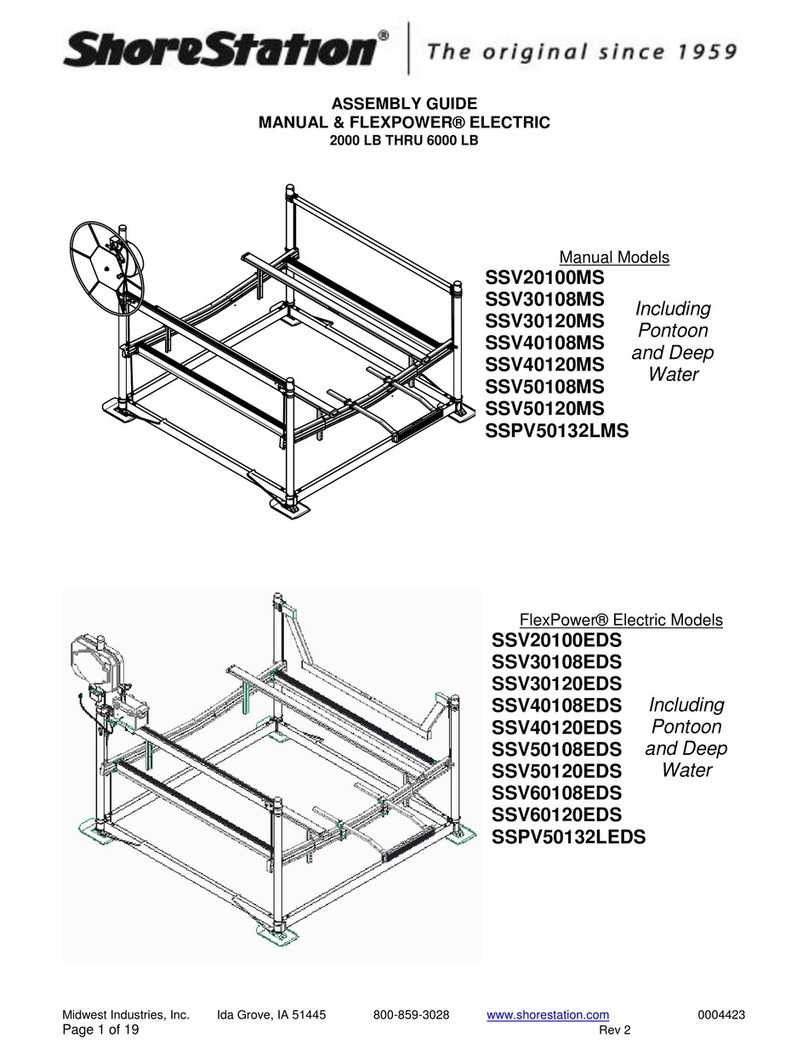

ShoreStation SSV40108HS User manual

This manual suits for next models

14

Other ShoreStation Lifting System manuals

ShoreStation

ShoreStation SSV30108EAC User manual

ShoreStation

ShoreStation WATERFRONT SYSTEMS User manual

ShoreStation

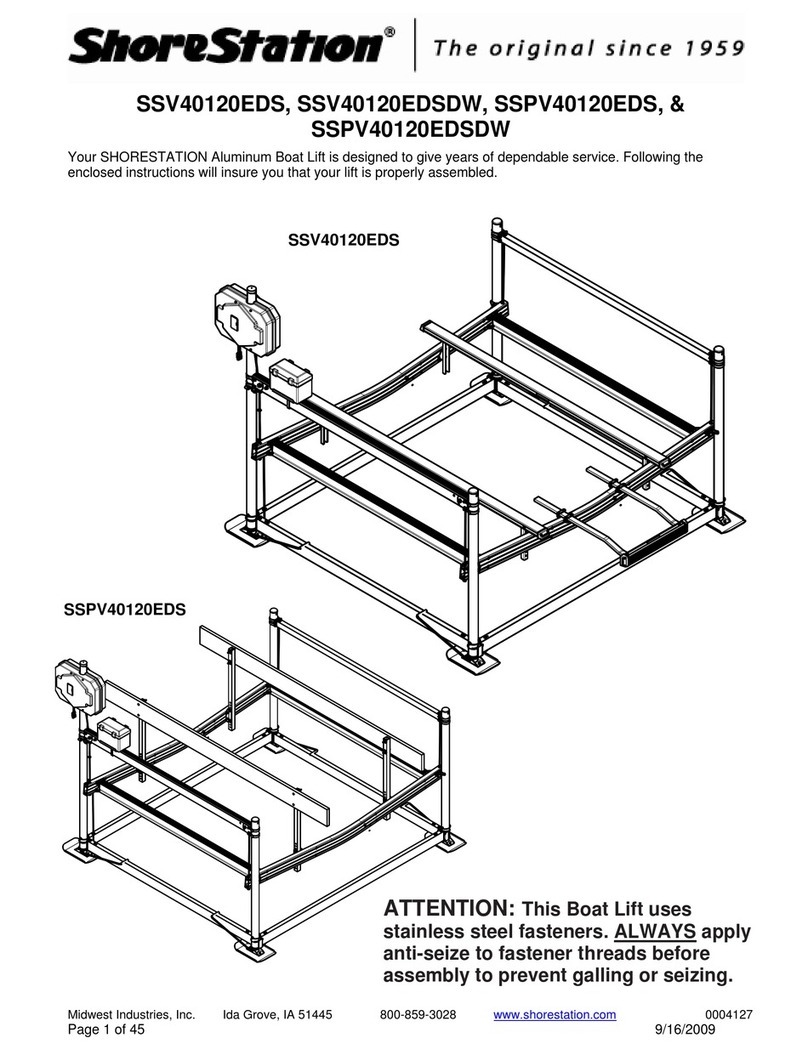

