Shin-Nippon BR-7 User manual

r

μπα

να

2

LT

|

SHIN-NIPPON

REFRACTOR

MODEL:

BR—

7

SERVICE

MANUAL

CONTENTS

1.

Introduction

1-1

Features

of

the

Product

1-2

Qualified

Service

Person

1-3

How

to

Use

the

Service

Manual

1-4

Layout

Plan

of

Optical

Parts

1-5

Name

and

Performance

of

Parts

2.

Service

Items

Disassembly/Inspection/Adjustment

Procedure

3.

Remarks

371

Adhesion,

Kind

of

Oil

and

Application

Point

3-2

Service

Tools

+14

18

q.

RS

a

σον

+

eee

meme

e

qe,

기

Introduction

Features

of

the

Product

We

offer

with

confidence

this

optometer

as

a

self-

canscious

optometer

completed

while

incorporating

necessary

and

sufficient

functions

on

the

basis

of

invaluable

experiment

of

those

who

actually

engage

in

optometry

and our

long

experience

in

this

field.

This

product

will

meet

the

demand

of

those

who

want

correct

and

rapid

optometry.

The

beautiful

appearance

and

comprehensive

functions

of

the

product

will

surely

prove

satisfactory:

(1)

The

cross

cylinder

and

rotary

prism,

which

are

of

a

double

loupe

(turret)

type,

help

keeping

a

constant

distance

from

the

eyes,

ensuring

precision

measurement

and

easy

use.

(2)

A

synchronous

mechanism

allows

the

cross

cylinder

loupe

to

move

automatically

while

being

interlocked

with

a

cylindrical

axis,

ensuring

highly

effective

precision

measurement

of

the

astigmatism.

(3)

Easy

operation

through

front

observation

and

front

operation

(4)

Large

power

indicator

window,

enabling

easy

reading

(S)

Wide-ranging

inspections

(binocular

visual

function

sette

e

TO

1-2

1-3

inspection,

etc.)

possible

through

combination

of

a

visual

acuity

tester

and

abundant

auxiliary

lenses

(6)

In

a

convergence

mechanism

for

near

distance

inspection,

the

entire

optical

mechanism

can

be

correctly

set

through

lever

operation.

(7)

Eaceïshieïlds

and

an

optometry

window

are

provided

With

a

coated

dust-proof

glass

which

prevents

light

reflection

and

contamination

of

the

lenses

in

the

equipment.

Qualified

Service

Person

Servicing

of

this

product

must

be

made

by

a

person

who

is

experienced

in

assembly

and

adjustment

of

the

medical

equipment

(in

particular,

the

reflector

head).

It

is

recommended

for

the

others

to

attend

the

course

on

servicing

technology

of

Towa

Co.,

Ltd.

How

to

Use

the

Service

Manual

(1)

The

service

operation

must

be

based

on

the

flow

chart

shown

below.

(

Trouble

Understanding

the

cause

of

trouble

|

pe

TTT

σος

ο

πο

一

一

一

Servicing

NO

一

necessary?

(2)

(3)

(4)

>

Servicing

Inspection

Cleaning

<

y

Packing

End

Carry

out

disassembly,

servicing,

assembly

and

adjustment

of

the

optical

system

in

a

clean

place

where

there

is

no

adverse

effect

on

the

product

due

to

dust,

etc.

Always

observe

the

manual

thoroughly

and

use

the

specified

materials

and

tools,

ensuring

correct

and

reliable

servicing.

Basically,

replace

the

metal

parts

as

individual

pieces

and

the

optical

system

components

as

a

unit.

~5-

a

art

verita

dl

=

(5)

For

disassembly

and

assembly

of

parts

not

described

in

this

manual,

refer

to

the

service

parts

list.

(6)

Never

use

the

lubricating

oil

other

than

the

one

specified.

(7)

Order

the

service

parts

while

referring

to

the

service

parts

list.

