SHOTO FTC Series User manual

FTC Series Front Terminal

VRLA Battery User Manual

Shuangdeng Group Co.,Ltd

Power the future

Statement

The copyright of this document only belongs to SHOTO. Any excerpt,

copyortranslation is prohibited without the written permissionof the writer.

Any pirate must be punished.

is our registered trademark. The name and trademark of the

product of China Shoto is our unique mark. Other products or companies’

names mentioned in this manual are perhaps belongs to their respective

owners. Without any prior written consent of SHOTO or the third party

trademark or the commodity name owners, this manual gives nobody any

right to use the mark appeared in this manual. This product complies with

the design requirement in environmental protection and human safety. The

storage, usage and discard of this product should be refer to the manual,

contract orrelative laws.

For the update and perfection of the product, please understand that

the information in this manual may differpartially fromthe real product.

Forthe latest information, pleasedial the market hotline.

Power the future

Foreword

ManualDescription

FTC Series Front Terminal VRLA Battery is the product of Shuangdeng Group. ” FTC Series

Front Terminal VRLA Battery User’s Manual” is the manual accompanied with the battery. Please

read the manual carefullyin advance.

Introduction

“FTC Series Front Terminal VRLA Battery User’s Manual” introduces the technical parameter,

principle, installation dimension and method, and maintenance.

Section 1 Safety introduction: containing some watchful safety proceedings during batteries’

installation, operation and maintaince.

Section 2 Summarization: containing FTC series battery model, product sampling, product

conveying and using ambient requirement, parts denomination, product specification and main

parameters.

Section 3 Usage and maintenance: containing maintenance watchful proceedings, charge

method, relationship of temperature and capacity, relationship of temperature and cycle life, capacity

checking, switch power parameters setting, using requirement under power off condition,

maintenance periods and requirements.

It is promised that:

We apply four eye-catching marks to showthe special noticed points in operating. notice,

caution, warning, danger: show the special operation precautions.

Power the future

Appendix

Chapter 1 Safety Instruction............................................................................................................1

1.1Safety Signs........................................................................................................................1

1.2 Precautions ........................................................................................................................1

Chapter 2 Summary.........................................................................................................................3

2.1 ModelIntroduction............................................................................................................3

2.2 Sampling............................................................................................................................3

2.3 Conveying .........................................................................................................................3

2.4 Storage...............................................................................................................................4

2.5 Dimension and Weight......................................................................................................4

2.6 Operation Environment and Precaution............................................................................5

2.7 Installation Instruction.......................................................................................................6

2.8 Check After Installation....................................................................................................7

Chapter 3 Operation and Maintenance............................................................................................8

3.1 Operations .........................................................................................................................8

3.1.1 Precaution................................................................................................................8

3.1.2 Battery Charging .....................................................................................................8

3.1.3 Temperature Effects the Battery Capacity...............................................................9

3.1.4 Temperature Impact on the Battery Life ...............................................................10

3.1.5 Capacity Determination.........................................................................................10

3.1.6 The Parameter Set of the Switch Power Supply ................................................... 11

3.1.7 The Application Requirements for Power SupplyInterruption Time ...................12

3.2 Maintenance Period and Requirements...........................................................................13

Operation Instruction of Battery Recharging

Power the future

1

Chapter 1 Safety Instruction

Abstract

This chapter introduces about the safety signs and the precautions. Please carefully read it

before operation to ensure safety.

1.1 SafetySigns

The safety signs indicate the safety issues that should be conformed to in installation, operation

and maintenance. The safety signs are shown as following Table1.1-1

Table1.1-1 Safety Signs and Meanings

Safety Signs

Meaning

Safety Notice

Electric Shock

1.2 Precautions

Before any operation of the equipment, please carefully read all the safety instructions in this

manual to avoid personal injury or equipment damage.

Shuangdeng Group bears no liability to the consequences incurred by violation of the general

safety operation requirement, or violation of the safety standards for designing, manufacturing and

using the equipment.

1. The battery pack has high voltage, so direct contact or indirect contact through wet objects

with any conducting cable may result in vital injury. The battery pack is energy-storing

equipment, so never short-circuit the battery pack during operation and maintenance in any

way.

2. Do not wear watch, hand chain, bracelet, ring and other conductive objects during operation.

3. Only qualified and professional personnel are allowed to install, operate and maintain the

equipment.

