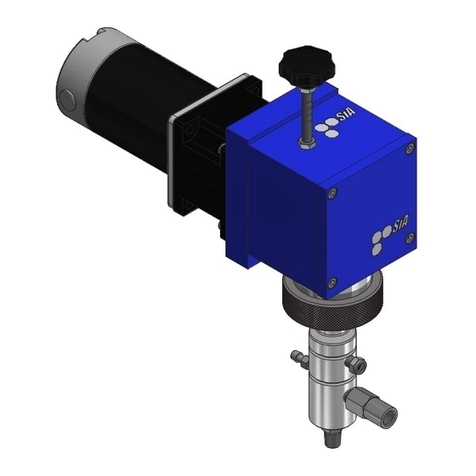

SIA SIA-24-L25-CR-TSB-6050-DC-S-PS User manual

MANUAL

INSTALLATION, OPERATION & MAINTENANCE

SiA CHEMICAL INJECTION PUMP

ILLUSTRATION & PARTS LIST SIA-24-L25-CR-TSB-6050-DC-S-PS

www.solarinjection.com.au

A

123 4 5 6

6

5

4321

B

C

D

E

F F

E

D

C

B

A

NO MANUAL REVISIONS ALLOWED

A3

592 Tarragindi Road,

Salisbury, Qld 4107 Tel: +61 7 3277 8822

SCALE STATUS

SIZE

SHEET OF

DWG NO. REV

TITLE

NOTES

FILE NAME

THIS DRAWING CONTAINS

CONFIDENTIAL INFORMATION

AND IS COVERED BY COPRIGHT

LAWS. REPRODUCTION EITHER

PARTIAL OR COMPLETE IS

PROHIBITED, UNLESS PRIOR

CONSENT HAS BEEN GIVEN IN

WRITING BY SOLAR INJECTION

AUSTRALIA PTY LTD

SIA-24-L25-CR-TSB-6050-DC-S-PS.idw

1

SIA-24-L25-CR-TSB-6050-DC-S-PS

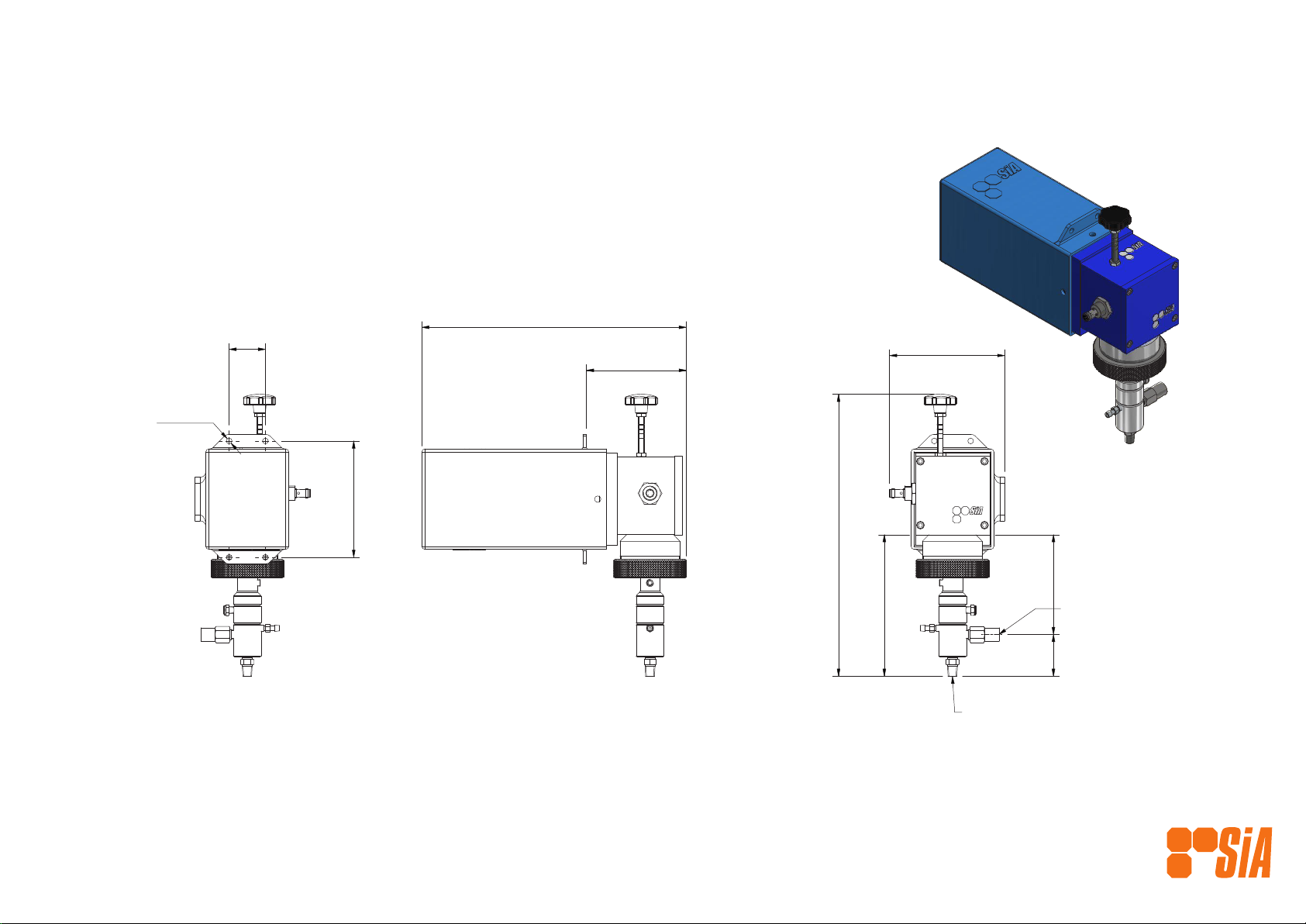

GENERAL ARRANGEMENT

SIIA-24-L25-CR-TSB-6050-DC-S-PS10

F.P.

A.S.

04/09/2021

1:5

DRAWN TO AS1100-1992

UNLESS NOTED OTHERWISE:

- ALL DIMENSIONS IN mm (in)

- TOLERANCES:

MACHINING ±0.1 mm

WELDING ±1.0 mm

ANGULAR ±0.5°

DRAWN

CHECKED

DATE

5

TOTAL MASS

15.2 kg

MATERIAL

10 REVISIED FOR VAULT 7/09/2021 A.S.

REV DESCRIPTION DATE APP'D

159 APPROX

388APPROX

364

IN 1/4" NPT

OUT 1/4" NPT

160

50

8 TYP

137.5

137

195

58

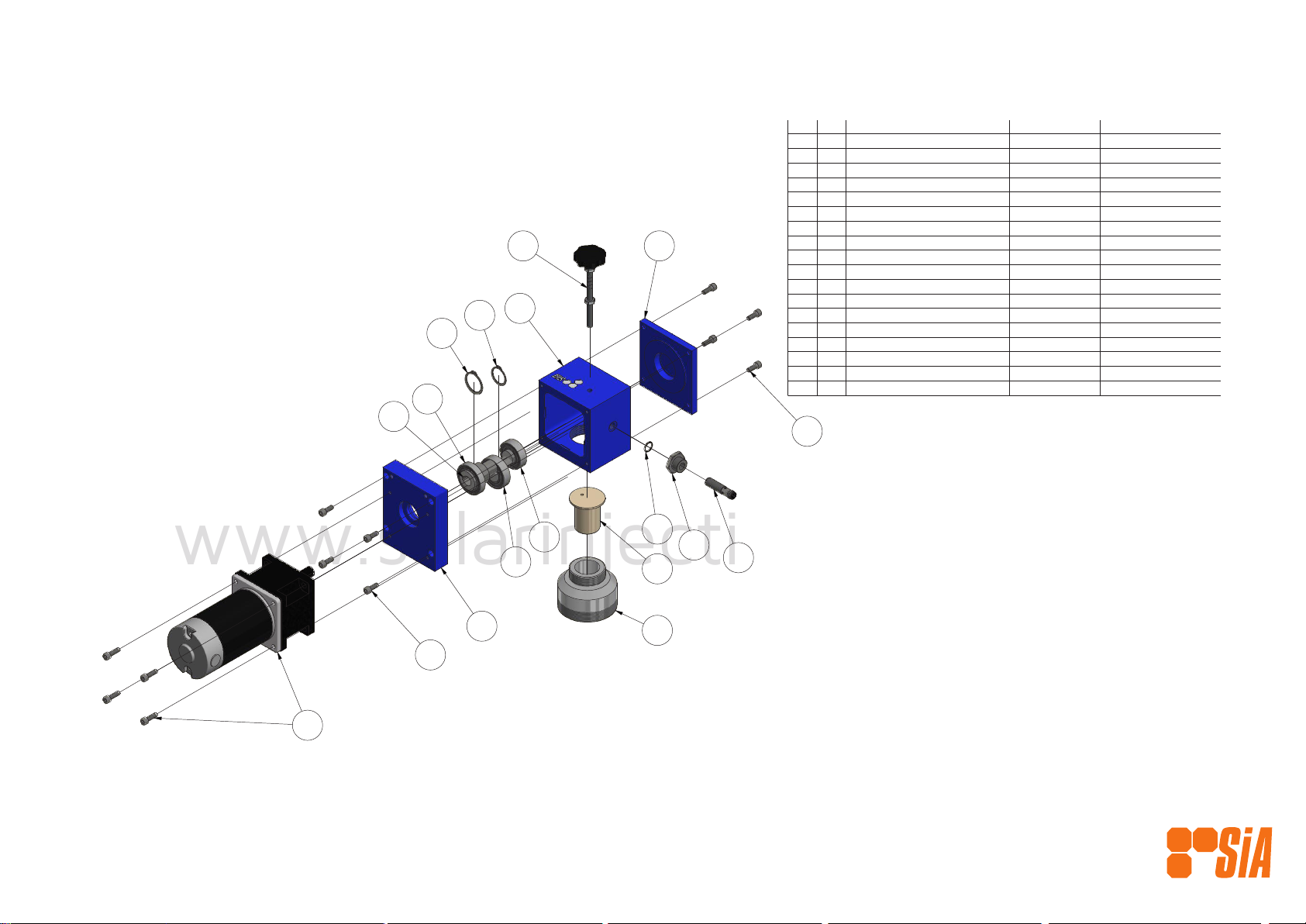

ILLUSTRATION & PARTS LIST

www.solarinjection.com.au

www.solarinjection.com.au

SIA-24-L25-CR-TSB-6050-DC-S-PS

MaterialPart NumberDescriptionQTYItem

Aluminum 606140042-1DRIVE CASE11

Aluminum-606140044-1

MOTOR END PLATE

12

Aluminum 606140047BEARING END PLATE13

431 SS40045-15-SSCRANK SHAFT 15 mm14

40023Bearing15

40024

Bearing

16

30032Bearing1

7

Steel, Mild40029Circlip18

Steel, Mild

40033

Circlip

19

Aluminum-606140046-WPump Adaptor - W Series110

Ertalyte TX40043PLUNGER ADAPTOR UPPER111

Zinc Plated40011-16

Cylinder Head Cap Screw

412

40084STROKE LENGTH ASSEMBLY113

316 SS40220SENSOR HOUSING114

Viton40067-014ORING VITON115

Stainless Steel30103SENSOR116

40069-24-6050GEARBOX 50:1, 24 VDC 60w MOTOR117

Steel, Mild40011-10Cylinder Head Cap Screw419

A

123 4 5 6

6

5

4321

B

C

D

E

F F

E

D

C

B

A

NO MANUAL REVISIONS ALLOWED

A3

592 Tarragindi Road,

Salisbury, Qld 4107 Tel: +61 7 3277 8822

SCALE STATUS

SIZE

SHEET OF

DWG NO. REV

TITLE

NOTES

FILE NAME

THIS DRAWING CONTAINS

CONFIDENTIAL INFORMATION

AND IS COVERED BY COPRIGHT

LAWS. REPRODUCTION EITHER

PARTIAL OR COMPLETE IS

PROHIBITED, UNLESS PRIOR

CONSENT HAS BEEN GIVEN IN

WRITING BY SOLAR INJECTION

AUSTRALIA PTY LTD

SIA-24-L25-CR-TSB-6050-DC-S-PS.idw

4

DRIVE ASSEMBLY

EXPLODED VIEW 2

SIAL70000-24-6050-DC-PS 10

F.P.

A.S.

04/09/2021

1:3

DRAWN TO AS1100-1992

UNLESS NOTED OTHERWISE:

- ALL DIMENSIONS IN mm (in)

- TOLERANCES:

MACHINING ±0.1 mm

WELDING ±1.0 mm

ANGULAR ±0.5°

DRAWN

CHECKED

DATE

5

TOTAL MASS

11.5 kg

MATERIAL

10 REVISIED FOR VAULT 7/09/2021 A.S.

REV DESCRIPTION DATE APP'D

19

313

16

14

15

11

10

1

9

8

7

6

5

4

2

12

17

ILLUSTRATION & PARTS LIST

www.solarinjection.com.au

www.solarinjection.com.au

SIA-24-L25-CR-TSB-6050-DC-S-PS

MaterialPart NumberDescriptionQTYItem

316 SS40057-SFLANGE - LEGACY SERIES11

316 SS

40049-1

PUMP ADAPTOR RING

12

Ertalyte Tx40008-LPLUNGER ADAPTOR LOWER - LEGACY 0.25 UNC13

TZP Ceramic / 316 SS40066-1PLUNGER CERAMIC 0.250"14

316 SS / Ceramic40130-MINLET CHECK VALVE 1/4"15

316 SS40064

BLEED VALVE

16

316 SS40068LUBE PLUG1

7

316 SS40061PUMP BODY UPPER18

Delrin40055-1-5

BACKUP SEAL 0.250"

29

316 SS40060PUMP BODY MIDDLE110

SS Filled PTFE with Buna-N Energiser40065-1-6MAIN SEAL TSB 0.250"111

Viton40067-021

O-RING VITON

212

316 SS40059PUMP BODY LOWER113

UHMWPE40065-1-2MAIN SEAL UHMWPE 0.250"114

Stainless Steel40056-2- Compressed 1 Rev 10HELICOIDAL SPRING115

ASTM A 240 316L40089-40 Rev 101/8" NPT VENT SCREEN116

316 SS / PTFE40063-BCHECK VALVE117

A

123 4 5 6

6

5

4321

B

C

D

E

F F

E

D

C

B

A

NO MANUAL REVISIONS ALLOWED

A3

592 Tarragindi Road,

Salisbury, Qld 4107 Tel: +61 7 3277 8822

SCALE STATUS

SIZE

SHEET OF

DWG NO. REV

TITLE

NOTES

FILE NAME

THIS DRAWING CONTAINS

CONFIDENTIAL INFORMATION

AND IS COVERED BY COPRIGHT

LAWS. REPRODUCTION EITHER

PARTIAL OR COMPLETE IS

PROHIBITED, UNLESS PRIOR

CONSENT HAS BEEN GIVEN IN

WRITING BY SOLAR INJECTION

AUSTRALIA PTY LTD

SIA-24-L25-CR-TSB-6050-DC-S-PS.idw

5

CHEMICAL INJECTION PUMP

SiA LEGACY SERIES

EXPLODED VIEW 3

SIAP-L25-2-CR-TSB-S 10

F.P.

A.S.

04/09/2021

1:5

DRAWN TO AS1100-1992

UNLESS NOTED OTHERWISE:

- ALL DIMENSIONS IN mm (in)

- TOLERANCES:

MACHINING ±0.1 mm

WELDING ±1.0 mm

ANGULAR ±0.5°

DRAWN

CHECKED

DATE

5

TOTAL MASS

1.9 kg

MATERIAL

10 REVISIED FOR VAULT 7/09/2021 A.S.

REV DESCRIPTION DATE APP'D

3

15

1

2

4

7

8

9

11

12

10

16

9

14

12

6

13

5

17

4

TABLE OF CONTENTS

ILLUSTRATION & PARTS LIST

SECTION 1 GENERAL DESCRIPTION

1.0 Drive Assembly

1.1 Liquid End

1.2 Motor End

SECTION 2 INSTALLATION

2.0 Fuses

2.1 Mounting, Orientation & Environment

2.2 Installation - Step by Step

SECTION 3 PUMP OPERATION

3.0 Operating Pump With SiA Timer/Controller

3.1 Chemical Injection Flow Rate Adjustment

SECTION 4 MAINTENANCE

4.0 Routine Maintenance: Drive Assembly

4.1 Routine Maintenance: Liquid End

4.2 Routine Maintenance: Gearmotors tted to the drive

4.3 Corrective Maintenance

2

6

6

7

7

8

8

9

9

10

14

15

15

16

17

16

10

5

SECTION 1 GENERAL DESCRIPTION

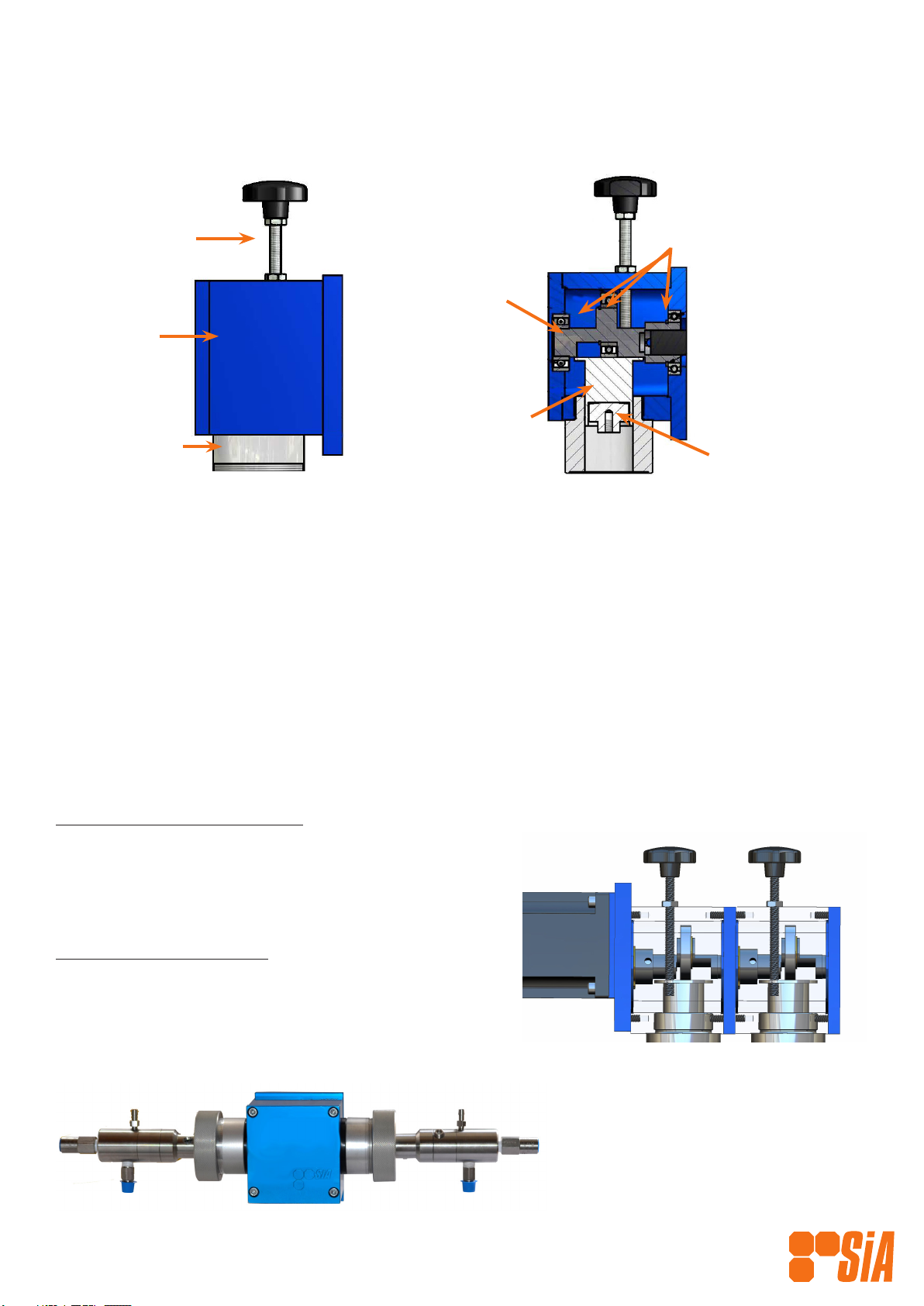

1.0 Drive Assembly

Drive Assembly Main Components

1.01 How the Drive Works

The SiA Drive Assembly has been designed to give a reliable means of driving a reciprocating

chemical injection pump by means of electricity in general, and solar energy in particular.

The standard motive force of the Drive Assembly consists of a PMDC, BLDC or A.C. motor driving

through an integrally mounted gearbox. This gear-motor mounts directly to the drive case’s ange

mount and the drive shaft connects to the drive crank shaft via a keyed connection. The crank

shaft is supported either end by oversized sealed bearings so as to eliminate all overhung loads.

This greatly increases the life of the gear-motor’s gearbox.

By applying a rotary force to the end of the crank shaft, the force is transmitted to the pump by

way of the plunger adaptor, which is directly acting on the pump plunger.

Multiplex Drive Conguration

The SiA multiplex conguration works as described

above, with the added benet of allowing combined or

multiple separate chemical ows in the one chemical

injection pump.

Liquid End Congurations

Simplex— One liquid end per drive case with Stroke

Adjustment.

Duplex— Two liquid ends per drive case without Stroke

Adjustment

Multiplex 2 Conguration

Duplex Conguration

Manual Stroke

Length Adjustor

Drive Case

Pump Adaptor

Bearings

Crank Shaft

Plunger Adaptor

Upper Plunger Adaptor

Lower

6

1.1 Liquid End

Liquid End Main Components

1.2 Motor & Gearbox

A number of motor/gearbox options are available with SiA pumps depending on your application’s

requirements. The table below provides an outline of these different options, refer to the Parts List

at the front of this manual for part numbers specic to your pump.

Voltage Watts Ratio Gearbox Type Hazardous Area

Certications

Standard

12; 24;

120/240;

220/415;

20; 40; 60;

90; 120;

150;

50; 75; 150 Spur N/A

Standard BLDC

12; 24;

100; 120; 200;

400;

40; 50; Spur N/A

Heavy Duty

(Motor Optional)

12; 24;

120/240;

220/415;

Motor

dependant

26; 32 Planetary IECex;

ATEX;

UL/CSA

SiA Pump

Connection Ring

Body Upper

Body Middle

Bleed Screw

Body Lower

Check Valve Inlet

Check Valve

Outlet

Flange

Plunger

Return Spring

Seals

7

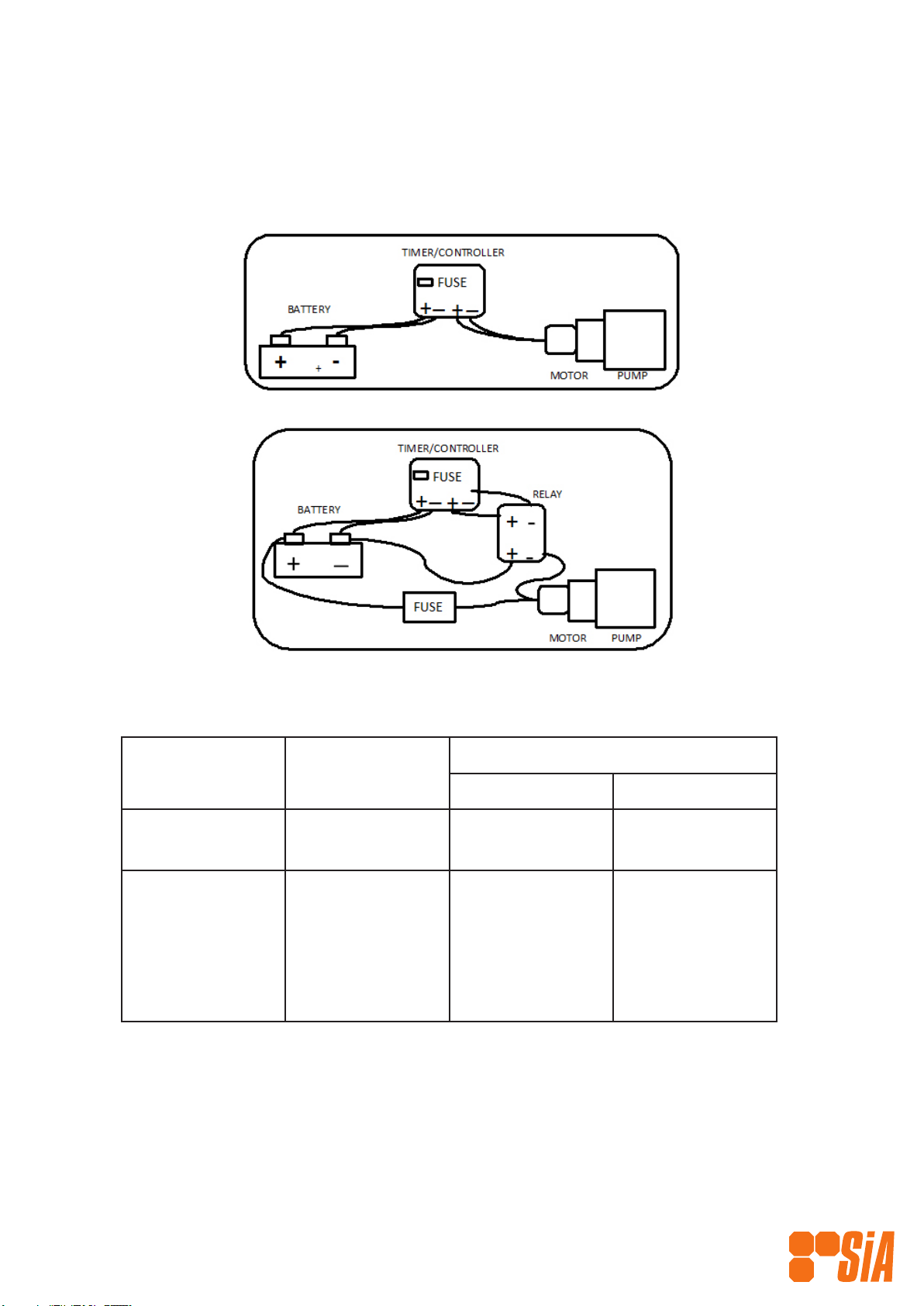

SECTION 2 INSTALLATION

2.0 Fuses (PLEASE READ BEFORE INSTALLING)

Always ensure the correct fuse is tted and connections are as per diagrams below to prevent

damage to the pump that could void warranty.