1-4

Layout

Plan

of

Optical

Parts

Sl

(spherical

disk)

Madox,

red

Deflection

45°

ACC

(accessory)

EL

pie

n

RE

NT

TR

τος.

R

L

Ro»

7

CNV

AORN

/

]

|

HY

ROD

Ap

Ci

astigmatic

disk

C2

astigmatic

disk

ses

Cross

cylinder

and

rotary

prism

1-5

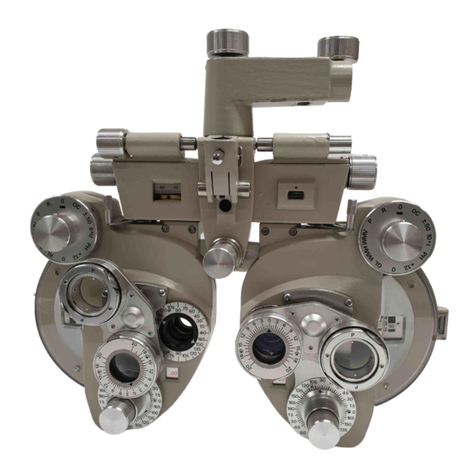

Name

and

Performance

of

Parts

M.

VĚ

1

28

ee

iai

gg

de

No.

Name

No.

_

Name

©

Level

adjusting

knob

02

Cross

cylinder

(2)

'

PD

scale

©

Loupe

3

Forehead

rest

adjusting

knob

©

Cornea

focus

A)

Level

shaft

09

Astigmatic

scale

plate

⑤

Level

⑯

Cylindrical

axis

scale

plate

©

Head

cover

00

Astigmatic

case

D

PD

adjusting

knob

08

Power

handle

©

Convergence

knob

©

Cylindrical

axis

knob

©

Auxiliary

lens

scale

plate

00

Astigmatic

lens

knob

00

Auxiliary

lens

knob

21

Forehead

rest

⑪

Rotary

prism

|

22

Cheek

rest

23

Spherical

case

Service

Items

D

Adjustment

of

the

lateral

movement

and

play

of

PD

Adjustment

of

the

deviation

and

play

of

the

astigmatic

lens

holder

Adjustment

of

the

turret

Adjustment

of

the

stopper

roller

of

each

disk

plate

Adjustment

of

the

cornea

scale

Replacement

of

the

cross

cylinder

σα

σας

or,

ποτ

καν

νο

ο."

πω,

”~

一

一

”下

Disassembly/Inspection/Adjustment

Procedure

Illustration

Procedure

6)

ta?

[es]

t £

th

lateral

daiane

jrs

Loosen

to

remove

Fa

spring

case

(#6)

and

remove

spring

guide

(#9)

and

level

coll

(#4).

loosen

lwo

screws

6R

3x8

(#2)

and

remove

lhe

head

cover

(41).

Loosen

Lo

remove

6W

3x8

(#19)

and

remove

the

PD

knob

(#12),

Loosen

to

remove

two

screws

68

3x8

(411)

and

remove

the

PD

bearing

#10),

Turn

two

to

three

times

to

loosen

four

screws

6S

3x8

(#7)

on

the

Guide

plate

(#8)

and

adjusl

the

laleral

movement

and

play

of

pp

with

four

screws

GU

3x5

(#6)

of

the

nead

(#9),

(See

Fig.

1)

(2)

Adjusting

the

deviation

and

play

of

the

astigmatic

lens

holder

Tighten

or

lvwsen

the

holder

fixing

screw

(815)

and

serew

6U

2.6x3

(#16)

on

the

lens

holder

(#14)

and

adjusl

the

deviation

and

play

of

the

lens

holder.

(See

Fig.

2)

тот

о

р

unii

в

ere

이

게제

ae

ο

前

a

er

Illustration

Procedure

#18

(8)

Adjusling

the

lurret

(1)

Lateral

adjustment

1.

Adjust

the

lateral

movement

of

the

lurrel

wilh

a

Screw

U

4x4

(H18)

op

the

side

of

lhe

click.

mount

(#17),

(See

Fig.

