ShockWatch CS7520EDR Manual

Unpacking and Installation of the Switch System

Verifying Crate Condition

The crate has a shock sticker applied. When receiving the create, look for and inspect the shock sticker to confirm that it has not triggered.

The shock stickers turn red if the create has been mishandled or handled roughly. If one of the shock stickers is red, notify the shipper and Mellanox.

Shock Stickers

Opening the Chassis Crate

Before starting the procedure, put the ESD strap on and connect it to a valid ground.

Unscrew and remove the top cover of the crate.

Unscrew and remove the sides of the crate.

Crate Screws

IMPORTANT NOTE: The shock sticker does not necessarily indicate damage to the contents. However, be sure to carefully inspect the

contents of a crate with a triggered sticker.

It is highly recommended to have a screw gun or electric screwdriver for this step.

Remove the nylon covers from the chassis.

Visually inspect the chassis, make sure that:

There is no visible damage

4 PSUs are installed

Remove all protective plastic film from the sides and top of the chassis.

Physical Installation

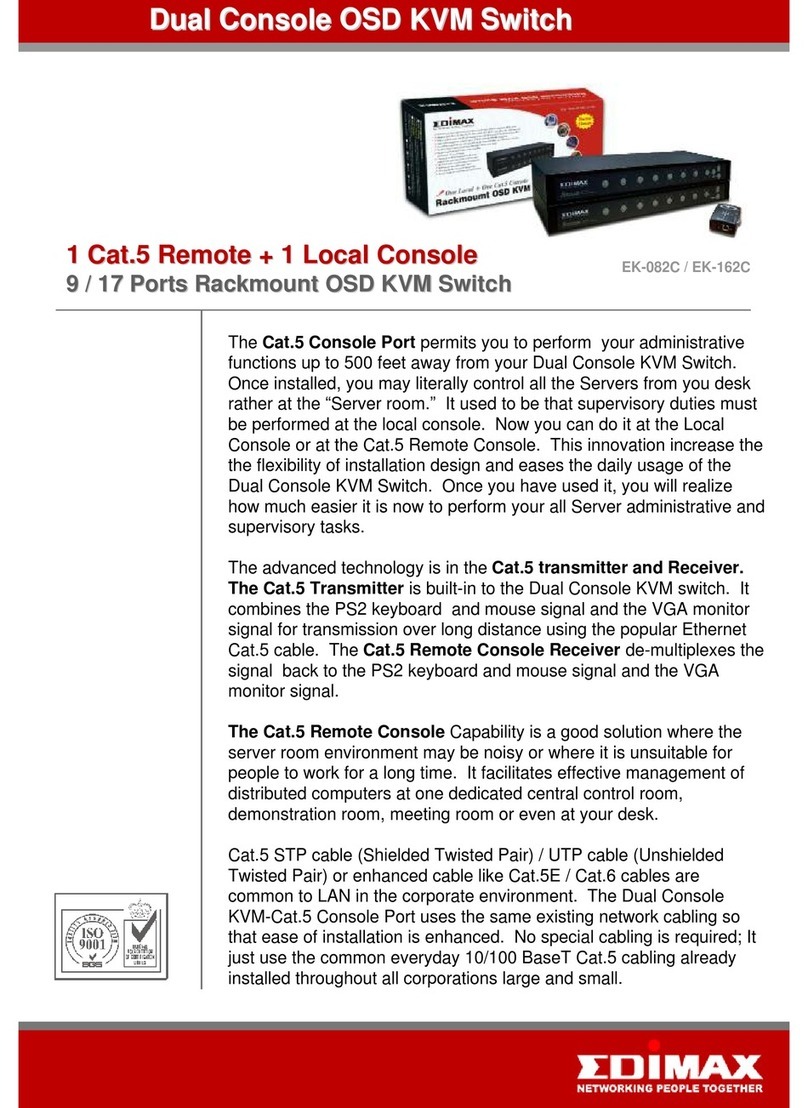

This chassis can be installed in standard 19” racks that have 715-850mm between the vertical supports of the rack.

