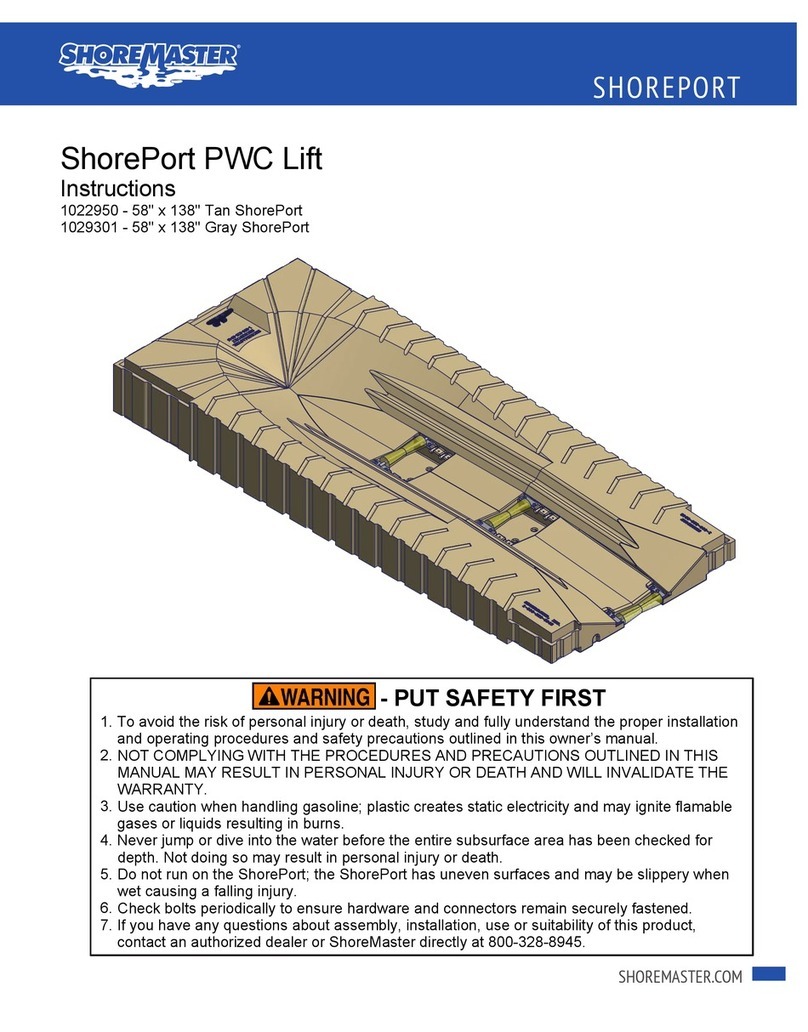

Shoremaster 1264 Instruction Manual

CAUTION - PUT SAFETY FIRST

Before attempting to install or operate this hoist, study and fully understand

the proper operating procedures and safety precautions outlined in this

owner's manual.

Never exceed the recommended weight capacity of your lift. The lifted

weight will include hull, engine, fuel, battery, and added accessories or

gear. Weigh your fully loaded boat at a certified scale to be absolutely

sure of the total weight.

Do not allow anyone on, in or under the lift while operating.

NOT COMPLYING WITH THE PROCEDURES AND PRECAUTIONS

OUTLINED IN THIS MANUAL WILL INVALIDATE THE WARRANTY AND

MAY RESULT IN PERSONAL INJURY OR DEATH.

If you have any questions about assembly, installation, operation or

suitability of this product, contact an authorized dealer.

1.

2.

3.

4.

5.