3)

(2)

Vertical

adjustment

l.

Loosen

three

screws

CRs

2x3

(#819)

and

remove

lhe

cover

(820),

Dm

lLoosen

a

serew

6U

2x3

($21)

and

remove

a

cenler

gear

(422).

3.

Carry

oul

verlical

adjustment

of

the

lLurret

wilt

a

ring

nul

(#24)

and

hexagon

nul

(#23).

,

(See

Fig.

4)

-10-

SE

AT

TO

ET

EE

ME

a

이

Illustration

,

Procedure

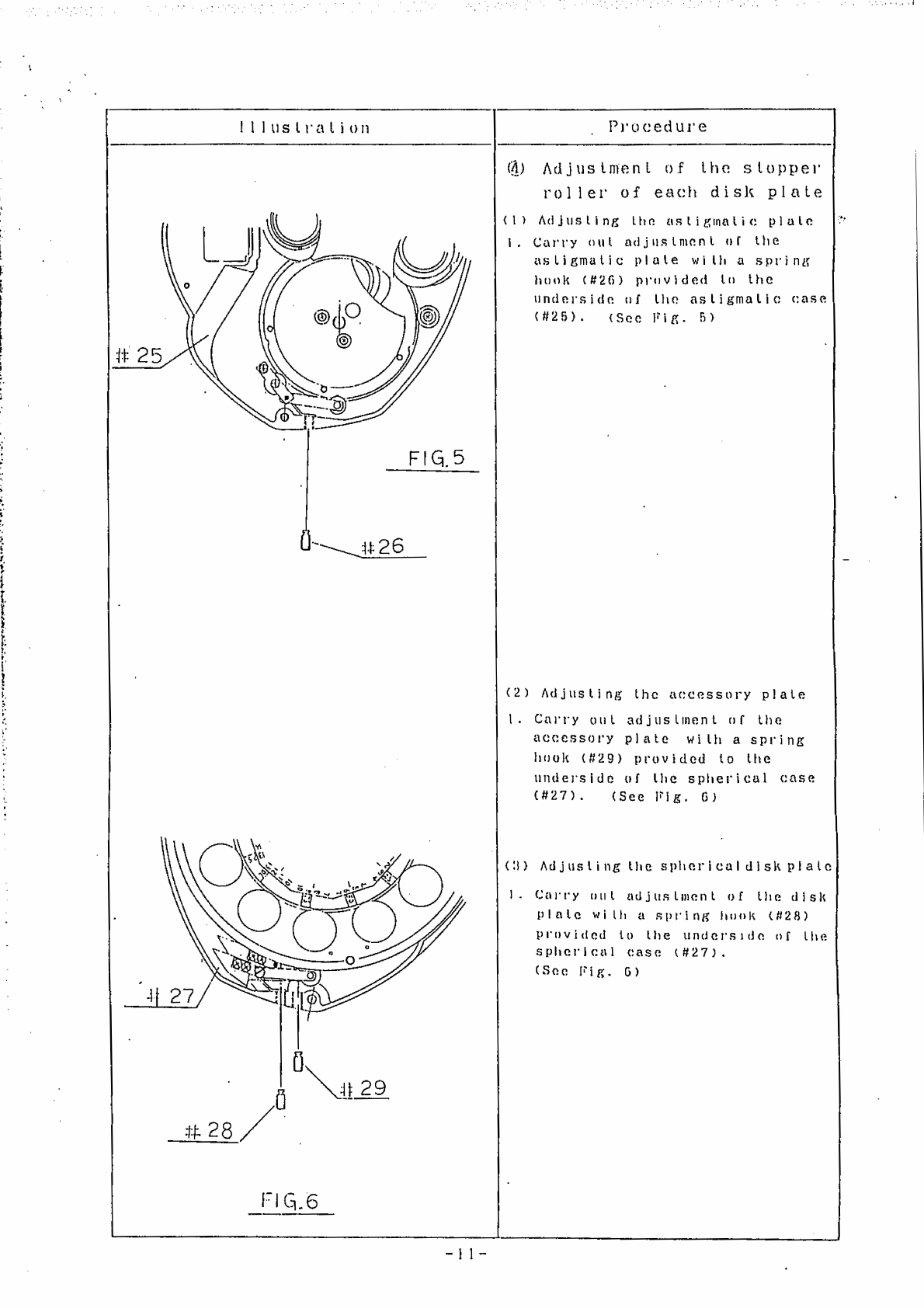

à)