Distance Between the Vertical Supports

Unpack the system and check against the parts list to make sure that all the parts have been sent. Check the parts for visible damage that may

have occurred during shipping. If anything is damaged or missing, contact your customer representative immediately.

Do not remove any of the blocks or the lock-down bars at this time.

The rack mounting holes conform to the EIA-310 standard for 19-inch racks. Guarantee proper ventilation, by leaving 8cm (3”) of space to the

front and rear of the switch. This ensures proper airflow through the chassis. This is crucial for maintaining good airflow at ambient temperature.

In particular, route cables such that they do not impede the air into or out of the chassis.

Warning: This equipment is very heavy. Make sure that adequate manpower and proper equipment is used for transporting and moving the

chassis. Before attempting to move and place the chassis make sure that it is empty of all leafs, spines and management modules and to use a

mechanical lift.

The vertical supports may have to be moved so that the vertical support closest to the door is a minimum of 6cm from the inside of the door. This is

required so that the shelf does not hit the door.

The switch platform uses 13U of rack space, 12U for the chassis and 1U for the shelf. The switch ships from the factory with mounting holes on the spine

side. There are upper brackets to connect the leaf side to the rack near the top of the chassis, and there are two lock-down bars to secure the chassis to

the shelf. The weight of the switch is supported from underneath the unit by the shelf.

Before starting any procedure on the switch system:

Put an ESD prevention wrist strap on your wrist, and make sure there is good contact between your body and the strap.

Plug the other end of the wrist strap to a valid ground. Make sure that this is a tight fit.

Installation Kit Parts

Chassis Installation Kit Items

Item No. Quantity Description Item No. Quantity Description

1 1 Shelf assembly 10 8 M6X16 hex-head screw

2 1 Riveted right chassis slide 11 20 M6 spring washer

3 1 Riveted left chassis slide 12 8 M6 flat washer

4 2 Support bracket 13 1 Weld bracket

5 8 M5 spring washer 14 12 10-32 hex-head screw

6 8 M5 pan-head screw 15 12 Spring washer #10

7 102M6X16 pan-head screw 16 12 M6X25 pan head screw

8 20 M6 cage nut 17 4 Shelf arm bracket

9 2 Perforated fixing bracket 18 12 Washer #10

If you move the vertical supports make sure that you reinstall them vertically plumb.

Due to the space required by up to 216 connector cables, it is recommended to use a rack that is 120cm long and 80cm wide. This should allow

for proper cable management and enough ventilation to properly cool the chassis.

You may need a mechanical lift to move and insert the chassis into the rack.

It is recommended to use an AWG6 or 4mm diameter wire for grounding purposes.

Shelf Installation Kit

The shelf installation kit includes 6 shelves only.

Shelf Installation Kit

Required Installation Tools

Shown below are the tools which are required for the installation of the director switch chassis.

Tools for Installation

Installation Procedure

Step 1. Insert 3 M6 cage nuts each from the inside of BEAM-1 and BEAM-2 on the spine side in order to support the shelf as shown in the figure below.

Cage Nut Placement for Shelf on BEAM-1 and BEAM-2

Step 2. Insert 6 M6 cage nuts from the inside each of BEAM-3 and BEAM-4 on the leaf side in order to support the shelf as shown in the figure below.

Cage Nut Placement for Shelf on BEAM-3 and BEAM-4

Some of the steps that follow are accompanied by figures that illustrate the installation of the switch system chassis. For the purpose of clarity,.the racks in those figures will have the side panels removed. You, however, do not need to remove the side panels to install the switch chassis

It is recommended to have at least three people for the duration of the installation procedure. Use a mechanical lift to raise this chassis. If not,

use enough manpower to ensure the safety and wellbeing of all of the people involved in the installation.

It is recommended to set the shelf at U3 since the chassis would roll off more easily on it from the pallet.