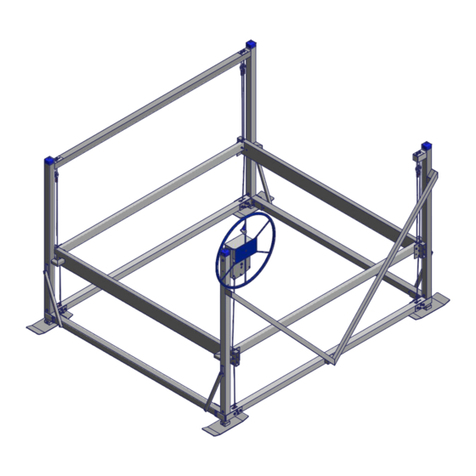

1264 Vertical Lift:

Instructions and Safety Tips

1200 lb. Capacity

Note: With 1502 DL Winch

10/1/13

11/12/2009 _1264 Complete Retail.idw

*Pulley Parts*

DESCRIPTIONPART NUMBERQTYITEM

Guide 1.0 - Plastic Guide Angle 2 x 2 x .5

10008504

Bolt Truss 1/4 - 20 x 3/410004774

Nut 1/4 Brass

10017974

Washer Lock 1/41002572

4

BRASS SHEEVE 3.125

100467310

BUSHING FRONT & SIDE100778912

SLEEVE FOR PULLEY10077902

BOLT TRUSS 3/8 X 2.25

10024308

NUT 3/8 NYLOC BRASS10024308

*1003932 - Bundle 1264 Vertical Lift*

DESCRIPTIONPART NUMBERQTYITEM

WHEEL100744811

Lift V Side100363812

Lift Opposite Side

100363913

Foot Pad 100363644

Bottom Beam100363725

Front Rack100740816

Front Rack Welded Only

10077581

Front Cable 10076691

Rack Side Right

100745217

Rack Side Tube10077941

Side Cable

10076651

Rack Side Left 100745118

Rack Side Tube10077941

Rear Rack100744319

Rear Rack Welded Only 10077911

Rear Cable

10076662

Leg Post1003112410

Lift Brace

1003084211

*1024595 - Hardware Box 1264*

DESCRIPTION

PART NUMBER

QTY

ITEM

Bunk Bracket

1005604

4

12

Hardware Bag - Winch 1002033113

Winch 1502 w/ Bolt Bag

1002028114

Cap Blue #15 - 2.313x2.3131001816415

*1004415 - Bolt Bag 1264*

DESCRIPTION

PART NUMBER

QTY

ITEM

Bolt 3/8 x 2.251002429816

Bolt 3/8 x 2.75

1002431817

Bolt 3/8 x 3.0 1002432418

Bolt 3/8 x 3.25

10024361019

Washer Flat 3/8 10025996320

Nut 3/8

10018032421

Nut Nyloc 3/810018051522

Nut Square 1/2

1001793423

Set Screw 1/2 x 1.25 1002563

4

24

Bolt Carriage 3/8 x 1.75 1001959225

Bolt 3/8 x 4.0

1002438226

Press-In Cap 1000986427

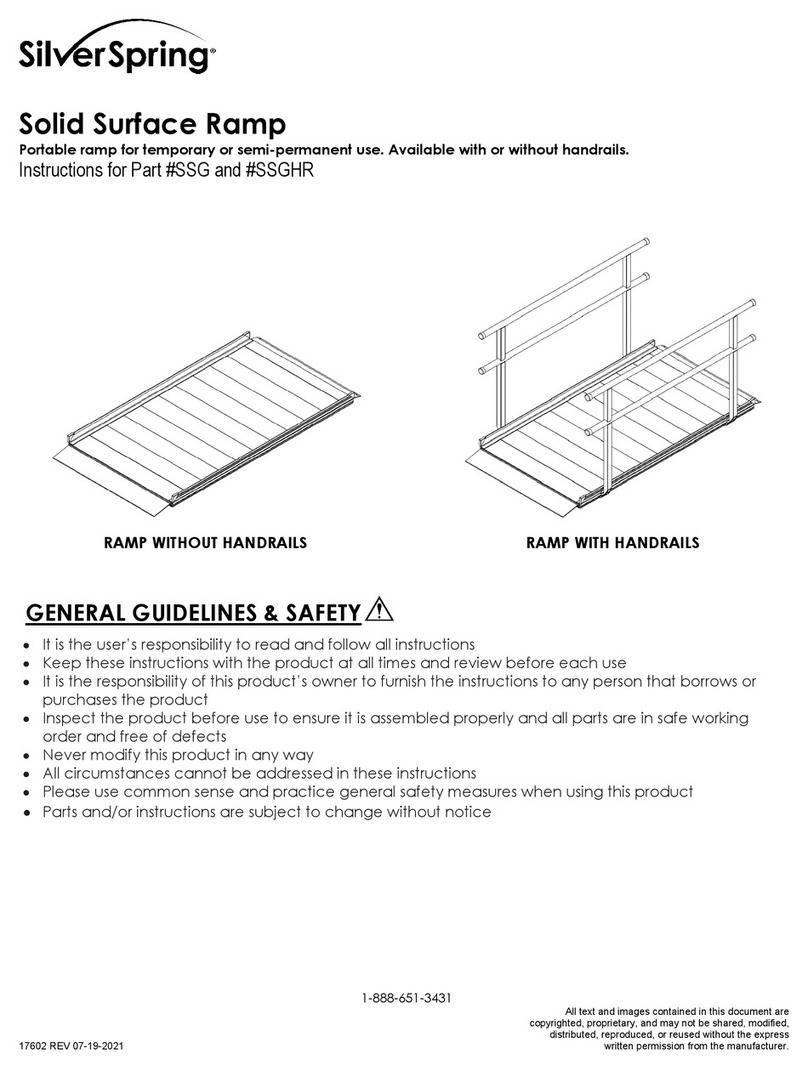

ShoreMaster

1264 Vertical Lift w/1502 Winch

Part Number: 1024594

PARTS LIST "A"

PARTS LIST "B"

PARTS LIST "C"

