg

FINISH RAL 3000

ORDERING 1. Size of Valve

INFORMATION 2. Flange specication

3. Valve trim vertical

or horizontal

4. Trim type

113

www.shieldglobal.com

in the top chamber of the deluge valve, allowing the del-

uge valve to open and water to ow into the system piping

& alarm devices. Recommended air supply pressure for

dry pilot trim system is 3.5 kg/sq.cm.

User must install non return valve at air supply connection

to deluge valve trim.

b) WET PILOT TRIM (HYDRAULIC RELEASE)

Wet pilot operation uses a pilot line of closed Sprinklers/

QB detectors containing pressurized water, supplied

through the upstream side of the Deluge valve, through

a restricted orice. All the release lines are connected to

a common release line. Due to release of any one of the

release device, the water pressure in the top chamber of

the Deluge valve drops and the Deluge valve opens.

c) ELECTRIC RELEASE TRIM

To actuate a Deluge valve electrically, a solenoid valve is

provided to drain the water from the top chamber of the

Deluge valve. A pressure switch is provided to activate an

electric alarm, to shut down the desired equipment or to

give “Tripped” indication of the Deluge valve. In addition to

this a pressure switch can also monitor “Low air pressure”

and “Fire condition” when used in dry pilot air line.

d) TEST AND ALARM TRIM

This trim is supplied with a test valve is provided to test

the normal operation of the sprinkler alarm bell. The sprin-

SH5-TW Basic Wet Pilot Trim Vertical Schematic 1

SH5-TD Basic Dry Pilot Trim Vertical Schematic 2

SH5-TWT Basic Wet Pilot Trim with Test and Alarm Trim Vertical Schematic 3

SH5-TDT Basic Dry Pilot Trim with Test and Alarm Trim Vertical Schematic 4

SH5-TWD Basic Wet Pilot Trim with Drip and Drain Trim Vertical Schematic 5

SH5-TDD Basic Dry Pilot Trim with Drip and Drain Trim Vertical Schematic 6

SH5-NTW Basic Wet Pilot Trim with Test and Alarm Trim & Drip and Drain Trim Vertical Schematic 7

SH5-NTD Basic Dry Pilot Trim with Test and Alarm Trim & Drip and Drain Trim Vertical Schematic 8

SH5-TW Basic Wet Pilot Trim Horizontal Schematic 9

SH5-TD Basic Dry Pilot Trim Horizontal Schematic 10

SH5-TWT Basic Wet Pilot Trim with Test and Alarm Trim Horizontal Schematic 11

SH5-TDT Basic Dry Pilot Trim with Test and Alarm Trim Horizontal Schematic 12

SH5-TWD Basic Wet Pilot Trim with Drip and Drain Trim Horizontal Schematic 13

SH5-TDD Basic Dry Pilot Trim with Drip and Drain Trim Horizontal Schematic 14

SH5-NTW Basic Wet Pilot Trim with Test and Alarm Trim & Drip and Drain Trim Horizontal Schematic 15

SH5-NTD Basic Dry Pilot Trim with Test and Alarm Trim & Drip and Drain Trim Horizontal Schematic 16

TRIM

MODEL

NO.

TRIM DESCRIPTION MOUNTING SCHEMATIC NO.

kler alarm can be supplied additionally, which bells on ac-

tuation of the Deluge valve.

e) DRAIN AND DRIP TRIM

This consists of main and system drain valve in addition

with drip valve.

TRIM TYPES

The trims are designated as following.

W =Wet Pilot trim. D = Dry Pilot Trim

a) Type SH5-TW and SH5-TD

This type of trim is basic trim required to operate the deluge

valve. A solenoid valve for electric remote actuation and

pressure switch for sensing & annunciation are optional.

b) Type SH5-TWD and SH5-TDD

This trim type is a combination of components of normal

trim along with the drip and drain trim. A solenoid valve for

electric remote actuation and pressure switch for sensing

& annunciation are optional.

c) Type SH5-TWT and SH5-TDT

This trim type is a combination of components of normal

trim along with the test and alarm trim. In dry pilot trim, an

actuator is provided. A solenoid valve for electric remote

actuation and pressure switch for sensing & announciation

are optional.

114 www.shieldglobal.com

d) Type SH5-NTW and SH5-NTD

This trim type is a combination of components of normal

trim along with the test and alarm trim as well as the drip

and drain trim. A solenoid valve for electric remote actua-

tion and pressure switch for sensing & annunciation are

optional.

