Shoremaster ShorePort 1022950 User manual

®

Shoreport

SHOREMASTER.COM

Shoreport

PRODUCT ASSEMBLY INSTRUCTIONS

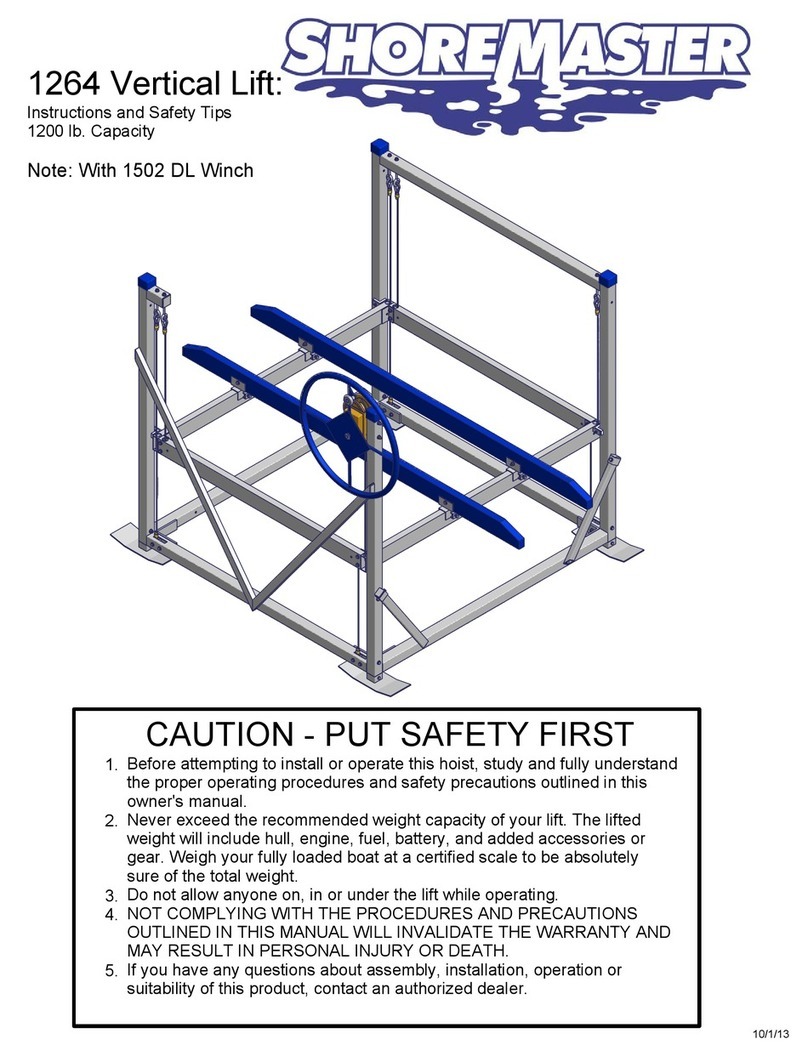

To avoid the risk of personal injury or death, study and fully understand the proper installation

and operating procedures and safety precautions outlined in this owner’s manual.

NOT COMPLYING WITH THE PROCEDURES AND PRECAUTIONS OUTLINED IN THIS

MANUAL MAY RESULT IN PERSONAL INJURY OR DEATH AND WILL INVALIDATE THE

WARRANTY.

Use caution when handling gasoline; plastic creates static electricity and may ignite flamable

gases or liquids resulting in burns.

Never jump or dive into the water before the entire subsurface area has been checked for

depth. Not doing so may result in personal injury or death.

Do not run on the ShorePort; the ShorePort has uneven surfaces and may be slippery when

wet causing a falling injury.

Check bolts periodically to ensure hardware and connectors remain securely fastened.

If you have any questions about assembly, installation, use or suitability of this product,

contact an authorized dealer or ShoreMaster directly at 800-328-8945.

- PUT SAFETY FIRST

1.

2.

3.

4.

5.

6.

7.