Power the future

2

4. Do use special tools.

Do use special tools, instead of common toolsduring electrical connections. In addition, keep

the tools in good insulation condition (e.g. wrap insulating tape around the bare metal parts)

before using them to avoid short circuit and personal injury caused by tool contact with any

live objects.

5. Using the batteries of the same model

Use batteries of the same model in the same set. Using different models in the same set will

damage the equipment.

6. Fire hazard

7. During battery installation, make sure to fix the connecting terminals of the conducting wire

tight, and keep the output terminals of the batteries clean. Otherwise, it may lead to a high

temperature of battery terminals and even to spark/fire.

8. Operation regulation

Before battery operation, read the safety precaution/instruction, and the operation

instructions, especially the battery interconnection instructions.

Substandard operation will cause danger. Prevent battery short circuit and prevent battery

electrolyte from flowing out. Overflowed electrolyte is a latent danger and it will erode the

metal object and circuit board, thus damaging the equipment and causing short circuit of the

circuit board.

9. The Operation Environment

The batteryshould be kept far away from fire, organic solution; avoid direct sunshine and the

temperature should be the same of the same set.

Power the future

3

Chapter 2 Summary

Abstract

This chapter mainly introduce FTC series battery’s model, product sampling, product conveying

and using ambient requirement, parts denomination, product specification and main parameters。

2.1 ModelIntroduction

FTC series valve-regulated lead-acid battery (following called FTC battery for short) belong to

SHUANGDENG GROUP’s second battery products, producing license size: QS:XK06-006-01178.

FTC battery is 6 cells structure,rated voltage per unit is 12V. Take FTC-100 for example, its mean as

fig.2.1-1 showing.

In the fig.2.1-1,”6” means six cells, “FTC” means Front Terminal valve-regulated lead-acid battery,

the figure presents battery’s rated capacity.

FTC–100

Fig.2.1-1 FTC-100 batterytype and description

2.2 Sampling

Choosing batteries should consider use frequency, discharge current, discharge time and so on.

The capacity should be a bit larger to prevent battery from damage caused by over-discharge or

larger current discharge.

2.3 Conveying

Terminal protection is well done, the coping of the battery can not suffer the pressure, and short

circuit is prohibited when batteries are conveyed. Batteries should lie down at the time of transporting

Front terminal

valve-regulated lead-acid

battery

Rated capacity C10

Unit: Ah

Power the future

4

and can not set upside down, roll, throw, bump, insolate or drench during conveying.

2.4 Storage

1. Batteries can be stored in the environment of 0-35°C before installation. The storage time is

usually 3-6months. Batteries should be charged if the storage time exceeds 6 months.

2. Batteries should be kept in the dry, clean and ventilated environment. They can not be kept in the

environment of radiation, organic solvent and corrosive gas. They should be kept away from fire

and avoid sun irradiation.

3. Batteries should lie down and batteries without package box can not be overlapped.

2.5 DimensionandWeight

Table2.5-1 Battery parameters

Type

Rated voltage

(V)

Rated capacity

(Ah)

Outer sizes

(L×W×H)mm

Reference

weight

(kg)