RESETTING PROCEDURE FOR THE

DELUGE VALVE

(i) Close the upstream side stop valve provided below the

deluge valve

ii) Open both the drain valves/ drain plugs and close when

the ow of water has ceased

(iii) Close the release device/replace the Sprinkler if re-

lease was through Sprinkler/QB Detector

iv) Inspect and release if required, or close the section of

the detection system subjected to “Fire condition”

(v) In case of dry pilot detection system, open the air sup-

ply valve to build-up air pressure. Open the priming valve

fully. Open the upstream side of the stop valve provided

below the Deluge valve. No water should ow into the sys-

tem.

vi) Where priming shut off valve (optional) is provided for

resetting, then the water need to be drained from up-

stream side of valve.

NOTE :

The valve can be reset without undergoing above proce-

dure, by just closing/replacing the release device as valve

is auto reset type. The reset time may be long or cause

vibration while closing depending on back pressure at the

outlet of the valve.

CAUTION

(a) Do not close the priming valve, downstream and up-

stream stop valves, while the system is in service.

(b) The releasing device must be maintained in the open

position, when actuated, to prevent the deluge valve from

closure if anti shut off valve is not provided.

(c) While using a Deluge valve in the wet pilot system the

height and the length of the wet pilot detection line is to

be limited as shown in the wet pilot sprinkler height limita-

tion graph.

(d) Do not connect the Sprinkler Alarm outlet drain line to

close a common drain as it may create back pressure and

Sprinkler Alarm may not function.

(e) Deluge valve must have support to absorb sudden

opening or closing vibration shock to the piping.

(f) To avoid water damage, take precautions when opening

the water supply main control valve, since water will ow

from all open system valves.

(g) The responsibility of maintenance of the protection sys-

tem and devices in proper operating condition lies with the

owner of the system.

(h) Deluge Valve & its trim shall be maintained at a minimum

temperature of 4ºC, Heat tracing is not permitted.

(i) Deluge Valve must be used in presssurised system

SYSTEM TESTING PROCEDURE

(i) Keep the upstream side of the stop valve partially open.

To avoid water ow to system side close the system side

stop valve. This valve is to be kept in open position after the

testing is completed.

(ii) Let any of the release devices to trip. This will result in

a sudden drop of water pressure in the deluge valve top

chamber which in turn will open the deluge valve. Close the

upstream side stop valve immediately.

(iii) Reset the valve as per the procedure given under head-

ing “RESETTING PROCEDURE FOR THE DELUGE VALVE”

INSPECTION AND MAINTENANCE

Installed system piping network must be ushed properly

before placing the Deluge valve in service.

A qualied and trained person must commission the sys-

tem. After few initial successful tests, an authorized person

must be trained to perform inspection and testing of the

system. It is recommended to have regular inspection and

test run of the system as per NFPA guideline or in accord-

ance to the organisation having local jurisdiction.

(i) WARNING

Inspection and testing is to be carried out only by author-

ised and trained personnel. DO NOT TURN OFF the water

supply or close any valve to make repair(s) or test the valve,

without placing a roving re patrol in the area covered by

the system. Also inform the local security personnel and

central alarm station, so that there is no false alarm signal.

It is recommended to carry out physical inspection of the

system at least twice in a week. The inspection should veri-

fy that all the control valves are in proper position as per the

system requirement and that there are no damages to any

component.

The frequency of inspections must be increased in the pres-

ence of contaminated water supplies, corrosive/ scaling

water supplies, and corrosive atmospheres.

115

www.shieldglobal.com

(ii) NORMAL CONDITION

(a) All main valves are open and are sealed with tamper

proof seal

(b) Drain valves must be kept closed

(c) No leak or drip is detected from the drip valve

(d) All the gauges except the system side water pressure

gauge, should show the required pressure

(e) There should be no leakage in the system

(iii) NORMAL CONDITION TEST

(a) The system should be checked for normal condition at

least once in a week

(b) Test the sprinkler alarm bell or electric alarm by turning

the alarm test valve to the test position. The alarm should

sound. This test should be carried out at least once in a

week

(c) Depress the drip valve knob. Signicant accumulation

indicates a possible seat leakage

(d) Conduct the water ow test as per the procedure of

system testing at least once a month

(iv) PERIODIC CHECK

Conduct the water ow test by actuating few of the release

devices provided in the system. Clean all strainer(s) and

priming line restriction. This test is to be carried out at least

once in three months.