ShoreStation FlexPower SSV40120EDS User manual

ShoreStation

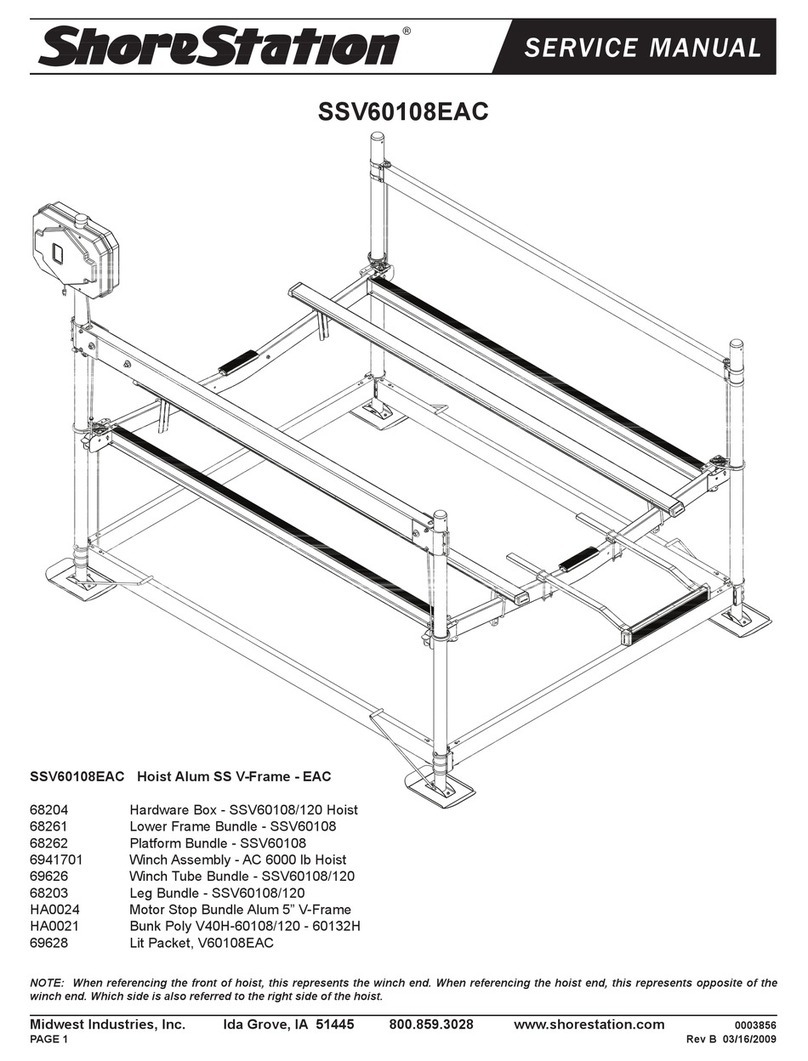

ShoreStation SSV60108EAC User manual

ShoreStation

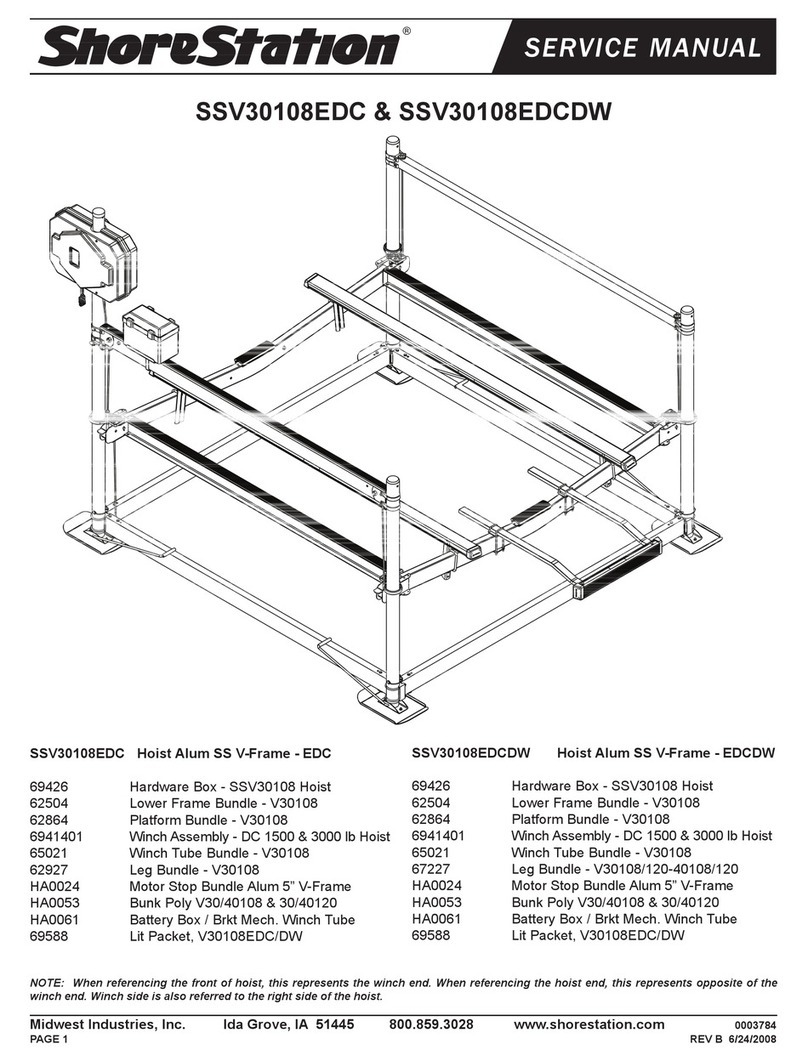

ShoreStation SSV30108EDC User manual

ShoreStation

ShoreStation SSV40108HAC User manual

ShoreStation

ShoreStation Manual SSV40120MS User manual

ShoreStation

