Shinko HR-701 User manual

Hybrid recorder

HR-700

(Pen writing type)

Instruction manual

㩷

㩷

㩷

㩷

㩷

㩷

㩷

㩷

㩷

㩷

㩷

㩷

Systems & Services

PO Box 1 Ilkley West Yorkshire LS29 8EU

PO Box 1 Ilkley West Yorkshire LS29 8EU

Phone: 01943 602001 Fax: 01943 816796

Phone: 01943 602001 Fax: 01943 816796

Ltd

instrumentation

n

㵪1㵪

For safety using

Thank you for purchasing our HR-701 type (HR-702 type) Hybrid Recorder.

In order to exhibit all the functions of this instrument effectively and correctly, read and understand this

instruction manual thoroughly before using the instrument.

The symbols below are used in this instrument for the cautioning information.

Symbols used in the instrument

This shows “Caution for handling”. This symbol is used on the parts need

to refer to the instruction manual for protecting human body and the

instrument.

This shows “Protective grounding”.

Be sure to provide protective grounding prior to the operation of this

instrument.

This shows “Risk of electric shock”.This symbol is used on the parts, which

has a risk of electric shock.

Be sure to observe the following warnings/cautions and those written in this

manual in order to secure safety in handling the instrument.

WARNING

In order to prevent electric shock; be sure to disconnect this instrument

from the main power source when wiring it.

(1) In order to prevent an electric shock; be sure to provide protective

grounding prior to turning on this instrument.

(2) Do not cut a protective grounding conductor or disconnect protective

grounding.

(1) Make sure that the supply voltage for this instrument conforms to the

voltage of the supply source.

(2) Attach a protective cover prior to turning on this instrument.

Do not operate this instrument in the environment where it is exposed to

a combustible/explosive/corrosive gas or water/steam.

Provide input and output wiring after turning off the power.

General

Protective㩷Grounding

Power Source

Working Environment

Input and Output㩷㪮㫀㫉㫀㫅㪾㩷

i

i

Tel: (01943) 602001 Fax: (01943) 816796

㵪2㵪

CAUTION

Do not unused terminals for other purposes such as relaying, etc.

Do not touch the switches, etc. inside this instrument. Also, do not

replace the main unit or printed circuit boards. When this is neglected,

we cannot guarantee functioning of the instrument. Contact our dealer

where you purchased the instrument, or our sales representative.

When transporting this instrument or the equipment with this instrument

incorporated in it, take measures to prevent opening the door and falling

out the inner module.

㨇Note 㨉

(1) Deliver this instruction manual to an end user.

(2) Prior to handling this instrument, be sure to read this manual.

(3) If you have any questions on this manual or find any errors or

omissions in this manual, contact our sales representative.

(4) After reading this manual, keep it carefully near the instrument.

(5) When the manual is lost or stained, contact our sales representative.

(6) It is prohibited to copy or reproduce this manual without our

permission.

(1) When installing this instrument, put on a protective gear such as

safety shoes, helmet, etc. for your safety.

(2) Do not put your foot on the installed instrument or get on it, because it

is dangerous.

Only our servicemen or people authorized by Shinko are allowed to

remove and take the inner module, the main unit and printed circuit

boards apart.

(1) Dispose the replaced batteries in a correct way.

(2) Do not incinerate plastics of maintenance parts and replacement

parts.

㩷㩷A harmful gas may be produced.

(1) Use dry cloth to clean the surface of this instrument.

(2) Do not use any organic solvent.

(3) Clean the instrument after the power is turned off.

This instruction manual is subject to change without prior notice.