Always ensure the correct fuse is tted and connections are as per diagrams below to prevent

damage to the pump that could void warranty.

Motor

Wattage

FUSE REQUIRED

12 Volt 24 Volt

High Eciency 150

100 (IEC)

NA

NA

7.5 amp

5 amp

Standard 40

60

90

120

150

5 amp

10 amp

15 amp

20 amp

25 amp

2.5 amp

5 amp

7.5 amp

10 amp

12.5 amp

For other wattage motors, or where no motor is supplied with the pump, please consult Solar

Injection Australia to ensure correct fuse.

If the motor is being driven directly via an SIAT71500 Timer/Controller the maximum fuse rating

is 10 amp.

Note: Drive case is limited to maximum input of 22 Nm, maximum of 150 Watts at 60 rpm. For

loads above this, our Heavy Duty Drive should be used.

8

2.1 Mounting,Orientation & Environment

The preferred orientation for mounting is with the Liquid End pointing down, the Timer Module

on top and the Gearmotor horizontal to the ground. This facilitates “bleeding” of the pump and

maximises the life of the seals within the pump. The inlet of the Liquid End should be no higher

than level with the lowest chemical level, to ensure a positive head on the inlet check valve. With

Duplex congurations (ie 2 liquid ends on 1 drive), the Liquid Ends will be horizontal to the ground

and the position of the inlet and outlet check valves will be reversed. Ensure that the inlet check

valves, which are gravity-style, are facing downwards.

We recommend installing the assembly within a weatherproof enclosure. Where this is not practical,

ensure as much weather and dust protection is afforded the whole assembly and the motor in

particular. An SiA custom cover for the motor and gearbox assembly can be ordered separately if

required.

Where environmental conditions are harsh, ie very wet, where there is salt water &/or dust or

snow, consider coating the assembly with an appropriate coating or cover. In wet conditions in

particular, we recommend use of a non hardening mastic on all mating parts, which is available

as an option. Please contact Solar Injection Australia or an SiA Authorised Technical Agent before

nalising the design of the installation.

Use the two M6 mounting holes to securely mount the assembly to any rigid frame or sub-

assembly with mounting brackets (not supplied but available).

2.2 Installation — Step by Step

1. Discard all plastic closures on the Liquid End and align pump connections as dictated by your

overall system design.

2. Connect the suction check valve to a gravity-fed chemical source. This pump requires a ooded

suction. We recommend installation of lters to the suction of each Liquid End and some form

of pump inlet isolation. Warranty may be affected if you do not.

3. Connect the discharge check valve to the process line. We recommend installation of a pressure

relief valve to the discharge of each Liquid End. Warranty may be affected if you do not.

4. Check that the pump adaptor ring is rm.

5. Open the bleeder valve until chemical starts to ow then re-tighten.

6. Ensure that the DC power supply that you are using corresponds to the DC power required. 12

volts supply to 12 volts equipment. 24 volts supply to 24 volts equipment

WARNING: Ensure the DC power supply to the DC Drive Motor is fused with the correct

fuse. See Section 2.0 for details.

WARNING: For AC models, all AC equipment must be installed by licenced electrical

personnel.

7. Before connecting the supply leads to the DC motor make ensure the supply is isolated.

8. Connect motor power leads to supply, Red to Red (+) and Black to Black (-).

If installing with an SIAT75001 Timer/Controller, connect the battery power supply and

motor leads to the four screw terminals clearly marked and located on the lower front

face of the timer.

WARNING: Connecting the main power supply in the reverse polarity can cause

immediate failure of the electronics within the timer module.

WARNING: As the control and isolation of the DC Drive is supplied by the operator,

care must be taken in selecting equipment to carry out these functions. We recommend

discussing alternative operator-designed control methods prior to installation.

