Shinko Electric CHC-S1245-5 Technical specifications

YQE8-J0092E

Date: March 8, 2005

Revised:

Revision: First Edition

Confirmation Signature

(Shinko Electric Co., Ltd.)

Approved Inspected Drew

(Custome

r

: )

Shinko Electric Co., Ltd.

Digital Photo Printer

CHC-S1245-5

Maintenance Specifications

YQE8-J0092E

Revision Record

Revised Date Correction

symbol

Descriptions ECN No.

3/8/2005 -First Edition

YQE8-J0092E

Contents

1.Scope....................................................................................................................................................1

2.Periodic Inspection................................................................................................................................2

2.1 Parts Required.................................................................................................................................................. 2

2.2 Tools Required ................................................................................................................................................ 2

2.3 Tool Required.................................................................................................................................................. 2

2.4 Maintenance Schedule..................................................................................................................................... 3

2.5 Inspection Contents ......................................................................................................................................... 4

2.6 Description for point of cleaning..................................................................................................................... 6

2.7 Description for point of lubrication............................................................................................................... 11

3.Adjustment ..........................................................................................................................................14

3.1 Power Unit Voltage Setting........................................................................................................................... 14

3.1.1 +5V Setting............................................................................................................................................. 14

3.1.2 Thermal Head Power (THV) Setting...................................................................................................... 15

3.1.3 +24V Verification................................................................................................................................... 15

3.2 Timing Belts Adjustment............................................................................................................................... 16

3.2.1 For Feed Roller Drive............................................................................................................................. 16

3.2.2 For Feed Roller Drive............................................................................................................................. 16

3.2.3 For Roll Paper Drive............................................................................................................................... 16

3.3 Print Density Adjustment .............................................................................................................................. 17

3.4 Resetting Maintenance Print Counter and Cutter Counter............................................................................. 18

4.Test Printing........................................................................................................................................20

5.Troubleshooting ..................................................................................................................................21

5.1 How to Use This Specification...................................................................................................................... 21

5.2 Troubleshooting Table................................................................................................................................... 22

5.2.1 Troubles during Power On and Off ........................................................................................................ 22

5.2.2 Error Messages on LCD Display when Power Is On ............................................................................. 24

5.2.3 Troubles in Operation Buttons and Indicators........................................................................................ 29

5.2.4 Troubles in Paper Feed........................................................................................................................... 31

5.2.5 Troubles in Feeding Ink Ribbon............................................................................................................. 34

5.2.6 Troubles in Printing and Contents of Printing........................................................................................ 36

5.2.7 Occurrence of Abnormal Noise.............................................................................................................. 39

5.2.8 Troubles in Connection........................................................................................................................... 41

Appendix 1: Maintenance Parts List (including Periodic Replacement Parts).........................................43

Appendix 2: BLOCK DIAGRAM................................................................................................................45

YQE8-J0092E

1

1.Scope

This document is applicable to the following Shinko Digital Photo Printer.

Applicable Model Name:CHC-S1245-5

Related Documents

・Maintenance Parts Replacement Procedures YQE8-J0093E

・Operation Manual YTE8-J0124E

YQE8-J0092E

2

2.Periodic Inspection

2.1 Parts Required

№Description Parts Number Q’ty Supplier Remarks

1 Head Cleaning Kit 060-91-7146 1Option

2 Isopropyl Alcohol (IPA) or Ethyl

Alcohol (more than 99% purity)

Some Available on

market

3 Bleached Cloth Some Available on

market

4 Grease (equivalent to MOLYKOTE

PG-671)

Some Available on

market

5Wire Tire (insulation lock) 060-64-8011 20

2.2 Tools Required

Description Model Type Q’ty

+Philips Screwdriver #0(Micro-driver)1

+Philips Screwdriver #11

+Philips Screwdriver(small)#2 (less than 100mm in length)1

+Philips Screwdriver #21

+Philips Screwdriver #2(more than 300mm in length)1

+Philips Screwdriver #2(Latch type)1

−Flat-blade Screwdriver(small)2.5×100 1

−Flat-blade Screwdriver(small)4.5×50 1

Nipper 1

Pliers 1

Scissors 1

Clip for Digital Voltmeter Refer to figure below for aspect 2

Clip for Digital Voltmeter

2.3 Tool Required

Description Remarks

Digital Voltmeter 0.1V unit of measurement

YQE8-J0092E3

2.4 Maintenance Schedule

Periodic inspection is performed according to the following schedule. If problem is detected during the inspection, adjustment or Replacement of parts may be

necessary. Schedule

○(circle) denotes to Perform, R denotes to Replace

Number of Prints

(K=1,000 prints)