Input and Output Wiring

Transportation

Inside of Instrument

Instruction Manual

Installation

Maintenance

Disposal

Cleaning

Revisions

i

i

Tel: (01943) 602001 Fax: (01943) 816796

㵪3㵪

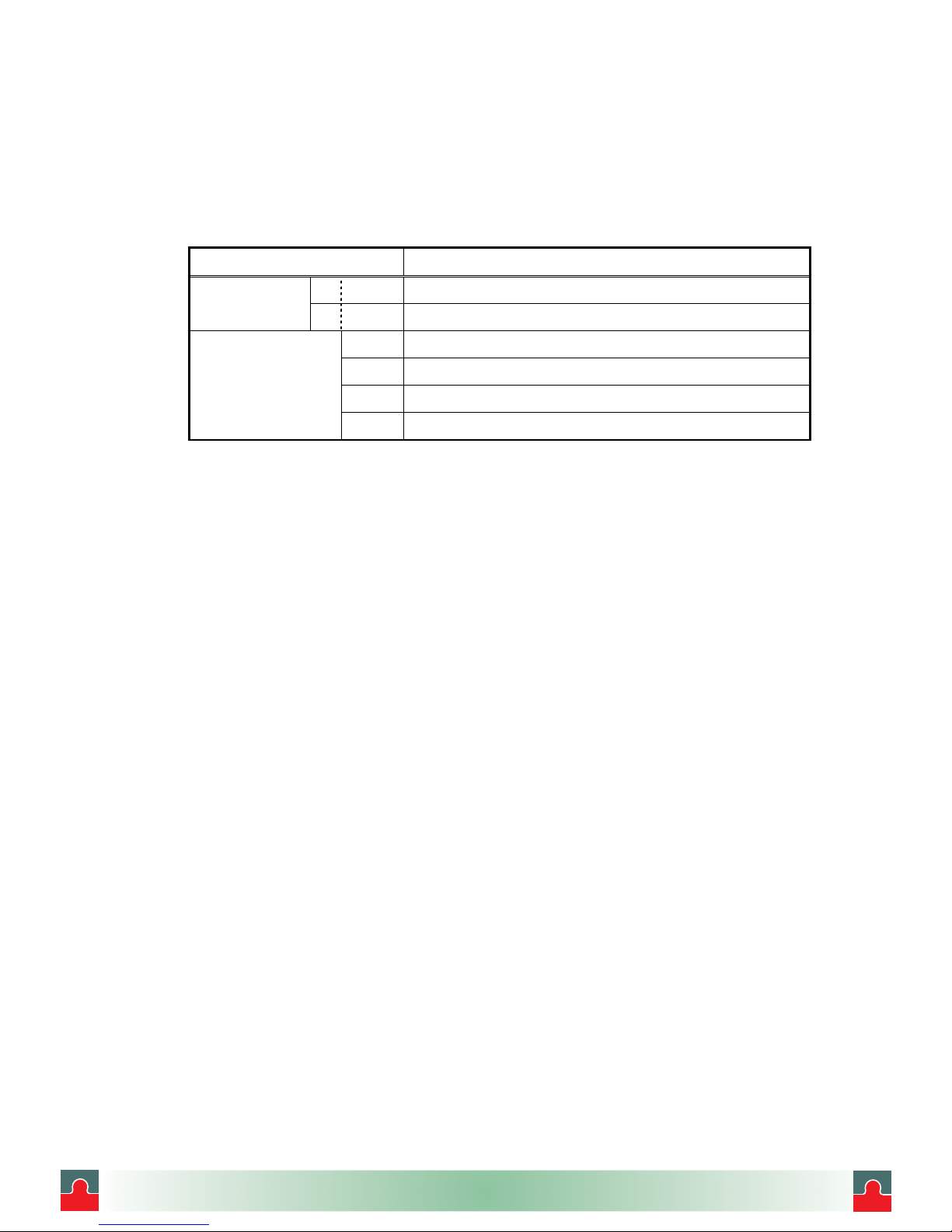

Using procedure for this manual

Using procedure

This instruction manual consists of “For safety using”, “Contents” and “Chapter 1 to Chapter 11” as below.

Read the corresponding sections for your purpose to use this instrument.

Chapter and TITLE For purchase

and install

For initial

setting and

change

setting

For daily

operation

For using

communication

For

maintenance

and

trouble-shootin

g

For safety using (page 1) ٧٧٧٧٧

1. INTRODUCTION ٧

2. CONSTRUCTION ٤٤٤ ٤

3. INSTALLATION ٧٤

4. WIRING ٧٤٤٤٤

5.PREPARATIONS FOR

OPERATION ٤٧

6. OPERATION ٤٧

7. DEVICE SETTING ٧٤٤

8.COMMUNICATIONS ٧

9. MAINTENANCE

٧

10.TROUBLESHOOTIG ٤٧

11. SPECIFICATIONS ٤٤

٤

䃁㩷 䋺Be absolutely certain to read this.

䂾㩷 䋺Be certain to read this if you need.

The symbols below are used on the warning and cautioning information in this manual.

Symbols used in this manual

WARNING Failure to observe this information could result in death or injury.

Be absolutely certain to read this.

CAUTION

Failure to observe this information could damage the instrument.

Be certain to read it.

㨇Note㨉This is cautionary information for correct use of the instrument.

Be certain to read it.

㨇Reference㨉This is information to help you use the functions of this instrument more

effectively.

Guide of Instruction manual

The instruction manuals of this instrument are as the table below.

Name Part No. Outline

㧝

HR-700 Hybrid Recorder

(Pen type) instruction

manual

HR72E

Explanation for installing,

wiring, standard operation.

And setting or operation for

using this instrument.

㧞

HR-700 Hybrid Recorder

Communication Command

instruction manual

HR7CE

Explanation for reading and

writing data of the recorder by

communication function.

This

manual

i

i

Tel: (01943) 602001 Fax: (01943) 816796

㵪4㵪

CONTENTS

1. INTRODUCTION..............................................................6

1.1Checking the Accessories.................................................... 6

1.2Checking the Type and Specifications ................................ 8

1.3Temporary Storage............................................................... 9

1.4Indication Card...................................................................... 9

2. CONSTRUCTION ..........................................................10

2.1Appearance ........................................................................ 10

2.2Display Screen and Operation Keys ..................................11

2.2.1Display Screen...............................................................11

2.2.2Operation Keys............................................................. 12

3. INSTALLATION..............................................................13

3.1 External Dimensions and

Panel Cutout Dimensions........................ 13

3.2Mounting to the Panel ........................................................ 14

3.2.1Procedure for Mounting to the Panel........................... 14

3.2.2Mounting to the Panel

in compliance with the IP65.................. 15

4. WIRING ..........................................................................16

4.1Terminal arrangement and Power Wiring.......................... 16

4.1.1Terminal Layout ............................................................ 16

4.1.2Power Wiring ................................................................ 16

4.1.3Wiring Procedure.......................................................... 17

4.2Input Wiring......................................................................... 18

4.2.1Wiring Procedure.......................................................... 18

4.3DI function/Alarm Output Wiring (Option).......................... 20

4.3.1DI function/Alarm Output Wiring Example................... 20

4.3.2Alarm Output Wiring Procedure................................... 21

4.3.3DI function Wiring Procedure ....................................... 21

4.4Communication Wiring....................................................... 22

4.4.1RS-232C Wiring............................................................ 22

4.4.2RS-485 Wiring .............................................................. 22

5. PREPARATIONS FOR OPERATION ...........................23

5.1Setting the Chart Paper...................................................... 23

5.2Setting the Cartridge Pen................................................... 30

5.3Setting the Ribbon Cassette .............................................. 32

6. RUNNING.......................................................................37

6.1 Running............................................................................... 37

6.1.1Status after Initial Screen ............................................. 37

6.2Recording............................................................................ 38

6.2.1Recording Colors.......................................................... 38

6.2.2Printing Color ................................................................ 38

6.2.3Pen Gap........................................................................ 38

6.2.4Gaps between Pens and Printer.................................. 38

6.2.5Print gap collection ....................................................... 39

6.3How to Record.................................................................... 39

6.3.1Starting/Stopping Recording Operation....................... 39

6.3.2Feed the Chart Paper................................................... 39

6.3.3Print Sample ................................................................. 40

6.4Digital Print.......................................................................... 41

6.4.1Manual Print.................................................................. 41

6.4.2List Print ........................................................................ 42

6.4.3Engineering List Print ................................................... 44

6.5Changing the Display ......................................................... 46

6.5.1Auto Display㧨㧪..........................................46

6.5.2Manual Display㧨㧪.........................................46

6.5.3Date Display㧨㧪..........................................46

6.5.4Time Display㧨㧪..........................................46

6.5.5Display Off㧨㧪.................................................46

7. DEVICE SETTING......................................................... 47

7.1Setting the Setup Mode ......................................................47

7.1.1Setting the Range..........................................................50

(1)Setting method...............................................................50