FTC-100

12

100

400×110×286

35.5

FTC-150

12

150

552×125×310

56

FTC-170

12

170

552×125×310

58

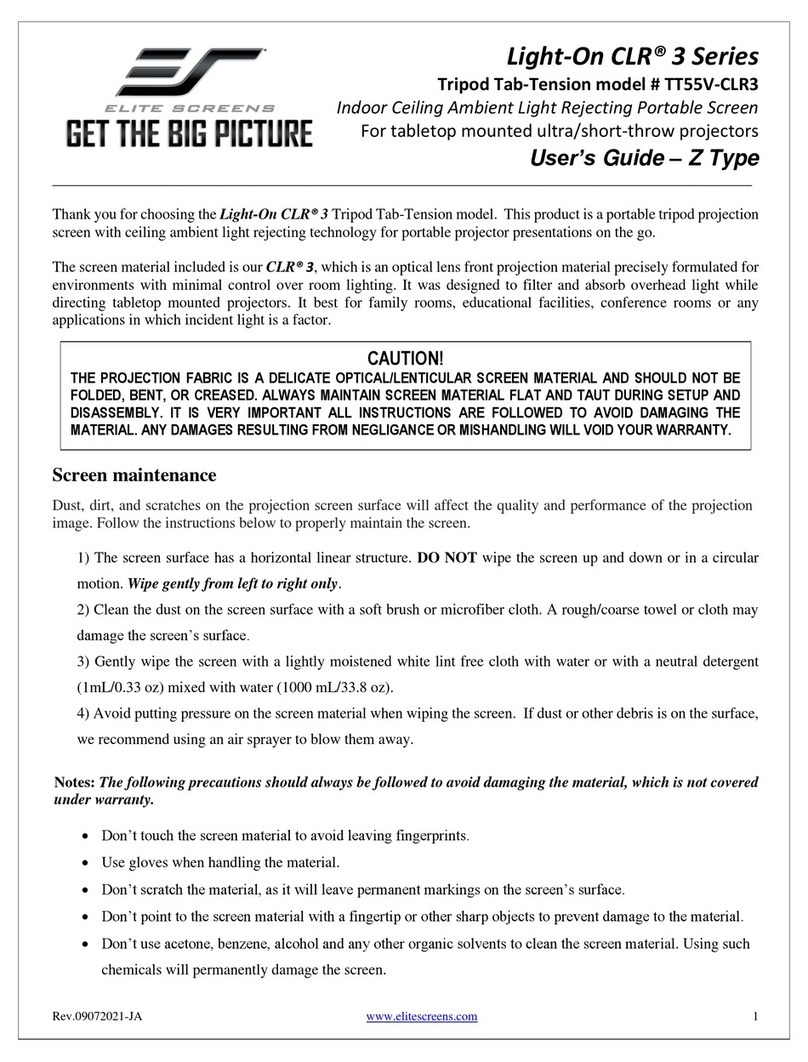

Type

Terminal structure

FTC-100

FTC-150

FTC-170

Fig.2.5-1 FTCseries battery terminal structure

Power the future

5

2.6 Operation EnvironmentandPrecaution

1. The battery servicing surroundings should be dry, clean and airy, without large quantity of

irradiation, infrared rayradiation, organic solvents and corrosive gas, and avoided the direct sun

shining. The battery is recommended to use temperature range of 15 °C ~ 35 °C .

2. The ventilation hole of the heater or air-conditioner should not directly face the battery, and the

temperature difference of the each part of the battery should not be higher than 3°C , and using

the infrared ray thermometer to determine the each part temperature of the battery is suggested.

3. The battery can be installed with the battery cabinet or shelf provided by the manufacturer. If the

battery is installed in the storied buildings, the load requirements should be inquired from the

construction department. The earthquake-preventing supporting shelf which is fixed with ground

foot bolt should be designed in order to diffuse the stress in the district whose anti-earthquake

intensity is more than 7 degree.

4. In order to avoid increasing the circuitry voltage decrease, the battery modules should be near

the load, and the cables, copper terminals and connecting wires selected should be suitable.

When the batteries are used by the way of parallel-connection, the circuitry voltage decrease

should be same to some extent to the best of one's best ability, and the fuses should also be

equipped in every battery module.

5. The total voltage of the battery modules is comparatively higher, i.e., the danger of electric shock

exists. Therefore, the insulation tools should be used and the protection gloves should be put on

when installing or removing the cable, copper terminals and connection wires etc.

6. Dirty contact or loosened connection will possibly lead to the temperature increase in the part of

the battery terminal, then spark will be produced, which will probably result in fire. Thus, the

cable, copper terminals, connection wires, and the battery terminals should be kept clean and

the connection should be fastened during the installation of the battery. Single battery should be

serially connected with stainless steel bolt, copper terminals (connection wires and cables)

electrodeposited with tin, and flat gasket. And the bolt must be fastened (Wring moment is

9~11N·m).

7. After the installation, carefully examine the total voltage, open circuitvoltage per cell, the polarity.

Power the future

6

Check to see if the supervising parameters in the switch power monitor unit consist with the

operation and maintenance manual (float charge voltage, equalization charge voltage,

equalization charging time and period, charge current limit, equalization charge current turned to

float charge, float charge current turned to equalization charge current, temperature

compensation value, the recovery voltage of the battery and so on.).

8. Check to see if the switch power has equipped with the temperature sensor, which should be

installed in the center of the big side of the battery.

9. Check the bolts and connection in order to confirm the connection between batteries isreliable.

10. The circuit switch should be disconnected, and the correctness mentioned in item has been

confirmed (it should be empathized that the positive terminals of the battery should be connected

with the positive counterpart of the charger, and negative to negative) before the battery system

is connected with the charger or load.