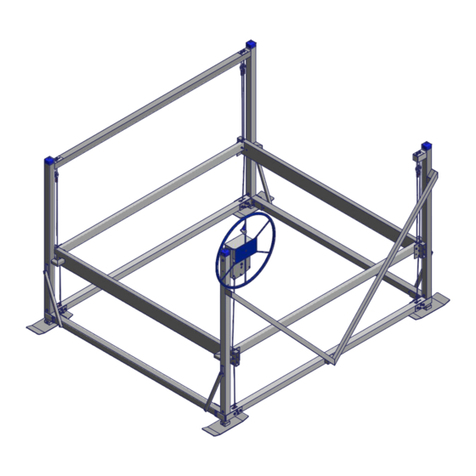

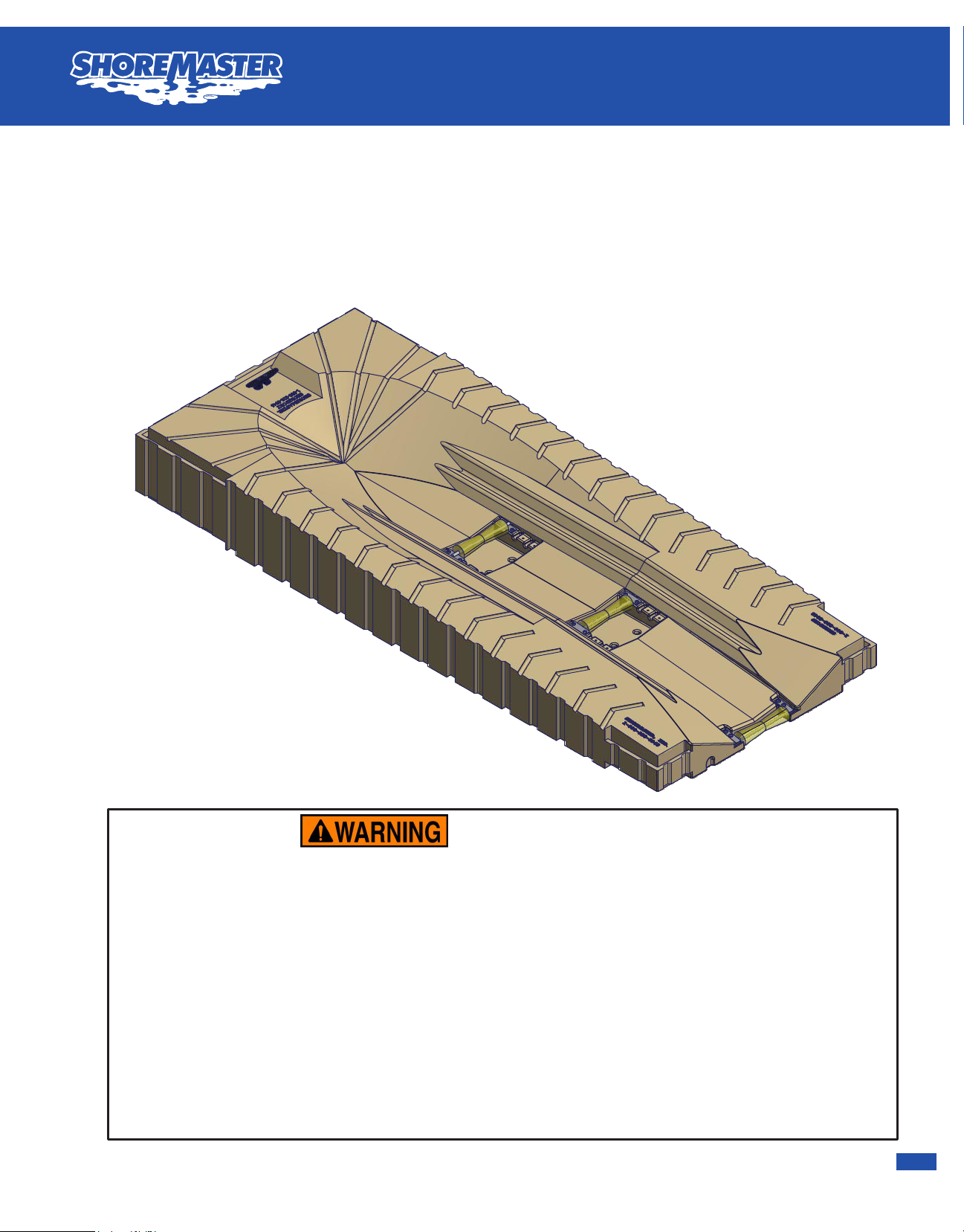

ShorePort PWC Lift

Instructions

1022950 - 58" x 138" Tan ShorePort

1029301 - 58" x 138" Gray ShorePort

® ®

Shoreport

SHOREMASTER.COM

Parts List

DESCRIPTION

PART NUMBER

QTY

ITEM

Keel Roller Rear Assembly

100178611

Washer Flat 3/8 SS

100259942

3/8 x 3/4 Button Head Socket Cap Screw

1001788

4

3

Keel Roller Assembly with Hardware10065951

-

Front Keel Roller Assembly

10017761

4

Shoreport 58" x 138"

-

1

5

Washer Flat 3/8 x 1.25 x .125 Rubber

1000613

4

6

Keel Roller Spacer Kit

10034751

-

3/8 x 1-1/2 Button Head Cap Screw

1000655

4

7

Keel Roller Spacer Plate

101337528

Optional Float (adds 50lbs cap each)

