Stratus SAE-F12X Guide

Table of contents

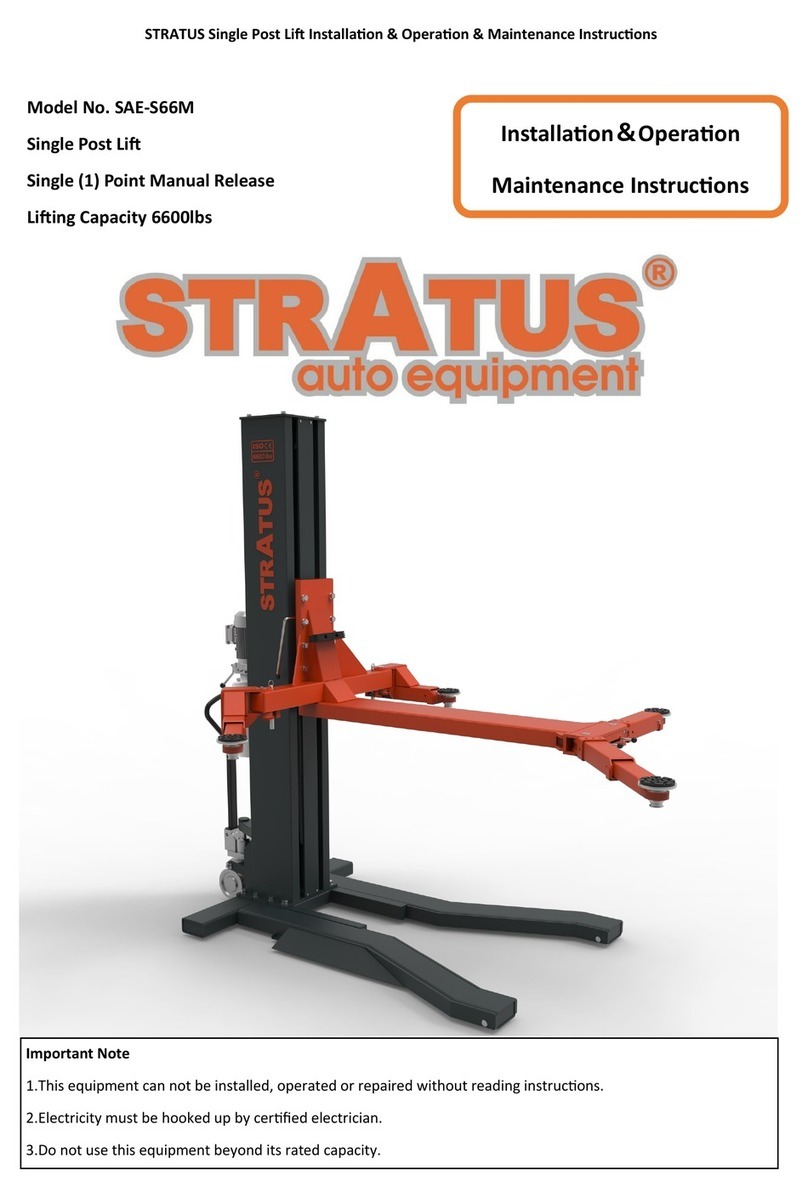

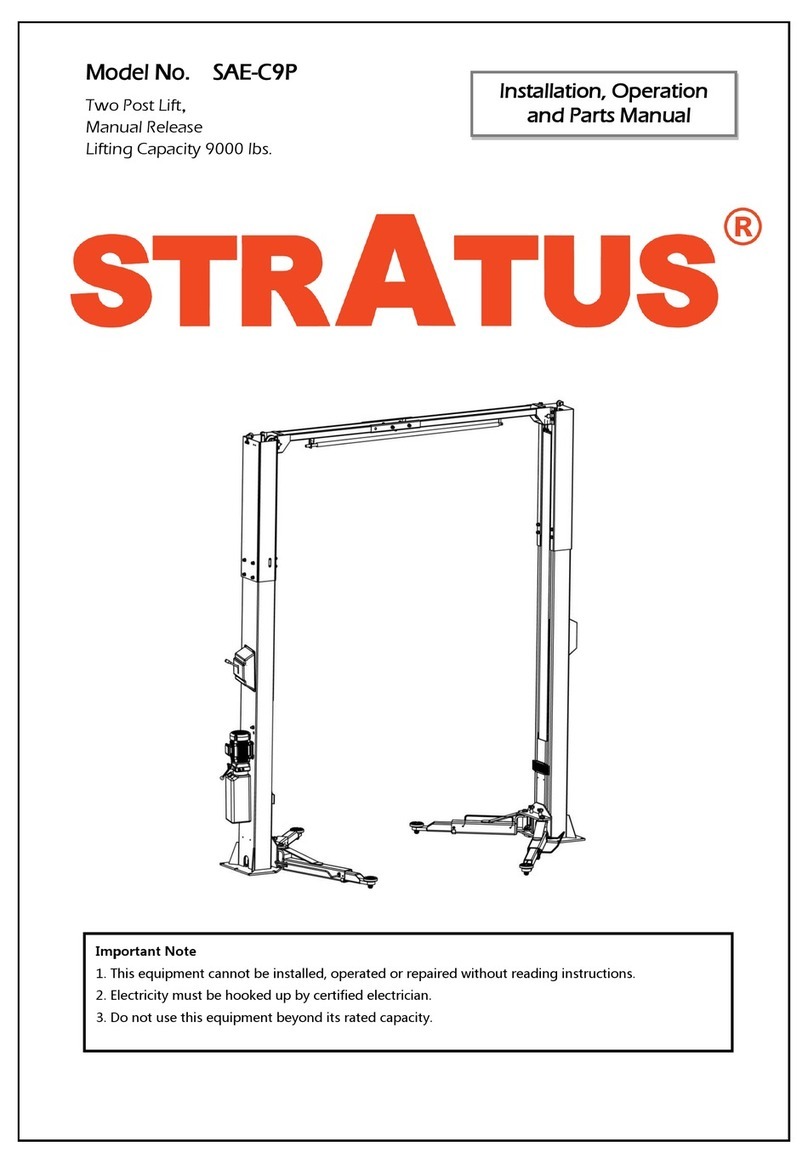

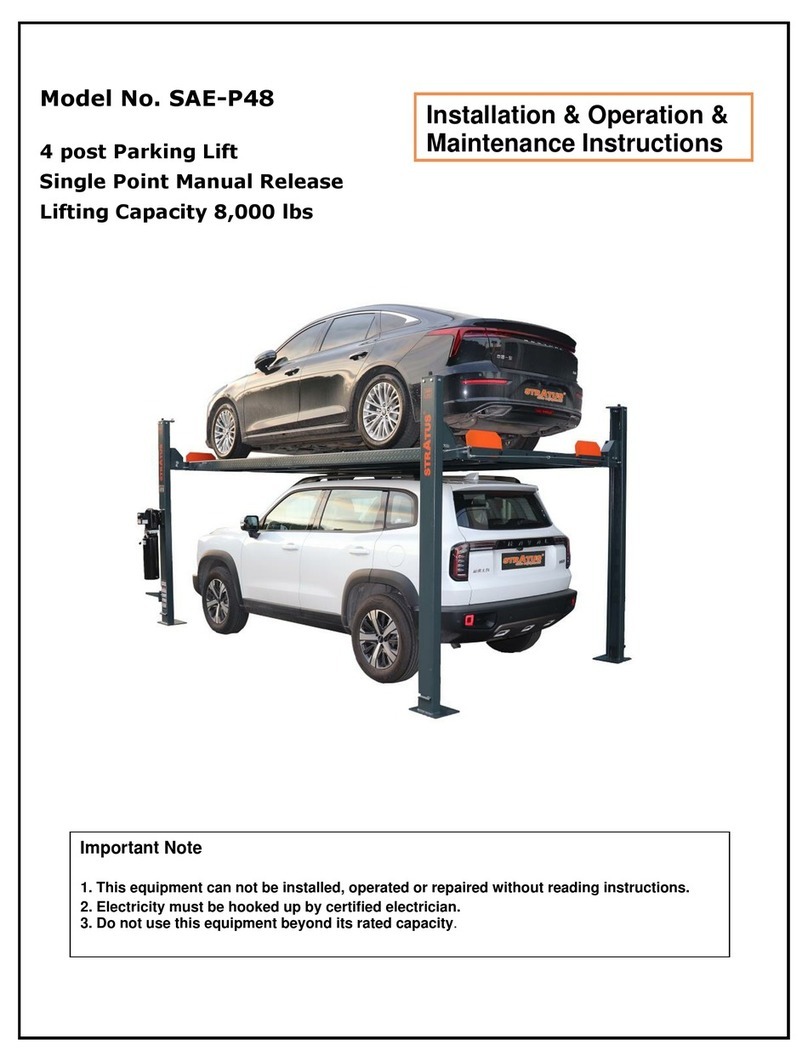

Other Stratus Lifting System manuals

Stratus