1

A

2

A

3

A

4

A

5

A

6

A

7

A

8

A

9

A

10

A

12

B

13

B

14

B

15

B

19

C

18

C

16

C

20

C

20

C

21

C

22

C

23

C24

C

11

A

27

C

Shipping Information

Description Weight Dimensions Cubic Ft

Bundle 145 LBS 7" x 65" x 68" 17.91

Hardware Box

26

C

25

C

17

C

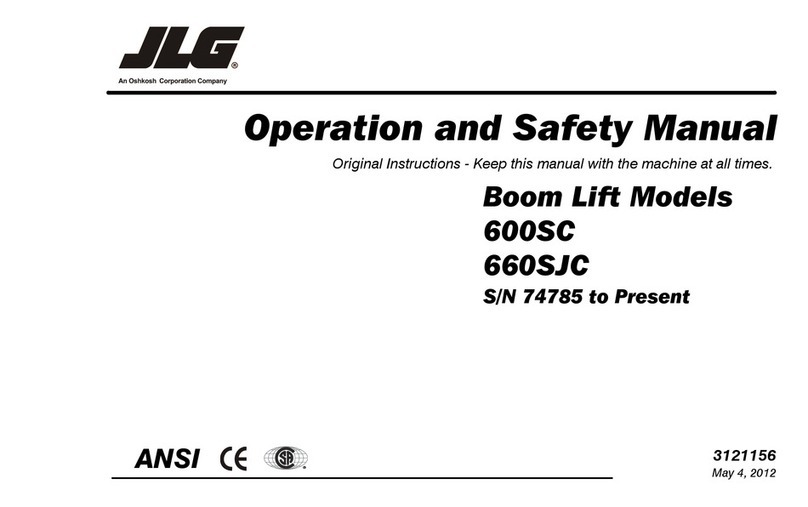

WINCH HARDWARE KIT

CABLE CLAMP

QTY. ONE

NUT 1/4 W/

STAR WASHER

QTY. ONE

BOLT CARRIAGE 1/4 X .75

QTY. ONE

BOLT 5/16 X 1 NYLOC

QTY. ONE WASHER FLAT 5/16

QTY. ONE WHEEL SPACER

QTY. ONE

10/1/13

DETAIL A

DETAIL A

A

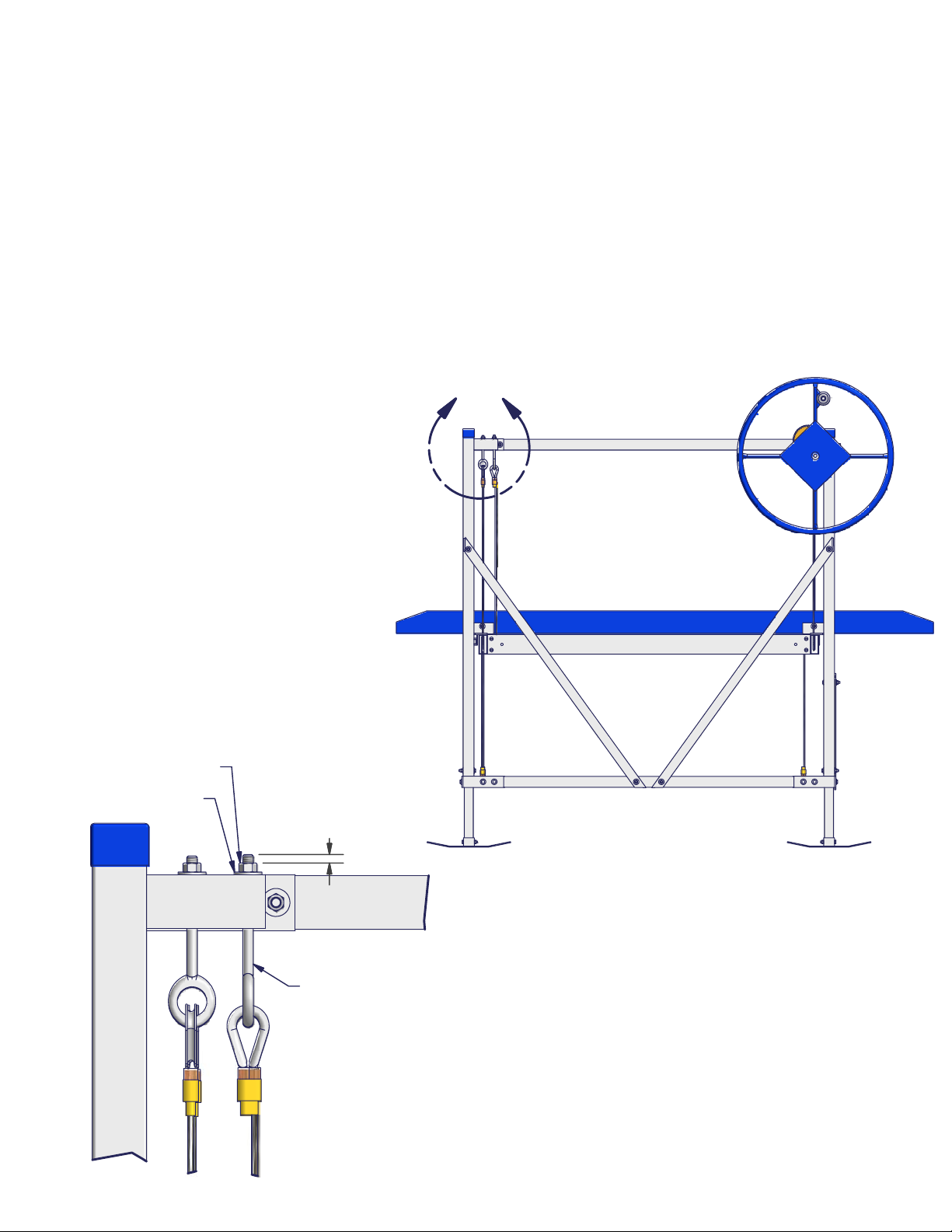

ASSEMBLY INSTRUCTIONS

Your safety is the most important issue related to this product.

Fully read and understand each step before proceeding with that step.

Wear protective gloves, clothing and eyewear when assembling and installing the lift.

Do not assemble, install or use this product if items are missing or damaged.

For ease of assembly find a flat area with plenty of room to assemble lift. The following tools will be

needed for assembling lift:

1. 7/16" Wrench

2. Pair of 9/16" Wrenches

3. Measuring Tape

4. Sharp Knife or Razor

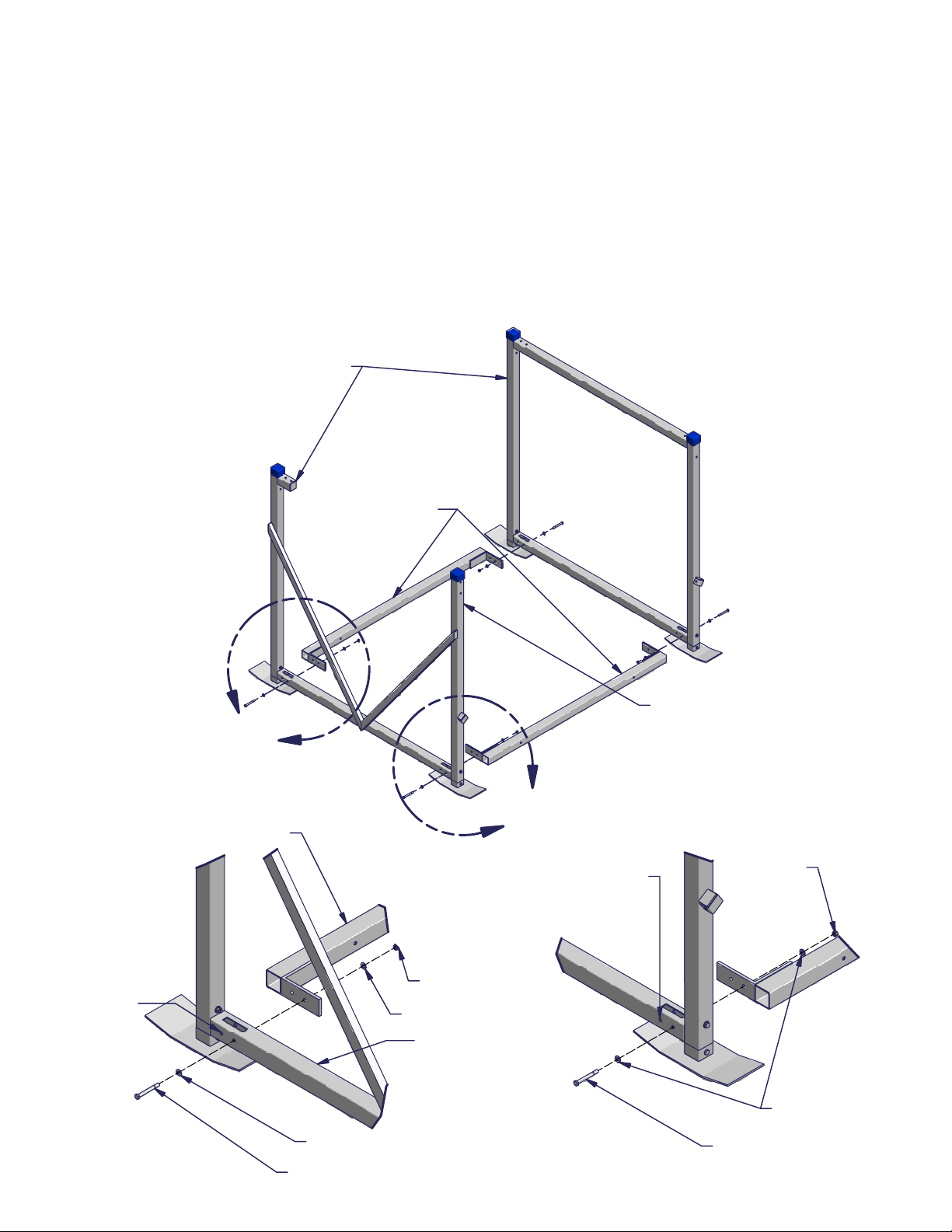

STEP 1

Slide Blue Caps on uprights as shown. Insert all four Leg Posts into Foot Pads, secure using one Bolt

3/8 x 2.75 and one Nut 3/8 in each place. Insert Leg Posts into Lift V Side and Lift Opposite

Side as shown. Use one Bolt 3/8 x 2.75, two Washers Flat 3/8 and one Nut 3/8 for each Leg

Post.

Blue Cap

Foot Pad

Leg Post

Lift Side

Nut 3/8

Washer Flat 3/8

Bolt 3/8 x 3.0

Bolt 3/8 x 2.75

Nut 3/8

10/1/13

DETAIL A

(Front Attachment)

DETAIL A

(Front Attachment)

DETAIL B

(Rear Attachment)

DETAIL B

(Rear Attachment)

A

B

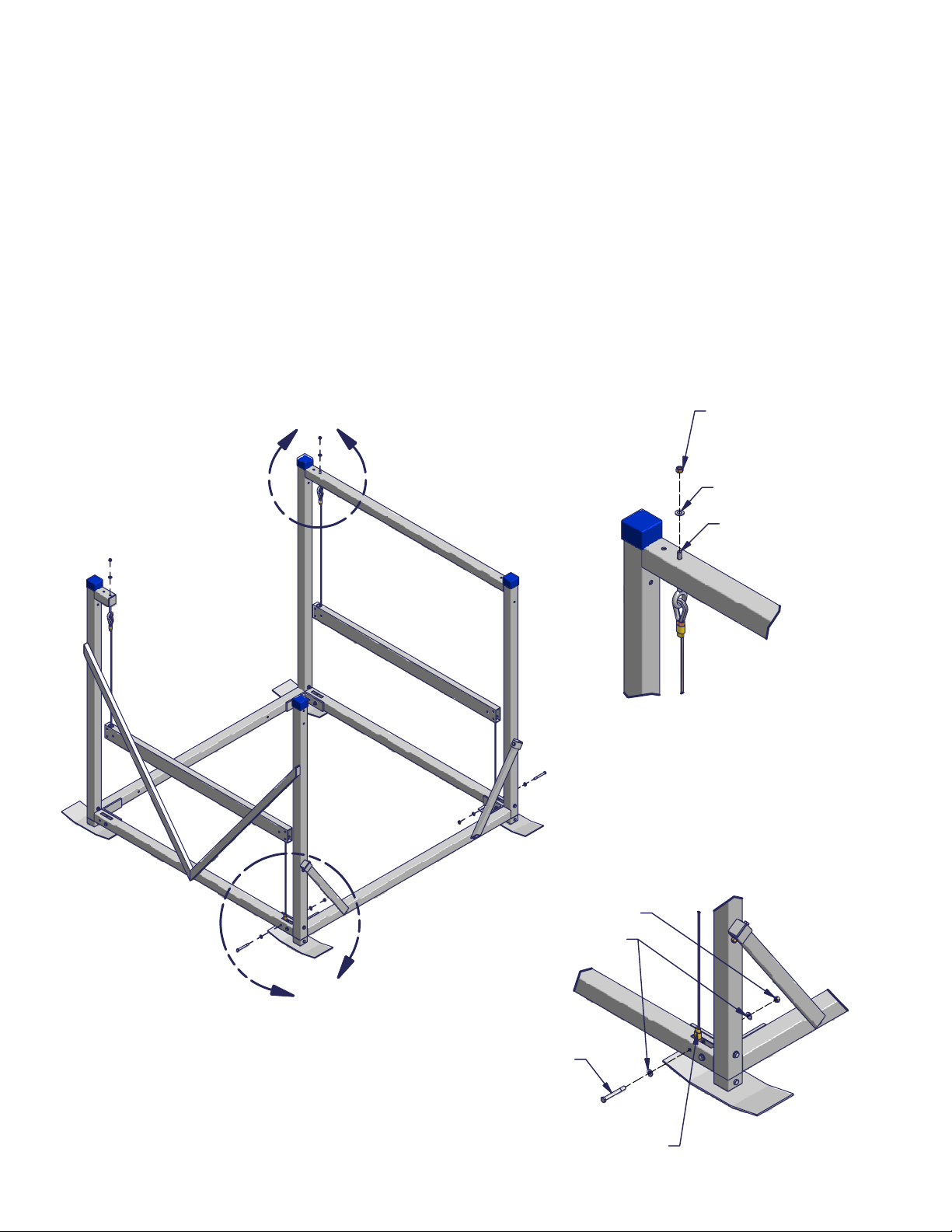

STEP 2

Place the Lift V Side and Lift Opposite Side about 5 feet apart as shown. Attach one Bottom Beam

to the front of the Lift Sides. Secure to each side with one Bolt 3/8 x 3.25, two Washers Flat 3/8

and one Nut 3/8 - as shown in Detail "A."