Step 3. Insert 4 M6 cage nuts (from the box) on the inside of each of the spine side beams of the rack in the slots indicated inChassis Installation Kit Items

the figure below.

Cage Nut Placement for Switch System Chassis on Spine Side

The indexes in the figure below count from the first rack hole above the shelf.

Step 4. Insert 3 M6 cage nuts (from the box) on the inside of each of the leaf side beams of the rack in the slotsCable Management Installation Kit Parts

indicated in the figure below.

Cage Nut Placement for Cable Holders on Leaf Side

The indexes in the figure below count from the first rack hole above the shelf.

Step 5. Using a ratchet wrench, loosen the shelf arms’ M6 hex screws enough to allow for slight movement.

Loosening the Leaf-Side Shelf Arms

Step 6. Adjust the shelf’s leaf-side arms so that the distance between the leaf-side and spine-side arms is at least 5mm longer than the distance between

the rack beams.

Adjusting the Leaf-Side Shelf Arms

Step 7. Place the shelf in U3 of the rack by inserting it at a tilt.

Placing Shelf

At least 2 people are necessary for installing the shelf.

Step 8. Assemble the spine-side M6X25 pan-head screws and the arm brackets at an intermediate 3Nm torque.

Tightening Shelf Cage Nut Screws on Spine Side

Step 9. Tighten the M6X25 pan-head screws of the shelf arms on the spine side at 9Nm torque.

Tightening Spine-side Shelf Arm Screws

Step 10. Tighten the 10 hex head screws of the shelf’s leaf-side arms at 9Nm torque on both sides.

Tightening Spine-side Shelf Arm Screws

Step 11. Tighten the 6 M6X25 pan-head screws of the shelf’s leaf-side arms at 9Nm torque now that the shelf has been placed.

Tightening Leaf-side Shelf Screws

Step 12. Assemble the bracket weld to the shelf on the spine side and tighten at 5Nm with 2 hex screws, 2 spring washers and 2 flat washers.

Weld Bracket Assembly

Step 13. Before placing the chassis in the rack, make sure to leave more room on the leaf (port cables) side to allow room for cable management.

Placement of Chassis in Rack - Top View

Step 14. Put the crate on the fork lift or a mechanical lift.

Mechanical Lift Fork Lift

Step 15. Position the chassis in front of the installation rack.

Step 16. Unscrew both lock-down bars.

Step 17. Using a fork or mechanical lift, position the middle of the leaf-side of the chassis in front of the spine-side of the rack.

Rack and Chassis Alignment

From Steps 14-21, three people should participate in the installation process.

The chassis is on ball bearings and can roll easily. Beware that the chassis can roll off of the pallet possibly causing grave bodily harm should it

fall on someone.

Step 18. Place the rotated strip on top of the bracket weld.

Rotated Strip and Bracket Weld

Step 19. Unscrew the lock-down bar facing the rack.

Step 20. Slide the switch system chassis halfway into the rack.

Sliding Chassis in Rack

Note that the chassis is on ball bearings, and with the lock-down bars removed, the chassis can roll off!

Push only from the spine side so as to not injure your fingers during insertion.

Step 21. Slide the switch system chassis all the way into the rack until it stops.

Step 22. Slide in the left and right chassis slides from the leaf side.

Sliding in Chassis Slides

Beware not to injure your fingers during insertion.

Step 23. Slide the switch system chassis all the way into the rack.

Sliding Chassis into Rack

Step 24. Screw the chassis to the rack on the spine side using 8 M6X16 screws where the cage nuts have been placed at 9Nm torque.

Step 25. Now remove the bracket weld on the spine side.

Screwing the Chassis to the Rack

Step 26. Assemble the 2 4-oval washer plates to the left and right chassis slides on the leaf side at 3.23-3.58Nm torque using 4 M5 pan-head screws on

each side.

Screwing the 4-Oval Washer Plates

Step 27. Remove the M6X16 screws holding the weld bracket on the spine side using a ratchet wrench.

Removing the Weld Bracket

Table of contents