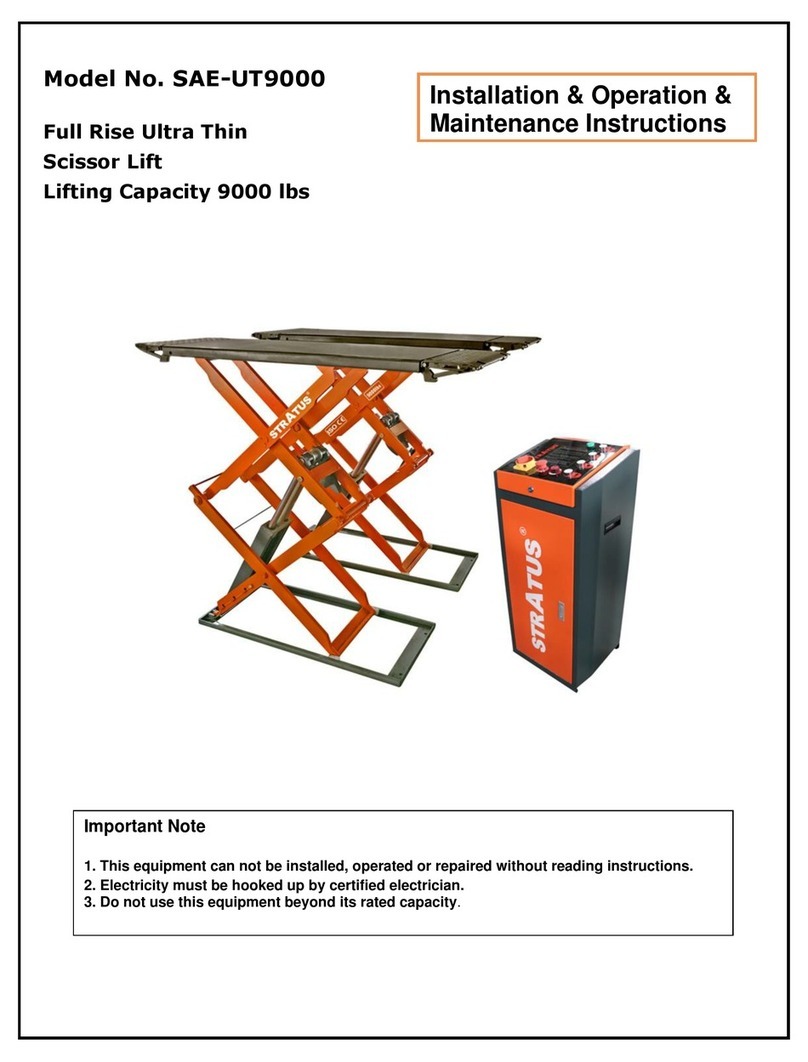

Stratus SAE-UT9000 Guide

Stratus

Stratus SAE-C10P Guide

Stratus

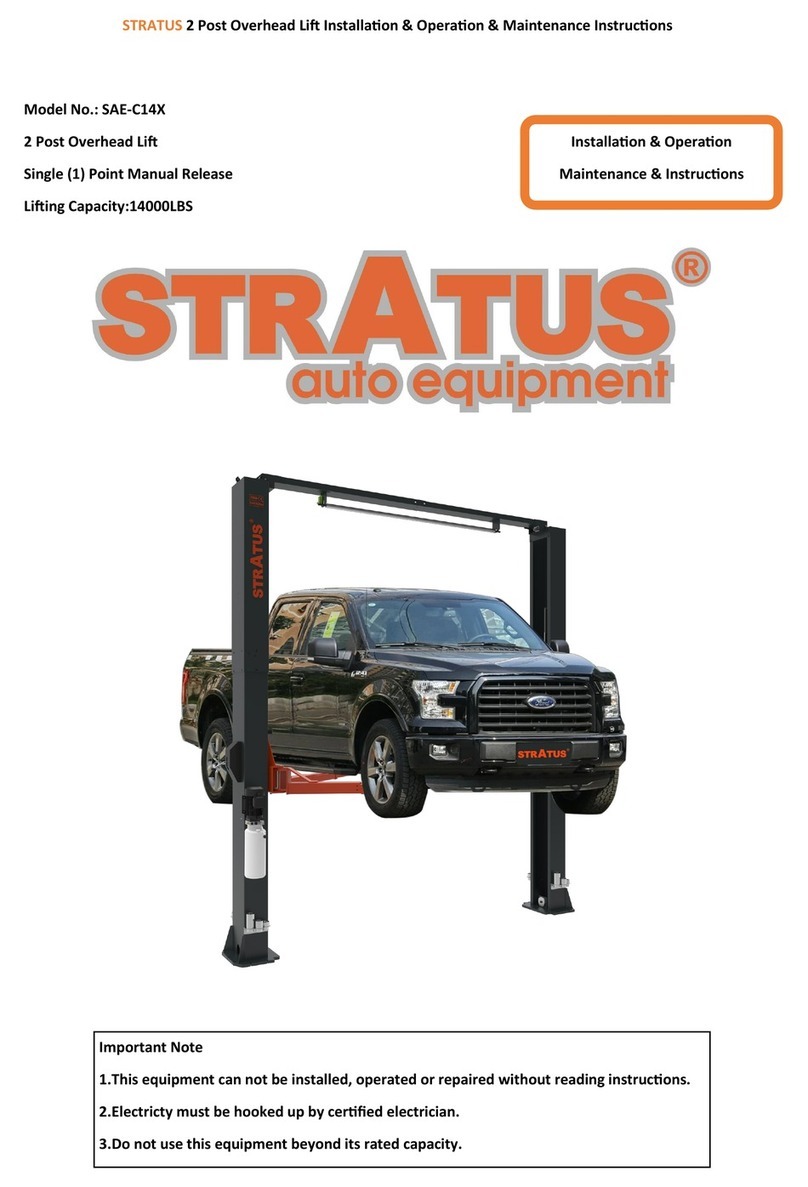

Stratus SAE-C14X Guide

Stratus

Stratus SAE-P166M Guide

Stratus

