ShowerLux LINEA TOUCH User manual

Issue 1 - 07/11 SL634

Due to a policy of continuous improvement and product development, Duscholux reserves the right to amend specification without notice.

Showerlux Spares ShopShowerlux Spares Shop

Showerlux Product made by The Duscholux GroupShowerlux Product made by The Duscholux Group

www.showersealspares.co.uk

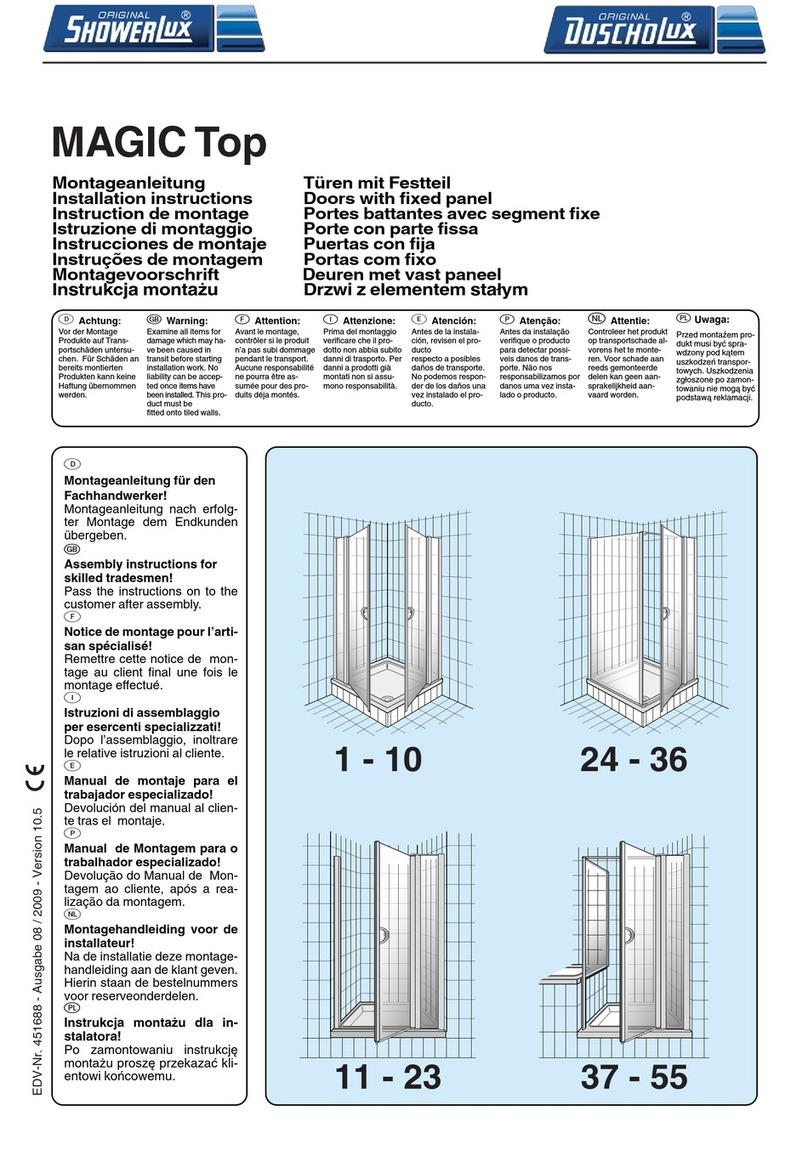

INSTALLATION INSTRUCTIONS

FOR THE LINEA TOUCH AND GLIDE PIVOT DOOR ENCLOSURES

Issue 1 - 07/11

IMPORTANT - PLEASE READ

●Please read these instructions carefully before assembly and installation.

●If installing with Side Panel please also read the side panel instructions carefully

before assembly and installation.

● Please note that this is a dual Installation Instruction for both the Linea Touch and

Glide product type. Linea Touch is the product type shown throught this Instruction.

When installing the Glide product please fit the Glide handle were supplied.

●Please inspect immediately upon receipt for damage that may have been caused in

transit. Please examine all exposed glass edges and corners prior to assembly,

damaged edges can cause spontanious breakage during product life time.