100423669

3/8 x 2-1/4 Flat Head Machine Screw

100050521 0

8" Plastic Cleat

100108911 1

1

5

3

2

ShorePort Parts List

Instructions

6

4

9

10

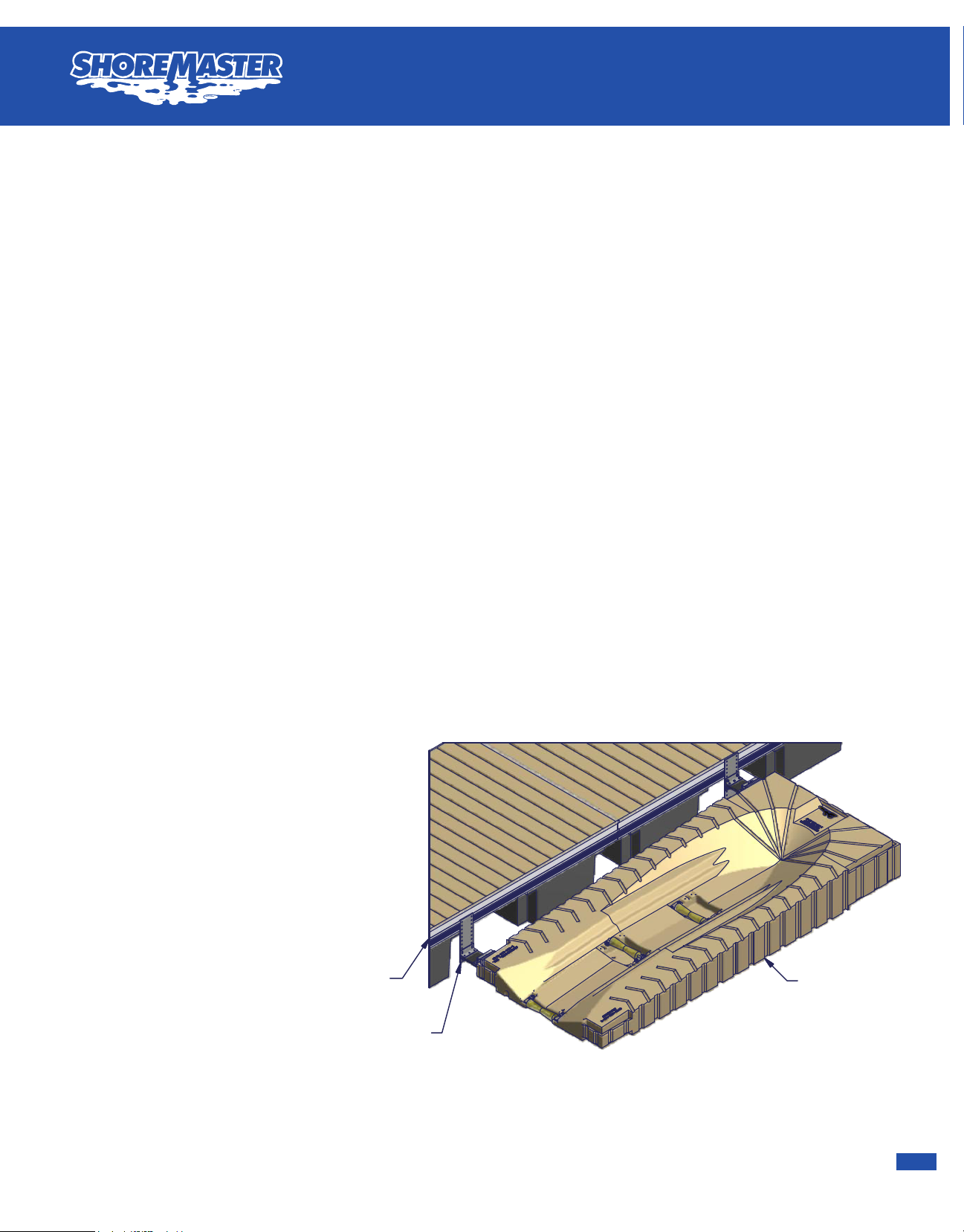

Note: The front of the ShorePort is 16" tall and will have a freeboard of about 14" without a PWC on it. The

rear roller should rest about half way out of the water without a PWC on it. The freeboard can be increased

by adding supplemental floatation (item 10).

11

Not complying with the

procedures and precautions outlined in

this manual may result in personal injury

or death and will invalidate the warranty.

Step 1. You may need to adjust rollers for best results. See next page

for adjustment options.

Step 2. See Shoreport anchoring and attachment options page for

available methods to anchor the Shoreport. (Pile guides, flexi-hinges,

connectors, etc.)

Note: Add optional floats if necessary. (adds 50lbs each)

4

8

2

3

DETAIL Position - A DETAIL Position - B

DETAIL Position - C DETAIL Position - D

DETAIL Position - E

DETAIL Position - F

DETAIL Position - G

Position - A

Position - B

Position - C

Position - D

Position - E

Position - F

Position - G

ShorePort Keel Roller Adjustment

Instructions

The rollers on the Shoreport have multiple adjustment locations in order to adjust the Shoreport to your personal

water craft.

The front and middle rollers can be placed in three different slots and can also be flipped with axle above or below the

plates. The rear roller can also be flipped but has only one location.

To adjust, use a 7/32" hex key to remove the four 3/8 button head bolts holding the roller in, move to desired position,

and put the bolts back in to secure in place.