(2)(Current/Voltage)㧘(Thermocouple)㧘

(Resistance Temperature Detector) ...................51

(3)(Scaling) ......................................................53

(4)(Square Root) .................................................55

(5)(Decade)......................................................57

(6)(Difference)㧘(Sum)㧘

(Average)......................59

(7)(Skip) ...............................................................60

7.1.2Setting the Alarm...........................................................61

7.1.3Setting the Unit ..............................................................63

(1)Character Code Table ...................................................64

7.1.4Setting the Chart Speed................................................65

7.1.5Setting the Date and Time ............................................66

7.1.6Copying the Setting Data ..............................................67

7.1.7Setting the Other Functions ..........................................68

(1)(Zone Recording)............................................69

(2)㧔Partial Compression/Expansion㧕.............70

(3)㧔Digital Print㧕...........................................71

(4)㧔Ta g 㧕...............................................................72

(5)㧔Comment Words㧕.....................................73

7.2 Setting the Engineering Mode to

use this more smoothly...........................74

7.2.1Alarm Hysteresis ...........................................................77

7.2.2Burnout ON/OFF ...........................................................77

7.2.3Channel Offset...............................................................78

7.2.4Reference Junction Compensation ..............................78

7.2.5Digital Filter ....................................................................80

7.2.6Settings Related to Recording ......................................80

(1)Recording start/stop trigger setting ...............................80

(2)Tag/channel print selection............................................81

(3)Alarm print ON/OFF ......................................................81

(4)Logging print ON/OFF ...................................................82

(5)Logging print Synchronous/Asynchronous...................82

(6)Print gap correction ON/OFF ........................................83

7.2.7Setting the Communication Function ...........................84

7.2.8Initializing the Setup Data .............................................84

7.2.9DI functions....................................................................85

7.2.10Temperture Unit...........................................................85

7.2.11Point Calibration ..........................................................86

7.2.12Data Calibration...........................................................87

7.3Terminating the Engineering Mode...................................89

i

i

Tel: (01943) 602001 Fax: (01943) 816796

㵪5㵪

8.COMMUNICATIONS.......................................................90

8.1General Description............................................................ 90

8.1.1General Description of Functions ................................ 90

8.1.2Transmission Specifications......................................... 90

8.1.3Data Construction......................................................... 90

8.2Opening/Closing the Link................................................... 91

8.2.1Open Command ........................................................... 91

8.2.2Close Command........................................................... 92

8.3Outputting the Process Variable ........................................ 92

8.3.1Specifying the Process Variable

Output ............................................................................ 92

8.3.2Updating the Data......................................................... 92

8.3.3Specifying the Process Variable Data

Output Order (At BINARY Mode Output) .. 92

8.3.4Outputting the Data ...................................................... 92

8.3.5Process Variable Data Transmission Format

(ASCII) ................................ 93

8.3.6Process Variable Data Transmission Format

(BINARY) ....................................... 94

8.4Outputting the Unit and Decimal Point

Position Data............................................ 95

8.4.1 Specifying the Unit and Decimal Point

Position Data Output ......................... 95

8.4.2Updating the Data......................................................... 95

8.4.3Outputting the Data ...................................................... 95

8.4.4Data Format.................................................................. 95

8.5Outputting the Status.......................................................... 96

8.5.1Status Output Command ............................................. 96

8.5.2Status Output................................................................ 96

8.6Data Reception Example ................................................... 97

9. MAINTENANCE.............................................................98

9.1Inspection............................................................................ 98

9.2Cleaning.............................................................................. 98

9.3Replacing Consumables .................................................... 99

9.4Adjusting the Pen Recording Position

(Point Calibration) ...................................... 99

9.5Calibration (Data Calibration)............................................. 99

(1)Calibration of Voltage.................................................. 100

(2)Calibration of Resistance temperature detector ........ 100

(3)Calibration of Reference Junction Compensation..... 101

10. TROUBLESHOOTING ..............................................102

10.1Troubleshooting.............................................................. 102

10.1.1Trouble Items ............................................................ 102

10.1.2When the Recorder Does

not Work at All....................................... 102

10.1.3When There is a Big Error........................................ 103

10.1.4When the Pen Recording Deflected ........................ 103

10.1.5When Prints Nothing ................................................ 104

10.1.6When Printing is Faint .............................................. 104

10.1.7When the Chart Paper is not Fed at All ................... 105

10.1.8When the Chart Paper is not Fed Properly ............. 105

10.2Self Diagnosis Function (ERROR) ................................ 106

10.2.1Self Diagnostic Items................................................ 106

10.2.2Error Display ............................................................. 107

11. SPECIFICATIONS .....................................................108

11.1Common Specifications.................................................. 108

11.1.1Input Signal ............................................................... 108

11.1.2Performance and Characteristics............................. 108

11.1.3Structure.................................................................... 109

11.1.4Power Source ........................................................... 109

11.1.5Normal Operating Conditions .................................. 109

11.1.6Alarm Output (Option : LH3) .....................................110

11.1.7Safety Standard and EMI Standard..........................110

11.1.8DI Function (Option : RE1)........................................110

11.1.9Paper-empty Detecting Function (Option : FL) ........110

11.2Standard Setting Specifications...................................... 111

11.2.1Measurement Range................................................. 111

11.2.2The Accuracy at the Computation ............................114

(1) Scaling ............................................................................114

(2) Square root computation................................................114

(3)Decade.........................................................................115

(4)Difference, Sum, and Average....................................115

11.2.3Individual Specifications............................................116

11.2.4Standard Functions ...................................................117

11.3Standard Setting Functions.............................................118

11.3.1Standard Setting Functions.......................................118

11.4Optional Functions .....................................................118

11.4.1Remote Function of DI ..............................................118

11.4.2Alarm Board...............................................................118

11.4.3Communication Unit..................................................118

i

i

Tel: (01943) 602001 Fax: (01943) 816796

㵪6㵪

INTRODUCTION

1.1 Checking the Accessories

Upon delivery of this instrument, unpack and check its accessories and appearance.

If there are any missing accessories or damage on the appearance, contact our dealer where you㩷

purchased the instrument, or our sales representative.

Following accessories should be attached.