●Damage reported later cannot be accepted.

●Please assess the weight of this product prior to assembly and installation. Seek

assistance should you require it.

● Before installation, you must ensure that the shower tray is level in all directions and

completely sealed to the tiles.

● This product must only be fitted onto tiled or waterproof surfaces.

●The wall plugs and screws supplied are for use on solid walls and floors only. Any

other surface will require alternative fixings.

●The enclosure when fitted, must not overhang the front of the tray.

●Please leave this instruction leaflet with the customer.

SL634

1

HINTS & TIPS

●Surfaces to be siliconed should be de-greased in

accordance with silicone suppliers instructions, observing

any safety instructions.

●Ensure there are no hidden pipes or cables in the wall

before drilling.

●If using power tools (e.g. to drill holes) wear safety

glasses and always disconnect tools from the power

supply after use.

●If drilling holes in ceramic tiles use a piece of masking

tape on the tile to stop the drill bit from slipping.

●DO NOT use your drill on hammer action when drilling

holes in ceramic tiles.

●Use the opened out enclosure packaging to protect your

floor and wall while assembling.

CARE & MAINTENANCE

●To prevent the formation of water spots on the glass, use

the squeegee supplied in the installation fixing pack to

wipe down the glass after every shower.

●Always use plenty of water and a soft cloth or sponge to

wipe down all aluminium sections and plastic parts.

●Do not use any solvent or abrasive chemicals to clean

this product.

●We recommend that this product is cleaned with

Showerlux ‘Showerclean’ once a week. This will help to

reduce the build up of lime scale.

●Showerlux enclosures and screens are generally

maintenance free. However, it may be necessary to

lubricate roller assemblies or other moving hinge parts

occasionally. Use a high quality silicone spray on the

moving parts as required.

Issue 1 - 07/11

2

62158

Glass squeegee ...... x 1

●Crosshead screwdriver ●Drill ●8mm Masonry bit ●Hammer●Rubber mallet ●Tape measure ●Pencil

●Fine tooth saw● Spirit level ●Masking tape ●Silicone sealant / Applicator ●De-greaser e.g White spirit

EQUIPMENT NEEDED

Issue 1 - 07/11

PIVOT CONTENTS

BAG 3.1

SEALS

60140

9.5mm Screw .......... x 8

L

60005

13mm Screw ........... x 2

M

62064

65mm Screw ........... x 8

N

25006

Wall plug .................. x 8

O

62092

Centre punch .......... x 1

P

62072

2.8mm Drill bit ......... x 1

Q

20795

Screw cover ............ x 8

R

Frame cap ............ x 1/1

S

T&J

V

24828

Measuring

tool ............ x 1

W

2361

Horizontal seal ....... x 2

Z5

2211 (L)

2212 (R)

2210

Wall channel cap .... x 2

2550

Pivot Block

Screw Cover Cap ...... x 2

A

2292

Screw Hole Plug ..... x 8

B

BAG 2

BAG 1

62428

3mm Allen key ........ x 1

U

24828

Linea Touch

Handle....... x 1

I

Glide Handle....... x 1

I

DS-2-123

3

P

P

P

P

P

P

P

P

STEP 2

STEP 3

Issue 1 - 07/11

STEP 4

Do not remove the packing blocks on the unit until step 8,

doing so may result in damage to the product.

Remove the wall channels from the door and put to one side.

Note:- Use the opened out enclosure packaging to protect

your tray/floor & wall while assembling.

Before installation choose which side you want to open the unit from. The current illustrations show a left hand installation

with the door opening from right to left. Should you require a right hand installation, rotate the unit from top to bottom for the

opposite configuration to the one shown.

STEP 1

Check that the tray is level in all directions as shown above.

O

Ø 8mm

fig.1

fig.2

Position the wall channels 10mm from front edge of the tray using the

measuring tool (W). Holding the wall channels to the wall and ensuring

they are perfectly vertical and parallel to each other, mark off drill hole

positions onto the tiles using centre punch (P).

Note: failing to postion the wall channels as described above will

reduce the action and performance of the door.