9

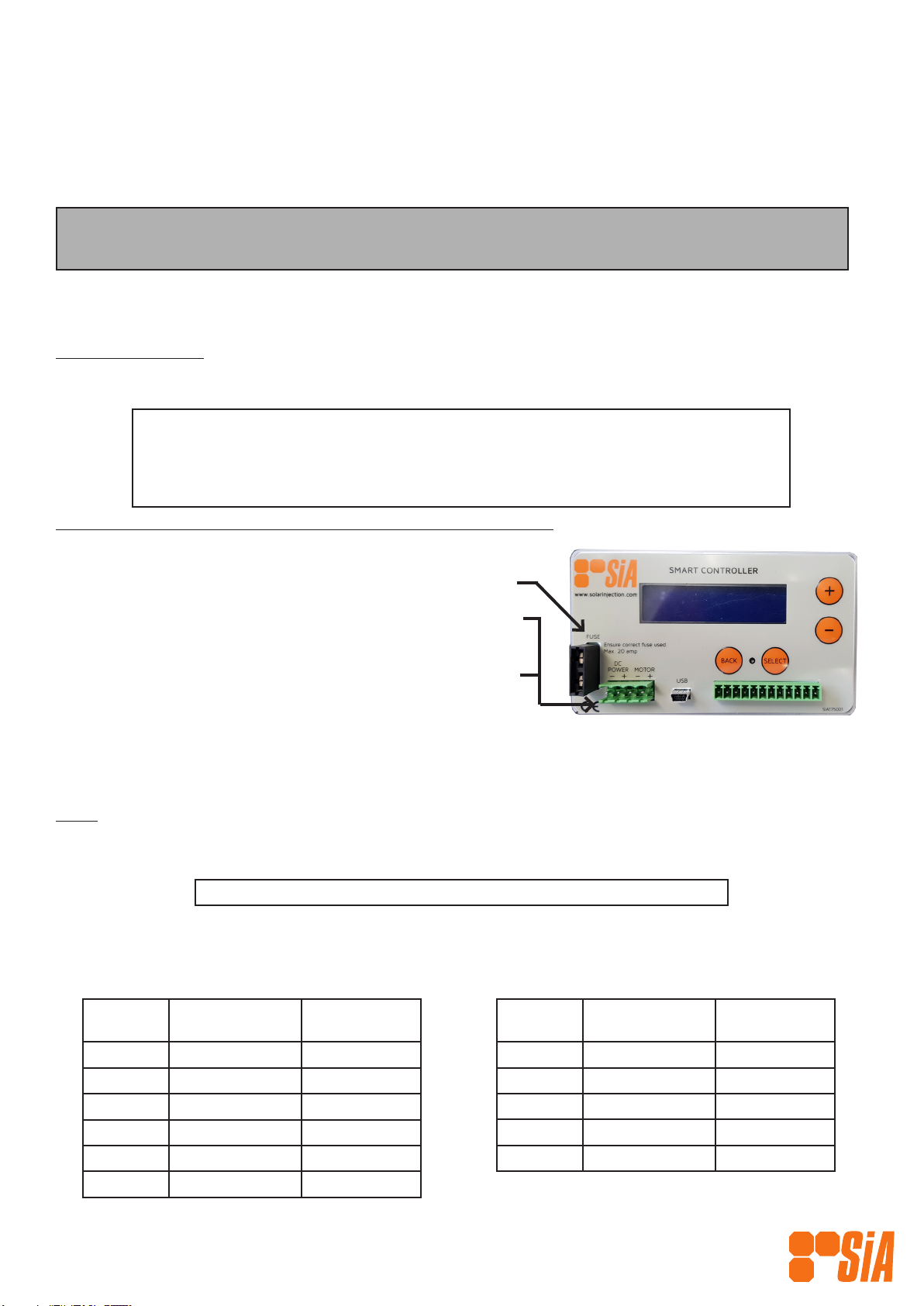

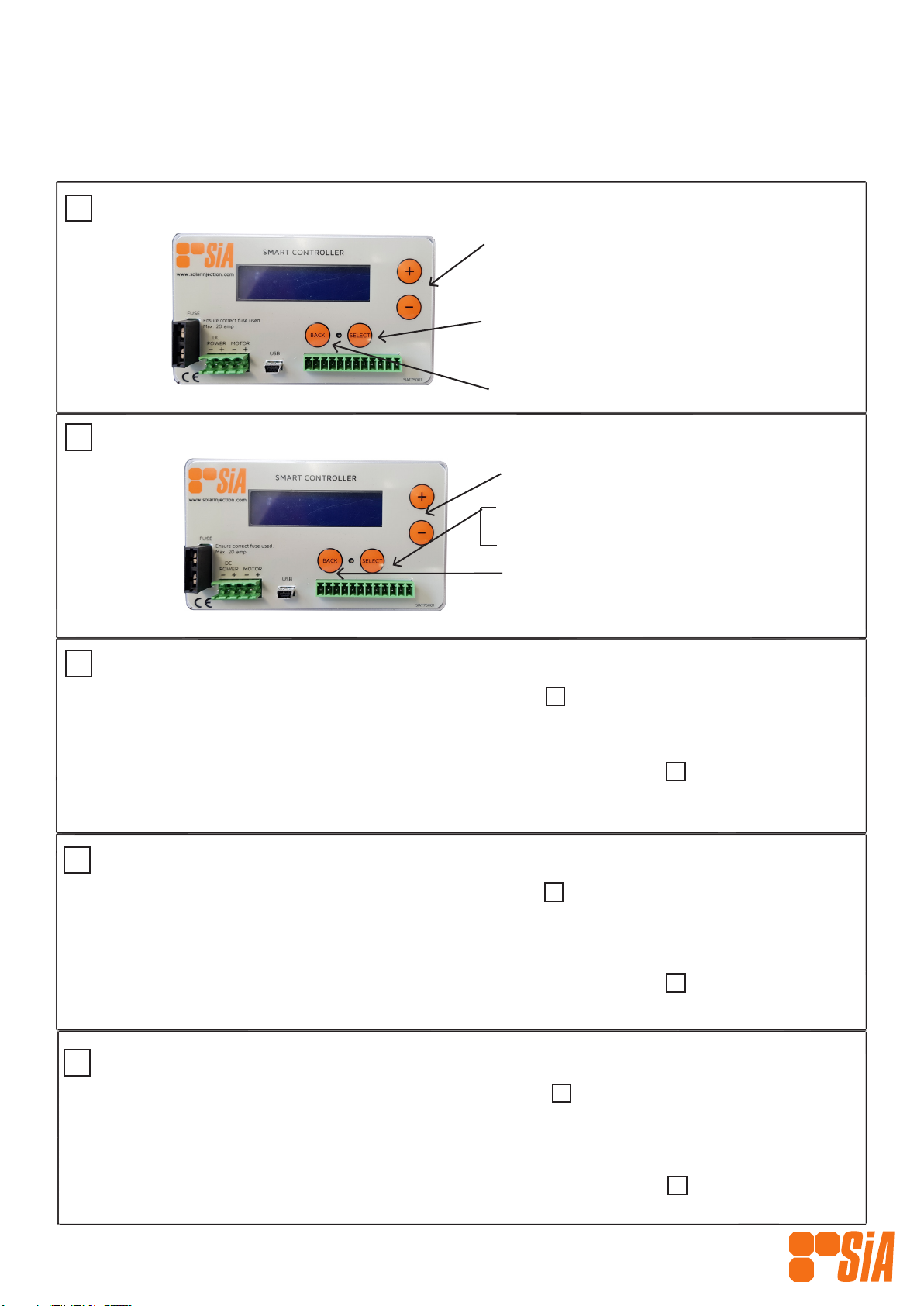

SIAT75001 SiA Smart Controller

Revision: TH1

QUICK START GUIDE

Thank you for purchasing an SiA Smart Controller.

INSTALLATION

Physical Installation

Use the DIN Rail mounts at the back of the controller to mount timer within a suitable enclosure.

Ensure the enclosure provides a dry, well-ventilated environment that prevents

direct sunlight reaching timer.

The SIAT75001 must not be installed or operated in a dened Hazardous Area.

Important Information Before Connecting Power to the Controller

1. Ensure the correct rated fuse is installed in the Fuse Holder.

Refer to Fuses Section for details

2. Ensure your have correctly wired the power connections to the

Power Terminal Header (PTH).

3. Ensure only either 12 VDC or 24 VDC power is connected to the

“IN” terminals.

NOTE:As the controller will always return to the state it was last in before power was disconnected, the timer could

give an output to the Motor Terminals on the PTH immediately when the power is connected. To avoid this, t an

On/Off isolating switch between the timer’s Motor Terminals on the PTH and the motor’s terminals.

Fuses

It is very important that the correctly sized fuse is installed on the Controller. We suggest using Littlefuse ATO

Automotive Quick Acting Fuses.

Never use a fuse greater than 20 amps.

Choose a fuse that is suited for the protection of other equipment within the electrical circuit (providing it calls for

a fuse of no more than 20amps). Usually, the most important piece of equipment within the timer circuit is the DC

Motor. To work out the appropriate fuse rating to protect the motor, refer to the data-plate attached to the motor.

For SiA PMDC motors the following table is a guide:

Power

(watts)

Voltage Recommended

Max. Fuse Rating

25 12 5

25 24 2

40 12 5

40 24 3

60 12 10

60 24 5

Power

(watts)

Voltage Recommended

Max. Fuse Rating

90 12 10

90 24 5

120 12 15

120 24 7.5

HE 24 5

If the motor power selected requires a fuse greater than 15 amps, SiA recommends the use of a suitable relay that

can carry the extra load required.

SECTION 3 PUMP OPERATION

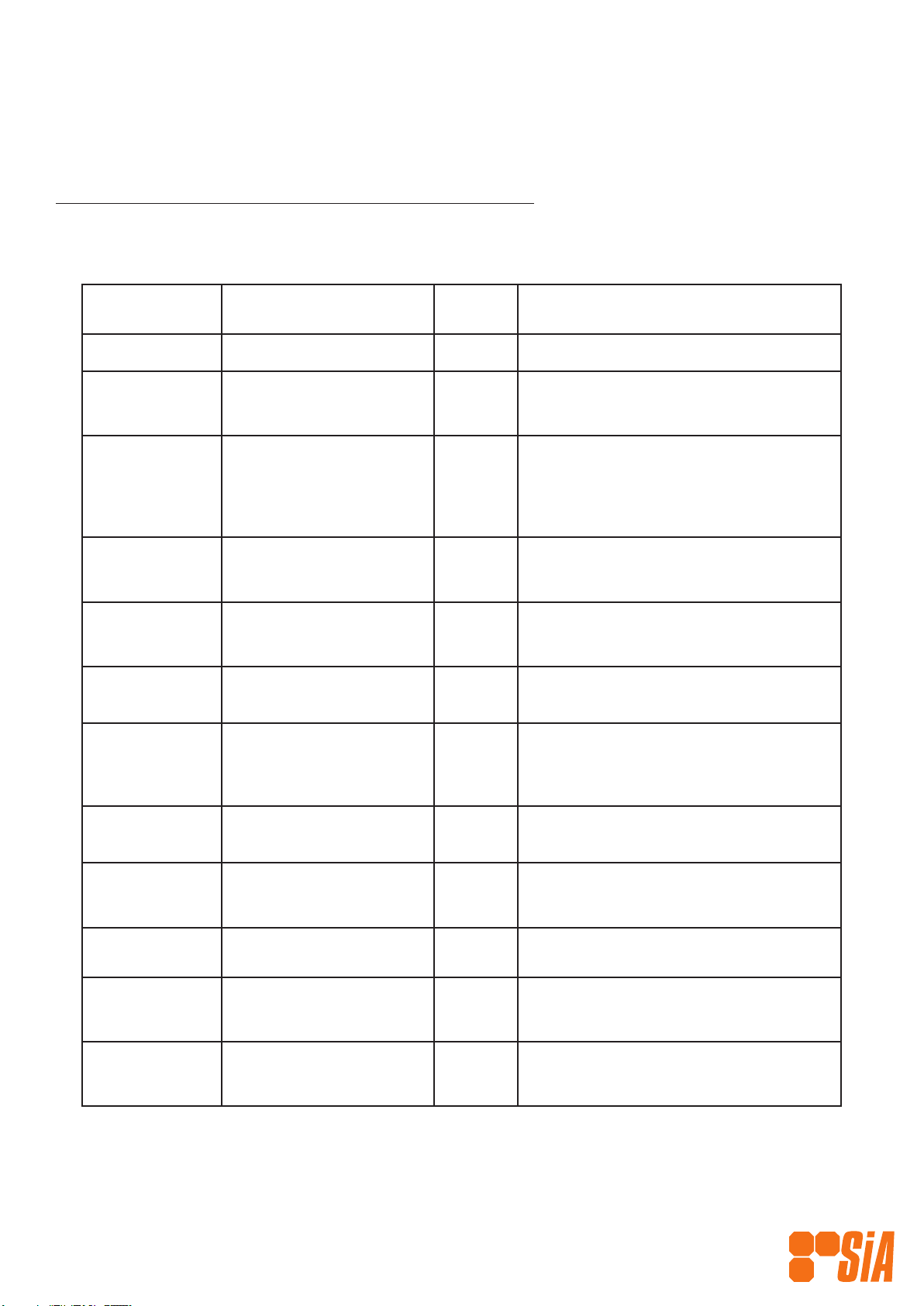

3.0 Operating Pump with SiA Timer/Controller: SIAT75001

10

OPERATION

First time connection of power (standard software & default settings)

It is important to review the default settings (see table below). Please note your controller may have been pre-

programmed to your application’s specications.