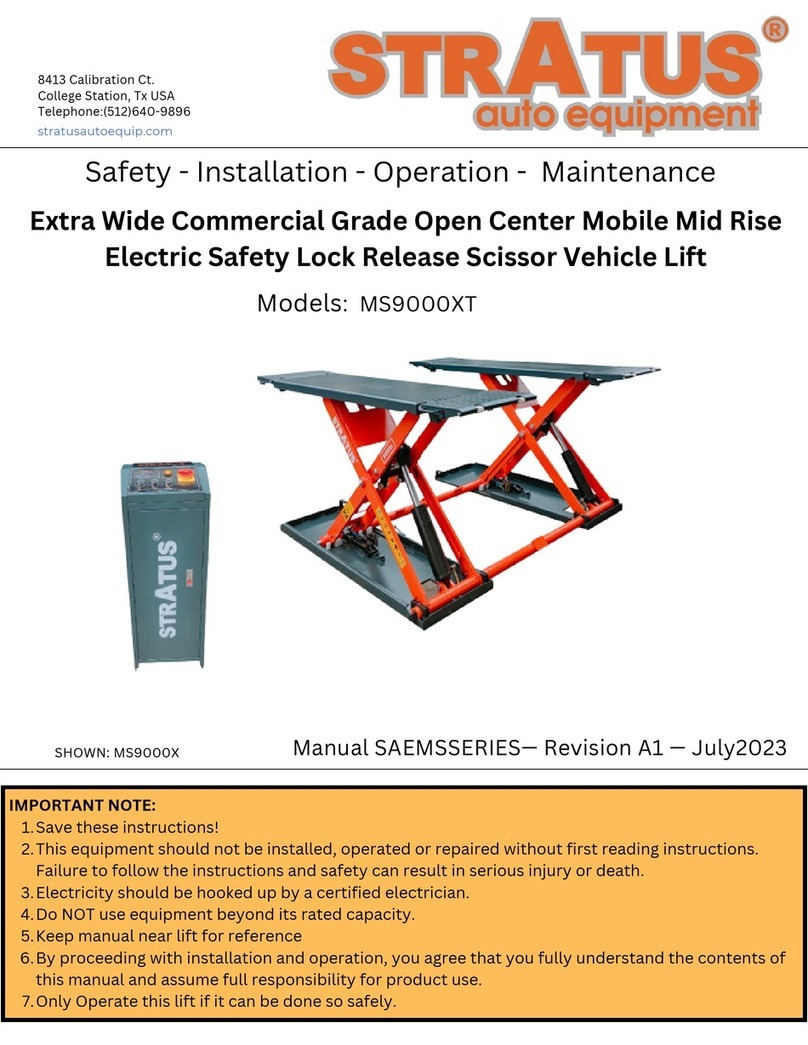

Stratus MS9000XT User manual

Stratus

Stratus SAE-UT8000 Guide

Stratus

Stratus SAE-C12X Guide

Stratus

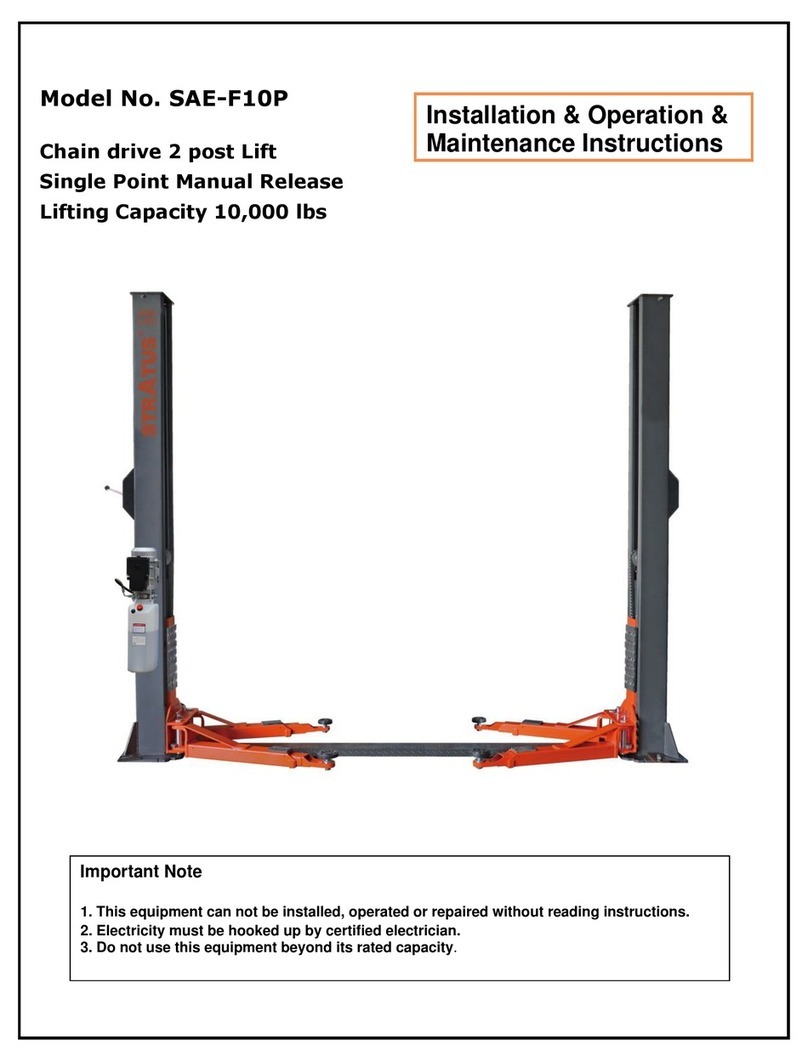

Stratus SAE-F10P Guide

Stratus