Drill 8mm dia. holes to a depth of 50mm (fig.1). Push-fit wall plugs (O)

in beyond depth of tile (fig.2). Important: Do not fix the wall channels

to the wall yet.

*

S

Fit the wall channel caps (S) to the top of the wall channels

with the end tab (*) in the position shown. Note: Tapping in

place with a rubber mallet may help.

Insert the wall channels into the sides of the enclosure.

10mm

Packing Block

Packing

Block

4

STEP 6

Lift and place the enclosure onto the tray, seek assistance

should you require it. The enclosure should sit with an even

gap all along the front of the tray with no part overhanging.

Line up the enclosure with the pre drilled holes in the walls.

Using the 65mm countersunk screws (N) fix through the

enclosure sides into the fitted wall plugs.

Issue 1 - 07/11

N

STEP 5

N

N

N

N

N

N

N

N

With the tray level, centre the enclosure within the wall channels and ensure the frame is vertical.

Note: Make certain that the frame profile is not bowed on either side. Also check down the length of the unit on the handle side

that the main seal flipper is making full contact with the glass edge (see illustrations above).

From inside the enclosure, drill through the eight holes in the side profiles (as shown) into the wall channels using the 2.9mm drill

bit supplied (Q).

Fix the sections together using the 9.5mm pan head screws (L) and push-fit screw covers (R).

STEP 7

Q

Q

Q

Q

R

L

Ø 2.9mm

Q

Check for

bow.

Check for

bow.

Q

Q

Main Seal Flipper.

Dry/outside enclosure.

Wet/inside enclosure.

Main Seal Flipper.

Correct set-up

for handle side

of pivot door.

Incorrect set-up

for handle side

of pivot door.

Glass.

Glass.

Q

Q

Attach the door handle (I) to the door as shown above.

N.B. Linea Touch Handle: Please ensure that the door knob

on the inside is in the top position as shown above.

I

Inside

Outside

Door Knob

I

Inside

Outside

LINEA TOUCH HANDLE GLIDE HANDLE

5

It is important that the door is kept square within the frame to allow the door to open freely.

When setting up the closing tension of the glass door on to the vertical seal, adjust the door by loosening the top and bottom

hinge adjustment screws. Then move the pivot block left or right to create a pressure on the vertical frame seal (see illustrations

above). Make certain that the seal has contact with the full edge of the glass.

When tension has been set as desired, re-tighten the screws.

Orientate the pivot block screw cover caps (A) and push-fit on to the pivot blocks top and bottom.

Issue 1 - 07/11

Remove packing blocks shown in step 2. Measure between the frame and the pivot block, then with the drip deflector (Z5) cut a

short piece from it, to the same length as that measured. Fit this short piece between the frame and the pivot block with the drip

deflector to the outside of the enclosure as illustrated above.

Now measure between the frame and the pivot block on the longer side. Using the remainder of the seal (Z5) cut a length to that

just measured. Fit to the bottom of the door and ensure the lip of the drip deflecter is to the outside of the enclosure as illustrated

above.

STEP 8

Drip

deflector

(Z5)

Bottom

of door

Outside

enclosure

STEP 9

Bottom of door

(A)

Drip deflector

lip

Main Seal

Flipper.

Dry/outside

enclosure.

Wet/inside enclosure.

Correct set-up for handle side of pivot door.

Glass.

6

Issue 1 - 07/11

From the inside of the shower enclosure, silicone the entire

vertical length of the wall channels up against the walls.

Important: Do not silicone the lower horizontal frame of the

enclosure on the inside or the ends of the vertical profiles

of the frame.

STEP 12

Inside

10cm

From outside the enclosure, silicone along the bottom of the

enclosure on the shower tray all the way around and 10cm

up each wall.

Also silicone 10cm up the joint between the wall channel and

side profiles as shown.

STEP 13

STEP 11

Place the correctly handed frame caps (T& J) as shown and

fix using 13mm countersunk screws (M).

Push-fit all eight screw hole plugs (B) as shown.

MM

J

T

B

10cm

B

7

Issue 1 - 07/11

2138

Pivot Block

Assembly.