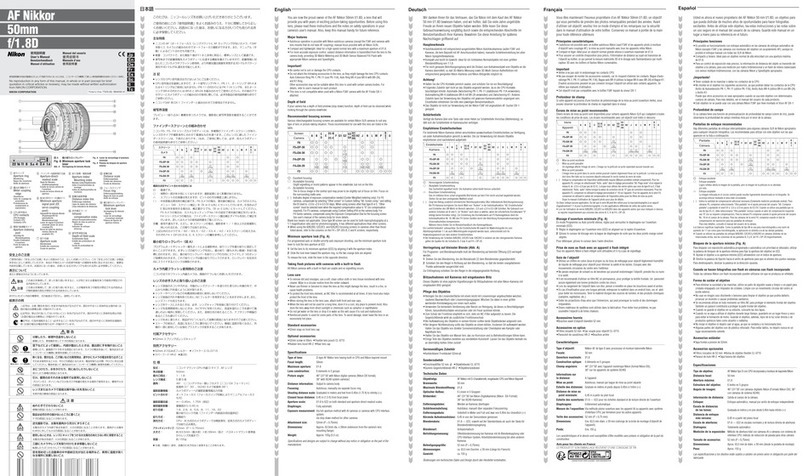

2.7 InstallationInstruction

Fig.2.7.1 FTC series installation instruction

-:Negative Electrode

+:PositiveElectrode

Power the future

7

2.8 CheckAfter Installation

After installation, check carefully and keep record, see Table 2.8-1 for the main items.

Table 2.8-1 The main items needed to be checked after installation

No.

Items

Results

1

The polarities are in right connection, the voltage of the battery

group between positive and negative output terminals are higher

than 48V

□Y □N

2

The voltage of each cell in the same battery group is between

12.80 and 13.50V.

□Y □N

3

If several battery groups are parallel connection, each output

positive terminals should be connected together and negative

terminals together.

□Y □N

4

The positive and negative output terminals of the battery group

should be connected with the counterparts of the charge device.

□Y □N

5

All of the bolts, nuts and screws are fastened tightly.

□Y □N

6

The rack has no deformation after installation, and its vertical

obliquity should be less than 5°.

□Y □N

7

No unnecessary connecting wires or tools etc. are left on the

batteries or racks.

□Y □N

8

The appearances of the batteries have no cracks or damages.

□Y □N

9

The ambient site of the batteries and rack is clean.

□Y □N

10

All of the parameters of the battery group, such as the

equalization charge and float charge currents, have been set

correctly.

□Y □N

11

The resistances between output terminals and the rack are

normal.

□Y □N

12

Other items need to be checked.

□Y □N

13

□Y □N

14

□Y □N

15

□Y □N

16

□Y □N

17

□Y □N

18

□Y □N

Power the future

8

Chapter 3 Operation and Maintenance

Abstract

Operation and maintenance,containing battery maintenance and precaution, charge method,

relationship of temperature and capacity, relationship of temperature and cycle life, capacity

checking, switch power parameters setting, usage requirement under power-off condition,

maintenance periods and requirement.

This chapter introducesbout the operation and maintenance of FTC battery.

3.1 Operations

3.1.1 Precaution

1. Never short circuit the battery.

2. Charge before operation after long period storage.

3. Keep the battery clean.

4. Equalized charge the battery for long storage.

5. After emergencydischarge, no continuous power supply without in time equalized charge.

6. Never parallel the battery of different capacity.

7. No burning feel when touch the battery terminalor the connecting part.

3.1.2 Battery Charging

3.1.2.1 Float Charging

The float charging voltage of the battery is set as 13.38V/unit (the mean value calculated from all

of the battery voltages at 35°C), the maximum charging current is set as 0.20C10A.The float and

balancing charging voltages should be correspondingly modified if the battery working environment

temperature exceeds the range of 35°C , and the modification voltage is Vmodification =V35°C -

0.018/°C ×(Tactual-35°C ), i.e., if the temperature increases by 1°C , then the float charging voltage

should decrease by 18mV/unit; and if the temperature decreases by 1°C , then the float charging

voltage should increase by 18mV/unit.

Power the future

9

3.1.2.2 Balancing Charging

Balancing charging voltage is usually set as 14.10V/unit (the mean value calculated from all of

the battery voltages at 35°C), and the maximum charging current is set as 0.2C10A, according to

setting table to set Balancing charging time.

Table3.1-1 Balancing charging parameters

Balancing charging condition

Balancing

charging time.