Attach the other Bottom Beam to the rear of the Lift Sides. Secure to each side with one Bolt 3/8 x

3.25, two Washers Flat 3/8 and one Nut 3/8 - as shown in Detail "B."

NOTE: The front is indicated by the winch mount attachment - as shown.

NOTE: Bolt only one of the two holes at each corner at this time. The remaining hole will be used in

a later step. See Detail "A" and "B" for the connection holes to use at this time.

Bottom Beams

Lift Sides

Winch Mount

Attachment

Bottom Beam

Lift Side

Nut 3/8

Washer Flat 3/8

Washer Flat 3/8

Bolt 3/8 x 3.25

This hole

not used

at this time

This hole

not used

at this time

Washer Flat 3/8

Nut 3/8

Bolt 3/8 x 3.25

10/1/13

STEP 3

Attach both Lift Braces to the Bottom Beam with one Bolt 3/8 x 4.0, two Washers Flat 3/8 and one

Nut 3/8 - as shown.

Attach one Lift Brace to the T-slot on the front of each Lift Side with one Bolt Carriage 3/8 x 1.75, one

Washers Flat 3/8 and one Nut 3/8 - as shown. Attach by sliding bolt into T Slot then placing

brace over bolt, and gently tighten.

Take two measurements between the Lift Sides, diagonally. The two measurements should be the

same. Once lift is square, tighten all bolts.

Insert Press-In Caps into Lift Braces and Lift Side Diagonals.

Washer Flat 3/8

Nut 3/8

Bolt 3/8 X 4.0

Push-In Cap

Bolt Carriage 3/8 x 1.75

Lift Brace

Lift Side Diagonal.

DETAIL A

DETAIL A

DETAIL B

DETAIL B

A

B

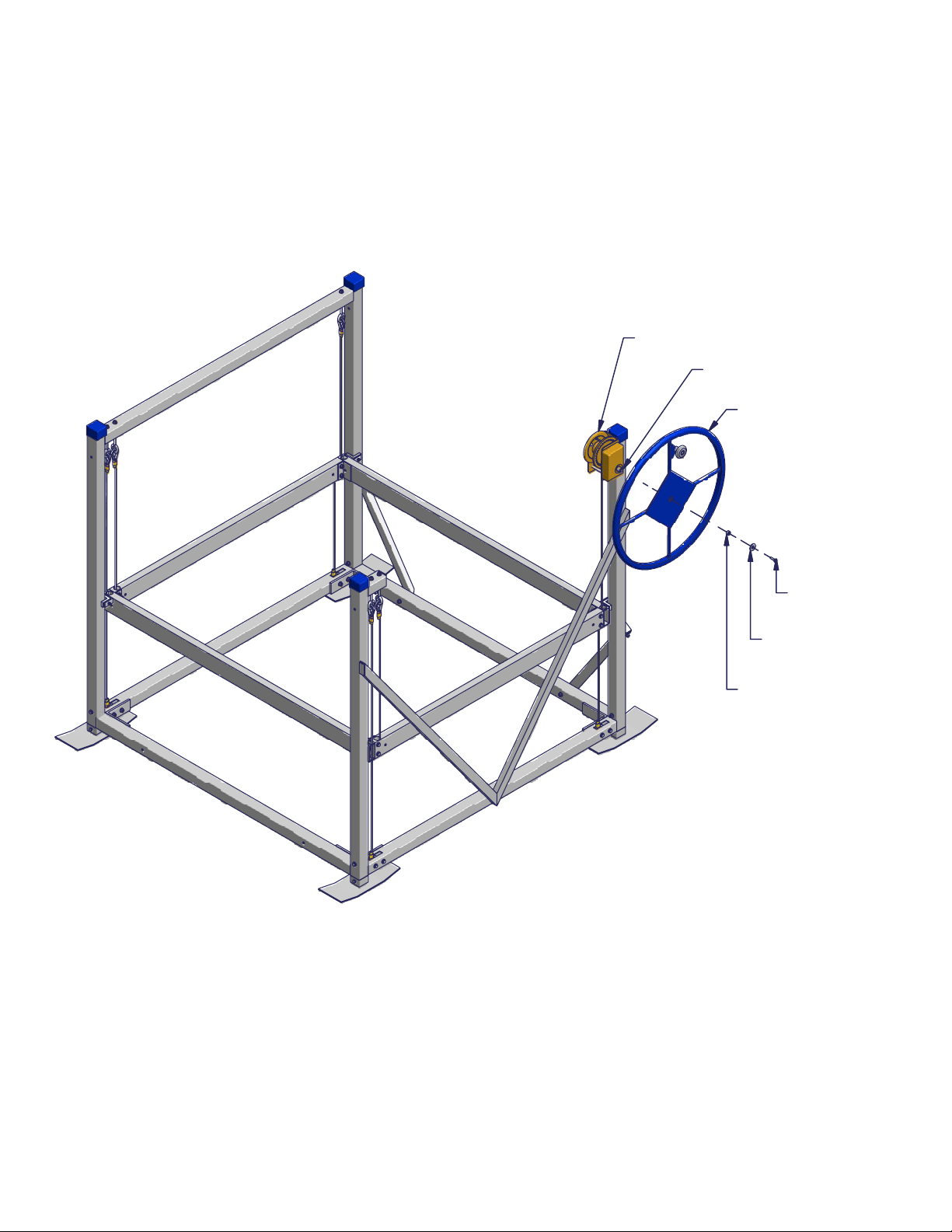

STEP 4

Set Rack Side Right in the Lift V Side and the Rack Side Left in the Lift Opposite Side - as

shown.