For PWC's that are difficult to unload we recommend having the front roller in the most forward position with the axle

flipped above the plates (Position B) so it is the highest it can be and the middle roller in the most forward position

with the axle facing down into the slots of the Shoreport (Position C).

With the many different designs of PWC's available you will need to adjust the rollers to fit your specific watercraft. As

a general guideline, raising the front and middle rollers makes it easier to unload the PWC. However if the rollers are

too high the PWC may not stay on the Shoreport and the rollers may need to be lowered. If the rollers do not provide

enough height in the forward position with the axle up, there is a spacer kit available to raise the roller another 1/2

inch, part number 1003475 as shown in Position A.

-The keel rollers on the ShorePort may be adjusted to make it

easier to get your PWC on and off of the ShorePort.

-The middle and front rollers can be adjusted in the different

positions as shown. The axle of the roller assembly can be

positioned facing up or down and can be placed in any three of

the roller positions.

-To move the rollers use a 7/32" hex key wrench and remove

the four 3/8" button head bolts holding the roller to the

ShorePort. Move the roller to the desired position and

re-attach using the same 3/8" button head bolts. For further

adjustment a Keel Roller Spacer kit (P/N: 1003475) is

available and can be used in positions D,E, and F as shown in

position G.

-The rear keel roller may also be adjusted by flipping it over so

the axle for the roller is on top of the mounting plates. Roller

positioning will vary depending on the type of PWC you have.

You will have to try different roller positions to find what works

best for your PWC.

A B CD E

A - Highest Position with Spacer Kit

B - Highest Position no Spacer Kit Axle Up

C - Roller in Forward (High) Position

D - Roller in Middle Position

E - Roller in Rear (Low) Position

The front and middle rollers can be used in

all of the above positions. Positions D and E

can also be used with the axle up. The axle

needs to be up in order to use the spacer kit.

The spacer kit can be used in any of the

three slots.

To the left, recommended roller position for

PWC's that are difficult to remove from the

Shoreport. Front roller in position B, middle

roller in position C.

®

®

Shoreport

SHOREMASTER.COM

Parts List

DESCRIPTION

PART NUMBER

QTY

ITEM

Keel Roller Rear Assembly

100178611

Washer Flat 3/8 SS

100259942

3/8 x 3/4 Button Head Socket Cap Screw

1001788

4

3

Keel Roller Assembly with Hardware10065951

-

Front Keel Roller Assembly

10017761

4

Shoreport 58" x 138"

-

1

5

Washer Flat 3/8 x 1.25 x .125 Rubber

1000613

4

6

Keel Roller Spacer Kit

10034751

-

3/8 x 1-1/2 Button Head Cap Screw

1000655

4

7

Keel Roller Spacer Plate

101337528

Optional Float (adds 50lbs cap each)

100423669

3/8 x 2-1/4 Flat Head Machine Screw

100050521 0

8" Plastic Cleat

100108911 1

1

5

3

2

ShorePort Parts List

Instructions

6

4

9

10

Note: The front of the ShorePort is 16" tall and will have a freeboard of about 14" without a PWC on it. The

rear roller should rest about half way out of the water without a PWC on it. The freeboard can be increased

by adding supplemental floatation (item 10).

11

Not complying with the

procedures and precautions outlined in

this manual may result in personal injury

or death and will invalidate the warranty.

Step 1. You may need to adjust rollers for best results. See next page

for adjustment options.

Step 2. See Shoreport anchoring and attachment options page for

available methods to anchor the Shoreport. (Pile guides, flexi-hinges,

connectors, etc.)

Note: Add optional floats if necessary. (adds 50lbs each)

4

8

2

3

DETAIL Position - A DETAIL Position - B

DETAIL Position - C DETAIL Position - D

DETAIL Position - E

DETAIL Position - F

DETAIL Position - G

Position - A

Position - B

Position - C

Position - D

Position - E

Position - F

Position - G

ShorePort Keel Roller Adjustment

Instructions

The rollers on the Shoreport have multiple adjustment locations in order to adjust the Shoreport to your personal

water craft.

The front and middle rollers can be placed in three different slots and can also be flipped with axle above or below the

plates. The rear roller can also be flipped but has only one location.

To adjust, use a 7/32" hex key to remove the four 3/8 button head bolts holding the roller in, move to desired position,

and put the bolts back in to secure in place.

For PWC's that are difficult to unload we recommend having the front roller in the most forward position with the axle

flipped above the plates (Position B) so it is the highest it can be and the middle roller in the most forward position

with the axle facing down into the slots of the Shoreport (Position C).

With the many different designs of PWC's available you will need to adjust the rollers to fit your specific watercraft. As

a general guideline, raising the front and middle rollers makes it easier to unload the PWC. However if the rollers are

too high the PWC may not stay on the Shoreport and the rollers may need to be lowered. If the rollers do not provide

enough height in the forward position with the axle up, there is a spacer kit available to raise the roller another 1/2

inch, part number 1003475 as shown in Position A.