ABNORMAL CONDITION

(i) ALARM FAILS TO SOUND

(a) Check for any obstruction in the alarm test line, make

certain that the sprinkler alarm is free to operate

(b) If an electric alarm is provided, check the electrical cir-

cuitry to the alarm

(ii) FALSE TRIPS

(a) Check for clogging in priming line, restriction orice

check valve, priming valve & strainer

(b) Leakage in the release system

(c) The deluge air panel orice clogged or low supply pres-

sure

(iii) LEAKAGE THROUGH THE DELUGE VALVE

(a) Damaged deluge valve seat or obstruction on the seat

face by foreign object

(b) Leakage in release system

(c) Partly clogged priming line restriction orice check valve

(d) Low air pressure on release system line or leakage in

release system

116 www.shieldglobal.com

NOMINAL PRESSURE LOSS VS FLOW

117

www.shieldglobal.com

DELUGE VALVE MODEL - SD-DVH5

PART LIST

ITEM

PART NO. DESCRIPTION QTY. MATERIAL

SPECIFICATION

200 NB 150 NB 100 NB 80 NB 50 NB 200 NB 150 NB 100 NB 80/50NB

1 H5201 H5601 H5101 H5801 H5501 Housing 1 1 1 1 Aluminium Bronze BS1400-AB2

2 H5202 H5602 H5102 H5802 H5502 “O” Ring 1111Neoprene Rubber

3 H5203 H5603 H5103 H3803 H5503 Seat 1111Aluminium Bronze BS1400-AB2

4 H5204 H5604 H5104 --- --- Bolt 844--- Monel 400

5 H5205 H5605 H5105 H5805 H5505 Rubber Clamp 1111Aluminium Bronze BS1400-AB2

6 H5206 H5606 H5106 H5806 H5506 Rubber Seat 1111Neoprene Rubber

7 H5207 H5607 H5107 H5807 H5507 Clapper 1111Aluminium Bronze BS1400-AB2

8 H5208 H5608 H5108 H5808 H5508 Diaphram 1111Neoprene Rubber

9 H5209 H5609 H5109 H5809 H5509 Clamp Ring 1111Aluminium Bronze BS1400-AB2

10 H5210 H5610 H5110 H5810 H5510 Bolt 12 888Monel 400

11 H5211 H5611 H5111 H5811 H5511 “O” Ring 1111Neoprene Rubber

12 H5212 H5612 H5112 H5812 H5512 Spindle 1111Monel 400

13 H5213 H5613 H5113 H5813 H5513 Nut 1111Monel 400

14 H5214 H5614 H5114 H5814 H5514 Lock Nut 1111Monel 400

15 H5215 H5615 H5115 H5815 H5515 Spring 1111Inconel-X-750

16 H5216 H5616 H5116 H5816 H5516 Adaptor 1111Aluminium Bronze BS1400-AB2

17 H5217 H5617 H5117 H5817 H5517 Cover 1111Aluminium Bronze BS1400-AB2

18 H5218 H5618 H5118 H5818 H5518 Bolt 16 12 12 12 Stainless Steel

19 H5219 H5619 H5119 H5819 H5519 “O” Ring 1111Neoprene Rubber

20 H5220 H5621 H5120 H5820 H5520 Plug 1111Aluminium Bronze BS1400-AB2

21 H5221 --- --- --- --- Allen Bolt 6--- --- --- Monel 400

Valve

Nominal Size ‘A’ ‘B’

200 NB 552 332

150 NB 462 282

100 NB 412 245

80 NB 372 232

50 NB 320 232

Dimension in mm. (Approximate)

118 www.shieldglobal.com

SCHEMATIC FOR WET PILOT BASIC TRIM FOR DELUGE VALVE

FOR VERTICAL MOUNTING

SCHEMATIC FOR DRY PILOT BASIC TRIM FOR DELUGE VALVE

FOR VERTICAL MOUNTING

DV Deluge Valve

SV Solenoid Valve

G Sprinkler Alarm (WMG)

M Emergency Release Station

RN Restriction Nozzle (Priming Line)

PS1 Low Air Alarm Pressure Switch

PS2 Waterow Pressure Alarm Switch

Valve

--- By User

** Optional

Strainer

OD Open Drain

PG Pressure Guage

Swing Check Valve

Angle Valve

DPA Dry Pilot Actuator

RN-A Restriction Nozzle (Air Line)