№Inspect Item

10K 20K 30K 40K 50K 60K 70K 80K 90K 100K

Remarks

1 Thermal Head ○R○R○R○R○R

2 Platen Roller ○○○○○○○○○○

3 Timing Belt ○○○○○○○○○○

4 DC Power Supply ○

5DCMotorASSY

(Ribbon winding)

RRR

6DCMotorASSY

・Thermal Head Up/Down

・Pinch Roller UP/Down

・Paper Feed Pinch Up/Down

・Paper Ejection Pinch Up/Down

R

7 Ribbon Brake 2 ASSY R

8 Pinch Roller ASSY ○○○○○○○○○○

9 Cleaning ○○○○○○○○○○

Lubricate ○○○○○

10

Lubricate (DC Motor ASSY) ○○○○○○○○○○

Remarks: Replace DC Power Supply and DC fan (Control box cooling) every 30,000 hours of total printer working time.

YQE8-J0092E4

2.5 Inspection Contents

№Inspection Items Inspection Contents

1 Thermal Head Perform test printing, and replace the Thermal Head ASSY if the following

problem occurs (Refer to Section 4 of this document for test printing

procedures)

-Visible white line on output surface (ink does not transfer to the paper

even after cleaning the thermal print head.

-Using pattern with fairly even density, there is extreme uneven density the

output. (Refer to Maintenance Parts Replace Procedures for replacement

procedures)

2 Platen Roller Roll the Platen Roller to check for unevenness or scratches on the surface.

Replace the platen if problem occurs with the output. (Refer to Maintenance

Parts Replace Procedures for replacement procedures)

3 Timing Belt Inspect the timing belt tension (Refer to Section 3.2 of this document).

Turning the pulley to check for scratches and split on the timing belt.

Replace the timing belt if the problem occurs (Refer to Maintenance Parts

Replacement Procedures for replacement procedures).

4 DC Power Supply Inspect the +5V, +24V, and THV output value. (Refer to Section 3.1 of this

document for more details)

5 Pinch Roller Roll the Pinch Roller to check for unevenness or scratches on the surface.

Replace the pinch Roller if problem occurs with the output (Refer to

Maintenance Parts Replace Procedures for replacement procedures).

6 Cleaning (1) Clean the thermal head with Head Cleaning Kit (Refer to Section 2.6 for

more details).

(2) Clean the surface of rubber rollers with Isopropyl Alcohol (IPA) in

bleached cloth (Refer to Section 2.6 for more details).

①Platen

②Cleaning Roller

③Paper Feed Roller (Paper feed)

④Paper Feed Roller (Paper transport)

⑤Ejection Roller

(3) Clean the front of peeling plate and ribbon mark sensor reflector with

Isopropyl Alcohol (IPA) in bleached cloth (Refer to Section 2.6 for more

details).

(4) Clean the paper sensor and ink ribbon sensor with Head Cleaning Kit.

(5) Clean the surface of Pinch Roller with dry and bleached cloth.

(6) Vacuum and/or clean the paper dust inside the printer.

(7) Clean the covers with dry and bleached cloth (Refer to Operation Manual

for more details).

(8) Clean the fan filters at upper and side cover (Refer to Operation Manual

for more details).

YQE8-J0092E5

№Inspection Item Inspection Contents

7 Lubricate Apply some grease (Molykote PG-671) to each of the following

sections.

(1)DC Motor ASSY (Ribbon roll-up)

①Circumference of Worm Gear

(2)DC Motor (Pinch Roller)

①Circumference of Worm Gear

②Circumference of the Pinch Cam (left and right)

③Circumference of Gear

(3)DC Motor (Thermal Head)

①Circumference of Worm Gear

②Circumference of Head Cam

(4)DC Motor (Paper Feeding Pinch Roller)

①Circumference of Worm Gear

②Circumference of Feed Pinch Roller Cam

(5)DC Motor (Paper Ejection Pinch Roller)