60005

60042

2210

2207

2543

2292

2361

60042

2208

2211

2543

2292

60005

60042

2210

2207

2212

60042

2208

2361

2138

Handle Assembly (see

separate diagrams).

2138

LInea Touch Pivot Door Components.

8

Issue 1 - 07/11

Linea Touch Handle Assembly - 24828.

201748

201744

62059

311215

601221

251127

9

Issue 1 - 07/11

Glide Handle Assembly - DS-2-123.

03012

03014

03012

03014

10

Issue 1 - 07/11

This page is intentionally blank.

This manual suits for next models

1

Table of contents

Other ShowerLux Shower Cabin manuals

Popular Shower Cabin manuals by other brands

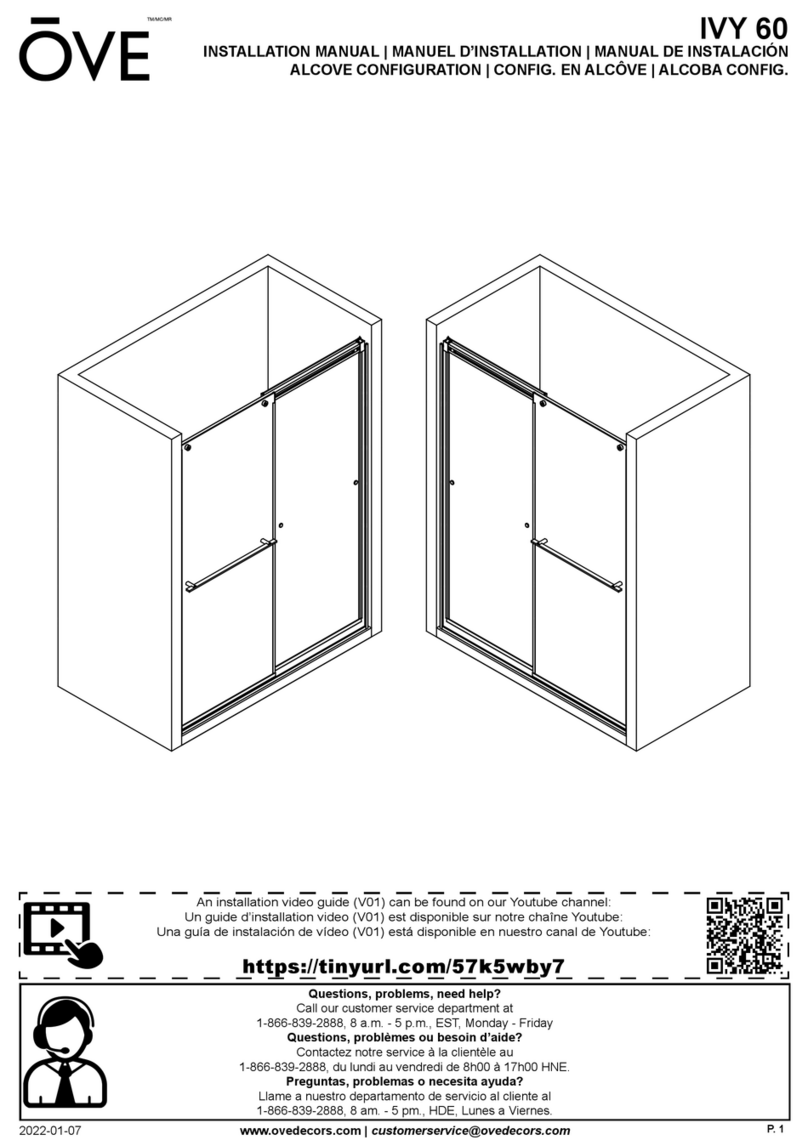

OVE

OVE ARUBA manual

Radaway

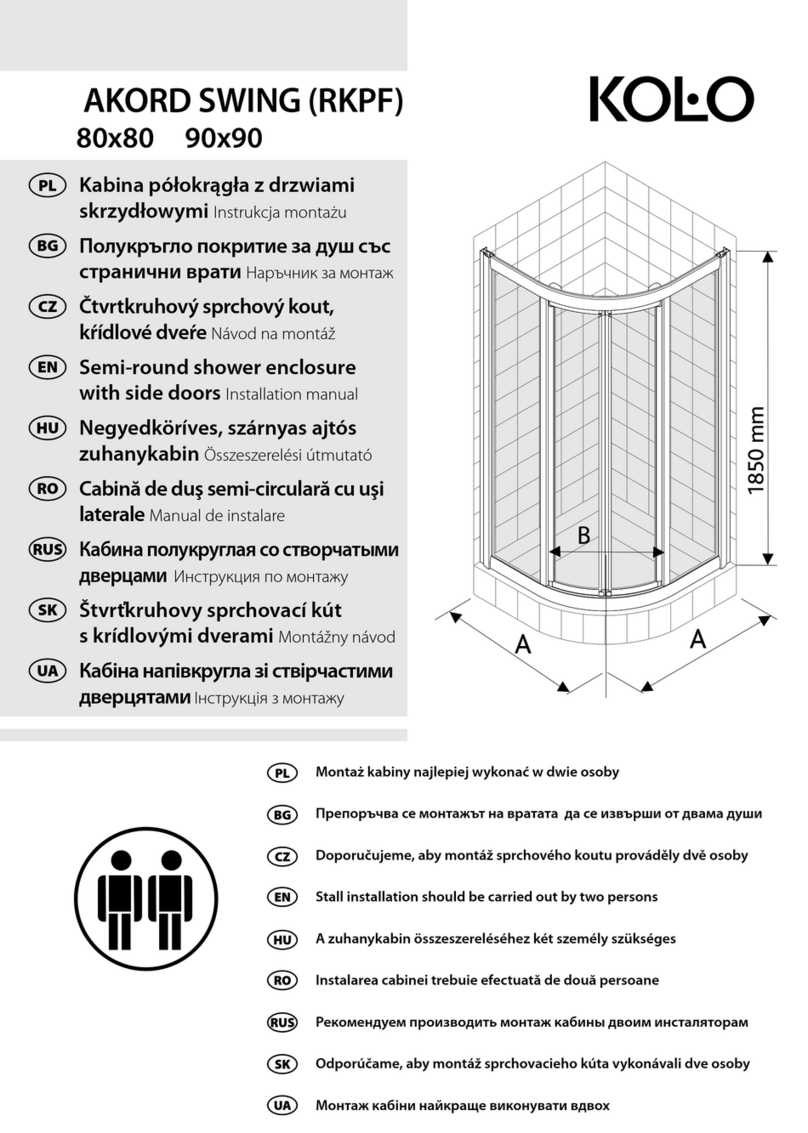

Radaway EOS KDD-B Assembly instruction

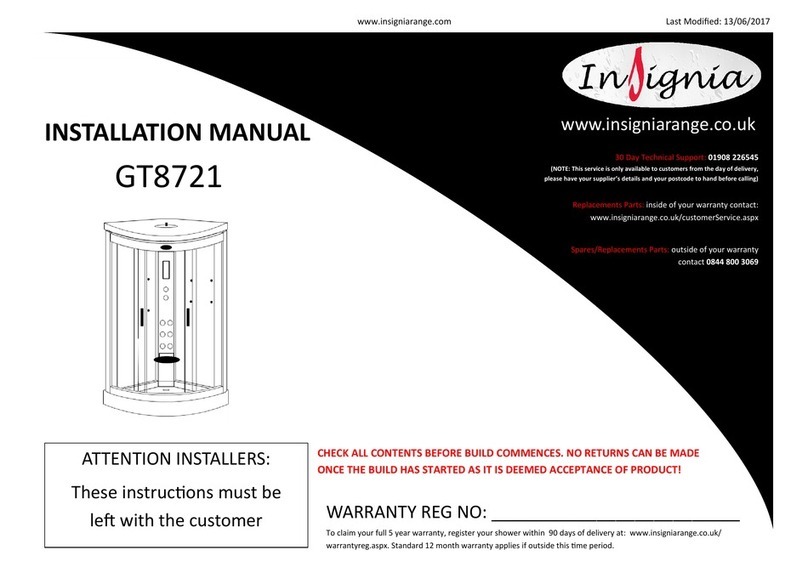

Insignia

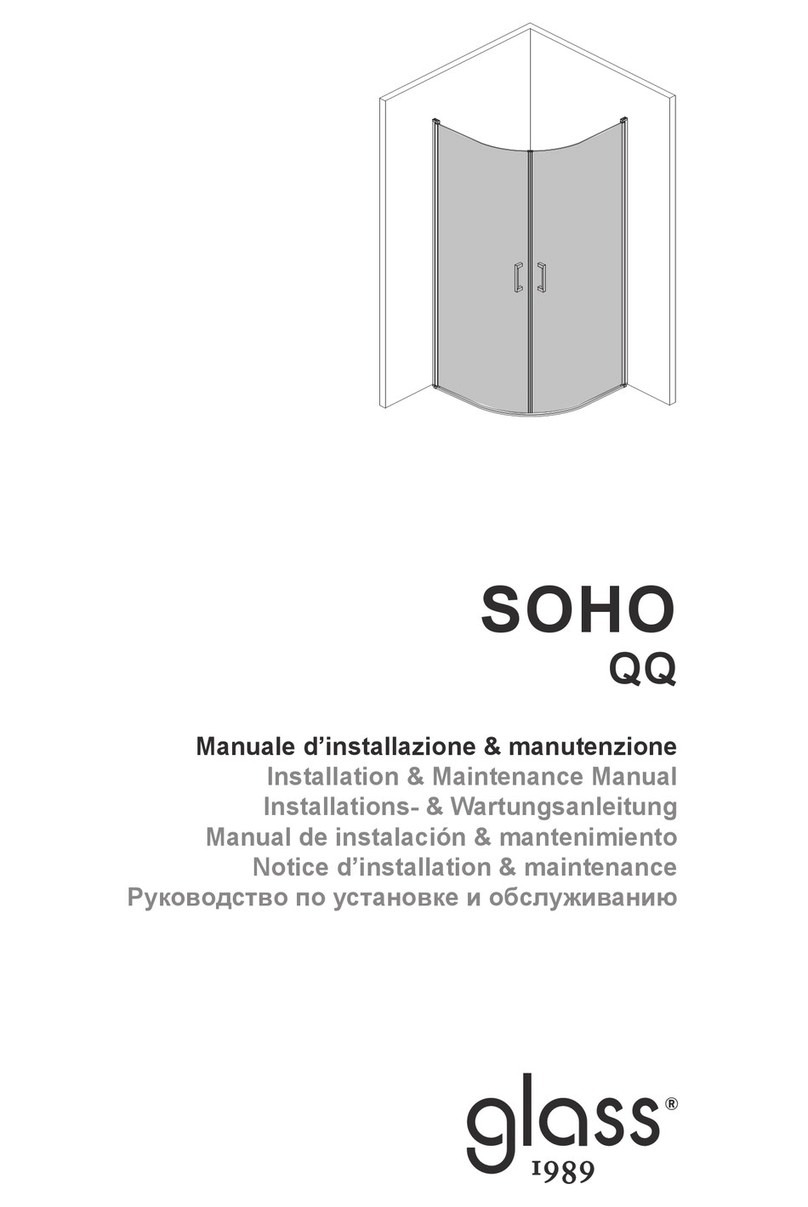

Insignia GT8721 manual