Adjustment

of

the

stopper

roller

of

each

disk

plate

(1)

Adjusling

the

asligmatic

plale

I.

Carry

oul

adjustment

of

the

asligmatic

plale

with

a

spring

hook

(#26)

provided

to

the

underside

of

the

astigmalic

case

(#25).

(See

Fig.

5)

FIGS

—

4426

(2)

Adjusting

the

aceessory

plate

し.

Carry

out

adjustment

of

the

accessory

plate

wilh

a

spring

hook

(#29)

provided

to

the

underside

of

the

spherical

case

(#27).

(See

Fig,

6)

(3)

Adjusting

the

sphericaldisk

plate

1.

Carry

oul

adjuslment

of

the

disk

pPlale

wilh

a

spring

hook

(828)

provided

to

the

underside

of

Lhe

spherical

case

(#27).

(See

lig.

6)

=]]-

Ань

+.

ль

1

dii

İNE

RR

lele

ln

A

PR

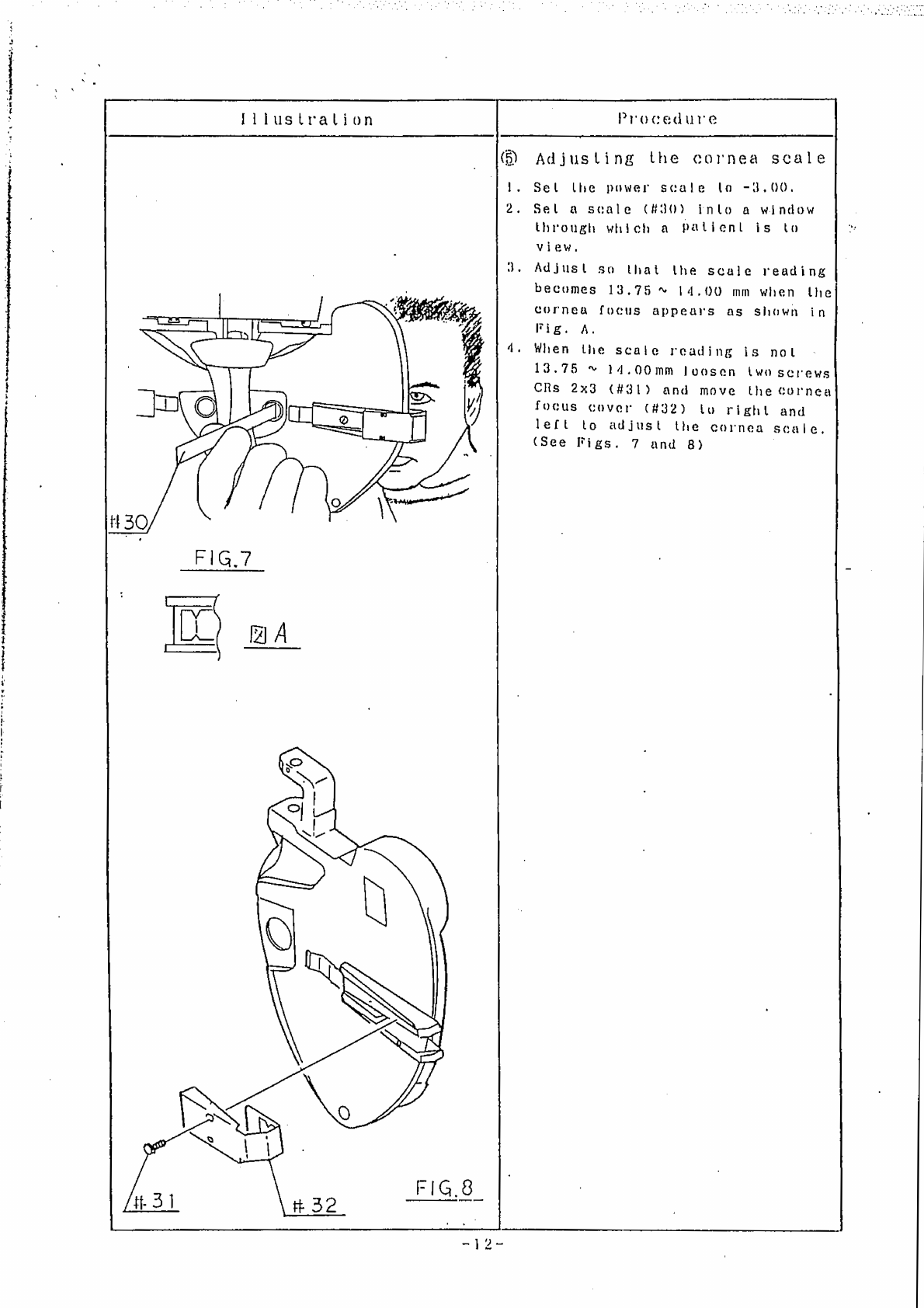

Iliustralion

Procedure

#

31

FIG.8

bhe

©

Adjusting

the

cornea

scale

Sel

lhe

power

scale

lo

-3,00,

Sel

a

scale

(#30)

inlo

a

window

through