SCV Swing Check Valve

SH5-TW

SH5-TD

119

www.shieldglobal.com

SCHEMATIC FOR WET PILOT BASIC TRIM FOR DELUGE VALVE

FOR VERTICAL MOUNTING

SCHEMATIC FOR DRY PILOT BASIC TRIM FOR DELUGE VALVE

FOR VERTICAL MOUNTING

DV Deluge Valve

SV Solenoid Valve

G Sprinkler Alarm (WMG)

M Emergency Release Station

RN Restriction Nozzle (Priming Line)

PS1 Low Air Alarm Pressure Switch

PS2 Waterow Pressure Alarm Switch

Valve

--- By User

** Optional

Strainer

OD Open Drain

PG Pressure Guage

Swing Check Valve

Angle Valve

DPA Dry Pilot Actuator

RN-A Restriction Nozzle (Air Line)

SCV Swing Check Valve

SH5-TWT

SH5-TDT

120 www.shieldglobal.com

SCHEMATIC FOR WET PILOT BASIC TRIM FOR DELUGE VALVE

FOR VERTICAL MOUNTING

SCHEMATIC FOR DRY PILOT BASIC TRIM FOR DELUGE VALVE

FOR VERTICAL MOUNTING

DV Deluge Valve

SV Solenoid Valve

G Sprinkler Alarm (WMG)

M Emergency Release Station

RN Restriction Nozzle (Priming Line)

PS1 Low Air Alarm Pressure Switch

PS2 Waterow Pressure Alarm Switch

Valve

--- By User

** Optional

Strainer

OD Open Drain

PG Pressure Guage

Swing Check Valve

Angle Valve

DPA Dry Pilot Actuator

RN-A Restriction Nozzle (Air Line)

SCV Swing Check Valve

SH5-TWD

SH5-TDD

121

www.shieldglobal.com

SCHEMATIC FOR WET PILOT BASIC TRIM FOR DELUGE VALVE

FOR VERTICAL MOUNTING

SCHEMATIC FOR DRY PILOT BASIC TRIM FOR DELUGE VALVE

FOR VERTICAL MOUNTING

DV Deluge Valve

SV Solenoid Valve

G Sprinkler Alarm (WMG)

M Emergency Release Station

RN Restriction Nozzle (Priming Line)

PS1 Low Air Alarm Pressure Switch

PS2 Waterow Pressure Alarm Switch

Valve

--- By User

** Optional

Strainer

OD Open Drain

PG Pressure Guage

Swing Check Valve

Angle Valve

DPA Dry Pilot Actuator

RN-A Restriction Nozzle (Air Line)

SCV Swing Check Valve

SH5-NTW

SH5-NTD

122 www.shieldglobal.com

SCHEMATIC FOR WET PILOT BASIC TRIM FOR DELUGE VALVE

FOR HORIZONTAL MOUNTING

SCHEMATIC FOR DRY PILOT BASIC TRIM FOR DELUGE VALVE

FOR HORIZONTAL MOUNTING

DV Deluge Valve

SV Solenoid Valve

G Sprinkler Alarm (WMG)

M Emergency Release Station

RN Restriction Nozzle (Priming Line)

PS1 Low Air Alarm Pressure Switch

PS2 Waterow Pressure Alarm Switch

Valve

--- By User

** Optional

Strainer

OD Open Drain

PG Pressure Guage

Swing Check Valve

Angle Valve

DPA Dry Pilot Actuator

RN-A Restriction Nozzle (Air Line)

SCV Swing Check Valve

SH5-TW

SH5-TD

123

www.shieldglobal.com

DV Deluge Valve

SV Solenoid Valve

G Sprinkler Alarm (WMG)

M Emergency Release Station

RN Restriction Nozzle (Priming Line)

PS1 Low Air Alarm Pressure Switch

PS2 Waterow Pressure Alarm Switch

Valve

--- By User

** Optional

Strainer

OD Open Drain

PG Pressure Guage

Swing Check Valve

Angle Valve

DPA Dry Pilot Actuator

RN-A Restriction Nozzle (Air Line)

SCV Swing Check Valve

SCHEMATIC FOR WET PILOT BASIC TRIM FOR DELUGE VALVE

FOR HORIZONTAL MOUNTING

SCHEMATIC FOR DRY PILOT BASIC TRIM FOR DELUGE VALVE

FOR HORIZONTAL MOUNTING

SH5-TWT

SH5-TDT

124 www.shieldglobal.com

SCHEMATIC FOR WET PILOT BASIC TRIM FOR DELUGE VALVE

FOR HORIZONTAL MOUNTING

SCHEMATIC FOR DRY PILOT BASIC TRIM FOR DELUGE VALVE

FOR HORIZONTAL MOUNTING

DV Deluge Valve

SV Solenoid Valve

G Sprinkler Alarm (WMG)