Conditions to exit the

balancing charging

1

Before operation and after installation and

debug of the battery

1h~10h ,The

idiographic time

according to the

condition of

exiting Balancing

charge

When the pile’s equalize

charge current lower

than 10mA/Ah, it

switches to float charge

automatically(for parallel

≤10mA/Ah×pieces)

2

The charge current after power off≥50mA/Ah

(for parallel≥50mA/Ah×pieces)

3

Balancing charge starts after battery capacity

checking

4

Balancing charge should start when the float

voltage lower than 13.10V/unit during the using

process

10h

When the balancing

charge time arrive 10h, it

switches to float charge

5

For net battery, it should execute periodic

balancing charge one time six months

commonly

3.1.3 Temperature Effects the Battery Capacity

Temperature effects the battery capacity. Usually, the higher the temperature, the larger the

discharge capacity. During discharging time, if the temperature isn’t 25°C , it needs to convert the

measured capacity C t to 25°C benchmark capacity C25 according to the following formula.

1+K(t-25)

Ct

C25

In the formula: t is the discharging ambient temperature, K is temperature coefficient. In the 10hr

capacity experiment, K=0.006/°C and 3hr capacity experiment, K=0.008/°C, 1hr capacity experiment,

K=0.01/°C .

Float charge characteristic: Float charge voltage should choose the manufactory

recommendatory voltage value. And the float charge voltage value should make correspond

Power the future

10

adjustment according to the ambient temperature. When the switch power have temperature

equalization function, but have no sensor or no temperature auto-equalization function, VRLAbattery

float charge voltage with different temperature should make correspond adjustment according to the

following table.

Table3.1-2 Float charge voltage under different ambient temperature

Ambient temperature(°C )

Float charge voltage(about

V±0.01V/unit)

0~10

13.68

11~15

13.56

16~25

13.44

26~35

13.38

36~40

13.32

3.1.4 Temperature Impact on the Battery Life

The battery is recommended to use temperature range of 15°C ~ 35°C and has the longest

service life and the best performance if the environment temperature is kept at 25°C~35°C. When the

temperature is at the range of 15°C ~ 25°C, the charging efficiency and performance of the batteries

will slightly decrease. And if the temperature is lower than 15°Cor higher than 35°C, the service life of

the batteries will be shortened. The reference data are listed below:

Table3.1-3 Effect of temperature on the battery service life

Battery mean

temperature

Service life

decreasing rate (%)

(25~35)°C

0

40°C

30

45°C

50

50°C

75

3.1.5 Capacity Determination

Balancing charging should be done before capacity determination. After balancing charging

changes into float charging, float charging current will be between 1~2 mA/Ah, and if the float

charging current is stable for about 2~3hours, itshows that the battery system has been fully charged.

The capacity determination can be carried out only after confirming that float charging has been

Power the future

11

continued for about 24h, then charging has been stopped for 1h.

Table3.1-4 Capacity examination method

Discharge rate

Discharge

current, A

Discharge single battery final

voltage,V

Capacity determination

standard

10h

1.0I10

10.80

≥1.00C10

5h

1.6I10

10.80

≥0.80C10

3h

2.5I10

10.80

≥0.75C10

1h

5.5 I10

10.50

≥0.55C10

3.1.6 The Parameter Set of the Switch Power Supply

The controlparametersof the switch power supply to the batteries should be set according to the

value of the load current. The parametersnormallyset are listed in Table.

Table3.1-5

The ratio of

load current

and I10

Stop the work of programmed exchange

machine, the final discharge voltage of

the single battery,( V)(the first

discharge-stopping)

Stop the work of signal exchange

transition,the final discharge voltage of

the single battery,(V)

(the first discharge-stopping)

6/6

11.40(45.6V/48V system)

11.28(45.0V/48V system)

5/6

11.70(46.8V/48V system)

11.58(46.3V/48V system)

2/3

11.76(47.0V/48V system)

11.64(46.5V/48V system)

1/2

11.82(47.3V/48V system)

11.70(46.8V/48V system)

1/3

11.88(47.5V/48V system)

11.76(47.0V/48V system)

1/6

11.88(47.5V/48V system)

11.76(47.0V/48V system)

Note:

1. I10 means 10-hour rate discharge current in Table 6, its value is one-tenth of C10 which is the

rated capacity of the battery. If the batteries are parallel connected, then C10, the rated capacity

is the sum of the rated capacity of all of the individual battery paralleled (Batteries which have

different rated capacities can not be parallel-connected).

2. If bad battery whose finaldischarge voltage is below 10.80V when discharging itwith I10 after 5

hours occurs in the battery system, the very bad battery should be displaced with a good one

or restore its capacity as soon as possible.