Setting Setting Purpose Default

Value

All Values

Units The type of units used. Metric Metric; US

Power On State Sets what happens to

the Timer when power is

applied.

Resume

Mode Sets the pump running

conditions.

Auto Cont - Pumps continuously

Auto - Pumps to chosen Flow Rate

Fixed - Pumps to chosen On/Off Times.

Batch - Pumps to chosen On/Off Times

at different times/days of week.

On Time Sets the On Time (in

seconds) used in Fixed

Mode

2 1 - 60

Off Time Sets the Off Time (in

seconds) used in Fixed

Mode

10 1 - 60

Flow Rate Sets the desired ow rate in

Auto Mode.

1.0 LPH

Pump Size Aligns the Timer with the

pump size.

L25 1/4” L15 1/8” L75 3/4”

L25 1/4” L100 1”

L35 3/8” L150 1 1/2”

L50 1/2” L225 2 1/4”

Battery Voltage Sets the battery voltage. Auto 12V; 24V; AUTO

Low Power

Voltage

Sets the battery voltage

that will trigger Low Power

Mode.

12.1

Cut Out Voltage Sets the battery voltage that

will turn the pump off.

11.8

Restore Voltage Sets the battery voltage that

will turn the pump back on

after Cut Out.

11.9

Power Save

Percentage Sets the percentage of the

ow rate in Low Power

Mode.

50

SIAT75001 SiA Smart Controller

Revision: TH1

11

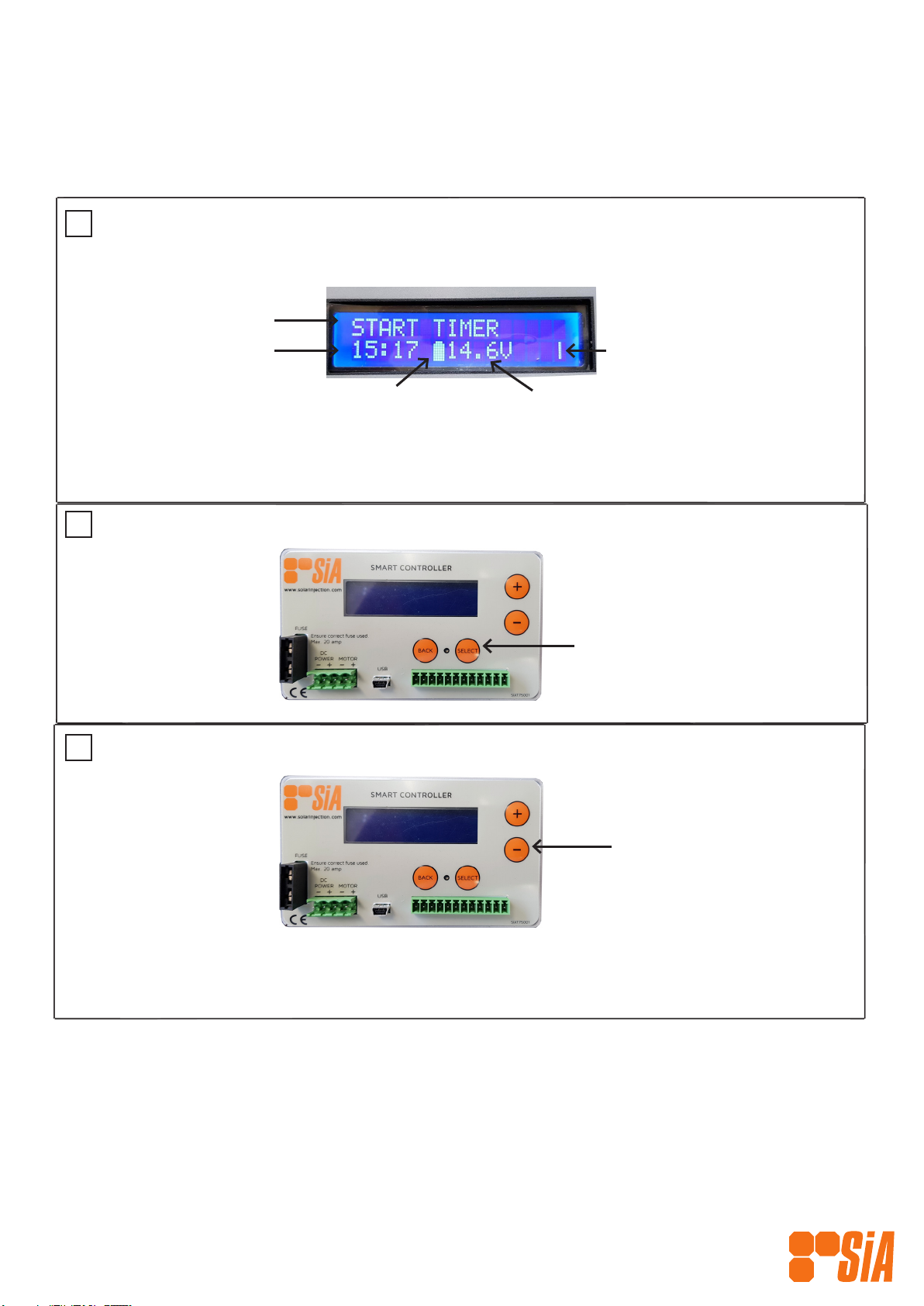

Select Mode

1. Depress the ‘+’ & ‘-’ buttons until ‘Mode Select’

appears on the screen.

2. Depress “Select” button and cycle to required

mode.

3. Depress “Select” again to select.

4. Depress the “Back”button to return to the

“Start Timer” screen and start controller as per

step 2.

OPERATION (cont.)

Show Current Settings

1. Depress the ‘+’ & ‘-’ buttons until ‘Show Settings’

appears on the screen.

2. Depress “Select” button to cycle through settings.

3. Depress “Back” to exit.

4

5

Set Units

1. Ensure the controller has power on and the display shows as per on the previous page.

2. Depress the ‘+’ twice or until the display shows ‘OPTIONS’ and then depress the ‘Select’ button.

3. Depress the ‘+’ or ‘-’ buttons until the display shows ‘UNITS’ and then depress the ‘Select’ button.

4. Use the ‘+’ or ‘-’ buttons to choose either ‘Metric LPH’ or ‘US GPH’ and then depress the ‘Select’ button.

5. From here you can either depress the ‘Back’ button until the display shows as per to start the controller

or you can go on to set other parameters such as ‘PUMP SIZE’; FLOW RATE’; or ‘MODE SELECT’.

1

1

6

Set Pump Size

1. Ensure the controller has power on and the display shows as per on the previous page.

2. Depress the ‘+’ twice or until the display shows ‘OPTIONS’ and then depress the ‘Select’ button.

3. Depress the ‘+’ or ‘-’ buttons until the display shows ‘PUMP SIZE’ and then depress the ‘Select’ button.

4. Use the ‘+’ or ‘-’ buttons to get to the correct pump size (e.g ‘L150 1 1/2” ’)and then depress the ‘Select’

button.

5. From here you can either depress the ‘Back’ button until the display shows as per to start the controller

or you can go on to set other parameters such as ‘UNITS’; FLOW RATE’ or ‘MODE SELECT’.

1

1

Set Flow Rate

1. Ensure the controller has power on and the display shows as per on the previous page.

2. Depress the ‘+’ twice or until the display shows ‘OPTIONS’ and then depress the ‘Select’ button.

3. Depress the ‘+’ or ‘-’ buttons until the display shows ‘FLOW RATE...’ and then depress the ‘Select’ button.

4. Use the ‘+’ or ‘-’ buttons to set your desired ow rate (in LPH or GPH depending on the UNITS selected

previously), and then depress the ‘Select’ button.

5. From here you can either depress the ‘Back’ button until the display shows as per to start the controller or

you can go on to set other parameters such as ‘UNITS’; PUMP SIZE’ or ‘MODE SELECT’.