-The keel rollers on the ShorePort may be adjusted to make it

easier to get your PWC on and off of the ShorePort.

-The middle and front rollers can be adjusted in the different

positions as shown. The axle of the roller assembly can be

positioned facing up or down and can be placed in any three of

the roller positions.

-To move the rollers use a 7/32" hex key wrench and remove

the four 3/8" button head bolts holding the roller to the

ShorePort. Move the roller to the desired position and

re-attach using the same 3/8" button head bolts. For further

adjustment a Keel Roller Spacer kit (P/N: 1003475) is

available and can be used in positions D,E, and F as shown in

position G.

-The rear keel roller may also be adjusted by flipping it over so

the axle for the roller is on top of the mounting plates. Roller

positioning will vary depending on the type of PWC you have.

You will have to try different roller positions to find what works

best for your PWC.

A B CD E

A - Highest Position with Spacer Kit

B - Highest Position no Spacer Kit Axle Up

C - Roller in Forward (High) Position

D - Roller in Middle Position

E - Roller in Rear (Low) Position

The front and middle rollers can be used in

all of the above positions. Positions D and E

can also be used with the axle up. The axle

needs to be up in order to use the spacer kit.

The spacer kit can be used in any of the

three slots.

To the left, recommended roller position for

PWC's that are difficult to remove from the

Shoreport. Front roller in position B, middle

roller in position C.

® ®

Shoreport

SHOREMASTER.COM

How to Grease Rollers

If your keel rollers are hard to turn, you can add

grease to them by using a grease gun with a

snap in needle (the needle can be purchased

from ShoreMaster with part number 1017538 or

through a parts store). To add grease to the keel

roller you will have to make sure your ShorePort

came with the keel rollers that have a small hole

drilled into the middle of the roller. If you have

the hole, insert the needle on the grease gun into

the hole and pump grease into the roller until

grease comes out the end of the roller. If your

keel rollers do not have the hole in the middle of

them you can insert the needle between the

roller and the shaft the roller rides on and pump

grease into it until it comes out the other end. If

the roller is still hard to turn the keel roller is

probably bent and will have to be replaced.

Note: Use marine grade grease.

Keel Roller

ShorePort

Grease Access Hole

DETAIL F

SCALE 1 / 25

DETAIL G

SCALE 1/20

F

G

ShorePort Anchoring and Attachment Options

ShorePort to Poly Dock

Front Connector

P/N: 1007011 - Tan

1029365 - Gray

ShorePort to ShorePort

Side Front Connector

P/N: 1006631 - Tan

1029360 - Gray

ShorePort to ShorePort

Notched Side Front Connector

P/N: 1003472 - Tan

1029359 - Gray

ShorePort to ShorePort

Side Rear Connector

P/N: 1007016 - Tan

1029358 - Gray

Single Hinge Assembly

ShorePort to Floating Dock

(In calm water).

P/N: 1007015 (Pair)

Heavy Duty Pipe

Bracket with

connector

P/N: 1022952 - Tan

1029310 - Gray

Small Pipe Bracket

(works best on side of

ShorePort)

P/N: 1022953 - Tan

1029312 - Gray

ShorePort Rear Pipe Bracket

(works only on side of

ShorePort)

P/N: 1022951 - Tan

1029314 - Gray

Heavy Duty Pipe

Bracket with Chain

Guide

P/N: 1023737 - Tan

1029304 - Gray

Stand-off Bracket

Secures Pipe to Dock

P/N: 1006715 (Pair)

2.375

0.150

2" Schedule 40 Pipe (2-3/8" O.D.)

3' Pipe P/N:1007729

5'-3" Pipe P/N:1007732

7' Pipe P/N:1007736

10'-6" Pipe P/N:1007737

21' Pipe P/N:1002676

Side Mount Flexi-Hinge

Assembly ShorePort to

Floating Dock

P/N: 1013365

®

®

Shoreport

SHOREMASTER.COM

DETAIL F

SCALE 1 / 25

DETAIL G

SCALE 1/20

F

G

ShorePort Anchoring and Attachment Options

ShorePort to Poly Dock

Front Connector

P/N: 1007011 - Tan

1029365 - Gray

ShorePort to ShorePort

Side Front Connector

P/N: 1006631 - Tan

1029360 - Gray

ShorePort to ShorePort

Notched Side Front Connector

P/N: 1003472 - Tan

1029359 - Gray

ShorePort to ShorePort

Side Rear Connector

P/N: 1007016 - Tan

1029358 - Gray

Single Hinge Assembly

ShorePort to Floating Dock

(In calm water).

P/N: 1007015 (Pair)

Heavy Duty Pipe

Bracket with

connector

P/N: 1022952 - Tan

1029310 - Gray

Small Pipe Bracket

(works best on side of

ShorePort)

P/N: 1022953 - Tan

1029312 - Gray

ShorePort Rear Pipe Bracket

(works only on side of

ShorePort)

P/N: 1022951 - Tan

1029314 - Gray

Heavy Duty Pipe

Bracket with Chain

Guide

P/N: 1023737 - Tan

1029304 - Gray

Stand-off Bracket

Secures Pipe to Dock

P/N: 1006715 (Pair)

2.375

0.150

2" Schedule 40 Pipe (2-3/8" O.D.)