①Circumference of Worm Gear

(6)Sub-Motor

①Circumference of Pinion Gear

YQE8-J0092E6

2.6 Description for point of cleaning

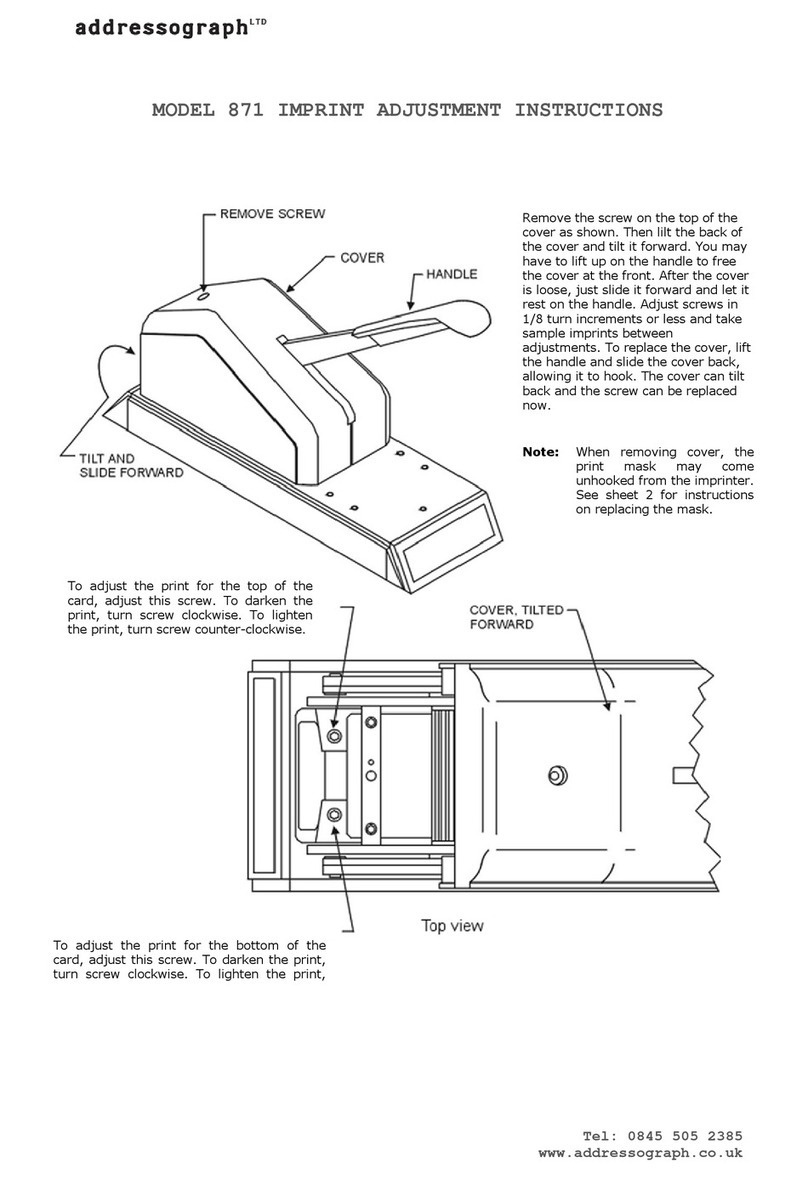

(1)Covers for remove

(2)Thermal Head Heat Element

Cleaning while opening Upper Unit

(3)Platen

Cleaning while opening Upper Unit

Platen

Thermal Head

Heat Element

Front CoverSide Cover L2 Side Cover R2

Side Cover R

Side Cover L

Upper Cover

YQE8-J0092E7

(4)Cleaning Roller(Paper Ejection side)

Remove the Cleaning Roller and clean while opening Upper Unit

(5)Cleaning Roller(Paper Feed side)

Remove the Cleaning Roller and clean while opening Upper Unit

(6)Paper Feed Roller

Clean the Paper Feed Roller while opening Paper Cover.

Cleaning Roller(Paper Ejection side)

Cleaning Roller(Paper Feed side)

Paper Feed Roller

YQE8-J0092E8

(7)Paper Feed Roller (For Paper Transport)

①Remove Cleaning Roller(Paper Feed side)

②Remove 2 screws (M3 x 6) which hold Print Position Sensor Cover, and remove Print Position Sensor

Cover.

③Remove side cover R.

④Remove a screw (M3 x 6) which holds Feed Pinch Up Lever and remove Feed Pinch Up Lever.

⑤Remove the spring (roller side) which holds Feed Pinch Roller, move the Feed Pinch Roller upwards, and

then clean the Pinch Roller.