7

8

1

1

SIAT75001 SiA Smart Controller

Revision: TH1

12

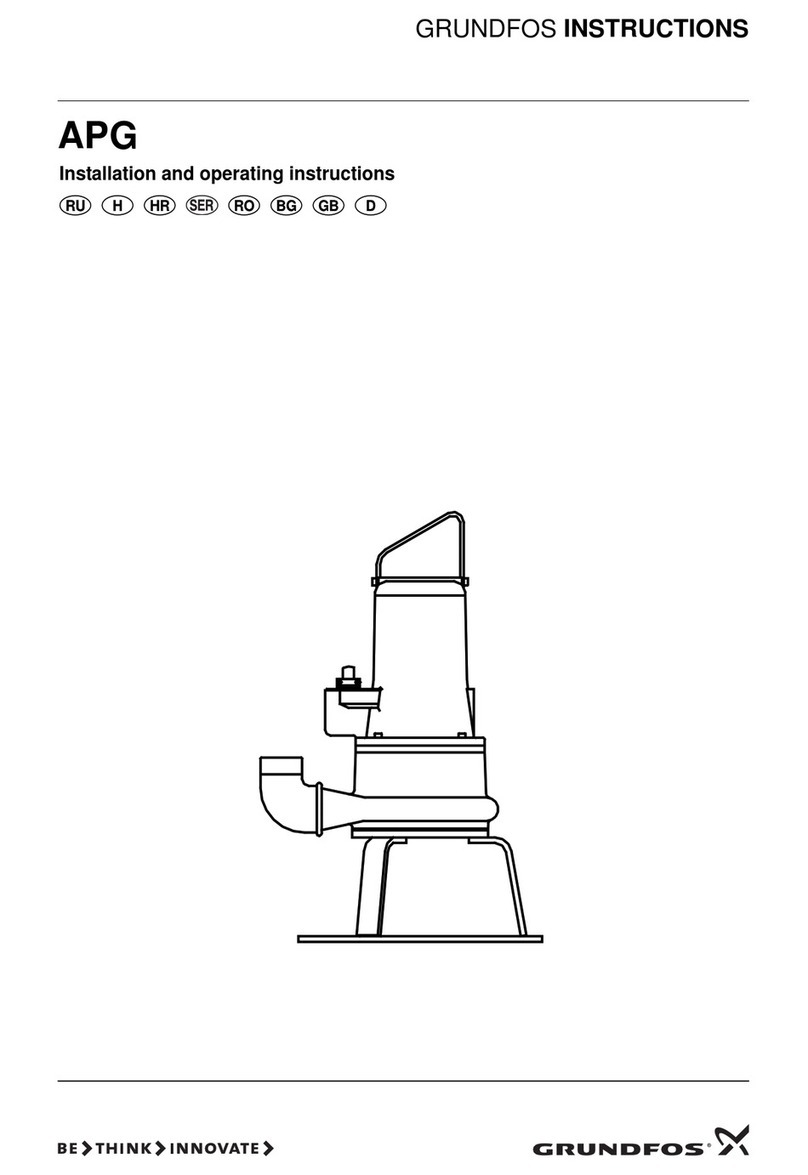

Stop Timer

Depress the ‘+’ button

until you cycle to the ‘Stop

Timer’ screen and then press

‘Select’.

Alternate option for stopping the Timer:

1. Cycle to the ‘Kill Timer’ screen by pressing the ‘+’ button and then press ‘Select’ to initiate the operation

command. This will stop the Controller instantly, turning the pump off if it was on.

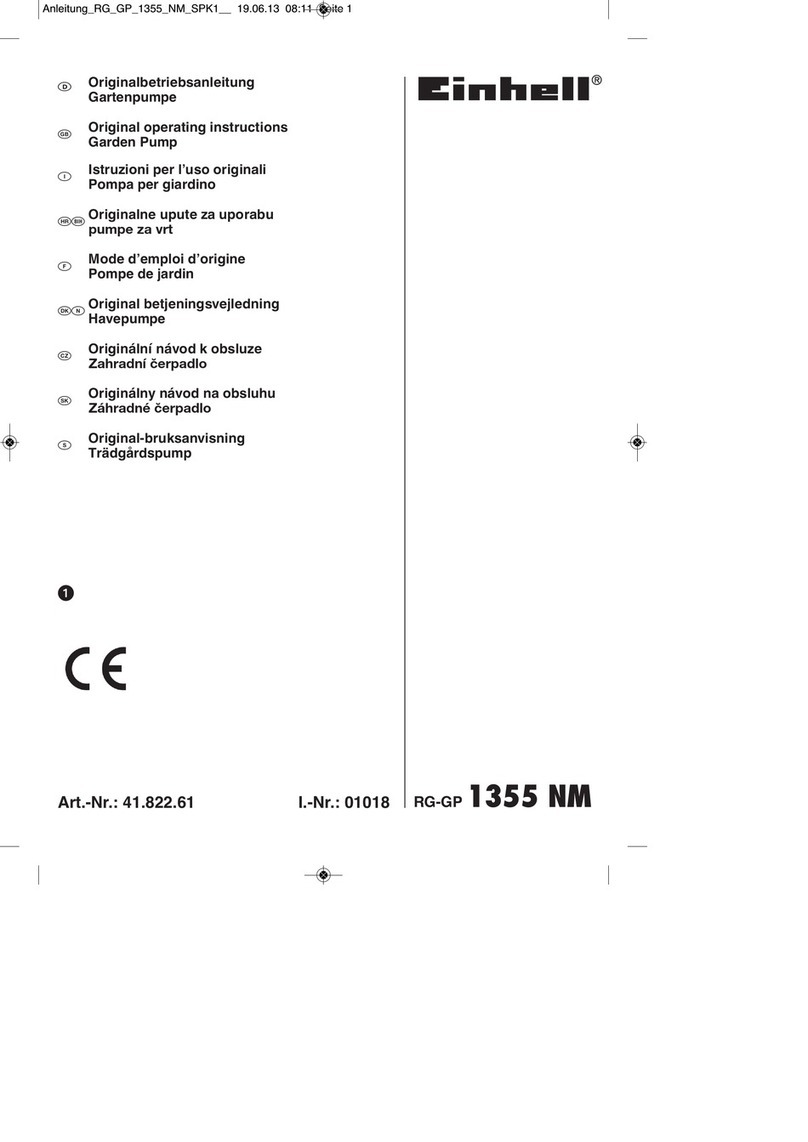

OPERATION (cont.)

1Power On

LCD DISPLAY

When rotating, indicates

Controller is running.

Clock

Indictaes operation

Start Timer

Depress ‘Select’ button to

quick start Controller from

this screen.

Battery Status Voltage

Full - normal state

Half - low power state

Empty - power cut state

Note: This will stop the Controller at the next ‘Pump Off’ state ie if the pump is running when you are pressing

the ‘Select’ button, it will continue until the pump is in an “off’ state.

2

3

SIAT75001 SiA Smart Controller

Revision: TH1

13

3.1 Chemical Injection Flow Rate Adjustment

There are two ways of adjusting the injection ow rate, 1) electronic variable ow and 2) stroke

length adjustment .

The two methods can be used together to nely tune the ow rate.

Depending on the type of electric motor selected, two types of electric variable ow control can

be achieved. The cycles per minute (cpm) can be altered from maximum by either slowing the

electric motor with an electronic variable speed control device or preferably by using a Cycle Timer

to ‘start’, ‘stop’ and vary the ‘stop’ time of the electric motor. We recommend using a cycle timer

as it is simpler, more cost effective, robust, capable of operating at more extreme ambients and

has been found to use less energy per volume of chemical injected.

Solar Injection Australia manufactures a range of DC Timers, please contact us or an SiA Distributor

for details.

3.11 Electronic Variable Flow Adjustment

All drives, except those with a Duplex Liquid End conguration (ie 2 liquid ends on the 1 drive),

are tted with a mechanical stroke length adjustor that allows the operator to adjust the length

of the stroke and therefore the output per cycle innitely between 0% and 100% while the pump

is running.

Simply twist the adjustor until the desired ow is achieved. The lock nut provided will hold the

chosen setting.

An optional micrometer stroke adjustor is available on request.

3.12 Stroke Length Adjustment

Manual Stroke

Length Adjustor

Lock Nut

14

SECTION 2 MAINTENANCE

4.0 Routine Maintenance: Drive Assembly

Providing the Drive Assembly is selected and installed correctly, the Drive should perform for a

long period of time with little or no routine maintenance. We recommend however, that checks

are made at least every 6 months. The only wearing parts of the Drive are the Bearings and the

Plunger Adaptors.

4.01 Bearings

Inspection of the bearings should take place regularly. If operating in clean and dry conditions we

recommend 6 monthly inspections of moving parts. If operating in wet and/or dirty conditions,

we recommend more frequent inspections, starting with monthly inspections until the operator is

comfortable with longer service intervals.

To inspect bearings, follow these steps (refer to ILLUSTRATION & PARTS LIST, Page 2):

1. For Simplex pumps, ensure the Liquid End is facing downwards, so that no liquid runs into the

Drive Case.

2. For all pump congurations unscrew the Pump Connection Ring by hand to loosen and remove

the Liquid End/s.

3. Remove the Gearmotor or Gearbox by removing the 4 long screws attaching it to the Drive

Case

4. Unscrew the Bearing End Plate by removing the 4 screws

5. Remove the Crank Shaft and Bearings and inspect. You may need to move the Plunger Adaptor/s

to enable you to do this.

WARNING: Should the bearings become worn in any way they should be replaced

immediately with new parts available from Solar Injection Australia or SiA Distributors.

6. Place the Crank Shaft and Bearings (or replacement Bearings) into the Drive Case

7. Place the Bearing End Plate back on the Drive Case and secure with the 4 screws

8. Reattach the Liquid End/s and tighten the Pump Connection Ring/s. You may need to carefully

push down and hold the Plunger into the Liquid End to enable you to do this.