NOTE: The bolt heads for the pulleys must be facing out.

A - Set Aluminum Eye end of cable in the slot of the front of the lift side bottom. Secure with one Bolt 3/8

x 3.25, two Washers Flat 3/8 and one Nut 3/8 - as shown in Detail "A."

B - Insert the Eye Bolt end of cable through the hole in the lift side top. Secure with one Washer Flat 3/8

and one Nut 3/8 Nyloc.

NOTE: Be sure the washer is in place and that the nyloc nut is tightend so at least 1/4" of Eye Bolt thread

is exposed.

Nut 3/8 Nyloc

Washer Flat 3/8

Bolt 3/8 x 3.25

Washer Flat 3/8

Nut 3/8

Aluminum Eye

end of cable

Eye Bolt end

of cable

10/1/13

DETAIL ADETAIL A

DETAIL BDETAIL B

DETAIL BDETAIL C

A

B

C

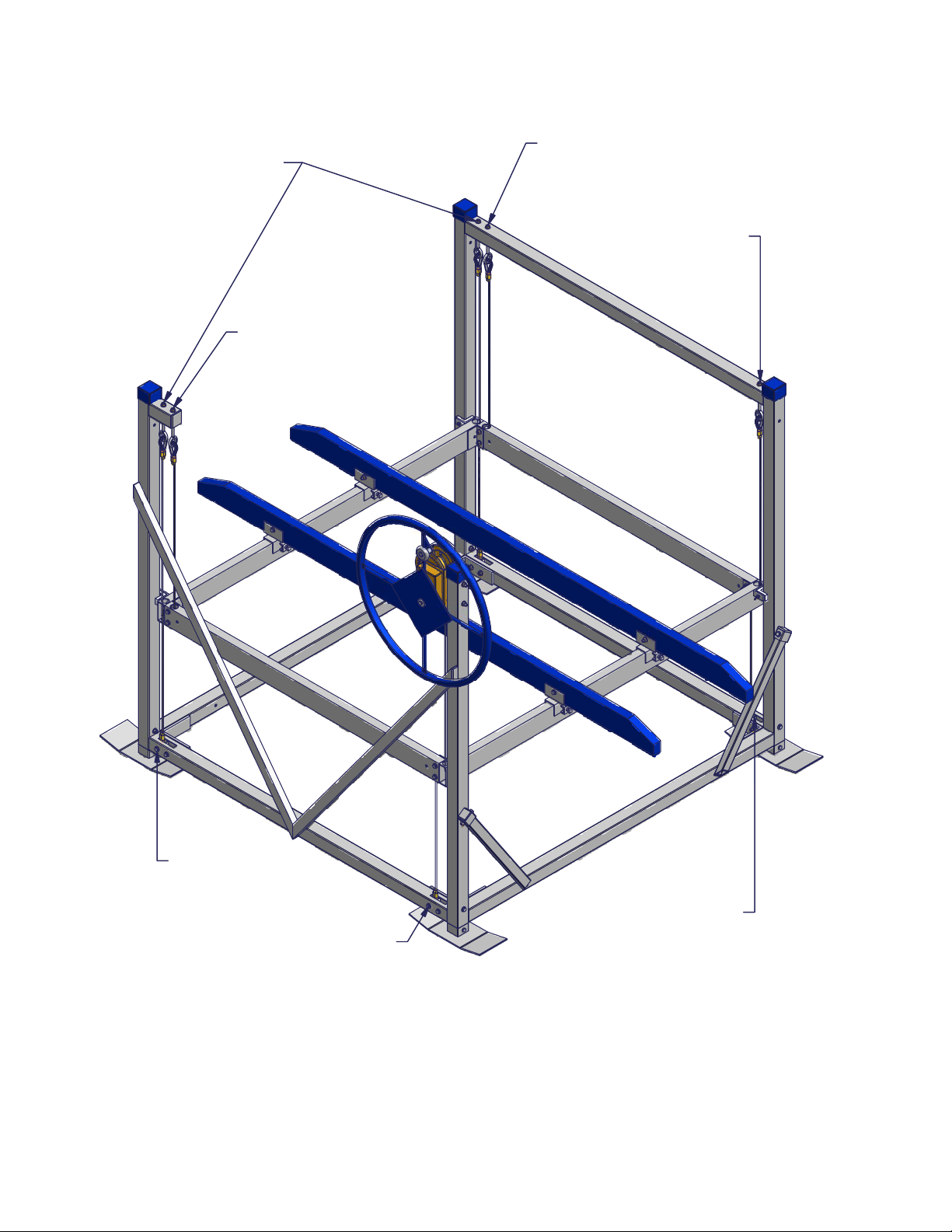

STEP 5

A - Attach the Rear Rack to each Rack Side. Secure at each end with two Bolts 3/8 x 2.25, four

Washers Flat 3/8 and two Nuts 3/8 Nyloc - as shown in Detail "A."

B - Set Aluminum Eye end of cable into the slot in the rear of the Lift Side bottom. Secure with one Bolt

3/8 x 3.25, two Washers Flat 3/8 and one Nut 3/8 - as shown in Detail "B."

C - Insert the Eye Bolt end of cable through the hole in the Lift Side top. Secure with one Washer Flat

3/8 and one Nut 3/8 Nyloc - as shown in Detail "C.".

NOTE: Be sure the washer is in place and that the nyloc nut is tightend so at least 1/4" of Eye Bolt

thread is exposed.

Nut 3/8 Nyloc

Washer Flat 3/8

Use this hole

Eye Bolt

Lift Side

(top)

Bolt 3/8 x 2.25

Rack Side

Rear Rack

Nut 3/8 Nyloc

Washer Flat 3/8

Lift Side

(bottom)

Bolt 3/8

x 3.25

Washer Flat 3/8

Nut 3/8

Aluminum Eye

end of cable

10/1/13

DETAIL ADETAIL A

DETAIL BDETAIL B

A

B

STEP 6

Set the Front Rack in place and attach to the Rack Sides. Secure at each end with two Bolts 3/8 x 2.25,

four Washers Flat 3/8 and two Nuts 3/8 Nyloc - as shown in Detail "A."

