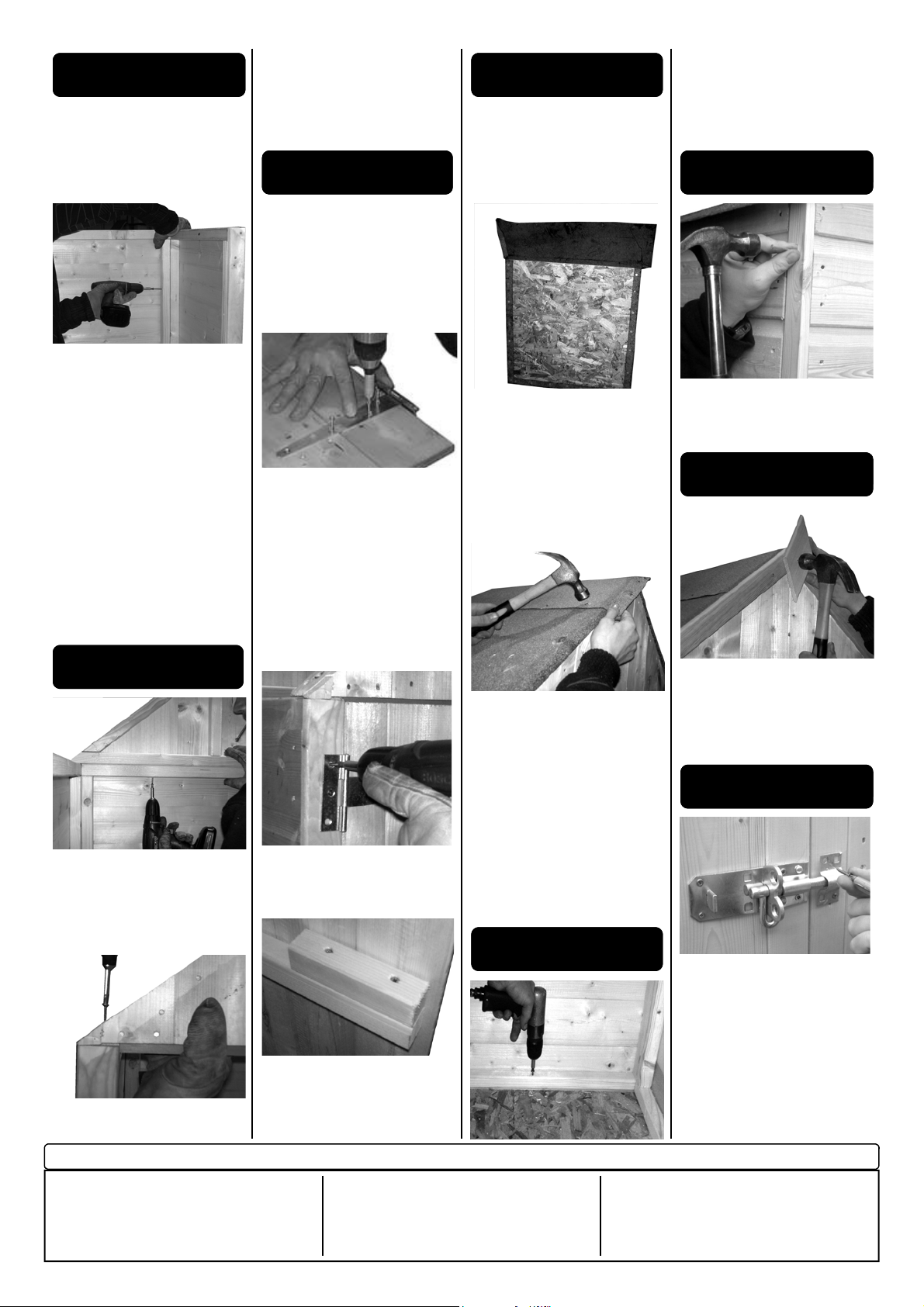

1. Ensure your base is firm and

absolutely level.

2. Lay floor panel down onto your

base.

3. Pre drill holes at top, middle and

bottom of each panel.