which

a

Patienl

is

to

view,

Adjust

sa

that

the

scale

reading

becomes

13.75»

14,00

mm

when

the

cornea

focus

appears

as

shown

in

Fig.

A,

When

the

scale

reading

is

nol

13.75

%

14,00

mm

Ivosen

two

screws

CRs

2x3

(#31)

and

move

lhe

cornea

focus

cover

(#32)

lu

right

and

left

to

adjust

the

cornea

scale.

(See

Figs.

7

and

8)

|

ー1

2ー

In

es

tampar

rt

pao

da

ARS

porre

ae

Illustralion

Procedure

#

36

FIG.9

(6)

Replacing

the

cross

cylinder

1.

Loosen

four

serews

Chts

2x3

($23),

and

remove

an

indicalor

plale

|

(#34)

and

spring

(#35),

Then,

replace

the

cross

cylinder

(#36).

(See

Fig.

9)

Note:Replacement:

‘of

:C+—0.:37¢and.-

С+-0.

50

sis:possible

optionally:

=

13-

|

FN

nm

on

ュー

e

a

Ce

SORT

RR

a

ee

A

i

r

sj

“ro

es

:

ft

oy

Di

tae

2444

ту

Va

Note:

feripacemen

i

af

116,37

end

C1i0,56

te

pussibte

ο.