M Emergency Release Station

RN Restriction Nozzle (Priming Line)

PS1 Low Air Alarm Pressure Switch

PS2 Waterow Pressure Alarm Switch

Valve

--- By User

** Optional

Strainer

OD Open Drain

PG Pressure Guage

Swing Check Valve

Angle Valve

DPA Dry Pilot Actuator

RN-A Restriction Nozzle (Air Line)

SCV Swing Check Valve

SH5-TWD

SH5-TDD

125

www.shieldglobal.com

SCHEMATIC FOR WET PILOT BASIC TRIM FOR DELUGE VALVE

FOR HORIZONTAL MOUNTING

SCHEMATIC FOR DRY PILOT BASIC TRIM FOR DELUGE VALVE

FOR HORIZONTAL MOUNTING

DV Deluge Valve

SV Solenoid Valve

G Sprinkler Alarm (WMG)

M Emergency Release Station

RN Restriction Nozzle (Priming Line)

PS1 Low Air Alarm Pressure Switch

PS2 Waterow Pressure Alarm Switch

Valve

--- By User

** Optional

Strainer

OD Open Drain

PG Pressure Guage

Swing Check Valve

Angle Valve

DPA Dry Pilot Actuator

RN-A Restriction Nozzle (Air Line)

SCV Swing Check Valve

SH5-NTW

SH5-NTD

126 www.shieldglobal.com

SPRINKLER HEIGHT LIMITATION

127

www.shieldglobal.com

NOMINAL PRESSURE LOSS VS FLOW

* 2.3 PSI Pressure loss @ 15 feet per second (4.57 met/sec) velocity having ow of 594 LPM thru 50NB DV

* 4.7 PSI Pressure loss @ 15 feet per second (4.57 met/sec) velocity having ow of 1308 LPM thru 80NB DV

* 4.7 PSI Pressure loss @ 15 feet per second (4.57 met/sec) velocity having ow of 2255 LPM thru 100NB DV

* 7.5 PSI Pressure loss @ 15 feet per second (4.57 met/sec) velocity having ow of 5117 LPM thru 150NB DV

* 8.4 PSI Pressure loss @ 15 feet per second (4.57 met/sec) velocity having ow of 8854 LPM thru 200NB DV