ԘChart paper ԙRibbon cassette ԚCartridge Pen

ԛMounting bracket ԜInstruction manual ԝPacking

Fig. 1.1㩷Accessories

㩷㩷㩷㩷㩷㩷㩷㩷㩷Table 1.1㩷List of Accessories

Quantity

No. Part Name Type 1 pen 2 pen Remarks

㧝Chart paper H-10100 㧝㧝100 equal divisions

㧞Ribbon Cassette HPSROO1H0002C 㧝㧝

WPSR196A000001A 㧝㧝For 1 pen (Red)

㧟Cartridge Pen WPSR196A000002A 㧝 For 2 pen (Green)

㧠Mounting H4A14175 㧞㧞Panel mounting bracket

㧡Instruction HR72E 㧝㧝This manual

㧢Packing H4H14900 㧝㧝For IP65

䌛Note䌝

The ribbon cassette has been set in the instrument when this is shipped.

i

i

Tel: (01943) 602001 Fax: (01943) 816796

㵪7㵪

Take the chart holder out to check its accessories.

See Section 5.1 “Setting the Chart Paper” for pulling out the chart holder.

Fig. 1.2㩷Position of the Ribbon Cassette

Fig. 1.3㩷Position of the Chart Paper and the Cartridge Pen

The chart paper is contained in

the chart holder.

Open the Chart Guide to chec

k

it.

The cartridge pen is contained

in the storage chamber.

Open the chart cover to chec

k

it.

This instrument is shipped

with the ribbon cassette in

the back of the chart holder.

Chart Guide

Chart Cover

䌛Note䌝

ԘThis instrument is equipped with the ribbon cassette in back of the chart holder. Open the door

and pull out the chart holder to check it. (See Section 5.1 about taking out the chart holder.)

ԙThe chart paper and the cartridge pen are contained in the chart holder. Take the chart holder

out and open the chart cover to check it.

ԚMaximum angle of the door is 135 degrees when the door is fully open. Do not open the door

further, or the hinge will be broken.

i

i

Tel: (01943) 602001 Fax: (01943) 816796

㵪8㵪

1.2 Checking the Type and Specifications

A nameplate is put on the inside of the instrument. Remove the chart holder and make sure that the

nameplate is put in the middle far side of the instrument.

Make sure that this instrument meets your requested specification, seeing the following tables.

Table1.2 㩷Type

㧴㧾-㧣㧜غ㧘غغغ 㧝㧠㧠(㨃)㧝㧠㧠(㧴)㧝㧡㧜(㧰)mm

㧝㧝points

Measuring point 㧞㧞points

㧯㧡 Communication function (RS-485)

㧾㧱㧝 DI function

㧲㧸 Out of paper detection function

Options

㧸㧴㧟 Alarm output function

i

i

Tel: (01943) 602001 Fax: (01943) 816796

㵪9㵪

1.3 Temporary Storage

Store the instrument in the following environment.

When incorporated in the equipment, store it in the following environment as well.

1.4 Indication Card

An indication card has been affixed to the door upon delivery.㩷Enter a name as required.

㩷CAUTION㩷

Note that if a non-original nameplate㩷is attached, it may damage the door or mounting part.

㩷CAUTION㩷

Storage in a poor environment may damage the appearance, functions, and service life of the

instrument.

Storage Environment

䊶A place with little dust.

䊶A place free from combustible, explosive, or corrosive gases ( SO2, H2S, etc. ).

䊶A place free from vibrations or shocks.

䊶A place free from water or steam or high humidity ( 95% RH max. ).

䊶A place free from direct sunlight or high temperature ( 50㷄㩷 max. ).

䊶A place free from an extremely low temperature ( -20㷄min. ).