Stratus SAE-F14X Guide

Stratus

Stratus SAE-C10XE Guide

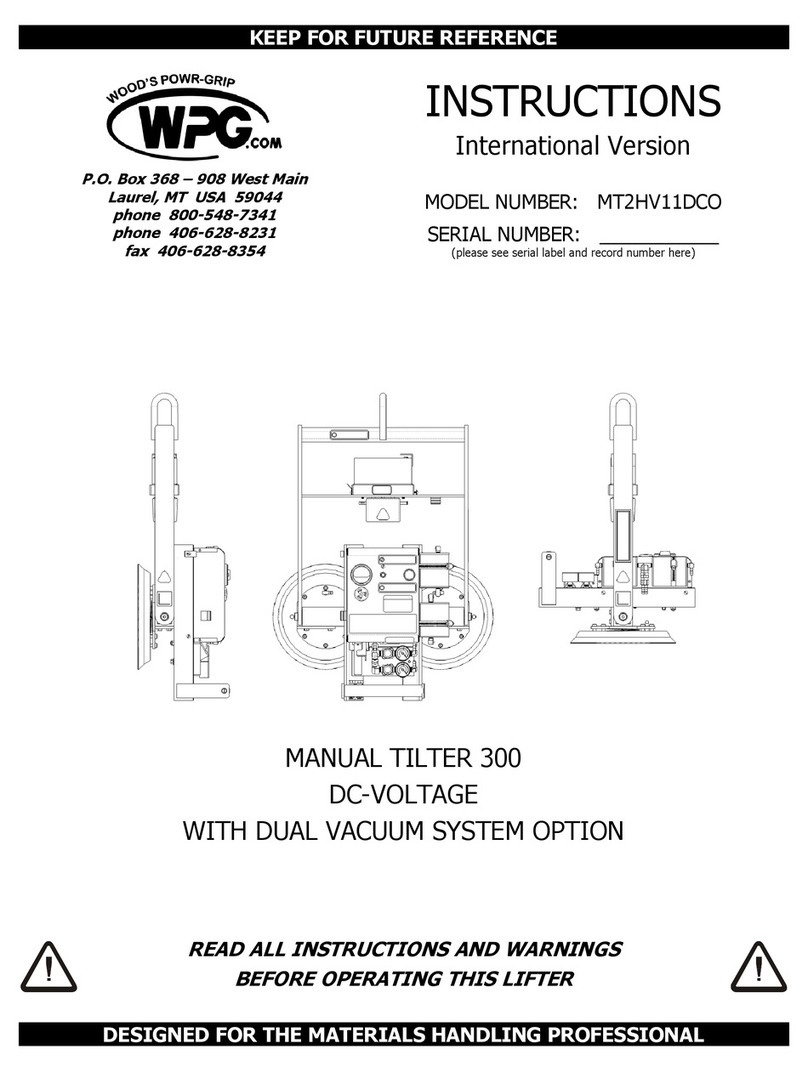

Popular Lifting System manuals by other brands

swaploader

swaploader SL-520X Parts and operation manual

Jet