Print Position Sensor Cover

Screw

Screw

Feed Pinch Up Lever

Feed Pinch Roller

Helical Torsion Spring

YQE8-J0092E9

(8)Cleaning Ejection Roller

①Remove Side Cover L, Side Cover R, Front Cover, and cleaning roller (ejection side).

②Remove 2 screws (M3x6) which hold PCB HSSV7-LCDSOSA-F ASSY and remove the PCB (removing

wire harness is not required).

③Remove 2 screws (M3x6) which hold the Paper Cutter Unit, then remove the Paper Cutter Unit, and clean

the Ejection Roller.

(9)Separation Plate and Ribbon Sensor Reflection Shield

Clean the Separation Plate and Ribbon Sensor Reflection Shield with the upper unit opened.

Separation PlateRibbon Sensor Reflection Shield

Warnin

g

: Do not touch the blade of the cutter unit in order to avoid in

j

ur

y

.

Screw

HSSV7-LCDSOSA-F ASSY

Paper Cutter Unit

Screw

YQE8-J0092E10

(10)Paper Edge Sensor and Ribbon Sensor

Clean the Paper Edge Sensor and Ribbon Sensor with the upper unit opened.

(11)Main Pinch Roller

Clean the Main Pinch Roller with the upper unit opened.

Main Pinch Roller

Paper Edge Sensor

Ribbon Sensor

YQE8-J0092E11

2.7 Description for point of lubrication

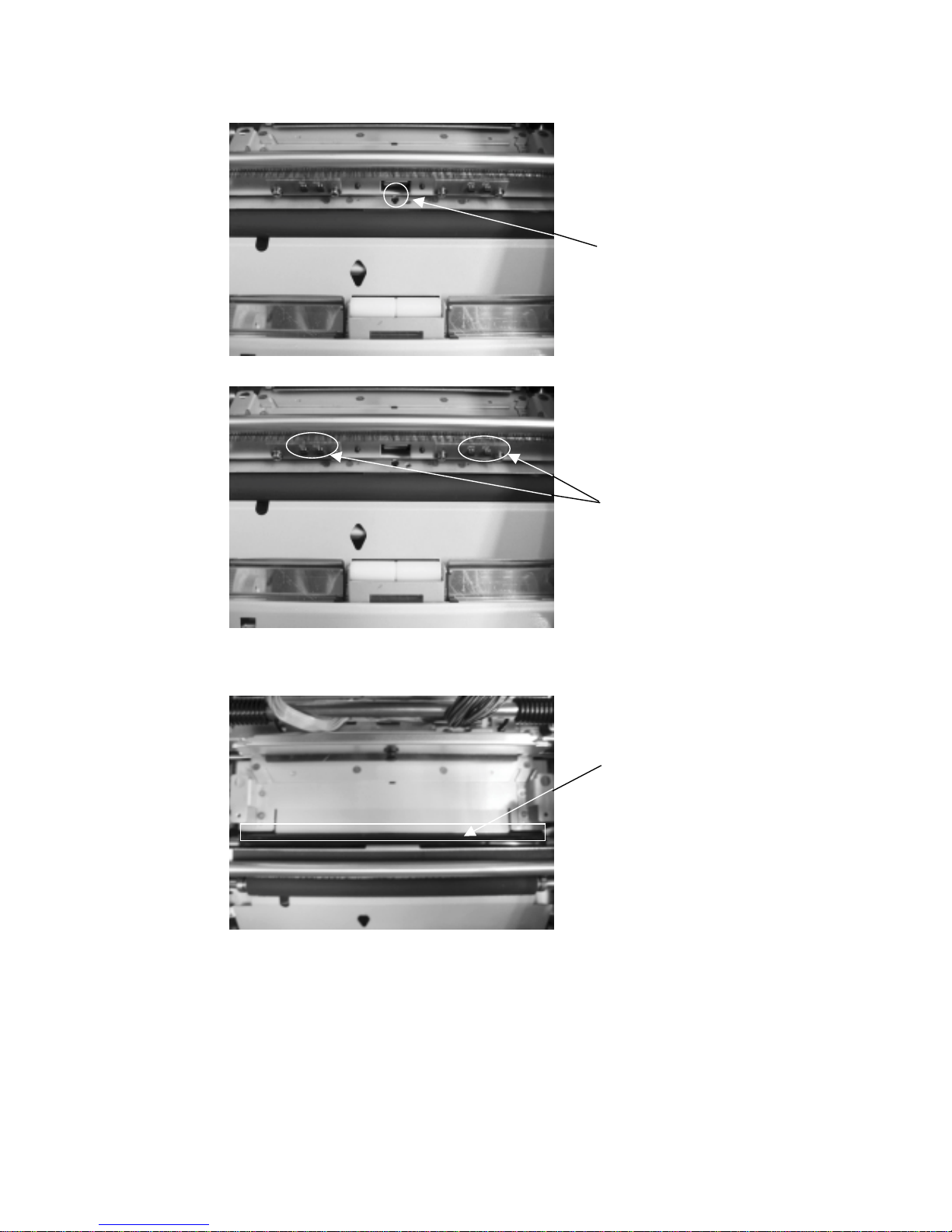

(1)Lubricating driving system of DC motor for ribbon winding

Lubricate the driving system of DC motor for ribbon winding with Side Cover L removed.

(2)Lubricating driving system of DC motor for pinch roller

Lubricate the driving system of DC motor for pinch roller with Side Cover L and Side Cover R removed.