i

i

Tel: (01943) 602001 Fax: (01943) 816796

㵪10 㵪

CONSTRUCTION

Appearance

Fig. 2.1 Appearance

Cartridge pen

Door

Chart Holder

Display

keyboard

Terminal block

Case

Mounting bracket

Indication card

i

i

Tel: (01943) 602001 Fax: (01943) 816796

㵪11 㵪

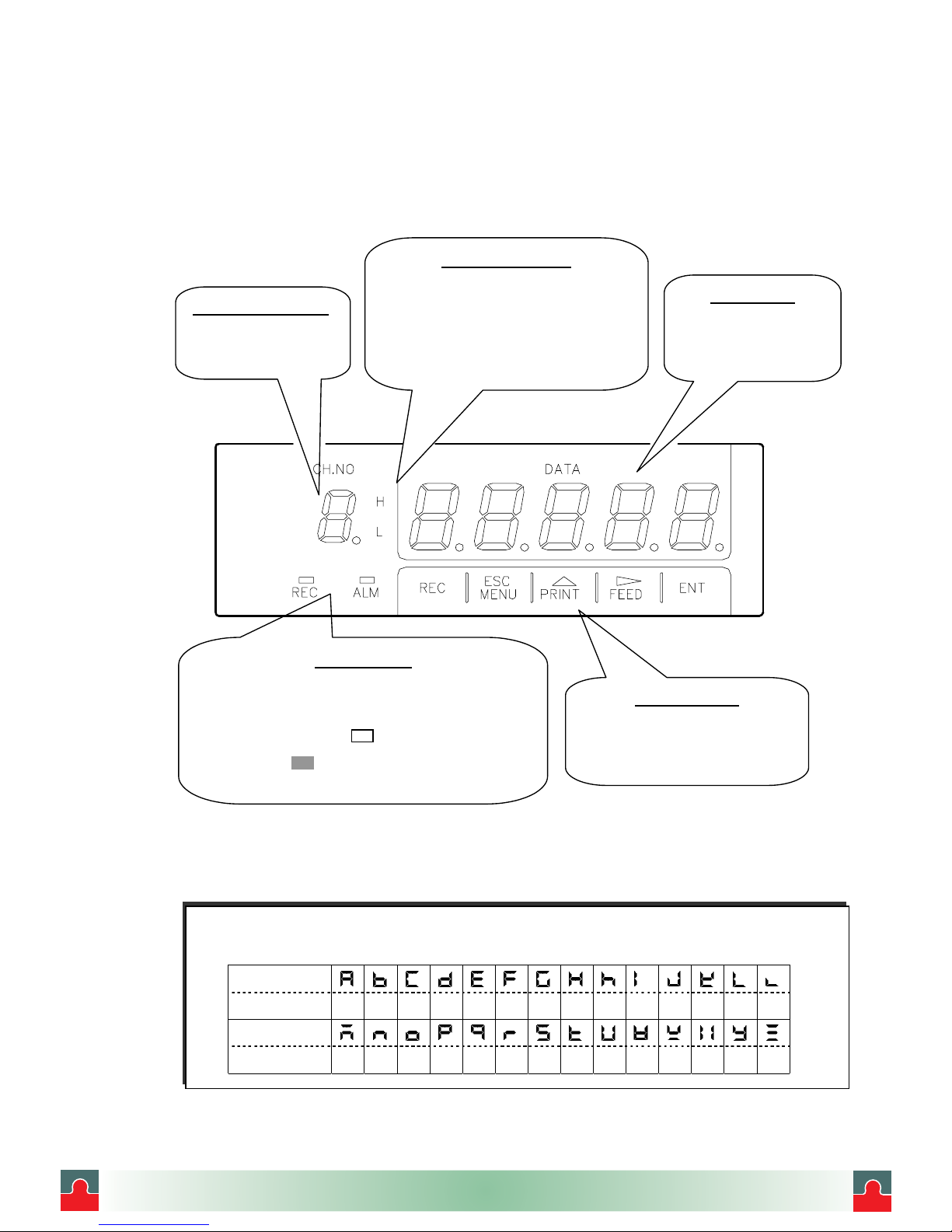

2.2 Display Screen and Operation Keys

2.2.1 Display Screen

The following describes the display screen. Since the channel numbers and data are indicated by a

7-segment LED, alphabets are symbolized to represent them.

For the LED display, see " Symbolized Alphabets for Display" at [Reference] below.

Fig. 2.2 Display

䌛Reference䌝㩷 Symbolized Alphabets for Display

Display

Alphabet A B C

DE F G H 㨔I J K L 㨘

Display

Alphabet M N O P Q R S T U V W X Y Z

Alarm Type Display

Indicates alarm type in red.

"H" is lit when the alarm is High. And

“L” is illuminated when the alarm is

Low. Neither of them is illuminated

when there is no alarm.

Channel No. Display

Indicates channel

number in orange.

Data Display

Indicates the process

variable, time, setting

screen, etc. in orange.

Operation Keys

Use these keys for setting and

other operations.

Status Display

The "REC" lamp (orange) is lit when recording.

The "ALM" lamp (red) is illuminated when the alarm

is being activated. 㩷㩷 denotes that the lamp㩷

goes out and denotes that it is illuminated.

i

i

Tel: (01943) 602001 Fax: (01943) 816796

㵪12 㵪

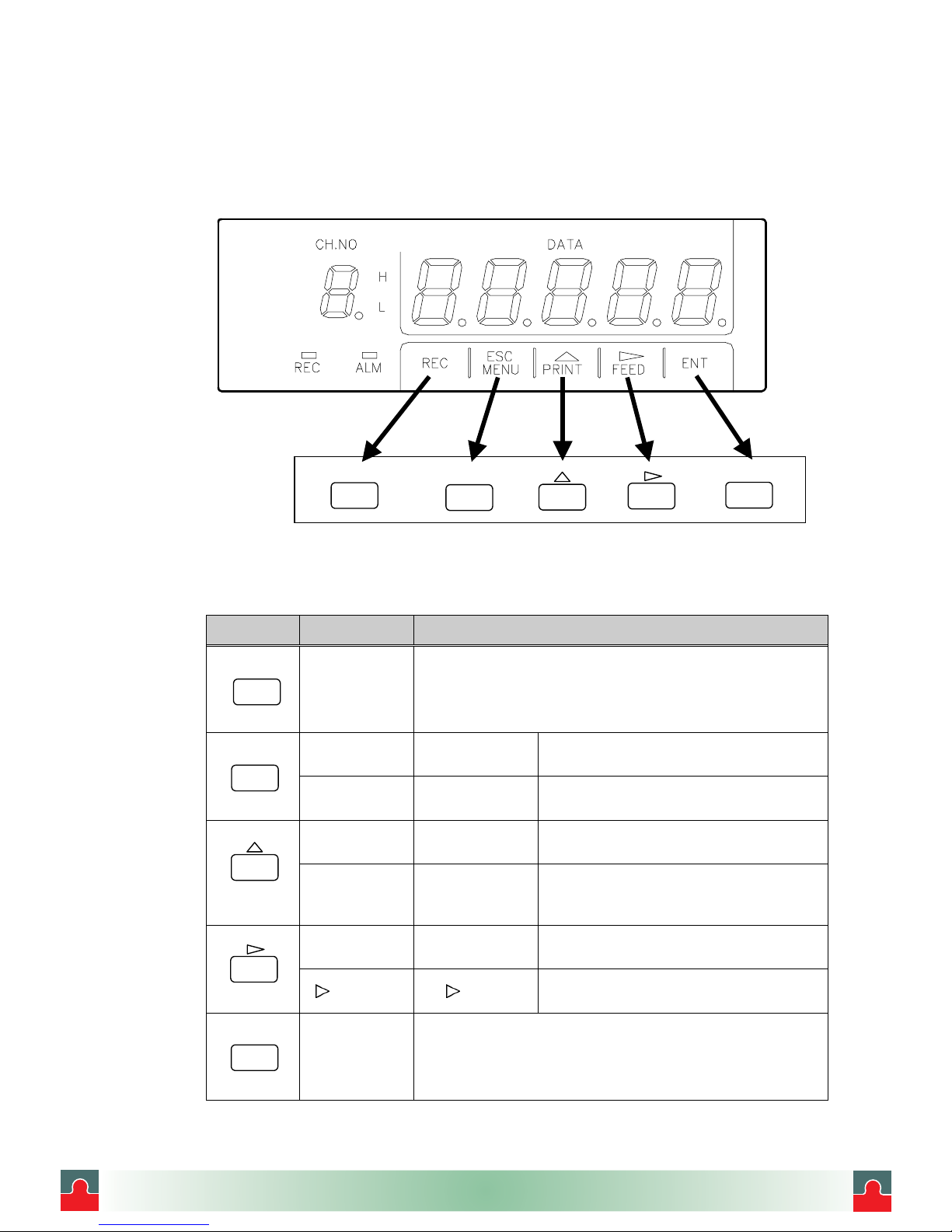

2.2.2 Operation Keys

The following describes the functions of each operation key.

The actual operation keys are represented as shown in the figure below in this manual.

㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷Fig. 2.3 㩷Operation Keys in This Manual

Table2.1㩷Names of Operation Keys and Their Functions

Key Name Function

㵰REC㵱key

Starts/stops recording. To stop, press the “REC” key for 3

seconds or more. (Puts out the “REC” lamp.) To start,

press the “REC” key. (Lights the “REC” lamp.)