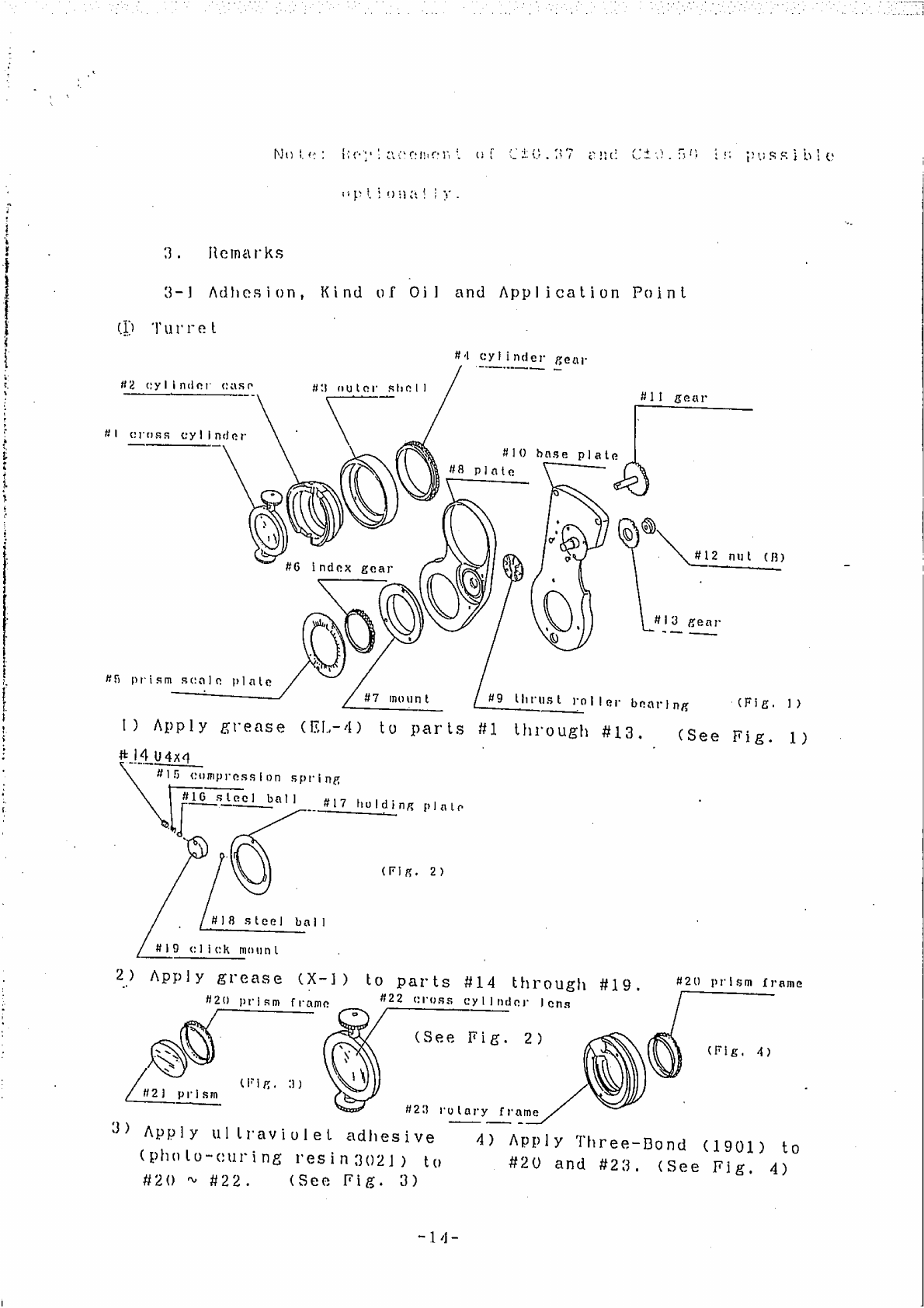

3.

Remarks

3-1

Adhesion,

Kind

of

Oi]

and

Application

Point

(D

Turret

Rd

cylinder

gear

#2

cylinder

case

#

outer

shell

gear

Bl

cross

cylinder

——

#10

base

plate

#8

plate

©,

Ne:

nut

(B)

—

—

mi

#6

index

gear

SIG

#13

gear

©

47

mount

#9

thrust

ist

roller

bearing

(Fig.

1)

1)

Apply

grease

(EL-4)

to

parts

#1

through

#13,

(See

Fig.

1)

#

14

0484

ТЕ

RR

prism

scale

plate

compression

spring

#16

stecl

bal]

#17

hulding

plate

mm,

©

(Fig.

2)

#18

steel

bail]

#19

click

mount

2)

Apply

grease

(X-1)

to

parts

#14

through

#

#20

prism

frame

:

420

prism

frame

#22

cross

cylinder

Jeng

SN

(See

Fig.

2)

(Fig.

4)

(Fig.