Circumference of Pinch Roller Cam Circumference of Pinch Roller Cam

Worm Gear

Worm Gear and Circumference

of Gear

YQE8-J0092E12

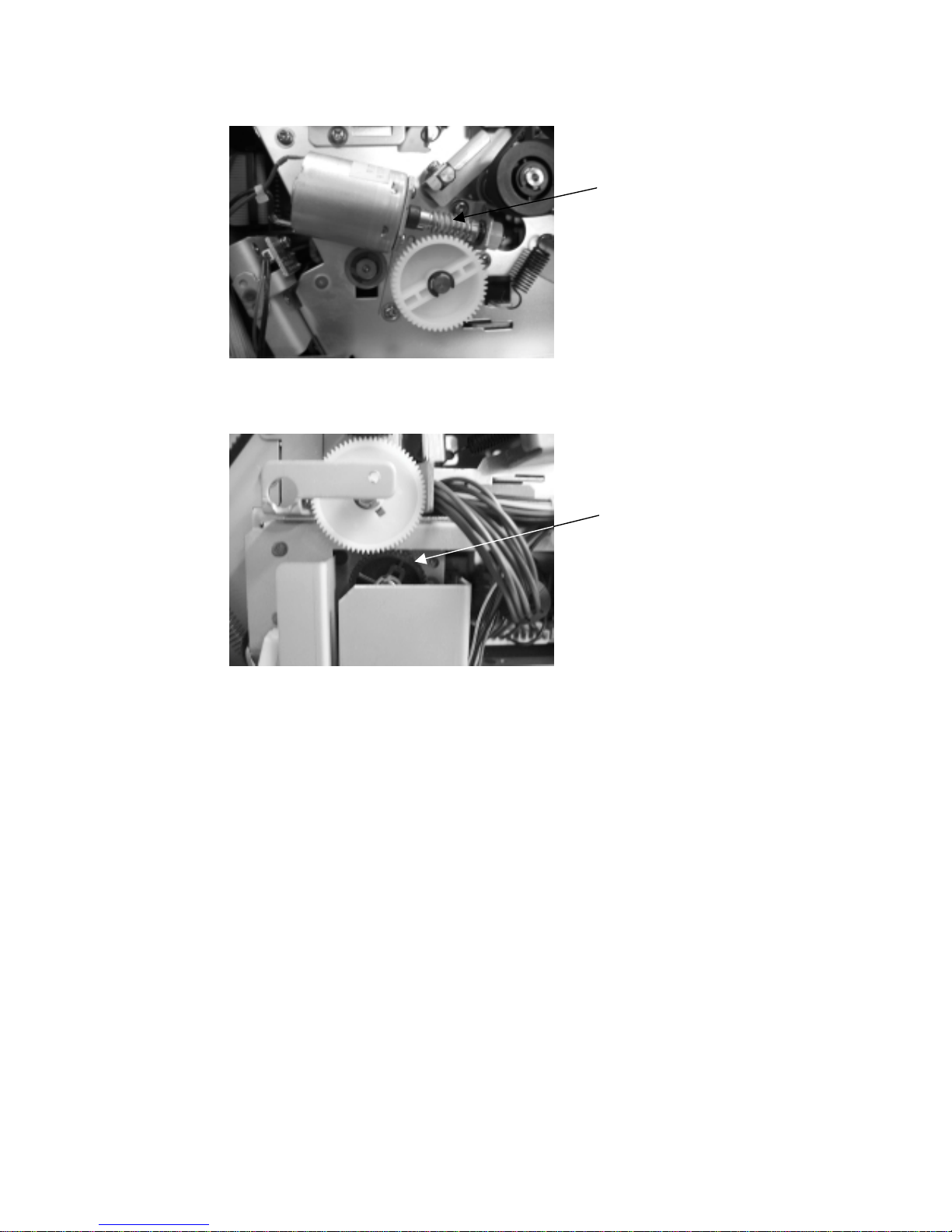

(3)Lubricating driving system of DC motor for thermal head

Lubricate the driving system of DC motor for thermal head with the Upper Cover and Head Gear Cover

removed.

Circumference of Head Cam Circumference of Head Cam

(4)Lubricating DC motor system for paper feed pinch roller

Lubricate the DC motor system for paper feed pinch roller with Side Cover L and Side Cover L2 removed.

Worm Gear

Worm Gear

YQE8-J0092E13

(5)Lubricating DC motor system for ejection pinch roller

Lubricate the DC motor system for ejection pinch roller with Side Cover R removed.

(6)Lubricating driving system of sub-motor

Lubricate the driving system of sub-motor with Side Cover L and Side Cover L2 removed.

Circumference of Pinion Gear

Worm Gear

YQE8-J0092E14

3.Adjustment

3.1 Power Unit Voltage Setting

Remove the main cover and set the power unit voltage by the following procedures.

3.1.1 +5V Setting

(1)Measurement Conditions

Turn the Power on, and measure under ready condition.

(Ink Ribbon and Paper are not required with control PC board connected)