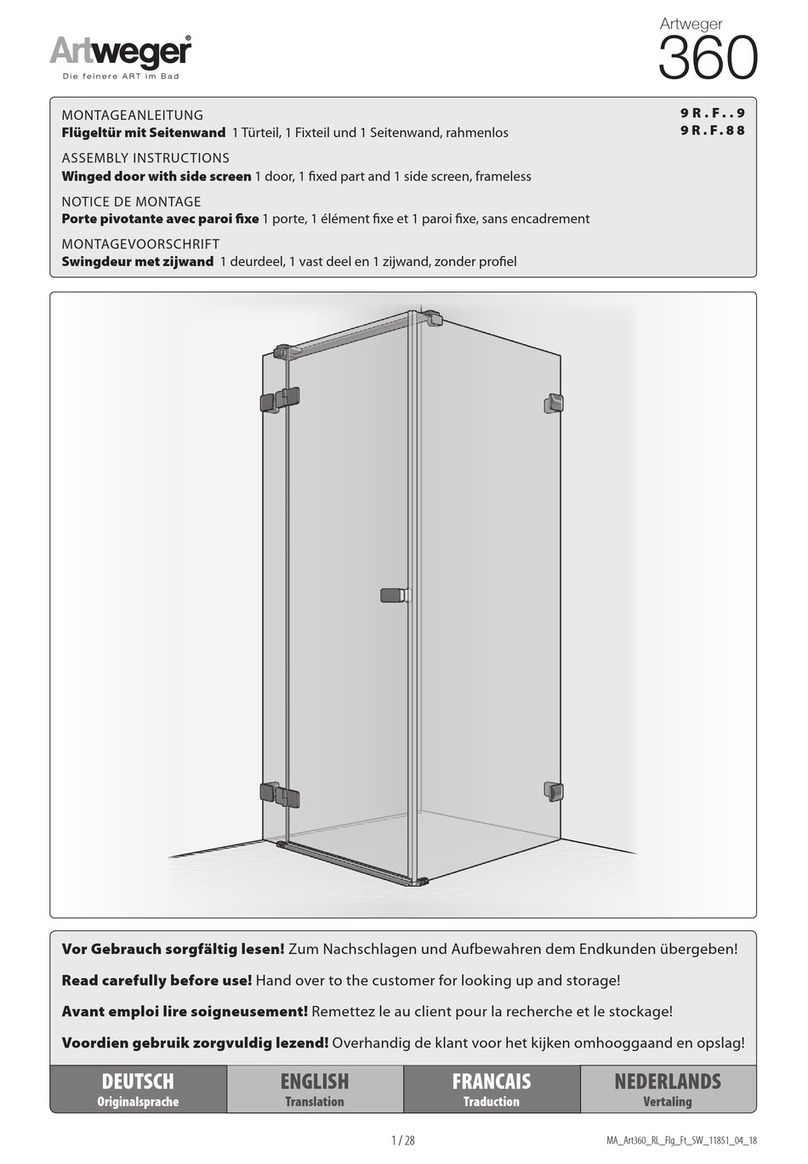

Artweger

Artweger 360 9R F 9 Series Assembly instructions

VINNOVA

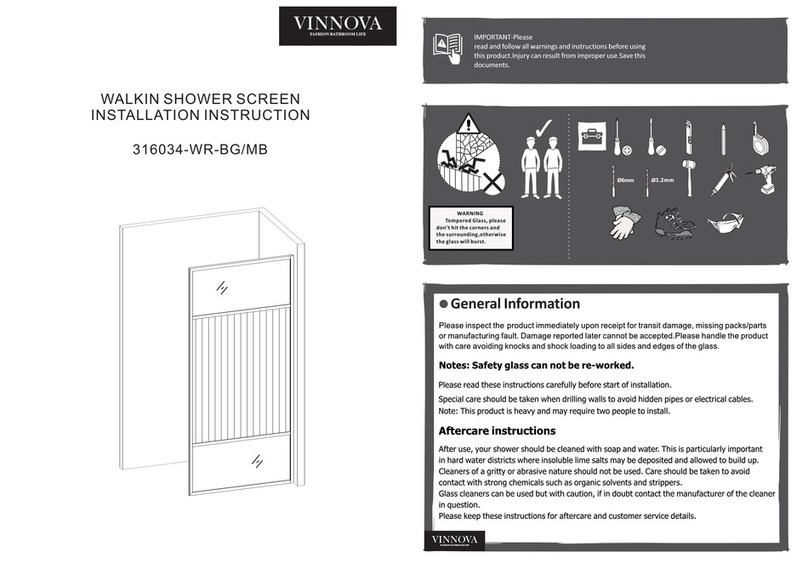

VINNOVA Tafaala 316034-WR-BG Installation instruction

Lakes Bathrooms

Lakes Bathrooms COASTLINE LEVANZO Cannes Installation & maintenance instructions