1)

#2)

prism

“一

一

一

一

#29

vulary

fr

frame

9)

Apply

ullravivolet

adhesive

4)

Apply

Three-Bond

(1901)

to

(pholo-curing

resin3021)

to

#20

and

#23.

(See

Fig,

4)

#20

~

#22. (See

Fig.

3)

-l4-

PAR

Mrs

OR

EAU

Fr

©

“lead

support

#24

forehead

|

#25

shaft

case

#26

thrust

roller

bearing

#27

forehead

resi

sorew

(Fig.

5)

#28

knob

1)

Apply

grease

(001)

to

Parts

#24

through

#28.

(See

Fig.

5)

#31

Knob

#39

level

bearing

#34

washer

#32

washer

#35

level

screw

#39

slide

3)

Apply

grease

(001)

to

parts

#31

through

#36.

(See

Fig.

7)

#41

PD

serew

and

nut

5)

Apply

grease

(005)

to

parts

#41

and

#42.

(See

Fig.

9)

(Fig.

7)

L

#36

level

Shaft

bearing

rest

shaft

#29

holder

Pin

(Fig.

6)

#30

scale

holder

2)

Apply

grease

(X-1)

to

parts

#29

and

#30.

(See

Fig.

6)

#37

leve]

coi]

#40

shaft

4)

Apply

grease

(X-1)

to

parts

#37

through

#40.

(See

Fig.

8)

#42

PD

bearing

#44

65

2x6

#43

Plate

(Fig.

10)

6)

Apply

silicon

(liquid

type

RTV

rubber

of

Shin-Etsu

Silicon)

to

parts

#43

and

#44,

(See

Fig.

10)

A

TT

©

Spherical

case

HAS

lens

$46

prism

#49

Madox

(Fig.

11)

(Fig.

12)

#48

filter

O

|

1)

Apply

ultraviolet

adhesive

(photo-curing

.#50

polaroid

disk

resin

3021)

to

parts

#45

»

#47.

|

2)

Apply

GS

cement

to

parts

(See

Fig.

11)

| |

#48

to

#50.

(See

Fig.

12)

#51

feed

Plate

shaft

4

#56

wheel

pipe

.

SÌ

m_

#51

seat

metal

.

#58

steel

ball

#57

thrust

#52

thrust

+

+

roller

bearing

Es

Me”

roller

bearing

(Fig.

14)

全

、

στο

#53

thrust

roller

bearing

|

$

RD

sa

nut

4)

Apply

grease

(X-1)

to

the

part

#58.

(See

Fig.

14)

(Fig.

13)

#55

gear

3)

Apply

grease

(EL-4)

to

parts

$51

through

#57.

(See

Fig.

13)

©

Near

point

scale

#59

spring

#60

sleel

ball

1)

Apply

grease

(X-1)

to

parts

#59

to

#61.

(See

Fig.

15)

#61

card

holder

(Fig.

15)

®

Near

point

scale

holder

(Fig.

16)

1)

Fill

a

port

A

with

machine

oil.

(See

Fig.

16)

#63

scale

holder

#62

level

angle

~

«16

--

Wee

о

mi

em a

+

Fair

sr

etě

ra

‘)

Asligmatic

case

#64

thrust

ruller

bearing

%

#65

cylinder

flange

(Fig.

17)

#67

shaft

1)

Apply

grease

(EL-4)

to

parts

#64

through

#67.

(See

Fig.

17)

#72

cylindrical

axis

gear

#71

bearing

(Fig.

19)

3)

Apply

grease

(X-1)

to

parts

#71

and

#72.

(See

Fig.

19)

D

Accessories

“ο

(Fig.

21)

#74

dust-proof

glass

~

j=

e

1)

Apply

Three-Bond

(1782)

to

the

part

#74.

(See

Fig.

21)

#06

holder

#70

astigmatic

case

#63

cylinder

cover

#69

washer

2)

Apply

ultraviolet

adhesive

(photo

-curing

resin

3021)

to

the

part

#68

and

apply

Three-Bond

(1782)

to

parts

#69

and

#70.