Jet DSLT-770 Operating instructions and parts manual

Parkside

Parkside 338547 2001 operating instructions

Pinguely-Haulotte

Pinguely-Haulotte HA20PX Repair manual

Autoquip

Autoquip FLH Installation, operation and service manual

morse

morse PILOT 900 Operator's manual

ATH-Heinl

ATH-Heinl ATH Comfort Lift 2.35 user manual

Cotterman

Cotterman MAXI-LIFT Operation, Maintenance and Training Manual

Stockmaster

Stockmaster Lift-Truk Assembly instructions

Southworth

Southworth PPA owner's manual

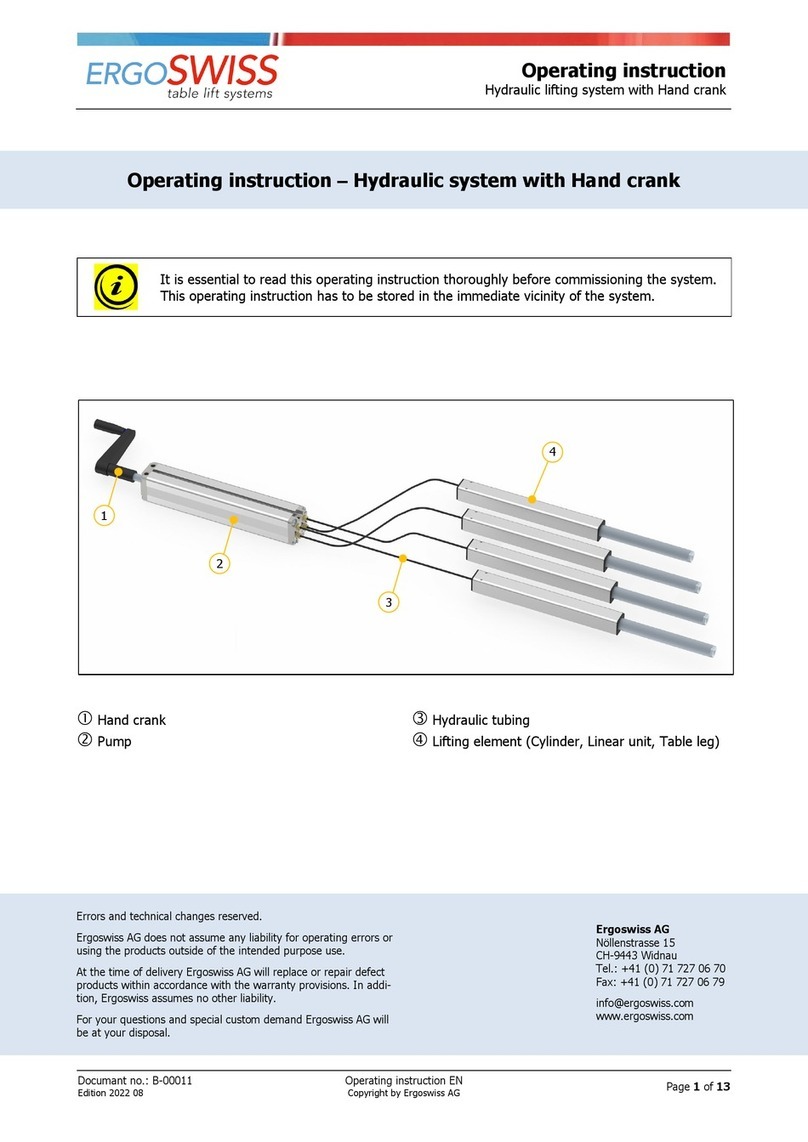

Ergoswiss

Ergoswiss PA 2830 Operating instruction

Jet

Jet JHS-2200A Operating instructions and parts manual