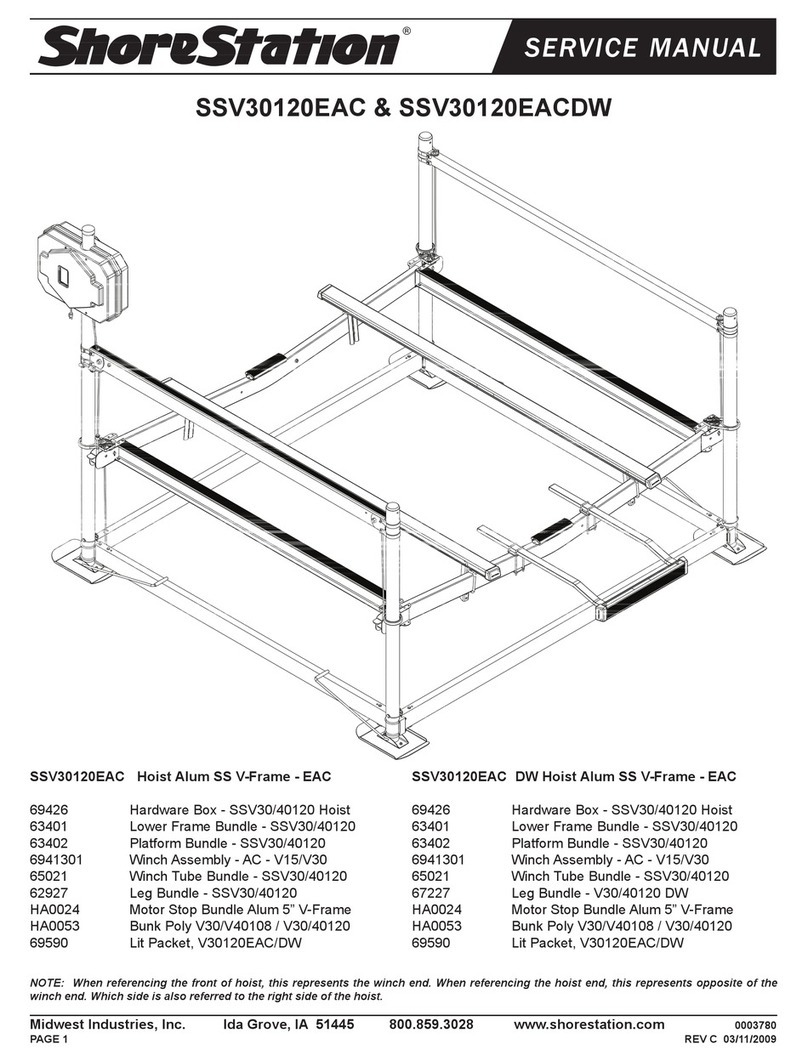

ShoreStation SSV30120EAC User manual

ShoreStation

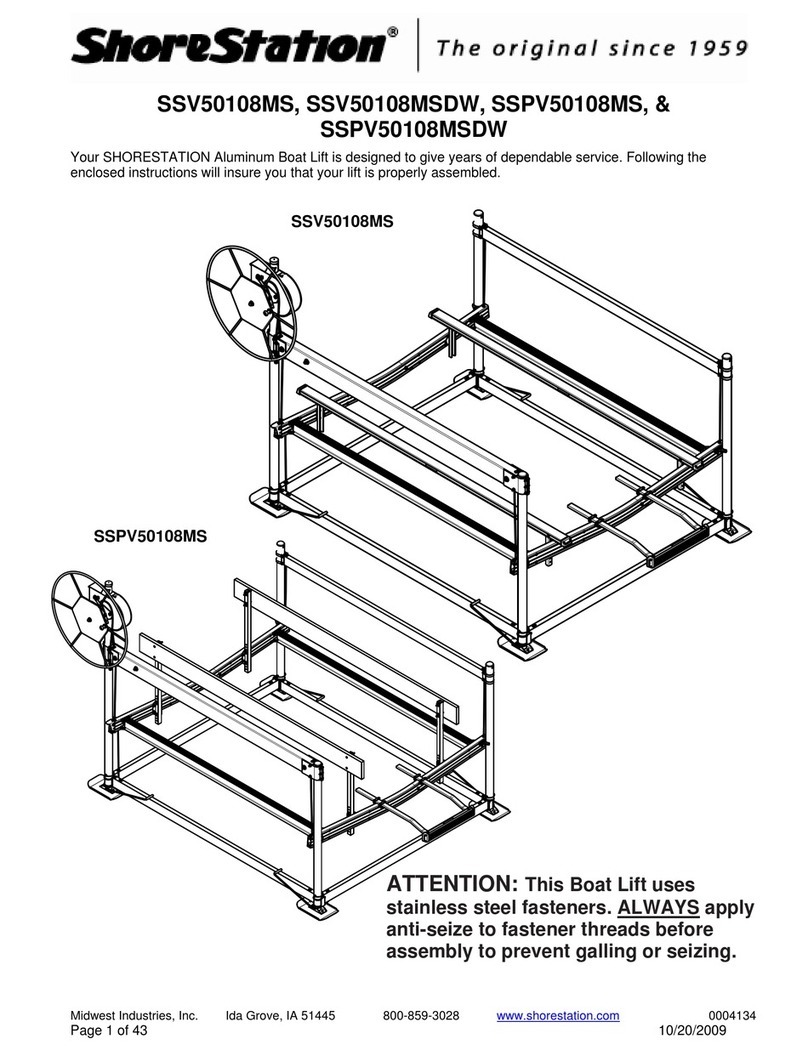

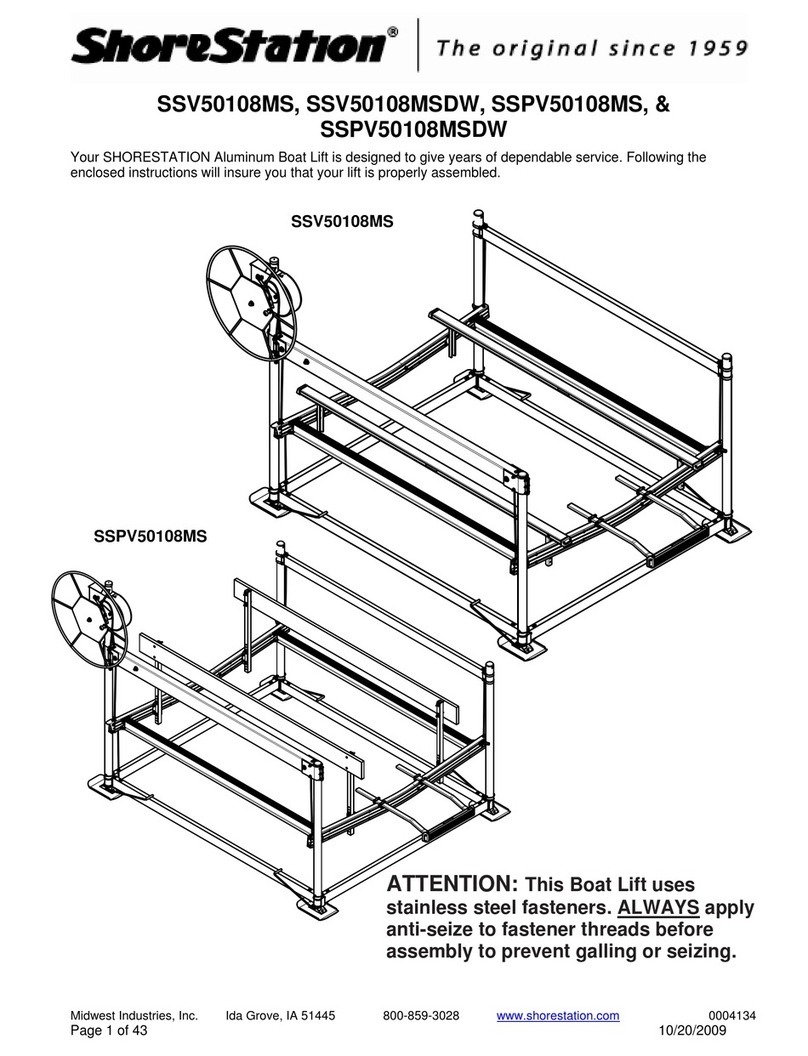

ShoreStation Manual SSV50108MS User manual

ShoreStation

ShoreStation SSV40120EAC User manual

ShoreStation

ShoreStation SSV40120EAS User manual

ShoreStation