Insert the Eye Bolt end of cable through the hole in the Lift Side top. Secure with one Washer Flat 3/8

and one Nut 3/8 Nyloc - as shown in Detail "B." The other end of the cable will be attached to the

Winch 1202.

NOTE: There are five Eye Bolts to attach. See

the drawing of Eye Bolts and cables on page

16 to ensure correct location.

NOTE: Firmly tighten all nuts and bolts at this time.

NOTE: Nyloc nuts should not be reused. If a nyloc nut is removed it must be replaced with a new one.

Bolt 3/8 x 2.25

Washer Flat 3/8

Nut 3/8 Nyloc

Rack Side

Front Rack

Nut 3/8 Nyloc

Washer Flat 3/8

Lift Side

Eye Bolt

10/1/13

DETAIL ADETAIL A

A

STEP 7

Route the Winch Cable in between the two cross-bolts of the

Winch. Insert the Winch Cable through the hole in the

Winch Hub and create a loop around the square hole.

Secure with one Bolt Carriage 1/4 x .75, one Cable Clamp, and

one Nut 1/4 w/ Star Washer as shown in Detail "A."

NOTE: Wear leather gloves while handling the cables.

STEP 8

Attach the Winch to the Winch Upright with two Bolts 3/8 x 3.25, four Washers Flat 3/8, and two

Nut 3/8 Nyloc - as shown.

NOTE: The Bolt Heads should be positioned on the Winch side and should protrude through the Winch

and out the Winch Upright - as shown.

NOTE: The Wheel Shaft of the Winch must be facing

to the outside of the lift - as shown.

GOOD Cable

Route BAD Cable

Route

Bolt Carriage

1/4 x .75

Cable

Clamp

Nut 1/4 w/

Star Washer Winch

Cable

Nut 3/8 Nyloc

Washer Flat 3/8

Bolt 3/8

x 3.25

Winch

Washer

Flat 3/8

Winch

Upright

10/1/13

STEP 9

Thread Wheel clockwise onto Wheel Shaft until it touches the Brake Pad. The wheel must be fully

against Brake Pad and a clicking sound must be heard when turning wheel up!

Using a sharp knife or razor blade, cut a small hole in the middle of the Wheel, where the wheel sticker

covers the attaching bolt hole.

Secure Wheel to Winch using one Bolt 5/16 x 1 Nyloc, one Washer Flat 5/16, and one Wheel

Spacer - as shown.

STEP 10

Thead excess cable onto winch hub by turning the wheel clockwise. Be sure cable wraps tight and

uniformly on hub with each strand lying snuggly next to the adjacent strand. Keep tension on the cable

by holding it tight when turning the wheel to develop a proper wrap. Do not allow cable to wind up

loosely on hub.

CAUTION

Use a leather glove or other hand protection to avoid cuts when applying cable pressure. Cables

wrapping incorrectly will result in rapid cable wear.

Winch

Wheel Shaft

Wheel

Bolt 5/16

x 1 Nyloc

Washer

Flat 5/16

Wheel

Spacer

10/1/13

DETAIL ADETAIL A

A

STEP 12

Make sure that all nuts and bolt are firmly tightened.

NOTE: Do not over tighten any connection using nyloc nuts or set screws.

STEP 11

Position the Bunk Bracket on Front and Rear Racks to fit watercraft. Secure each Bunk Bracket with

one Nut 1/2 Square, and one Set Screw 1/2 x 1.25 - as shown in Detail "A."

Attach optional ShoreMaster Carpeted Bunks to the Bunk Brackets with one Bolt 3/8 x 2.75, two

Washers Flat 3/8, and one Nut 3/8 in each place - as shown in Detail "A."

Bunk Bracket

Set Screw

1/2 x 1.25

Front Rack

Nut 1/2 Square

Nut 3/8

Washer Flat 3/8

Bolt 3/8 x 2.75

10/1/13

CAUTION

Be sure washer is in place and that Nyloc Nut is tightened so at least 1/4" is exposed. Failure to attach

cables, Eye Bolts, Washers and Nyloc Nuts correctly could result in a severe crushing, cutting or pinching

injury. Severe damage to lift or boat could also occur.

Proper Cable Locations

Front Rack (winch)

Cable Eye Bolt

Rear Rack Cable

Eye Bolt

Rear Rack Cable

Attached here

Right Rack Side Cable

Attached here

Left Rack Side Cable

Attached Here Front of Lift

Front of Lift

Rack Side Right

Cable Eye Bolt

Rack Side Left

Cable Eye Bolt

10/1/13

DETAIL ADETAIL A

A

Proper Cable Adjustment

a) There are four cables with Eye Bolts and nuts that must be adjusted to properly level cables.

These Eye Bolts are all located near the rear uprights as shown.

b) Turn wheel so front rack beam raises about 6" above the bottom of frame. Adjust cables so

all corners of rack are the same distance from frame.

NOTE: Adjust the cable length by turning the nut on top of the Eye Bolt. Hold the Eye Bolt stationary

while adjusting the top nut. Using the frame below the rack as your reference point, measure the

distance from frame to rack in each corner. These distances should all be within a 1/4 inch.

NOTE: Be sure washer is in place and that Nyloc Nut is tightened so at least 1/4" of Eye Bolt thread

is exposed.

Nut 3/8 Nyloc

Washer Flat 3/8

Eye Bolt

1/4"

10/1/13

INSTALLATION INSTRUCTIONS

Do not under any circumstances, endanger yourself or risk damage to your lift or boat when

installing.

• Situations will widely vary between installation sites. ShoreMaster recommends that your

dealer or other trained boat lift installer train you and perform the initial installation.

• Wear protective gloves, clothing and eyewear when assembling and installing the lift.