㵰MENU㵱key MENU

function

Selects engineering list print and

changes the mode to the setting mode.

㵰ESC㵱key ESC

function

Exits that menu halfway while selecting

a function.

㵰PRINT㵱key PRINT

function

Used to perform manual print or list

print.

㵰䂦㵱 key 䂦function

Used to select a setting parameter

(numeral or built-in

command)(ascending direction).

㵰FEED㵱key FEED

function

The chart paper is fed while the key is

pressed, and stopped when released.

㵰 㵱 key function Used to shift a digit in setting a

numeral.

㵰ENT㵱key

Used to register a setting parameter (numeral or built-in

command) after selecting it, or executing a function.

Pressing this key executes the setting.

REC

ENT

ESC

MENU

PRINT

FEED

REC PRINT FEED ENT

ESC

MENU

i

i

Tel: (01943) 602001 Fax: (01943) 816796

㵪13 㵪

INSTALLATION

3.1 External dimensions and panel cutout Dimensions

Unit㧦চ 㧨Front㧪㧨Rear㧪

㧨Side㧪㧨Panel cutout㧪

Fig. 3.1㩷External dimensions and panel cutout

㩷CAUTION㩷

For maintenance and using the instrument safely, it is recommended that spaces larger than the size

written in the bracket be secured per unit.

Dimensionrequired

when the door is full

y

opened (135ࠑ).

(Wall on the left side).

㧔㧕

㧔㧕

OCZ

㧔2CPPGNVJKEMPGUU

㧔㧕

OKP

OKP

.0

# %#% # %#% # %#%

$

$

#

$

$

#

$

$

#

$

$

#

$

$

#

$

$

#

5)

4&6&

&+

%1/

&+

&+

&+

i

i

Tel: (01943) 602001 Fax: (01943) 816796

㵪14 㵪

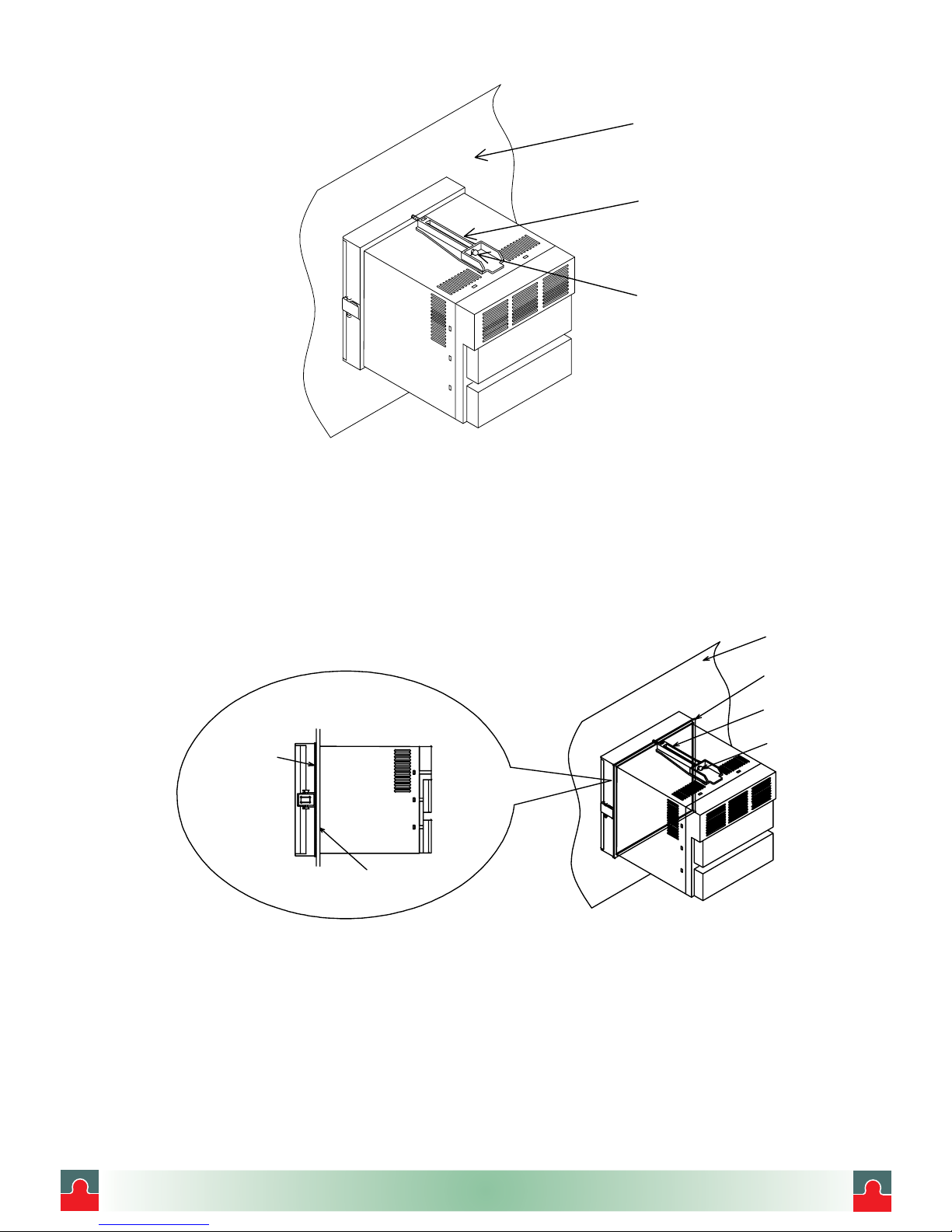

3.2 Mounting to the Panel

3.2.1 Procedure for Mounting to the Panel

1) Assemble the mounting bracket refering to Fig.3.2.

2) Insert this instrument through the front of the panel.

3) Hook the claws of the mounting bracket at the square holes in the top and bottom surfaces

of the case.

4) Tighten the screw of the mounting bracket with a screwdriver to attach it to the panel.

When the mounting unit does not move back and forth any more, tighten a screw by 180䉙.