ShoreStation Manual SSV50108MS User manual

ShoreStation

ShoreStation SSV15100EDC User manual

ShoreStation

ShoreStation SS1053 User manual

ShoreStation

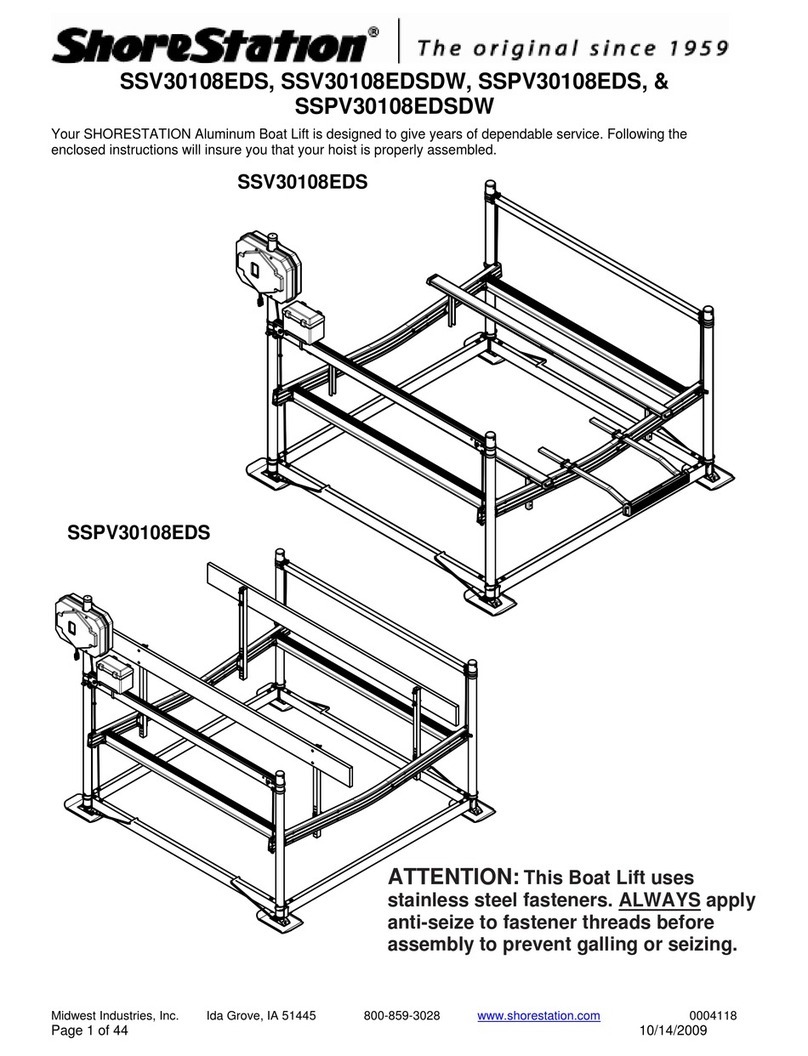

ShoreStation FlexPower SSV30108EDS User manual

ShoreStation

ShoreStation Manual SSV20100MS User manual

ShoreStation

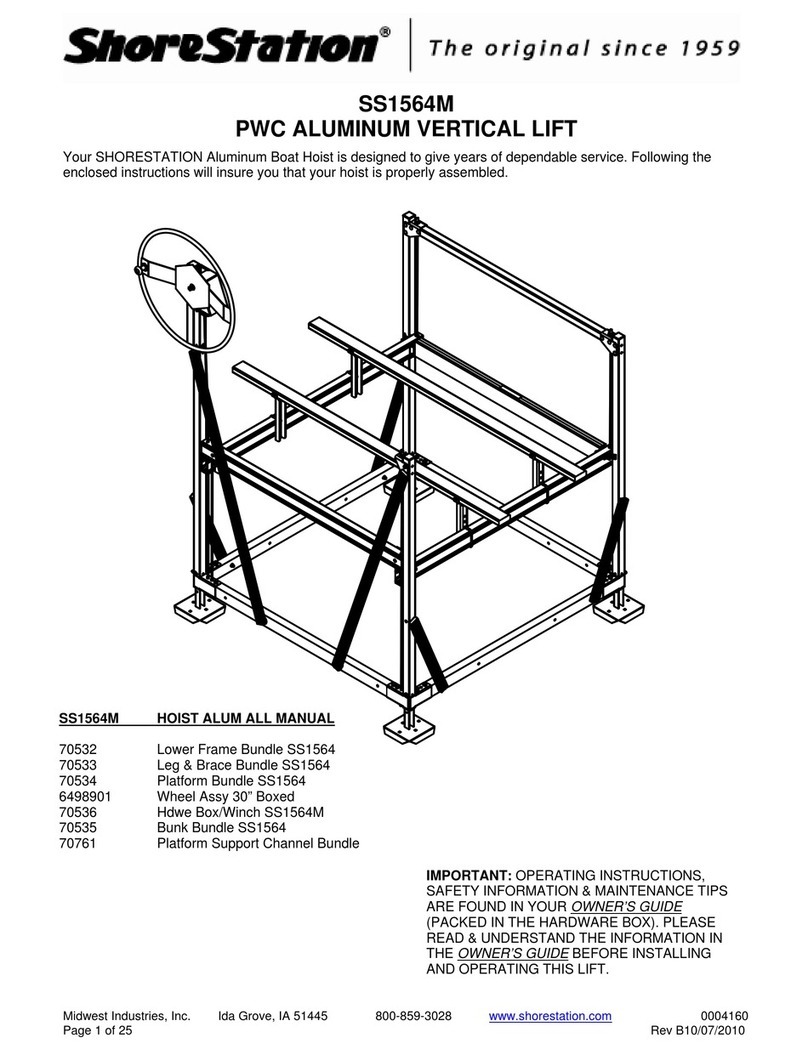