(2)Setting Voltage

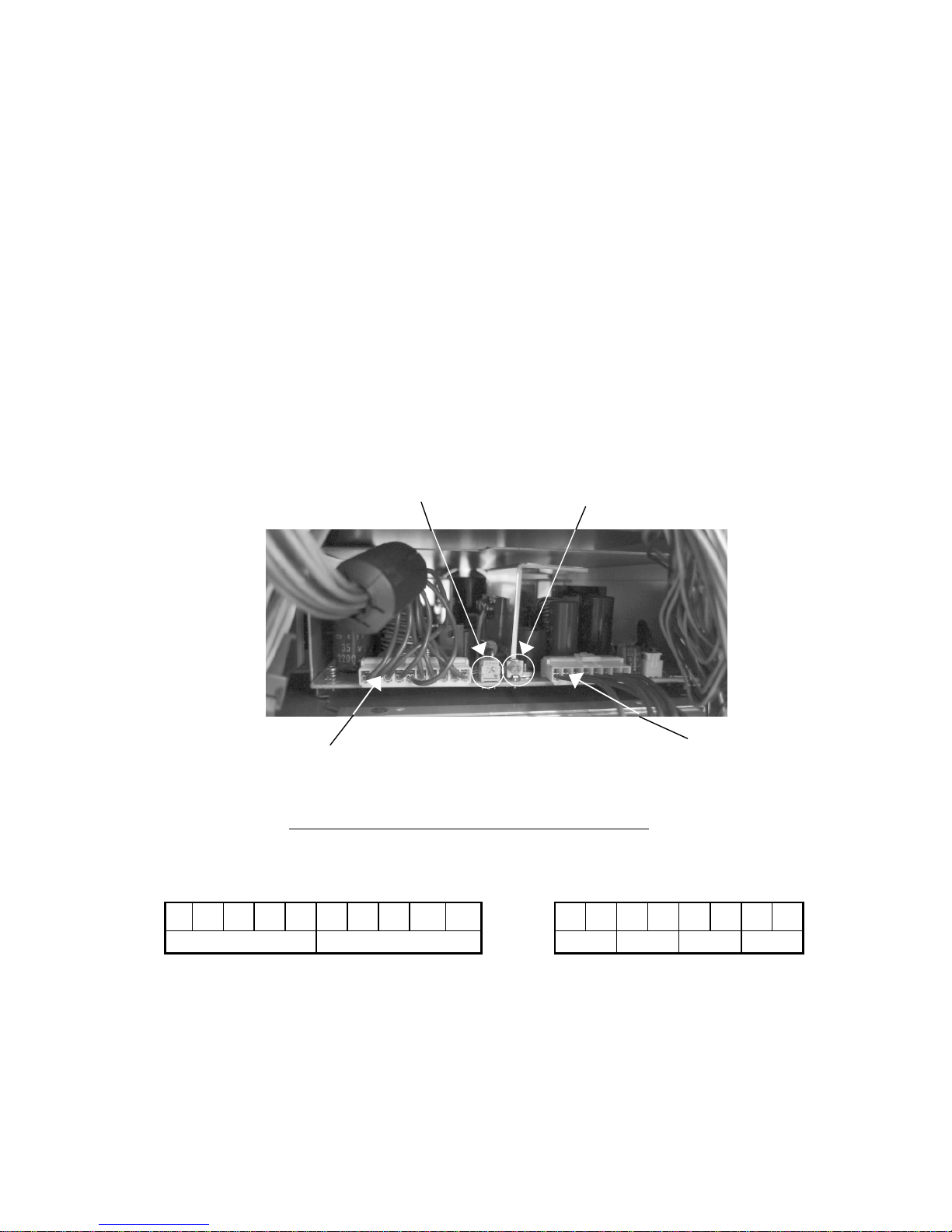

Connect the digital voltmeter directly to the +5V terminal (pin 1 or 2) and 0V terminal (pin 3 or 4) of CN3

connector on DC Power Supply and verify whether Power output is under the following figure.

+5V Voltage:5.15±0.1 [V]

If it is not set correctly, set the voltage by +5V adjustment volume of which shown at the following figure.

(Turning the volume clockwise increases the voltage.)

View of DC Power Supply from the left side of the Printer

CN2 pin assignment (10 pins) CN3 pin assignment (8 pins)

12345678910 12345678

THV GND +5V 0V +24V P0V

0V, P0V, and GND are jumpered.

THV Variable Volume +5V Variable Volume

CN3

Pin 1 〜 Pin 8

CN2

Pin 1 〜 Pin 10

YQE8-J0092E15

3.1.2 Thermal Head Power (THV) Setting

(1)Measurement Conditions

Turn the Power on, and measure under ready condition.

(Ink Ribbon and Paper are not required with control PC board connected)

(2)Setting Voltage

①Open the Upper Cover, and read the THV value that is stated in the nameplate on the Thermal Head cover

(see below).

②Close the Upper Cover.

③Connect the digital voltmeter directly to the THV terminal (pin 1) and GND terminal (pin 10) of CN2

connector on DC Power Supply and set Power output under the following figure.

Set the voltage to +/- 0.1V limit to the THV value.

To set the THV value, use the THV variable volume described in Section 3.1.1.

(Turning the volume clockwise increases the voltage.)