Fig. 0.2㩷Mounting bracket

A

ssemble in such a manner tha

t

the screw nose will be almos

t

aligned with the plate surface. Mounting Claw

Body

Mounting

䌛Note䌝

If it is tightened with an excessive force, the case may be distorted and the mounting bracket may be

deformed. An adequate tightening torque is about 0.2 to 0.3 N䍃m (2䌾3䋗䌦䊶䋙).

㩷WARNING㩷

Do not install the instrument in a place exposed to a combustible, explosive, or corrosive gas (SO2,

H2S, etc.).

㩷CAUTION㩷

Install the instrument in the following places㩷㩷

䊶A place without rapid humidity change.

䊶A place of normal temperature (25㷄or so).

䊶A place exposed to as little mechanical vibrations as possible.

䊶A place with as little dusts as possible.

䊶A place affected by the electromagnetic field as little as possible.

䊶A place not directly exposed to high radiant heat.

䊶A place where the altitude is up to 2000m.

䊶Humidity has an effect on the chart paper and ink. Use the instrument in a humidity range of 20

to80%RH (60%RH is optimum).

䊶This instrument needs the inside installation.

Mounting to the Panel

䊶㩷A steel plate not thinner than 1.2mm is recommended as a mounting panel.

䊶㩷The maximum thickness of the mounting panel is 7mm.

Inclination

䊶㩷Install the instrument horizontally.

The instrument should be installed so that its inclination should be 0䉙at the front and within 30䉙at the

i

i

Tel: (01943) 602001 Fax: (01943) 816796

㵪15 㵪

Fig. 3.3㩷Mounting to the Panel

3.2.2 Mounting to the Panel in compliance with the IP65

Prior to mounting the instrument to the panel, attach packing to the position shown in the figure.

The rest of the procedure is the same.

Fig. 3.4㩷Mounting to the Panel䋨in compliance with the IP65䋩

Panel

Mounting

Screw

Mounting of Packing

Packing

Panel

Mounting bracket

Packing

Panel

Screw

i

i

Tel: (01943) 602001 Fax: (01943) 816796

㵪16 㵪

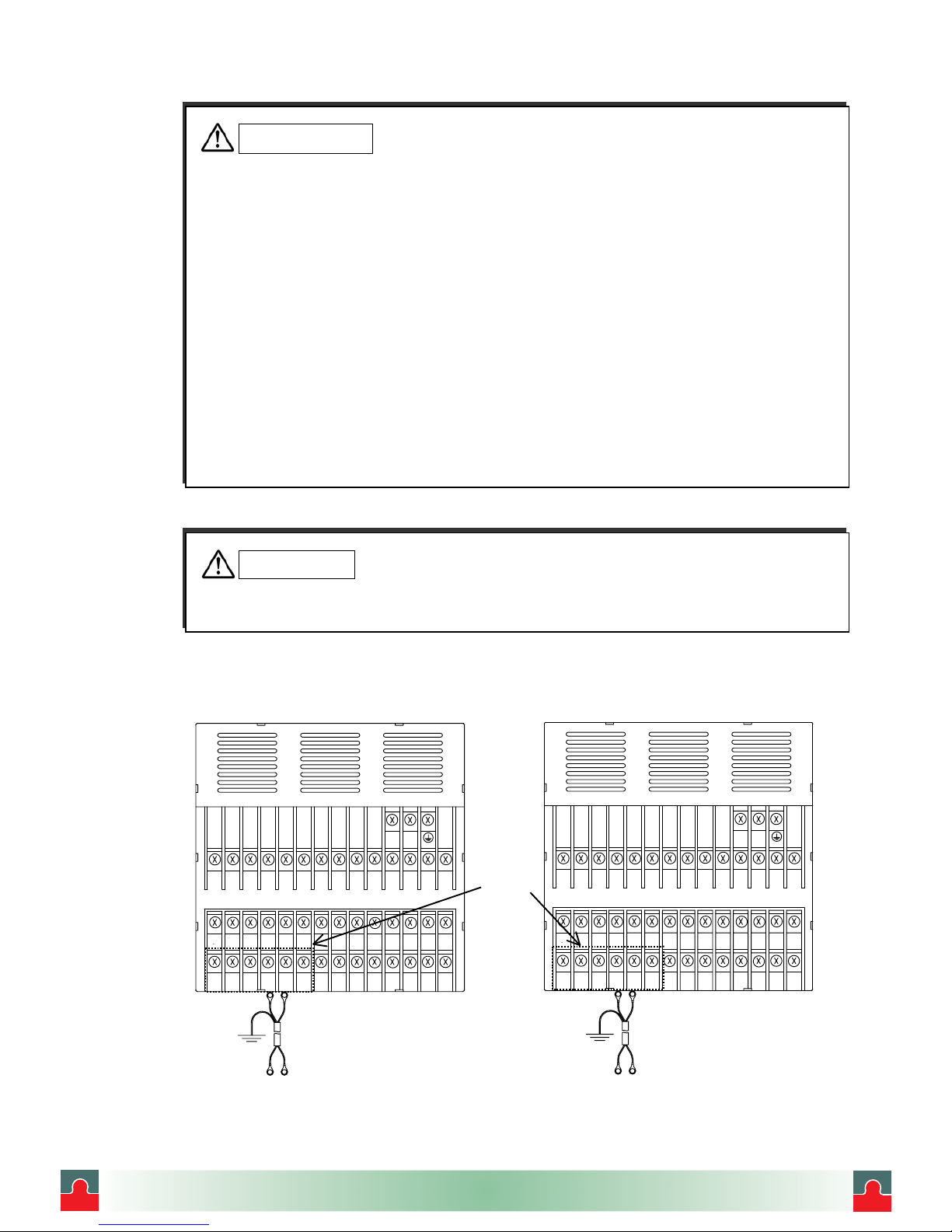

4. WIRING

4.1 Terminal arrangement and Power Wiring

4.1.1 Terminal arrangement

Fig. 4.1㩷Terminal Layout (Rear view)

4.1.2 Power Wiring

㩷WARNING㩷

㽲㩷 In order to prevent an electric shock, be sure to provide protective grounding prior to the power supply

to the instrument.

㽳㩷 Do not cut a protective grounding conductor or disconnect protective grounding.

㽴㩷 Make sure that the supply voltage for the instrument conforms to the voltage of the supply source.

㽵㩷 Attach a transparent protective cover prior to turning on the POWER of the instrument.

㽶㩷 Any interruption of the protective conductor inside or outside the instrument or disconnection of the

protective grounding terminal is likely to make the instrument dangerous under some fault conditions.