ShoreStation SS1564M User manual

ShoreStation

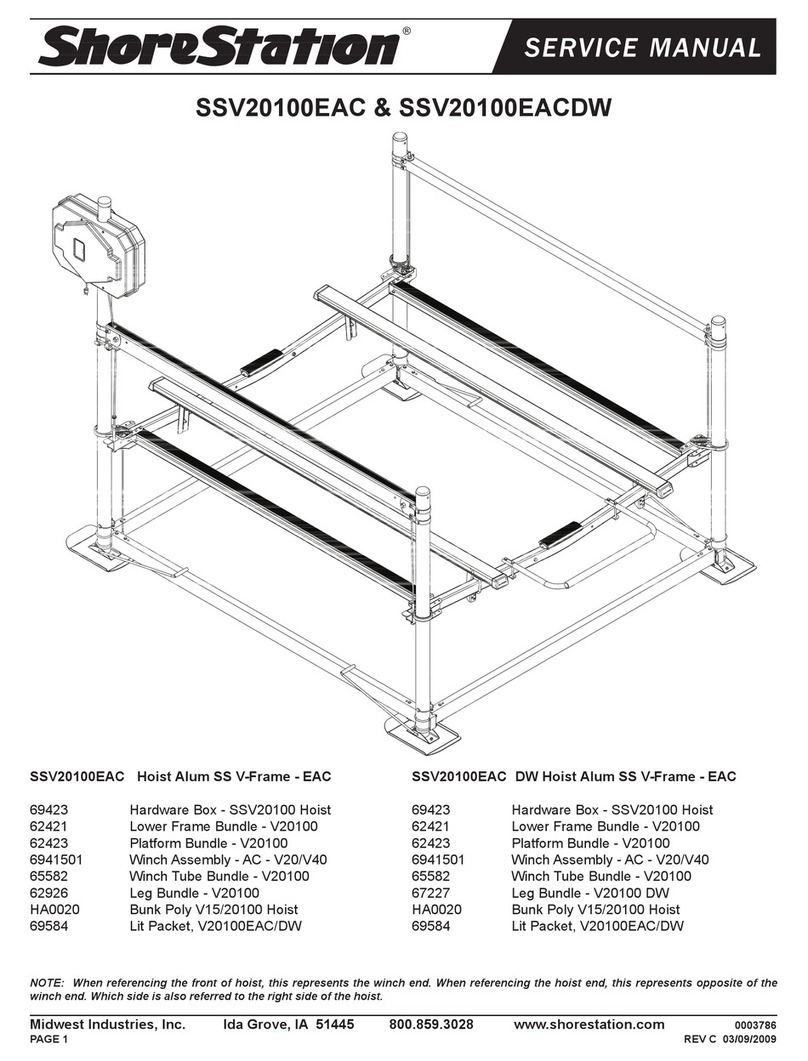

ShoreStation SSV20100EAC User manual

ShoreStation

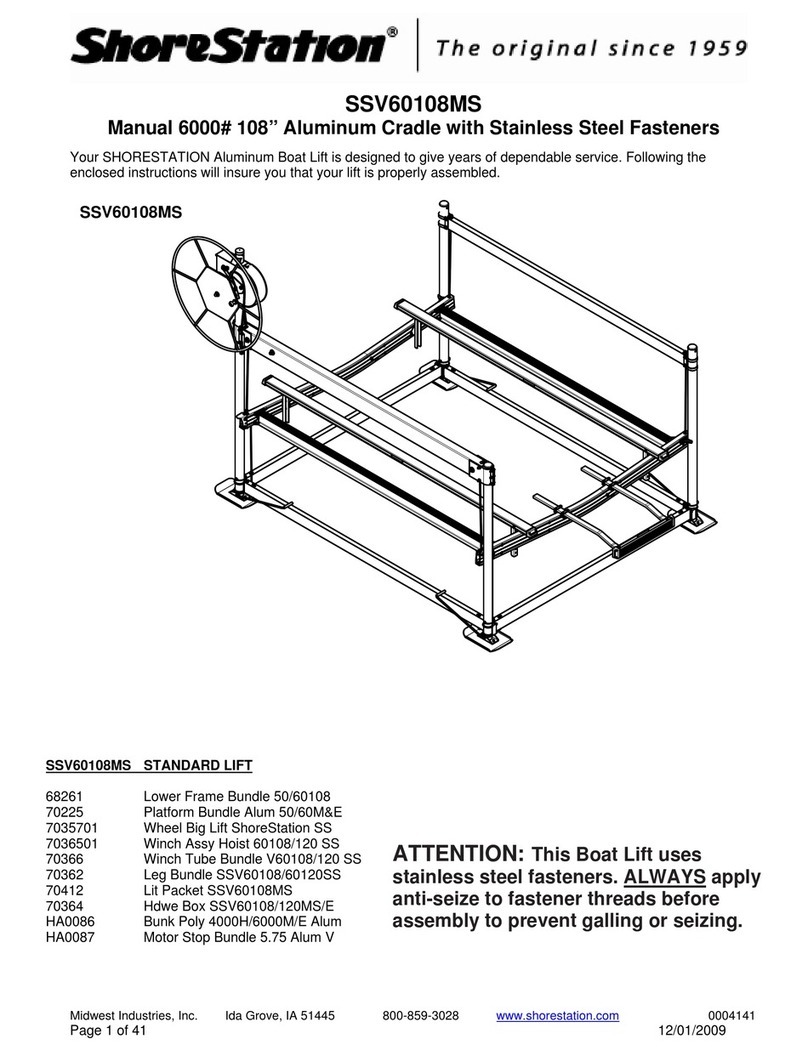

ShoreStation SSV60108MS User manual

ShoreStation

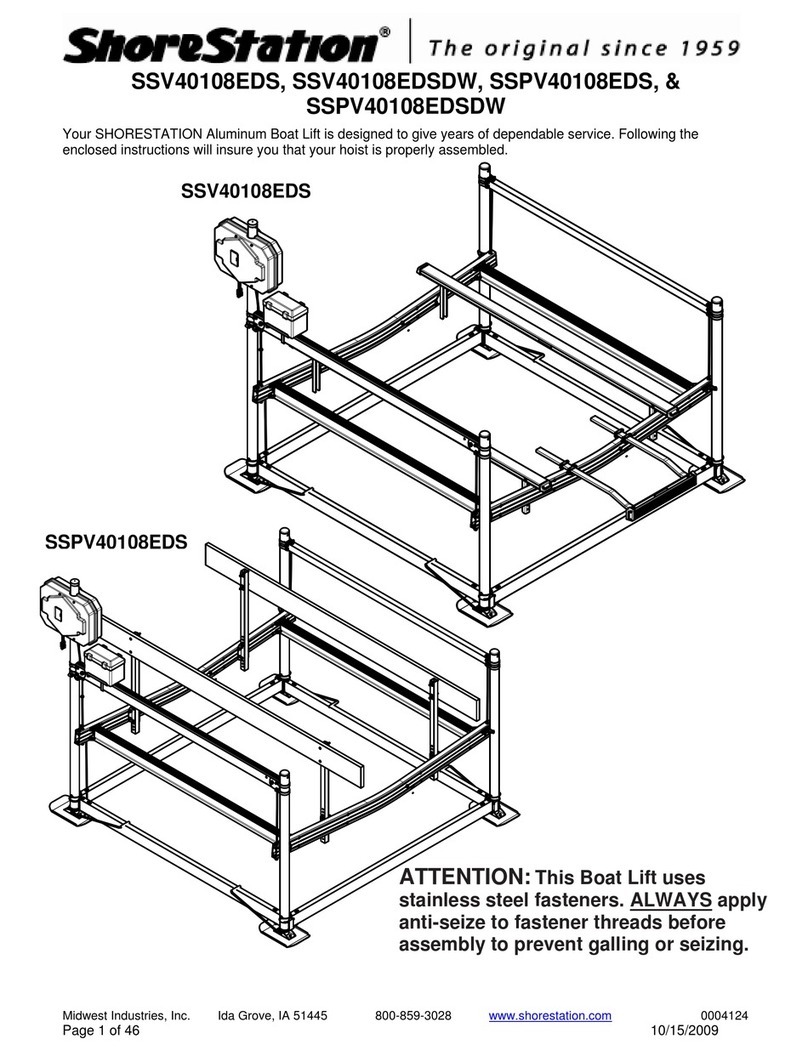

ShoreStation FlexPower SSV40108EDS User manual

Popular Lifting System manuals by other brands