3' Pipe P/N:1007729

5'-3" Pipe P/N:1007732

7' Pipe P/N:1007736

10'-6" Pipe P/N:1007737

21' Pipe P/N:1002676

Side Mount Flexi-Hinge

Assembly ShorePort to

Floating Dock

P/N: 1013365

® ®

Shoreport

SHOREMASTER.COM

Parts List

DESCRIPTIONQTY

ITEM

4' x 10' Floating Poly Dock21

ShorePort Front Connector

22

4' Poly Dock End Connector

13

Shoreport 1' Side Rear Connector

14

Shoreport

2

5

2' Notched Connector

16

Shoreport Rear Pipe Bracket with Hardware

2

7

The diagram below shows a typical ShorePort to poly dock installation. Before attaching ShorePorts to

dock make sure dock is anchored properly. Consult with your local dealer for anchoring requirements. If

needed you can attach ShorePorts rear pipe brackets to the back side of the ShorePorts. Remove the

bottom wear plate so the pile guide does not bind up on the pipe.

Note: Refer to Poly Dock installation instructions for connector instructions.

3

6

1

2

5

7

4

ShorePort to Poly Dock

Failure to follow instructions may

result in personal injury and may

invalidate the applicable warranty.

Step 1. Attach ShorePorts together

using 2' Notched Connector and

ShorePort 1' Side Rear Connector.

Step 2. Attach ShorePort to Poly Dock

using ShorePort front connectors.

Step 3. Slide 2" schedule 40 pipe into

pipe brackets and drive into ground

using post pounder.

DETAIL U

SCALE 1/35

U

ShorePort

Floating

Dock

Failure to follow instructions may result in personal injury and may invalidate the applicable warranty.

Note: Refer to exploded parts drawing on following page for details on flexi hinge assembly.

Step 1. Attach flexi hinge assembly extension plate to floating dock. Plates will have to be spaced about 116-1/4" between

plates so they will line up to corresponding plates on the ShorePort. Attach brackets to ShorePort and measure between to

verify spacing.

Step 2. Assemble flexi hinge assembly. Slide connecting rod through hole in bottom of flexi hinge assembly weldment and

attach using oval screw (you will have to drill a pilot hole for screw). Next insert 5/16 x 4-1/2" hex bolt through lock washer,

rectangular washer and insert through hole in accessory top connector and thread into connector rod just enough to hold it

together. Attach rubber plate to flexi hinge assembly weldment using one flexi hinge assembly angle, three 3/8 x 2 hex bolts

and 3/8 nylock nuts. Attach two other flexi hinge assembly angles to other end of rubber plate using three 3/8 x 2 hex bolts and

3/8 nylock nuts (make sure to bolt through the holes not the slots).

Step 3. Attach previously assembled portion of flexi hinge assembly to front of ShorePort so the connecting rod will end up

centered in the second vertical groove on the front of the ShorePort and attach the rear side flexi-hinge to the rear side of the

ShorePort so its connector rod is centered in second groove from the back of the ShorePort. Leave connecting rod bolt loose.

Step 4. With no weight on the ShorePort float ShorePort next to floating dock and attach flexi hinge assembly extension plate

to flexi hinge assembly angles using four 3/8 x 1-1/4 hex bolts, flat washers and nylock nuts. Make sure ShorePort is floating

level in the water and rubber plate is level before attaching. After attached tighten all hardware. Torque 5/16" x 4-1/2" connector

rod bolts to 20 ft/lbs. DO NOT OVERTIGHTEN AND DO NOT USE A HIGH SPEED DRILL.

Kit includes front and back

brackets to attach side of

ShorePort to floating dock.

ShorePort Side Mount Flexi-Hinge

Instructions

Part #: 1013365

Note: If you are in an area with heavy boat traffic or

waves greater than 1'-6" use stand-off brackets

and pipe brackets instead of the flexi hinge

assembly. Side mount flexi-hinge assembly should

be used to attach only one ShorePort parallel to

dock. If multiple ShorePorts are to be attached side

by side pipe brackets should be used instead of

side mount flexi-hinge.

Side Mount Flexi-Hinge

®

®

Shoreport

SHOREMASTER.COM

Parts List

DESCRIPTIONQTY

ITEM

4' x 10' Floating Poly Dock21

ShorePort Front Connector

22

4' Poly Dock End Connector

13

Shoreport 1' Side Rear Connector

14

Shoreport

2

5

2' Notched Connector

16

Shoreport Rear Pipe Bracket with Hardware

2

7

The diagram below shows a typical ShorePort to poly dock installation. Before attaching ShorePorts to

dock make sure dock is anchored properly. Consult with your local dealer for anchoring requirements. If

needed you can attach ShorePorts rear pipe brackets to the back side of the ShorePorts. Remove the

bottom wear plate so the pile guide does not bind up on the pipe.