Intentional interruption is prohibited.

.0

%# # %#%

$

$

#

$

$

#5)

4&6&

&+

%1/ &+

&+

&+

Power source

terminal block

Communication

terminal block(RS-232C)

Input terminal block

Alarm output terminal block

(Option : LH3) Communication

terminal block (RS-485)

(Option : C5)

DI terminal block

(

O

p

tion : RE1

)

i

i

Tel: (01943) 602001 Fax: (01943) 816796

㵪17 㵪

4.1.3 Wiring Procedure

1) Put your fingers on the left and right (both sides) hooks of the transparent protective cover on the

power source terminal block. Pushing them inside, pull out the cover to this side.

2) Connect the power source electric wire referring to Fig. 4.2. Connect the protective grounding to

㩷㩷㩷 the㩷㩷㩷 terminal. Connect the non-grounding side of the power source to "L" terminal. Connect

㩷㩷㩷the grounding side to the "N" terminal.

3) Put on the transparent protective cover.

4) Make sure that protective grounding is properly done.

㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷Fig. 4.2㩷Power source Terminal block

㩷CAUTION㩷

㽲㩷 As an electric wire for the power source, use a 600 V vinyl insulated wire (IEC 227-3) or its equivalent

or above.

㽳㩷 Attach a round press-fitting terminal with insulated sleeve (for M3.5) to the end of the electric wire.

㽴㩷 Connect a protective grounding (resistance:100 㱅or lower, a minimum diameter of a grounding

conductor:1.6mm) to the protective grounding terminal.

㽵㩷 If other instrument shares the protective grounding conductor, there may be an effect caused by

noise coming from the grounding conductor. It is recommended not to share it with other instrument.

㽶㩷 In order to comply with the requirements of safety standard EN61010, the recorder shall have one of

the following as a disconnecting device, fitted within easy reach of the operator, and labeled as the

disconnecting device.

㩷䌡䋮A switch or circuit breaker which complies with the requirements of IEC60947-1, IEC60947-2 and 㩷

㩷㩷㩷IEC60947-3.

㩷䌢䋮A separable coupler which can be disconnected without the use of a tool.

㩷䌣䋮A separable plug, without a locking device, to mate with a socket outlet in the building.

㽷㩷 This product has been designed to conform to IEC1010-1 installation category 㸈and pollution

degree 2.

㧸㧺

CAUTION

The transparent protective cover should surely remove the left and right (both sides) hooks simultaneously.

If it removes by turns, there is a possibility that it may be damaged.

i

i

Tel: (01943) 602001 Fax: (01943) 816796

㵪18 㵪

4.2 Input Wiring

4.2.1 Wiring Procedure

1) Put your fingers on the left and right (both sides) hooks of the transparent protective cover on the

input terminal block. Pushing them inside, pull out the cover.

2) Wire the input lines referring to Fig. 4.3, Fig. 4.4 and Fig. 4.5(Page 19).

3) Put on the transparent protective cover.

Fig. 4.3㩷Input Wiring (For mV, V and Thermocouple inputs)

㩷CAUTION㩷

㽲Precautions for the input electric wire

㩷䊶See to it that no noise is mixed in input wiring. For input wiring, it is recommended a shielding wire or 㩷㩷㩷

㩷㩷twisted wire effective for noise be used.

㩷䊶In the case of thermocouple input, connect a thermocouple wire directly or use a compensating lead

㩷㩷wire. It is recommended a shielded input line be used.

㩷䊶In the case of resistance temperature detector input, dispersion of 3-wire line resistance should be less

㩷㩷than the below mentioned values. It is recommended to use a shielded input line.

㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷For Pt 100, JPt 100 䋻50m 㱅max.

㩷䊶When it is likely to be affected by induction noise, particularly when wiring near the high-frequency

㩷㩷power source, it is recommended a shielded twisted wire be used.㩷

㩷䊶Attach a round press-fitting terminal with insulated sleeve (for M3.5) to the end of the electric wire.

㽳Precautions for wiring

㩷䊶The wiring between the instrument and measurement point should be kept away from the power circuit

㩷㩷(25V or higher circuit or DO circuit).

㩷䊶Short-circuit unused input terminals. (Short-circuit between "䋫" and "䋭" in the case of mV, V, or

㩷㩷thermocouple input, and short-circuit among A, B, and B in the case of resistance temperature detector

㩷㩷input.)

㩷䊶Be sure to ground the shield of connecting wire.

䋨䋫䋩㩷㩷㩷㩷䋨䋭䋩 䋨䋫䋩㩷㩷㩷㩷䋨䋭䋩

.0

# %#% # %

$

$

#

$

$

#

5)

4&6&

&+

%1/ &+

&+

&+

.0

# %#% # %

$

$

#

$

$

#

5)

4&6&

&+

%1/ &+

&+

&+

Shielded wire Shielded wire

Ground Ground

DC voltage input Thermocouple input

Connecting lead wire Connecting compensating lead wire

Input

terminal

block

CAUTION

The transparent protective cover should surely remove the left and right (both sides) hooks simultaneously.

If it removes by turns, there is a possibility that it may be damaged.

i

i

Tel: (01943) 602001 Fax: (01943) 816796

㵪

19 㵪

Fig. 4.4㩷Input Wiring (For Resistance temperature detector)

Fig. 4.5㩷Input Wiring (For mA input)

㩷CAUTION㩷

㽲㩷 Attach the shunt resistor to the input terminal block of the instrument.

㽳㩷 A shunt resistor influences input accuracy. Use the following recommended resistor.

Resistance䋺250 㱅㩷 Rated power䋺1/4W Tolerance䋺㫧0.1% max.

㩷Temperature coefficient䋺㫧50ppm max.

.0

# %#% # %

$

$

#

$

$

#

5)

4&

6&

㧗㧙

&+

&+

&+

&+

%1/

$$#

Shielded wire

3-core cord

(Identical wire diameter length)

Ground

Resistance temperature detector

Input terminal block

Shielded wire

Ground

DC current input

Input terminal block

.0

# %#% # %

$

$

#

$

$

#

5)

4&

6&

㧗㧙

&+

&+

&+

&+

%1/

Shunt resistor

Connecting lead wire

i

i

Tel: (01943) 602001 Fax: (01943) 816796

Table of contents

Other Shinko Recording Equipment manuals