Shop Tuff STF-40FCB User manual

Ver tical Sandblast Cabinet

OWNER’S MANUAL

WARNING:

Read carefully and understand all ASSEMBLY AND OPERATION INSTRUCTIONS

before operating. Failure to follow the safety rules and other basic safety

precautions may result in serious personal injury.

01062015

Model # STF-40FCB

Page of 10

2

Thank you very much for choosing this product! For future reference, please complete the owner’s

record below:

Model: STF-40FCB Purchase Date: _______________

Save the receipt, warranty and these instructions. It is important that you read the entire manual to

become familiar with this product before you begin using it.

This product is designed for certain applications only. The manufacturer cannot be responsible for

issues arising from modification. We strongly recommend this product not be modified and/or used

for any application other than that for which it was designed. If you have any questions relative to a

particular application, DO NOT use the product until you have first contacted us to determine if it

can or should be performed on the product.

For technical questions please call 1-218-943-6296.

INTENDED USE

The STF-40FCB Vertical Sandblast Cabinet helps keep your workspace clean and free of debris. The

large work area is at a height for a comfortable standing position while you work. The top window

provides excellent visibility. The cabinet is constructed of 19 gauge steel construction and includes

gun with ceramic nozzle, hose gloves and fluorescent lighting system.

TECHNICAL SPECIFICATIONS

Item

Description

Assembled Dimensions

55” x 22.5” x 34.5”

Weight

92 lbs

Electrical Requirements of Light

110V

Operating PSI

80 PSI (125 PSI max)

Media Types

Sand, glass and oxide media

Media Capacity (cu. ft.)

40 lbs

Nozzle Sizes

0.18”, 0.20”, 0.22”, 0.27”

Air Dryer

Use for your compressor

GENERAL SAFETY RULES

WARNING: Read and understand all instructions. Failure to follow all instructions listed

below may result in serious injury.

CAUTION: Do not allow persons to operate or assemble this sandblast cabinet until

they have read this manual and have developed a thorough understanding of how the sandblast

cabinet works.

WARNING: The warnings, cautions, and instructions discussed in this instruction

manual cannot cover all possible conditions or situations that could occur. It must be understood

by the operator that common sense and caution are factors which cannot be built into this product, but

must be supplied by the operator.

Page of 10

3

SAVE THESE INSTRUCTIONS

WORK AREA

•Keep work area clean, free of clutter and well lit. Cluttered and dark work areas can cause

accidents.

•Keep children and bystanders away while operating a sandblast cabinet. Distractions can cause

you to lose control, so visitors should remain at a safe distance from the work area.

•Be alert of your surroundings.

PERSONAL SAFETY

•Stay alert, watch what you are doing and use common sense when using a sandblast cabinet. Do

not use a sandblast cabinet while you are tired or under the influence of drugs, alcohol or

medication. Amoment of inattention while operating a sandblast cabinet may result in serious

personal injury.

•Dress properly. Do not wear loose clothing, dangling objects, or jewelry. Keep your hair, clothing

and gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in moving

parts.

•Use safety apparel and equipment. Use safety goggles or safety glasses with side shields which

comply with current national standards, or when needed, a face shield. Use a dust mask if working

in dusty work conditions. This applies to all persons in the work area.Also use non-skid safety

shoes, hardhat, gloves, dust collection systems, and hearing protection when appropriate.

SANDBLAST CABINET USE AND CARE

•Do not modify the sandblast cabinet in any way. Unauthorized modification may impair the

function and/or safety and could affect the life of the equipment. There are specific applications for

which the sandblast cabinet was designed.

•Always check for damaged or worn out parts before using the sandblast cabinet. Broken

parts will affect the sandblast cabinet operation. Replace or repair damaged or worn parts

immediately.

•Replace gloves. Cabinet gloves do wear. Replace as necessary

•Do not exceed the sandblast cabinet load capacity.

•Distribute the load evenly. Uneven loads may cause the sandblast cabinet to tip, resulting in

personal injury to the operator or others.

•Use the sandblast cabinet on flat and level surfaces capable of supporting the sandblast

cabinet and its maximum load. Pulling or pushing a load on a slanted or uneven surface can result

in loss of control.

•Store idle sandblast cabinet. When sandblast cabinet is not in use, store it in a secure place out

of the reach of children. Inspect it for good working condition prior to storage and before re-use.

•Use grounded receptacle only for electrical hookup. Requires 120V volts to operate the light.

•Disconnect incoming air line when adding abrasives or when servicing hoses, power gun or

other components.