3.1.3 +24V Verification

(1)Measurement Conditions

Be sure to perform the procedure for "+5V Setting" described in Section 3.1.1 first.

Turn the Power on, and measure under ready condition.

(Ink Ribbon and Paper are not required with control PC board connected)

(2)Setting Voltage

①Connect the digital voltmeter directly to the +24V terminal (pin 5 or 6) and P0V terminal (pin 7 or 8) of the

CN3 connector on DC Power Supply and set Power output under the following figure.

Verify whether the voltage is set at 24V +/- 1.44 V

If it is not set, replace DC Power Supply.

24.7V 4625Ω0707000001

5B04 6038 TPH216R66

THV value

YQE8-J0092E16

3.2 Timing Belts Adjustment

3.2.1 For Feed Roller Drive

①Loosen Tension Pulley Screw.

Tension pulley presses timing belt at appropriate strength by spring.

②Tighten Tension Pulley Screw.

3.2.2 For Feed Roller Drive

①Loosen Tension Pulley Screw.

Tension pulley presses timing belt at appropriate strength by spring.

②Tighten Tension Pulley Screw.

3.2.3 For Roll Paper Drive

①Loosen Tension Pulley Screw.

Tension pulley presses timing belt at appropriate strength by spring.

②Tighten Tension Pulley Screw.

Timing Belts

Tension Pulley Screw

Timing Belts

Tension Pulley Screw

Timing Belts

Tension Pulley Screw

YQE8-J0092E17

3.3 Print Density Adjustment

Print density setting is done for every Thermal Head. Therefore after replacing the thermal head, set the print

density by the following procedures.