• Do not assemble, install or use this product if items are missing or damaged.

The following are guidelines or suggestions for installation:

STEP 1

Measure the water depth of the position you want to locate the lift. Measurements should

be taken at both the projected position of the end nearest shore and end furthest from

shore.

STEP 2

Before installing, adjust lift legs so the boat can float into position before raising, while still

allowing a high enough position so the boat can be fully raised up and out of the water.

STEP 3

Carry, lift or slide the lift into position alongside the dock.

STEP 4

Ensure that your lift is level. Measure the distance from the top of the cross beam to the

water surface. The distance at each of the four corners of the lift should be within two

inches of each other. If they are not, adjust the legs accordingly.

Note: If the lift legs will extend 3 feet or more, ShoreMaster recommends deep water

braces to stabilize and strengthen the lift. Ask your dealer for more information.

STEP 5

CAUTION

The lift must be resting on the water bottom in a level, secure and

stable position for safe operation. An unstable lift installation could

result in tipping of the lift during operation, causing damage to

watercraft and a crushing or pinching injury to the operator or

bystanders.

10/1/13

Position the Bunk Bracket to fit watercraft so that it does not come in contact with the frame

of the lift. After loading and operating the lift pursuant to the operating instructions, remove

the boat and recheck that the lift remains level.

OPERATING INSTRUCTIONS

Now that you have installed and leveled the lift, you are ready to raise your boat for the first time.

Prior to use, see to it that anyone who may use the lift looks upon the unit not as a toy but a piece

of heavy equipment that deserves your respect and good judgment.

• Before allowing anyone to operate the lift, be sure they fully understand the proper operating

procedure.

• Do not exceed maximum capacity of the lift; overloading may cause mechanical failure and

serious personal injury.

• Do not allow anyone who is in the water within six feet of the lift.

• Do not allow anyone on, in or under the lift while operating.

When operating the lift, the following procedures should be adhered to:

STEP 1

Be sure the lift rack and cradles or bunks are positioned below the water surface so they

will not interfere with the boat floating into position.

STEP 2

Properly balance and center the boat on the lift prior to raising. The boat should be

positioned with the center of gravity near the middle of the lift. For most rear engine

mounted boats, this requires you to position the boat somewhat forward in the lift.

STEP 3

Turn wheel in direction of arrow (clockwise) to raise lift. A clicking

sound is heard when properly raising lift. Turning wheel and

wrapping cable in wrong direction may cause fast spin down of wheel.

WARNING

Stay clear of lifts (facing wheel) while operating. Do not allow anyone on, in or under lift.

A cable or lift part failure can cause a sudden drop of boat, resulting in a crushing or falling

injury or death!

CAUTION

Do not touch wheel or attempt to stop it if fast spin down of wheel occurs. Placing hands

or feet on spinning wheel can cause broken or cut limbs.

STEP 4

Carefully bring the lift up until the bunks or cradles have secured the boat. Then, stop the

lift and check to see that the bunks or cradles have automatically positioned themselves to

the shape of the hull, as they are designed to do. If so, continue bringing the boat out of

the water until it is about one foot above the surface. Stop the lift again and check the

stability of the lift, particularly to see that it is fairly level and will not topple over. Finally,

continue lifting the boat while paying close attention to the positioning of the lift until it is at

its desired height.

CAUTION

When first using the boat lift after installation, the weight of the boat may

cause the lift to settle and become unbalanced. Until you are certain the

lift has stabilized, make sure people are not in the immediate vicinity of

the lift.

10/1/13

CAUTIONS:

1. Do not over raise lift rack. Stop before top of rack hits cable loops attached to Eye Bolts. Over raising

could cause damage to winch, cables or other parts.

2. Do not over lower rack so slack develops in cable. Doing this could cause cable to jump off winch

spool. This may result in sloppy wrapping of cable next time you raise the lift, resulting in premature

wear or cable breaking.Turn wheel down one or two turns past point when craft begins to float (This

must always be at some point before lift rack is contacting rear bottom beam). Then turn wheel up

slightly until clicking sound is heard to secure wheel position and brake on winch.

3. Properly cover your boat, or pull your boat's plug when the boat is in a raised position. Rain water

accumulating in your bilge can quickly increase your gross weight over the capacity of the lift.

4. Do not leave lift, or boat on lift, in water if ice formation is possible. Ice can severely damage your

boatlift.

STEP 5

After loading and operating the lift, remove the boat and recheck that the lift remains level. (See

Step 4 of the Installation Instructions.) If the lift is not level, the legs should be adjusted accordingly.

Because the lift may settle and become unbalanced, the lift levelness should be rechecked two

weeks after installation and periodically as needed.

STEP 6

If lift is without a boat in it for more than one day, raise the rack (pulleys) fully out of the water

to help prevent corrosion of these parts. At all times, make sure the boat is stored high enough

out of the water to avoid wave action against the hull. A moving boat as a result of wave action

will damage the lift and can take the boat off the lift.

Monthly Checks

Check cables for frays, corrosion or breaks at least once a month. A cable breaking while

boat is in lift could damage boat or lift. Severe bodily injury could also occur.

SAFETY MAINTENANCE

1. Inspect nuts and bolts for damage, wear or loose connections. Tighten or replace parts as needed.

2. Inspect lift frame, pulleys, winch and pivot points for unusual wear, damage or bent parts. Replace

or repair as needed.

3. Check that the rack is level with the bottom frame of your lift. Cable stretching or settling of lift could

require you to adjust nuts on Eye-Bolts.

4. Lubricate winch and wheel threads. Do not get lubricant on brakepads! Brake will fail and wheel will

spin down if brake pads are lubricated.

5. Check and lubricate pulleys to ensure that they are turning freely.

6. Check Eye-Bolts to make sure they are not working themselves loose.

ShoreMaster dealers usually offer service visits. Please contact them if you are unable or unwilling

to perform maintenance or service to lift.~

Spring and Fall Checks

10/1/13

Table of contents

Other Shoremaster Lifting System manuals