•It is recommended to have an air dryer for your compressor being used for the Sand Blaster.

Page of 10

4

ASSEMBLY

OPERATION

Step 1 –Cabinet Rear Plate Assembly

Attach the Light Clamps (#37) on the inside of the

Cabinet Rear Plate(#19) using the Bolts (#50), Flat

washers (#59) and Hex Nuts (#54)

Step 2–Cabinet Front Plate Assembly

1. Install the Gloves Mounting Ring (#33) and Glove

Seal Ring (#30) on the Cabinet Front Plate (#17)

using the Bolts (#48), Flat Washers (#59) and

Hex Nuts (#54).

2. Slide the Glove (#41) over the Glove Mounting

Rings and secure in place with the Glove Clamp

(#31).

Step 3–Cabinet Left Plate Assembly

1. Attach the Dust Port (#22) to the outside of the Left

Cabinet Plate (#18) using the Bolts (#50), Flat

washers (#59) and Hex Nuts (#54).

2. Attach the Dust Port Cover (#29) to the Dust Port

(#22).

Step 1

Step 2

Step 3

Page of 10

5

Step 4 –Cabinet Assembly

1. Attach the Front Cabinet Plate (#17) and

the Rear Cabinet Plate (#19) to the top

edges of the Roof (#16) overlapping the

front and back flanges over the edges of

the roof using Bolts (#47), Flat Washers

(#58) and Nuts (#53) –use the middle

three holes first. Leave all bolts loose

until all bolts are in place.

2. Place the Left Cabinet Plate (#18) over the

edges of the Front and Rear Cabinet

Plates and the Roof. Secure in place using

Bolts (#47), Flat Washers (#58) and Nuts

(#53).

3. Align the holes of the Hinge (#24) along

the back edge of the Rear Cabinet Plate

and secure in place using Bolts (#47), Flat

Washers (#58) and Nuts (#53).

4. Attach the Door Frame (#15) to the other

side of the Front and Rear Cabinet Plates

and the Roof. Place the Hinge (#24) over

the back edge of the Door (#13), aligning

all holes. Secure in place using Bolts

(#47), Flat Washers (#58) and Nuts (#53).

5. After all hardware is in place, tighten all

bolts.

6. Attach Metal Liner (#35) using Tapping

Screw (#38).

Step 5 –Light and Switch Assembly

1. Place the Light (#39) in the Light Clamps (#37) and

secure with Cross Pan Head Screw M6x45 (#61),

Flat Washer (#57) and Flange Nut (#52).

2. Guide the wire of the Light out through the hole of

the Cabinet Left Plate and tighten the nuts to the

Left Plate.

3. Insert the end of the wire into the Switch (#21).

4. Install the Switch (#21) and Switch Box (#20) on the

Cabinet Left Plate with the Bolts (#50), Flat Washers

(#59), Nuts (#54) and Bolts (#51), Nuts (55). Install

the Latch (#12) on the Cabinet Front Plate with the

Bolts (#50), Flat Washers (#59) and Nuts (#54).

Step 4

Step 5

Page of 10

6

Step 6 –Funnel Assembly

1. Place the Funnel Left and Right Plates (#7) on the

inside flanges of the Funnel Front and Rear Plate

(#6) and secure in place with the Bolts (#47), Flat

Washers (#58) and Nuts (#53).

2. Slide the Funnel Mouth (#5) over the bottom of the

assembly and secure in place with the Bolts (#47),

Flat Washers (#58) and Nuts (#53).

Step 7 –Legs Assembly

Align the holes of the two rear Legs (#1) and Cabinet

holes as shown at right, and secure in place with the

Bolts (#43), Flat Washer (#57) and Nuts (#52). Repeat

with the front Legs (#1), sliding the Shims (#34)

between the Legs and Cabinet before inserting the

Bolts and securing in place. Slide Feet (#32) on to

bottom of legs.

Step 8 –Funnel and Cabinet Connection

1. Place the Bottom Plate (#9), Screen

Frame (#10) a Steel Screen (#11) on top

of the Funnel and secure the assembly to

the bottom of the Cabinet with the Bolts

(#44), Flat Washers (#57) and Nuts (#52).

2. Attach the Air Inlet Hose of the Abrasive

Gun (#8) to the inside lower right side of

the Cabinet and the Hose Inlet Fitting

(#45) to the outside, using the Flat Washer

(#56 and #62).

3. Slide the suction hose end of the Abrasive

Gun (#8) end into the Funnel through the

Screen.