Presto Lifts

Presto Lifts M100 Installation, operation and service manual

Genie

Genie SX-180 Service and repair manual

Skyjack

Skyjack SJKB-40-D Operating maintenance instructions & part list

JLG

JLG EcoLift70 Operation and safety manual

Nexus 21

Nexus 21 L-85 installation manual

CMC

CMC S19 Use and maintenance manual

ATH-Heinl

ATH-Heinl ATH-CROSS LIFT 50 user manual

Cruz

Cruz 940-22 Series Assembly instructions

MARTINS Industries

MARTINS Industries MPTC manual

WERTHER INTERNATIONAL

WERTHER INTERNATIONAL 232IH Instruction and maintenance manual

BINAR

BINAR Quick-Lift Arm 50i-300i user guide

Maber

Maber MBC2000/150 instructions

AAQ

AAQ AutoLift FP-VRC Installation manual & operation instructions

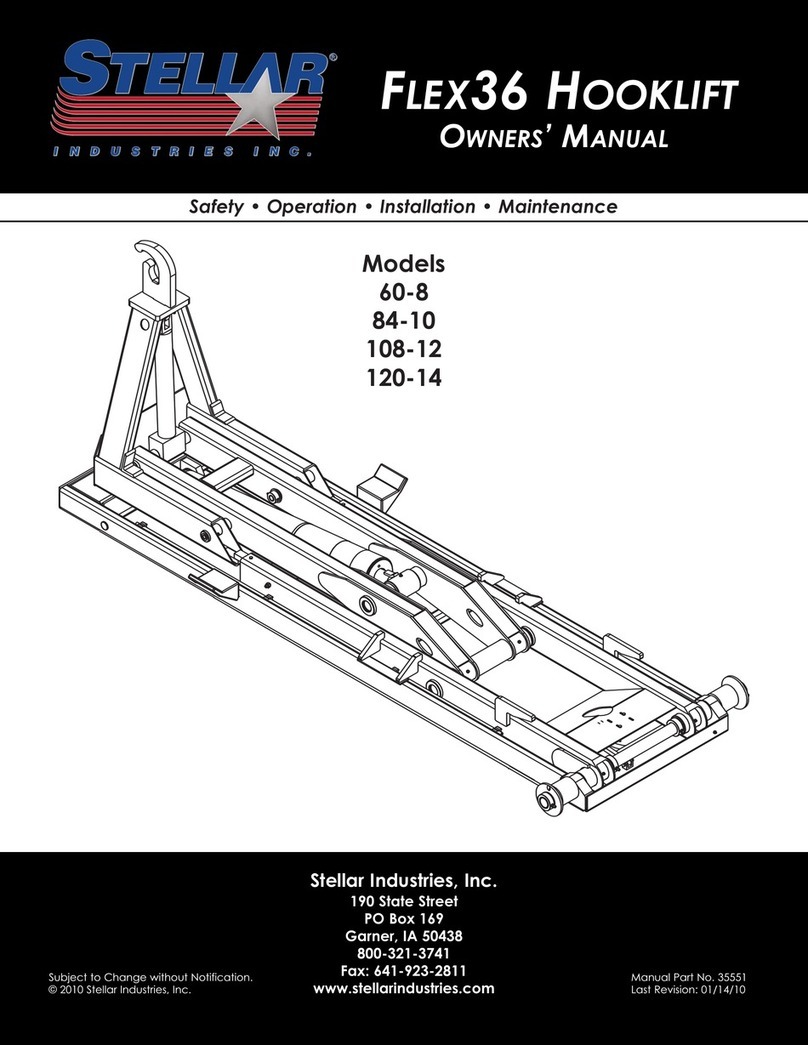

stellar labs

stellar labs Flex36 60-8 owner's manual

Mopedia

Mopedia MI190 instruction manual

Bike-Lift

Bike-Lift HQL 400 Use and maintenance manual

RUTHMANN

RUTHMANN ECOLINE RS200 Use and maintenance manual

Braun

Braun NL Millennium Series Service manual