4. Place back panel and a side

panel at one corner of the floor

ensuring the cladding has overhung

the floor. Secure together from the

inside using 3 x 60 mm screws.

THE SIDE PANELS EXTEND

FROM FLOOR EDGE TO FLOOR

EDGE. THE PANELS AT THE

BACK AND FRONT SCREW TO

AND FIT INSIDE THE SIDE

PANELS.

5. Place other side panel in position

and secure to back panel from the

inside using 3 x 60 mm screws.

6. Place wing panel in position at

the front and secure to side panel

from the inside using 3 x 60 mm

screws.

1. Place one gable on top of back

panel ensuring the outer edges are

flush with shiplap of side panels.

Secure from underneath panel

framework into gable using 2 x 60

mm screws.

2. Place other gable in position at

the front. Secure half of the gable

from the inside from underneath

wing panel framework into gable

using 1 x 60 mm screw. Secure

other end of gable from the outside

through gable framework into side

panel framework.

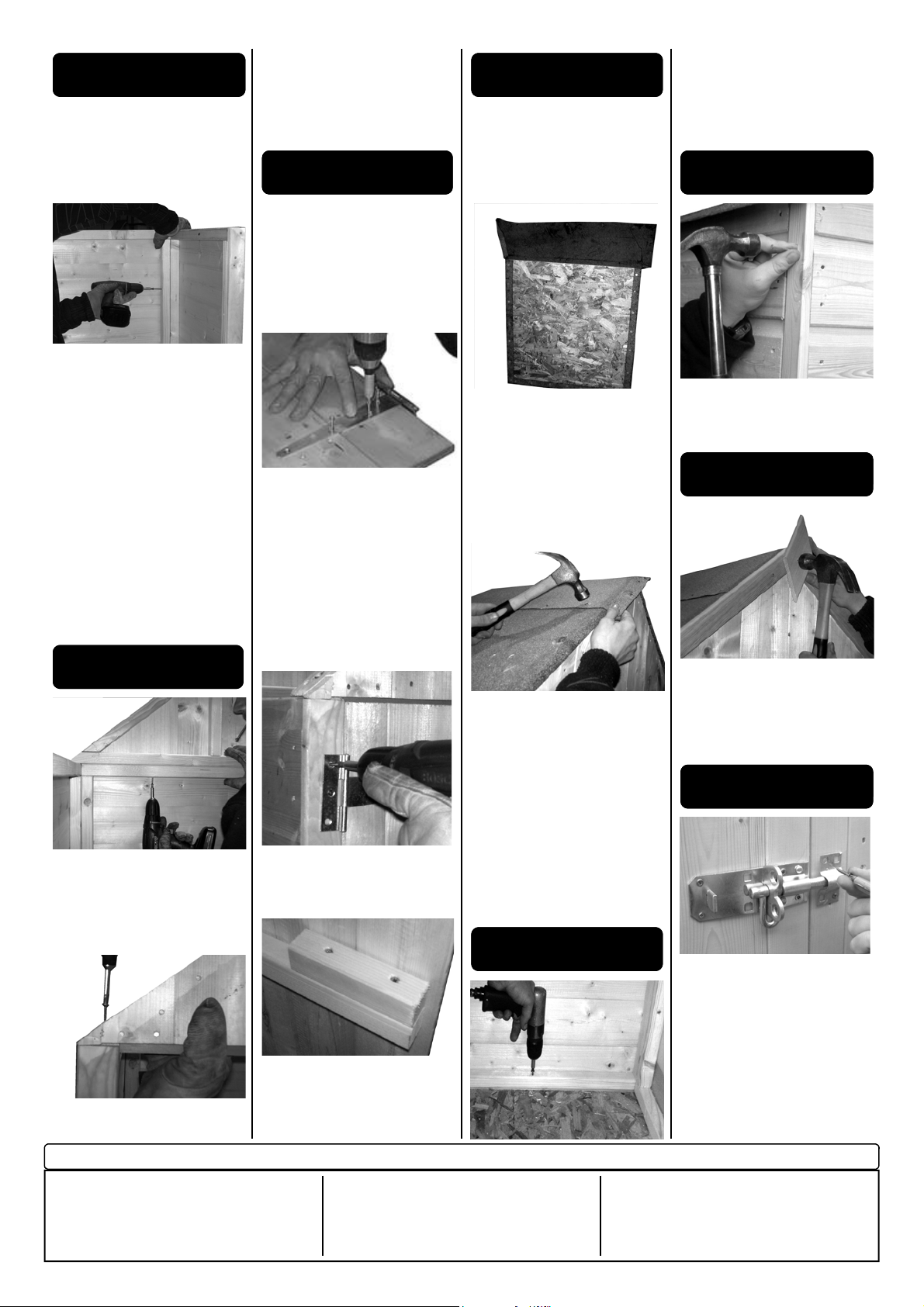

1. Position door stop strip at the top

of the door aperture flush with the

front of framework. Secure using 3

x 40 mm nails.

2. Secure the cover strip which

goes at the corner of the building

where the door is to be placed

using 3 x 40 mm nails.

3. Lay door down onto a flat level

surface. Check which side of the

door the hinges are to be fitted. The

side where the bracing does not

extend to the edge of the boarding

is the hinge side.

4. The hinges are to be fitted onto

the boarding which covers each

horizontal door bracing. Make sure

the movable part of the hinge over-

hangs the edge of the door. Secure

using 4 x 25 mm screws per hinge.

5. Place door into aperture, check

door is square and even all the way

round and secure in place using 3 x

25 mm screws per hinge.

6. Pre drill two holes in pad bolt

fixing block. Place block to the top

side of the central bracing frame-

work on the back of the door and

secure using 2 x 60 mm screws.

1. Place one roof panel onto piece

of felt allowing approx. 45 mm over-

hang on all sides. Fold felt over

onto roof panel and secure

together using felt nails spaced at

approx. 100 mm intervals

2. Place other roof panel onto the

remaining piece of felt, allowing an