Step 6

Step 7

Step 8

There is no Shim here.

Air Inlet Hose

8

Page of 10

7

WARNING: Keep door closed when in use.

WARNING: Only used media designed for this cabinet.

WARNING: Do not exceed maximum capacity of 40 lbs of media.

WARNING: Make sure legs are properly installed.

WARNING: Operate Sandblast Cabinet on a flat and level surface.

MAINTENANCE

•Maintain your sandblast cabinet. It is recommended that the general condition of any sandblast

cabinet be examined before it is used. Keep your sandblast cabinet in good repair by adopting a

program of conscientious repair and maintenance. If any abnormal vibrations or noise occurs, have

the problem corrected before further use. Have necessary repairs made by qualified service

personnel. Replace gloves as necessary.

Step 9 –Shelf and Frame Assembly

1. Install the Shelf (#2) with the Bolts (#43), Flat

Washers (#57) and Nuts (#52).

2. Layer the Protective Film (#25), Glass (#27), Acrylic

Glass (#26) and Frame (#28) over the opening on

the Roof (#16) using Bolts (#49), Flat Washers (#59)

and Nuts (#54).

3. Attach Large Cover (#36) using a Seal Ring (#23).

Step 9

2

Page of 10

8

DIAGRAM & PARTS LIST

Page of 10

9

Ref#

Description

Qty

Ref#

Description

Qty

1

Leg

4

32

Feet

4

2

Shelf

1

33

Gloves Mounting Ring

2

3

Handle

1

34

Leg Shim

3

4

Removal Cover

1

35

Metal Liner

1

5

Funnel Mouth

1

36

Large Cover

1

6

Funnel Plate (Front, Rear)

2

37

Light Clamp

2

7

Funnel Plate (Left, Right)

2

38

Nylon Threads M4x12

11

8

Section Hose

1

39

Light Lamp

1

9

Bottom Plate

1

40

Transformer

1

10

Screen Frame

1

41

Glove

2

11

Steel Screen

1

42

Abrasive Gun

1

12

Latch

1

43

Cross Pan Head Screw M6×12

24

13

Door

1

44

Cross Pan Head Screw M6×25

14

14

Foam Seal

1

45

Hose Inlet Fitting

1

15

Door Frame

1

46

Cross Pan Head Screw M5×50

1

16

Roof

1

47

Flange Bolt M5×12

60

17

Cabinet Front Plate

1

48

Cross Pan Head Screw M4×16

12

18

Cabinet Left Plate

1

49

Cross Pan Head Screw M4×20

12

19

Cabinet Rear Plate

1

50

Cross Pan Head Screw M4×10

11

20

Switch Box

1

51

Cross Pan Head Screw M2×10

2

21

Switch

1

52

Hex Nut with Flange M6

40

22

Dust Port

1

53

Hex Nut with Flange M5

60

23

Seal Ring

1

54

Hex Nut M4

35

24

Hinge

1

55

Hex Nut M2

2

25

Protection Film

1

56

Flat Washer Ø14

1

26

Acrylic Glass

1

57

Flat Washer Ø6

40

27

Glass

1

58

Flat Washer Ø5

60

28

Frame

1

59

Flat Washer Ø4

35

29

Dust Port Cover

1

60

PTFE Tape

1

30

Glove Seal Ring

2

61

Cross Pan Head Screw M6x45

2

31

Glove Clamp

2

62

Flat Washer Ø12

1

Page of 10

10

HOW IT WORKS

Your shop air hose enters front opening of cabinet and is connected to the air inlet of

power gun. Bottom handle of gun has 1/4" pipe threads which will fit most air hoses.

Cabinet pickup tube leads to clear siphon hose which connects to gun head assembly.

INSTRUCTIONS

Pour glass beads or other abrasive into cabinet hopper through the side loading door.

Place parts to be blasted in the cabinet and close the door. Do not over fill (1/2 full below

work area screen is best). With hands in cabinet gloves, aim abrasive gun at object. Pull

trigger and let our unique siphon recycling system do the rest. Rust, paint and scale are

quickly removed leaving the original metal clean and intact. The abrasive drops to the

bottom of cabinet for continual recycling each time power gun is activated.

Abrasive can be re-used until it eventually breaks down or becomes dusty. To discard

worn abrasive simply place empty box under spring loaded trap door. Add more abrasive

and resume blasting.