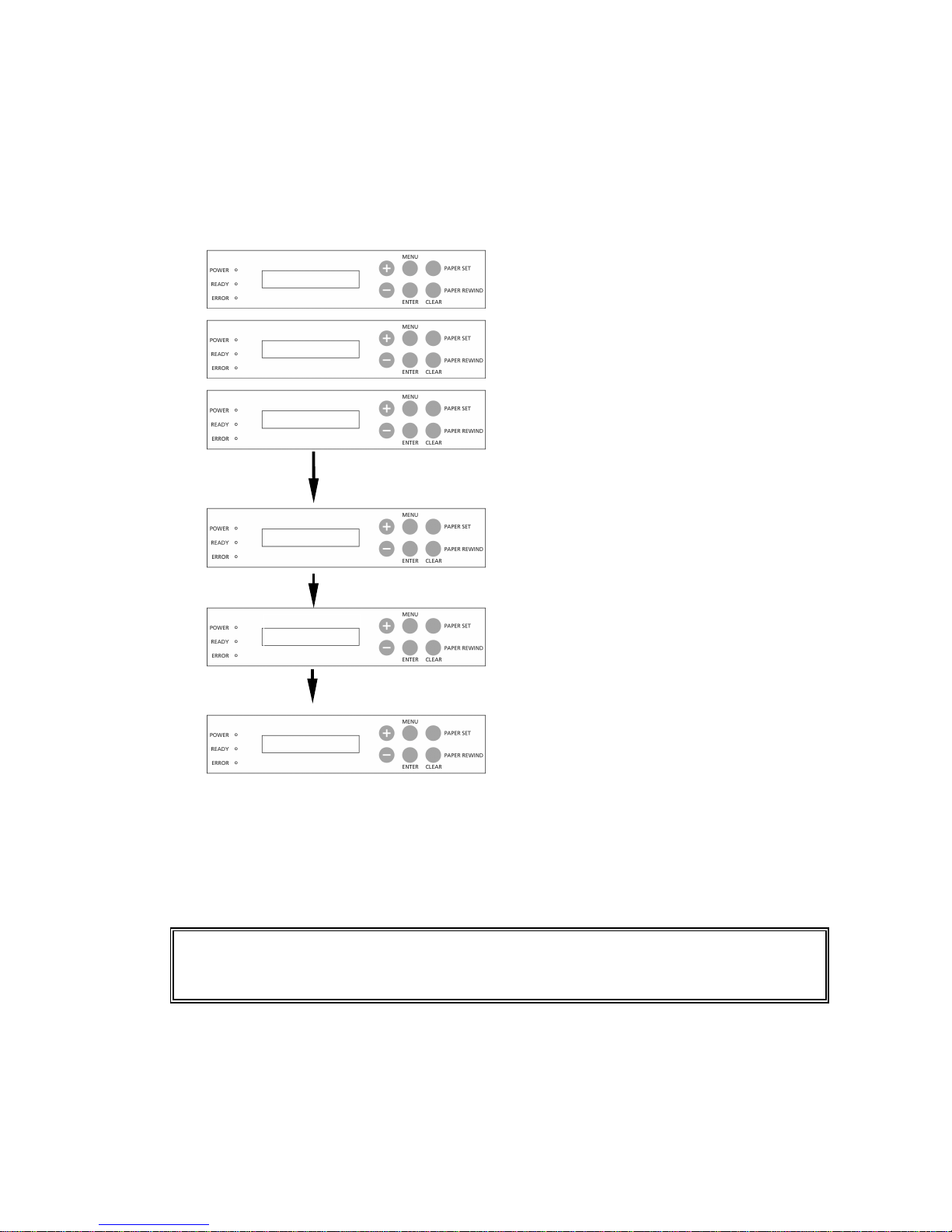

Turn the Power On by pressing “PAPER SET” and “CLEAR/PAPER REWIND” keys at the same time.

LCD displays “Density Setup Mode” afterwards.

Press “MENU” key.

Press “ENTER” key.

Press “ENTER” key.

This shows the current setting.

By pressing “+” or “-“ keys, change this value to the density that is stated in Thermal Head (Spare

Parts). Press “CLEAR” key until “Ready” appears on LCD.

Confirm the setting value by pressing the "ENTER" key, then press the "CLEAR" key until "Ready"

appears on LCD.

Remarks:Do not change the setting other procedures than explained above. If you have entered to

other setting mode, press “CLEAR” key or turn off the power.

Initializing

DensitySetUpMode

READY:8×10

Density

Density :YMC

Density YMC ***

Table of contents

Other Shinko Electric Printer manuals