Note: Refer to Poly Dock installation instructions for connector instructions.

3

6

1

2

5

7

4

ShorePort to Poly Dock

Failure to follow instructions may

result in personal injury and may

invalidate the applicable warranty.

Step 1. Attach ShorePorts together

using 2' Notched Connector and

ShorePort 1' Side Rear Connector.

Step 2. Attach ShorePort to Poly Dock

using ShorePort front connectors.

Step 3. Slide 2" schedule 40 pipe into

pipe brackets and drive into ground

using post pounder.

DETAIL U

SCALE 1/35

U

ShorePort

Floating

Dock

Failure to follow instructions may result in personal injury and may invalidate the applicable warranty.

Note: Refer to exploded parts drawing on following page for details on flexi hinge assembly.

Step 1. Attach flexi hinge assembly extension plate to floating dock. Plates will have to be spaced about 116-1/4" between

plates so they will line up to corresponding plates on the ShorePort. Attach brackets to ShorePort and measure between to

verify spacing.

Step 2. Assemble flexi hinge assembly. Slide connecting rod through hole in bottom of flexi hinge assembly weldment and

attach using oval screw (you will have to drill a pilot hole for screw). Next insert 5/16 x 4-1/2" hex bolt through lock washer,

rectangular washer and insert through hole in accessory top connector and thread into connector rod just enough to hold it

together. Attach rubber plate to flexi hinge assembly weldment using one flexi hinge assembly angle, three 3/8 x 2 hex bolts

and 3/8 nylock nuts. Attach two other flexi hinge assembly angles to other end of rubber plate using three 3/8 x 2 hex bolts and

3/8 nylock nuts (make sure to bolt through the holes not the slots).

Step 3. Attach previously assembled portion of flexi hinge assembly to front of ShorePort so the connecting rod will end up

centered in the second vertical groove on the front of the ShorePort and attach the rear side flexi-hinge to the rear side of the

ShorePort so its connector rod is centered in second groove from the back of the ShorePort. Leave connecting rod bolt loose.

Step 4. With no weight on the ShorePort float ShorePort next to floating dock and attach flexi hinge assembly extension plate

to flexi hinge assembly angles using four 3/8 x 1-1/4 hex bolts, flat washers and nylock nuts. Make sure ShorePort is floating

level in the water and rubber plate is level before attaching. After attached tighten all hardware. Torque 5/16" x 4-1/2" connector

rod bolts to 20 ft/lbs. DO NOT OVERTIGHTEN AND DO NOT USE A HIGH SPEED DRILL.

Kit includes front and back

brackets to attach side of

ShorePort to floating dock.

ShorePort Side Mount Flexi-Hinge

Instructions

Part #: 1013365

Note: If you are in an area with heavy boat traffic or

waves greater than 1'-6" use stand-off brackets

and pipe brackets instead of the flexi hinge

assembly. Side mount flexi-hinge assembly should

be used to attach only one ShorePort parallel to

dock. If multiple ShorePorts are to be attached side

by side pipe brackets should be used instead of

side mount flexi-hinge.

Side Mount Flexi-Hinge

® ®

Shoreport

SHOREMASTER.COM

Parts List

DESCRIPTIONQTY

ITEM

4' x 10' Floating Poly Dock11

ShorePort

12

Large Pipe Bracket wtih Connector

13

Poly Pipe Bracket / ShorePort Side Connector

1

4

Shoreport Rear Pipe Bracket with Hardware

1

5

2" Schedule 40 Pipe

26

ShorePort Parallel to Poly Dock

Failure to follow instructions may

result in personal injury and may

invalidate the applicable warranty.

Step 1. Attach ShorePort to Poly Dock

using poly pipe bracket / ShorePort side

connector.

Step 2. Attach poly pipe bracket to

ShorePort.

Step 3. Slide 2" schedule 40 pipe into

pipe brackets and drive into ground using

post pounder.

Note: DO NOT attach ShorePort to Poly

Dock using only poly pipe bracket /

ShorePort side connector you must also

use a pipe bracket on the outside of the

ShorePort (as shown).

1

4

6

3

2

5

6

Note: See Connector Instructions for directions on how to

assemble ShorePort connectors.

DETAIL A

H

Parts List

DESCRIPTIONQTY

ITEM

ShorePort

11

Universal Stand-off Plate Assembly (Pair)

12

2" Schedule 40 Pipe

23

Shoreport Rear Pipe Bracket with Hardware

1

4

Medium Pipe Bracket with Hardware1

5

Standing Dock or Sea Wall

16

Parts List

DESCRIPTIONQTY

ITEM

ShorePort

11

2" schedule 40 PIPE22

Standing Dock or Sea Wall

13

Universal Stand-off Plate Assembly (Pair)

14

Large Pipe Bracket wtih Connector

2

5

A

1

4

2

3

6

ShorePort to Standing Dock or Sea Wall

Failure to follow instructions may result in personal

injury and may invalidate the applicable warranty.