(See

Fig.

18)

(Fig.

20)

4)

Apply

GS

cement

ta

all

of

lenses

(#73)

in

the

lens

holder.

(See

Fig.

20)

‘#75

lens

holder

=

(Fig.

22)

4

a»

—

#76

lens

2)

Apply

ultrasonic

adhesive

(photo

“curing

resin

3021)

to

Parts

#75

and

#76.

(See Fig.

22)

—17

—

Service

Tools

1.

Set

screwdriver

(standard

and

Philips

screwdrivers

#0).

à,

2,

Hexagonal

wrenches

(1.5,

2.0,

2.5

and

3.0

mm)

3.

Radio

pliers

No

other

dedicated

tools

than

those

specified

above

will.

not

be

necessary

for

the

service

work

desoribed

in

this

manual.

-18-

Other manuals for BR-7

1

Table of contents

Other Shin-Nippon Medical Equipment manuals

Popular Medical Equipment manuals by other brands

sensiplast

sensiplast 298610 Instructions for use

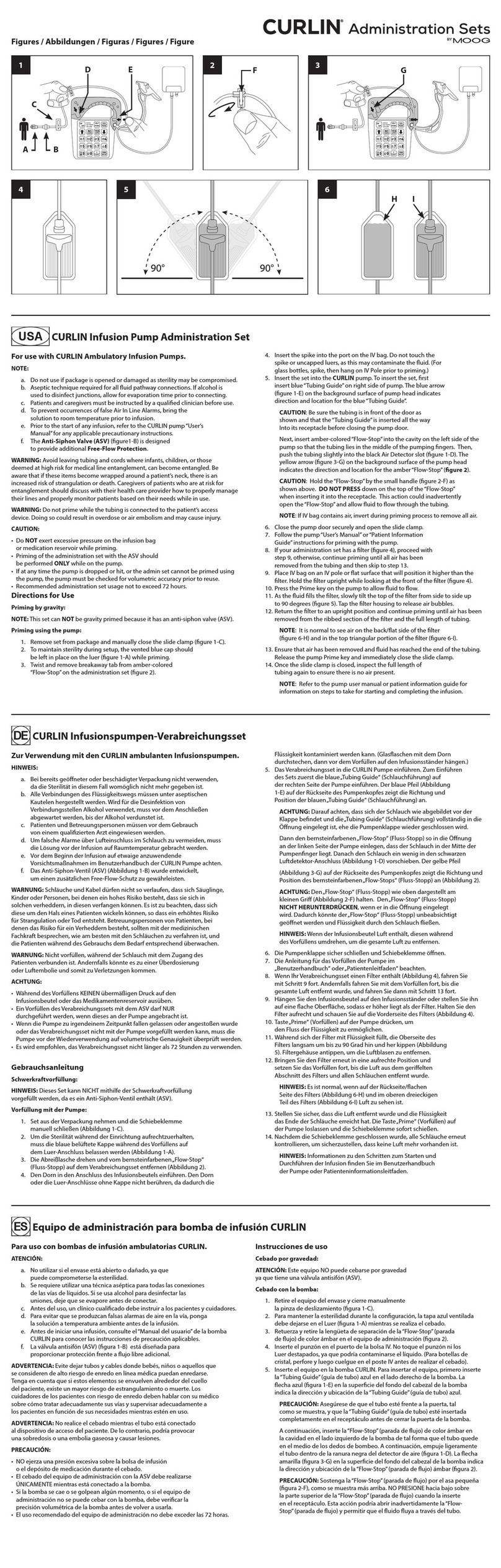

Moog

Moog CURLIN 340 manual

Dräger

Dräger Infinity Acute Care System Workstation Critical... Supplement to instructions for use

CSZ

CSZ Blanketrol_ii Operation and technical manual

Breas

Breas NIPPY Clearway Clinical Guide

ADC

ADC 5110N Series Instructions for use