Connect your shop vac to vacuum ferrule. It is necessary to remove the dust created in

blasting. When using a shop vacuum, be sure to install the paper filter over the standard

filter. Otherwise, abrasive could work its way into the vacuum motor, causing bearing

failure.

Located on right front of cabinet is an opening for your air hose from your compressor. An

ordinary 3/8" ID air hose should fit through this opening. Connect air hose to bottom

handle of power gun by screwing into place (use teflon tape or pipe compound-do not over

tighten).Close door and pull trigger a few times to test operation.

NOTE: Use a fine grade of abrasive to prevent clogging. We recommend straining through

a double layer of ordinary window screen. If it passes through the screen, it will pass

through the nozzle. YOU ARE READY TO START SAND BLASTING.

For replacement parts and technical questions, please call 1-218-943-6296.

WARRANTY

One-year limited parts warranty

TG

PO BOX 203

Miltona, MN 56354

Table of contents

Popular Power Tools manuals by other brands

BLACK DECKER

BLACK DECKER BDCJS18 manual

Thomas&Betts

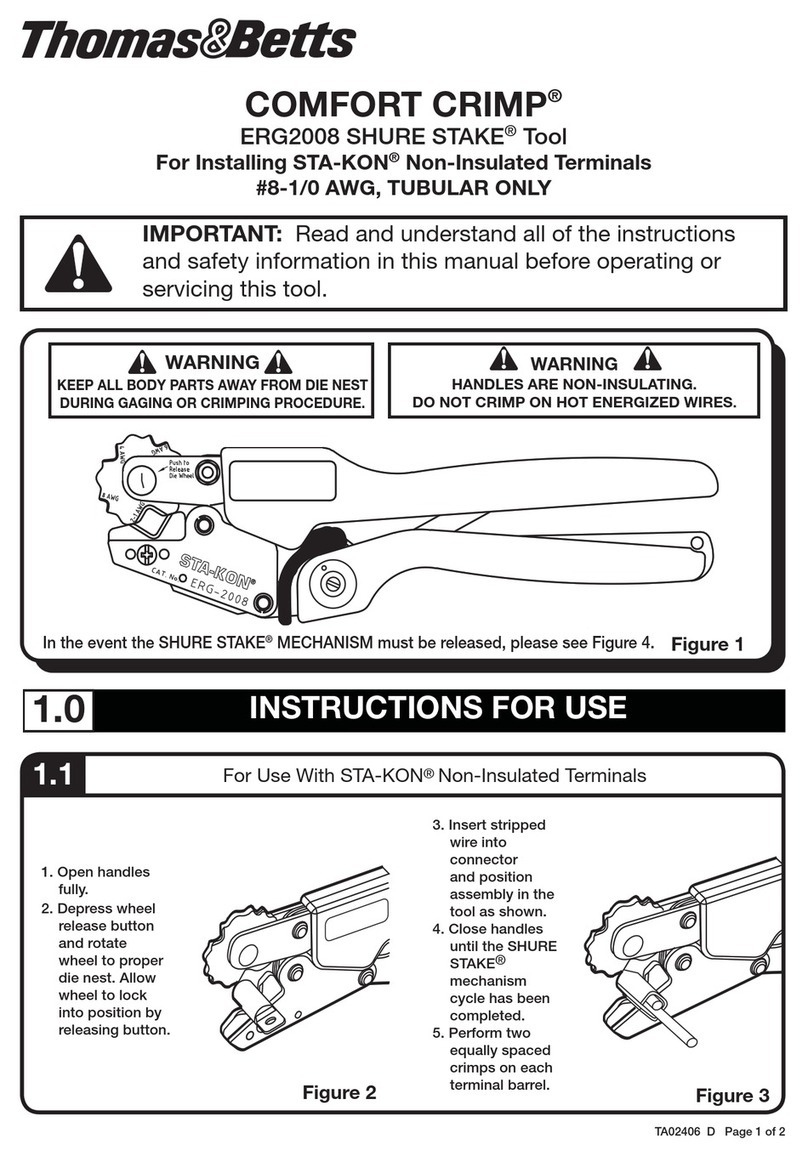

Thomas&Betts COMFORT CRIMP SHURE STAKE ERG2008 Instructions for use

woodmizer

woodmizer LTAGA-PLCBN Safety, Operation, Maintenance & Parts Manual

Power Tec

Power Tec DP801 owner's manual

Thomas&Betts

Thomas&Betts Stakon COMFORT CRIMP ERG4005 quick start guide

MEISTER CRAFT

MEISTER CRAFT MPS 710 E-P manual