Table of contents

Popular Control Unit manuals by other brands

Viessmann

Viessmann Vitocal WPR 300 Service instructions

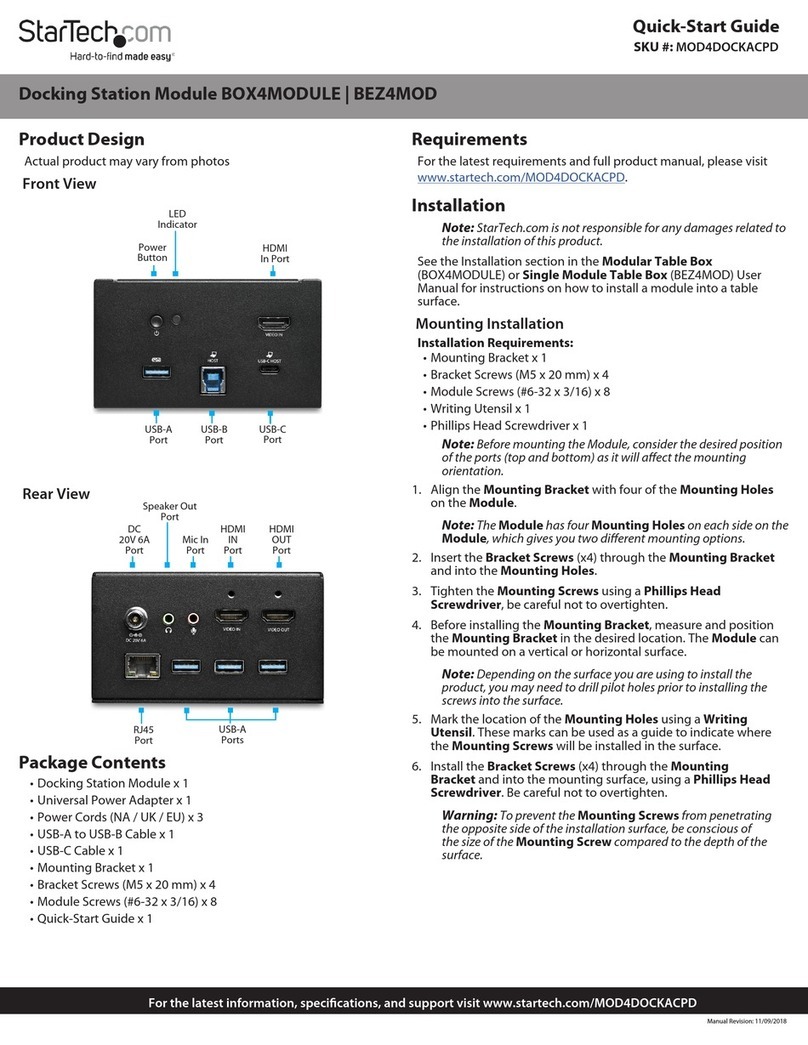

StarTech.com

StarTech.com BOX4MODULE quick start guide

VAT

VAT 570 Series Installation, operating, & maintenance instructions

Lincoln Electric

Lincoln Electric APEX 3000 Operator's manual

Grundfos

Grundfos CIM 500 Installation and operating instructions

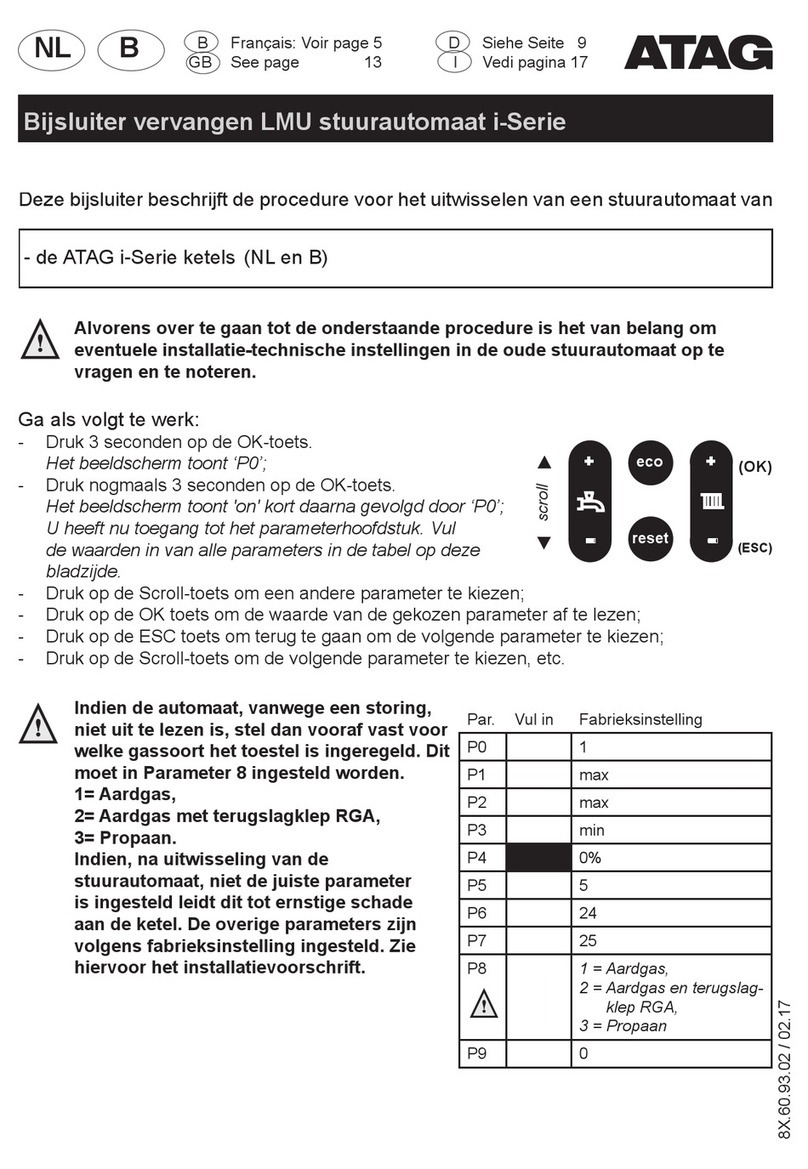

Atag

Atag LMU-C i-Series instructions