3. The parameters listed in Table 6 and 7 are only suitable for the situation that the discharge

Power the future

12

current is less than 0.1C10.

Table3.1-6 Switch power parameters setting

Item

Parameter

Float charging voltage

13.38V/unit

Equalized charging voltage

14.10V/unit

Charge current limiting

0.20C10A

Upper voltage alarm threshold

57V(14.25V/ unit)

Lower voltage alarm threshold

45V(11.25V/unit)

Temperature compensation coefficient of

battery

-18mV/unit·°C

Battery over temperature

40°C

LVDS Deviation Voltage

44V

LVDS Reposition Voltage

47V

48V series pile replacement working voltage

48V(avoiding battery deep discharge resulted by

the voltage rebound time after time and continue

work after arriving the working voltage)

Equalized charge period

6 months usually for batteries in equipment room

Periodical equalized charge time

10h

Precondition of float charge switching to

equalized charge

≥50mA/Ah

Equalized charge time with power cut

1~10h

Precondition to exit equalized charge

≤10mA/Ah

Capacity setting for battery diffluence

According to battery capacity

Batteries connection

Serial first, parallel next

Voltage difference between individual

batteries

50 mV for working mode

20 mV for open circuitmode

3.1.7 The Application Requirements for Power Supply Interruption Time

1. Under the situation that the battery system has not been recharged after accident discharge,

and just at the very time, the power supply of the communication station stops, often the

battery system can not be used to supply the power further. If continue working, it could lead

the battery life shorter because of the battery deep discharge

Power the future

13

2. If the accumulative discharge capacity reaches 50%~80% of the battery rated capacity for one

power supply interruption, the float charging time can not be less than 48h after balancing

charging changes into float charging. If the accumulative discharge capacity is less than 50%

of the battery rated capacity for several power supply interruption in one day, the float

charging time can not be less than 24h after balancing charging changes into float charging.

3. As far as the communication station, which has very good power supply conditions, is

concerned, protective C10 capacity discharge should be done every 6 months (depth of

discharge is 50%), and the battery system should be recharged in time.

4. Auxiliary power supply equipment, such as Oil Power Generator etc, should be equipped for

those communication stations in which frequent power interruption exists and the power

interruption time is very long. If discharge depth of the battery system is above 80%, and the

public power supply has not restore yet, Oil Power Generator should be used to supply power

to the communication station equipments and recharge the battery at the same time.

3.2 MaintenancePeriodandRequirements

1. The newly installed battery system should be checked in the following aspects when it is put

into use --- whether or not the terminal voltage of every battery is normal, charging and

discharging current are stable, fastening parts are loose, connecting parts and the battery

terminals are being heated up by touch during charge and discharge.

2. Individual battery terminal voltage should be determined every 3 months to judge their

evenness, good record should be done at the same time.

3. The maintenance person should periodically check that whether or not connection bars are

loose or move, single battery is damaged and leaks, vent valve normally vents gas, battery is

dry etc. And in site maintenance should be done if problem occurs, and manufacturer should

be contacted to settle the problem if in site maintenance is very difficult.

4. The maintenance person should periodically determine the battery float charging voltage, and

check that whether or not there is individual battery which has very high or lowfloat charging

voltage.

5. Check that whether or not there is difference between the total system voltage and the voltage

Power the future

14

displayof the Switch Power Supply. If difference exists, it should be rectified.

6. Check that whether or not there is difference between the total system voltage and the sum of

all of the individual battery. If difference exists, the reason should be checked out and then the

difference should be corrected.

7. Record the relative electricity interruption and charging parameters in the Switch Power

Supply internal memory, and if necessary, it is strongly suggested that the battery system be

fully recharged.

Power the future

1

Operation Instruction of Battery Recharging

Jiangsu Shuangdeng Group Co.,Ltd

Power the future

2

Appendix

1 Application Range........................................................................................................................1

2 Battery Recharging Requirement.................................................................................................1

3 Battery Recharging Method .........................................................................................................2

3.1 Recharging Parameter............................................................................................................2

3.2 Recharging Procedure............................................................................................................2

3.3 Cycle Procedure.....................................................................................................................3

3.4 Battery Capacity Test Method ...............................................................................................3

4 Charging Equipment and Tools....................................................................................................4

5 Attention Proceedings ..................................................................................................................4

This manual suits for next models

3

Table of contents

Other SHOTO Camera Accessories manuals