overhang of approx. 45 mm on

three sides and an approx. over-

hang of 200 mm on the forth side.

Fold felt over onto roof panel,

except for the side with the approx.

200 mm overhang, and secure in

place using felt nails.

3. Place roof panel, with felt on all

sides fixed, into position flush with

front and back of building. Secure

through roof panel into gable frame-

work using 3 x long felt nails per

gable edge and 2 x long felt nails

into side wall.

4. Repeat for other roof panel, en-

suring that the 200 mm felt over-

hang goes over the ridge of the

building to overlap felt of the other

panel. Secure panel as before and

secure overlapping felt using felt

nails.

1. Secure wall panels to the floor on

the inside of the building using 2 x

60 mm screws for back and side

panels and 1 x 60 mm screw for

wing panel, preferably into floor

bearer.

1. Secure remaining three cover

strips in position where the panels

meet using 3 x 40 mm nails per

strip.

1. Secure the four fascia boards to

gable ends using 3 x 40 mm nails

per fascia piece.

2. Secure diamond on top of and in

the centre of front fascia using 2 x

40 mm nails.

1. Place pad bolt on the outside of

the door directly over the horizontal

brace. Ensure the edge is flush with

the edge of the door. Secure to

door using 4 x 25 mm screws using

the round holes only.

2. Place pad bolt housing in position

to accommodate the pad bolt.

Secure using 2 x 25 mm screws

using the round holes only.

A Wall Assembly

B Gable Assembly

C DoorAssembly

D Roof Assembly

E Secure Walls to Floor

F Cover Strips

G Fascia & Diamond

H Bolt Assembly

1Check and ensure that no raised grain or splinters

are evident on timber components. Sand down

any raised grain or splinters using fine grade

sandpaper.

2Check that all screw, nail and pin heads are

properly tapped home and are not proud of the

timber surface.

3Check and ensure that no screws, nails or pins

protrude through any panel.

4 Check and ensure that all parts are properly

secured against reasonable force.

5Do not apply decorative wood finish/treatments to

wet or damp timber. Please observe the instruc-

tions of the wood finish/treatment manufacturer. 6

. Assembly Completion Checklist