Step 1. Attach pipe brackets to ShorePort (as shown)

depending on how you want your ShorePort fastened to your

dock or sea wall.

Step 2. Assemble and attach stand-off brackets to dock or

sea wall. If ShorePort is perpendicular to dock (as shown in

top picture) assemble stand-off brackets using last four holes

in plates so brackets will hold pipes further away from dock.

Measure from center of pipe bracket to the center of the other

pipe bracket and space stand-off brackets apart center to

center to that distance. If ShorePort is parallel to dock (as

shown in middle picture) assemble stand-off brackets so they

are as short as possible to keep ShorePort closer to the dock.

Measure from center of pipe bracket to the center of the other

pipe bracket and space stand-off brackets apart center to

center to that distance.

Step 3. Float ShorePort up next to dock and slide pipe down

through pipe brackets. Align pipe up with stand-off brackets

and pound pipe into lake bottom using a sledge hammer or

post pounder.

Step 4. Attach pipe to stand-off brackets using provided

U-bolts.

Note: If your dock is too close to the water bolt the stand-off

brackets to a treated 2" x 8" and bolt the 2" x 8" to the dock

(as shown in Detail A).

1

5

3

4

5

2

Treated 2" x 8"

®

®

Shoreport

SHOREMASTER.COM

Parts List

DESCRIPTIONQTY

ITEM

4' x 10' Floating Poly Dock11

ShorePort

12

Large Pipe Bracket wtih Connector

13

Poly Pipe Bracket / ShorePort Side Connector

1

4

Shoreport Rear Pipe Bracket with Hardware

1

5

2" Schedule 40 Pipe

26

ShorePort Parallel to Poly Dock

Failure to follow instructions may

result in personal injury and may

invalidate the applicable warranty.

Step 1. Attach ShorePort to Poly Dock

using poly pipe bracket / ShorePort side

connector.

Step 2. Attach poly pipe bracket to

ShorePort.

Step 3. Slide 2" schedule 40 pipe into

pipe brackets and drive into ground using

post pounder.

Note: DO NOT attach ShorePort to Poly

Dock using only poly pipe bracket /

ShorePort side connector you must also

use a pipe bracket on the outside of the

ShorePort (as shown).

1

4

6

3

2

5

6

Note: See Connector Instructions for directions on how to

assemble ShorePort connectors.

DETAIL A

H

Parts List

DESCRIPTIONQTY

ITEM

ShorePort

11

Universal Stand-off Plate Assembly (Pair)

12

2" Schedule 40 Pipe

23

Shoreport Rear Pipe Bracket with Hardware

1

4

Medium Pipe Bracket with Hardware1

5

Standing Dock or Sea Wall

16

Parts List

DESCRIPTIONQTY

ITEM

ShorePort

11

2" schedule 40 PIPE22

Standing Dock or Sea Wall

13

Universal Stand-off Plate Assembly (Pair)

14

Large Pipe Bracket wtih Connector

2

5

A

1

4

2

3

6

ShorePort to Standing Dock or Sea Wall

Failure to follow instructions may result in personal

injury and may invalidate the applicable warranty.

Step 1. Attach pipe brackets to ShorePort (as shown)

depending on how you want your ShorePort fastened to your

dock or sea wall.

Step 2. Assemble and attach stand-off brackets to dock or

sea wall. If ShorePort is perpendicular to dock (as shown in

top picture) assemble stand-off brackets using last four holes

in plates so brackets will hold pipes further away from dock.

Measure from center of pipe bracket to the center of the other

pipe bracket and space stand-off brackets apart center to

center to that distance. If ShorePort is parallel to dock (as

shown in middle picture) assemble stand-off brackets so they

are as short as possible to keep ShorePort closer to the dock.

Measure from center of pipe bracket to the center of the other

pipe bracket and space stand-off brackets apart center to

center to that distance.

Step 3. Float ShorePort up next to dock and slide pipe down

through pipe brackets. Align pipe up with stand-off brackets

and pound pipe into lake bottom using a sledge hammer or

post pounder.

Step 4. Attach pipe to stand-off brackets using provided

U-bolts.

Note: If your dock is too close to the water bolt the stand-off

brackets to a treated 2" x 8" and bolt the 2" x 8" to the dock

(as shown in Detail A).

1

5

3

4

5

2

Treated 2" x 8"

This manual suits for next models

1

Other Shoremaster Lifting System manuals

Popular Lifting System manuals by other brands

Ergoswiss

Ergoswiss SLA 13 Series Operating instruction

Aqua Creek

Aqua Creek F-03EZPL Installation, assembly and operating instructions

PRO LIFTS

PRO LIFTS VMB TL-A300 Operating instructions & user manual

Bend-Pak

Bend-Pak HDS-37 Installation and operation manual

Stage right

Stage right AlphaRoll Series Product information packet

U.S. General

U.S. General 91960 Assembly and operating instructions