9. Position the Gearmotor or Gearbox back on the Drive Case and secure with the 4 screws.

All three Precision Roller Bearings are sealed type and do not require in-eld lubrication. They

have been selected using design loads far in excess of the loads that should be generated by the

design limitations of the product. Providing no moisture or dirt penetrates and that the Drive is

used in accordance with its design parameters a long life can be expected.

We have both Ertalyte and stainless steel versions of our Plunger Adaptors. No grease is applied

on assembly and providing abrasive dirt does not come between the Cam Bearing and the Plunger

Adaptor, negligible wear should take place through millions of cycles. If replacing Plunger Adaptor/s,

ensure you replace like for like as Ertalyte and stainless steel versions are not interchangeable.

To inspect Plunger Adaptor/s follow the steps outlined above for inspecting Bearings. After step 5,

remove and inspect Plunger Adaptor/s and then replace and continue to follow steps 6—9.

4.02 Plunger Adaptors

15

4.1 Routine Maintenance: SiA Liquid Ends

The maintenance of any Chemical Injection Pump (CIP)/Liquid End, other than an SiA unit is not

covered in this document.

WARNING: Solar Injection Australia accepts no responsibility should a Liquid End be tted

to an SiA Drive without rst seeking a recommendation from SiA to ensure correct

matching of the Gearmotor, Drive and Liquid End (pump).

4.10 Pressure Seal Grease

Check main pressure seal grease periodically and rell when necessary. This is done by removing

the Lube Plug on the side of the Liquid End and if required, injecting a small quantity of SiA

approved grease.

CAUTION: If injecting chemicals that cause the lubricant to foam, select an alternative

lubricant compatible with the injected uid. When it is essential that the injected

chemical must have a high level of purity, use distilled water as the lubricant.

4.11 Injection Chemicals

Ensure the chemicals being injected are clean and free of foreign matter to prevent damage to the

seal and the Liquid End’s plunger assembly. We recommend the installation of a suitable chemical

lter.

4.12 Seals

Check the seals regularly. Seal material and chemical compatibility is paramount. Our standard

plunger seal (TS) is a specially formulated PTFE and stainless steel compound that is energized

with a Viton o’ring, which is compatible with most chemicals, however we do have numerous

alternative materials available, please consult Solar Injection Australia or an SiA Distributor for

further assistance with choosing the right seal or when changing the chemicals you are injecting.

To inspect Seals & Back Ups follow these steps (refer to ILLUSTRATION & PARTS LIST,Page 2):

1. For Simplex pumps, ensure the Liquid End is facing downwards, so that no liquid runs into the

Drive Case.

2. For all pump congurations unscrew the Pump Connection Ring by hand to loosen and remove

the Liquid End/s.

3. Carefully remove the Plunger section and place gently on a at surface.

4. Remove the Flange and the Pump Connection Ring

5. Unscrew the three parts of the Pump Body (Upper, Middle, Lower)

6. Very carefully remove the Back Ups and Seals using either the plunger or a brass or plastic pick.

To use the plunger, insert it into the pump body below the seal and push the seal and back up

out. To use the pick, hook the seal and back up carefully and pull them out.

CAUTION: Be very careful not to damage the seal or other surfaces when extracting.

7. Replace the Seals and Back ups and then Follow Steps 1– 5 in reverse to complete.

16

4.2 Routine Maintenance: Gearmotors tted to the Drive

Generally, the gearmotor does not require routine maintenance other than periodic brush

replacement on our Standard DC models. Apart from these brushes there are no service parts

available. Should the DC gearmotor fail (or separately the motor or gearbox), we recommend the

whole DC gearmotor be replaced with a new unit, available from Solar Injection Australia or an

SiA distributor.

We recommend that the brushes be inspected as often as practical until the operator obtains

experience of the expected brush life for each situation, but at least every 6 months.

Note: There are no brushes in a BLDC Motor.

To inspect and or replace brushes on our Standard PMDC Gearmotor models, please follow the

steps below:

1. Disconnect power to pump before any servicing takes place.

2. Use large at blade screwdriver to unthread the plastic caps on either side of the motor.

3. Remove the brushes carefully (they are spring loaded).

4. Examine them. They should be at least 1/8” thick. If they are not, replace them. They will not

last much longer.

5. Replace new brushes into the holes on either side of the motor’s outer shell and rethread the

plastic caps.

6. As with the moving internals of the Drive, the operator can expect longer service intervals and

life by keeping the gearmotor clean and dry.

WARNING: Should the gearmotor show signs of wear in any way it should be replaced

immediately with new parts available from Solar Injection Australia or SiA Distributors.

17

4.3 Corrective Maintenance

Situation Cause Resolution

NO PUMP DISCHARGE • Suction &/or discharge check

valves not seating

• Pump vapour locked

• Suction or discharge line

plugged/blocked

• Clean or replace suction &/or

discharge check valves

• Open bleed plug & prime

• Check for closed isolating valve

• Check inlet and discharge lines for

blockage

PUMP DOES NOT CYCLE • Plunger stuck due to tight or

dry seal

• Process line pressure too high

for unit selected

• Blown fuse

• No power supply to DC motor

drive

• Timer switch in OFF position

• Timer set to minimum cycle

rate

• Check seal, if swollen , check

chemical compatibility and replace

• Check selection and ensure

discharge line is not blocked

• Check and replace fuse in DC

supply. If this condition repeats

itself, check the drive mechanism

for seizure.

• Check and connect correct power

supply

• Set switch to CONTINUOUS for

testing

• Adjust timer accordingly

SHORT SEAL LIFE • Nick, Burr or scratches on

plunger

• Seal &/or plunger materials not

compatible with chemical being

injected

• Lack of lubricant

• Incorrect lubricant or chemical

crystallising on plunger and

scoring seal/plunger

• Replace plunger

• Refer to chemical compatibility

charts or contact Solar Injection

Australia

• Maintain visible lubricant level in

reservoir.

• Change lubricant to be compatible

with chemicals being pumped.

18

APPENDIX: CHEMICAL COMPATIBILITY CHART

Key to Rating: A - Substantial Resistance, B - Moderate Resistance, C - Severe Effect, Blank - No Data

Corrosive Agent Steel 304 SS 316 SS C-20 Teflon PVC Viton Buna-N Fluoraz

Acetaldehyde B A A A A C C B C

Acetate Solvents B A A A A C C C C

AceticAcid,20% B A A A A A C A C

Acetic Acid Concentrated to

l5O°F(66° C)

B A A A C C C

Acetic Acid Concentrated to

2l2°F(100 C )

C B A A A C C C

Acetic Anhydride C B A A A C C A C

Acetone B A A A A C C B C

Alum C C B A A A A A A

Aluminum Chloride C C C B A A A A A

Aluminum Nitrate B A A A A A A

Aluminum Sulfate C C B A A A A A A

Ammonia Anhydrous A A A A A C A A

Ammonium Bicarbonate A A A A A A A C

Ammonium Bisulfite B A A A A A A

Ammonium Bifluoride C B B A A A A

Ammonium Hydroxide C A A A A A B A A

Ammonium Nitrate B A A A A A B C

Ammonium Phosphate C B A A A A A A

Ammonium Sulfate C B B B A A A A C

Ammonium Sulfite C A A A A A A

Amyl Acetate Dry A A A A A C C C C

Amyl Alcohol A A A A A B A A B

Amyl Chloride C B A A A C C C

Aniline Chloride C B A A A B

Aniline Dyes C A A A A C B C

Animal Fats and Oils A A A A A A C A

Aqua Regia C C C C A B C

Ascorbic Acid C A A A A

Barium Chloride C C C B A A A A A

Barium Sulfite B A A A A A A A

Benzaldehyde B A A A A C C C

Benzene A A A A A C B C C

Benzene Sulfonic Acid lO% C B B A A A A C C

Benzoic Acid C B B A A A C A

Benzoyl Chloride C C C C A B

Boric Acid C A A A A A A A A

Bromine Anhydrous C C C B A C A C C

Bromine Dilute C C C C A B A C C

Bromine Trifluoride C C B B A C C

Butadiene C A A A A A C

Butane B A A A A A A A A

Butyric Acid 2O% C A A A A C A A

Butyric Acid, Concentrated C B B B A C A

Calcium Bisulfite B A A A A A A A A

Calcium Carbonate AAAAAAAAA

Calcium Chlorate C A A A A A A A A

Calcium Chloride C B B A A A A A A

Calcium Hydroxide AAAAAAAAA

Calcium Hypochlorite C C C C A A A C A

Calcium Nitrate C A A A A A A

Calcium Sulfite C A A A A A A

Calcium Sulfate A A A A A A C

Camphor Alcohol Sol B A A A A

Carbon Disulfide C A A A A A C

Carbon Tetrachloride Dry B A A A A C C

Carbon Tetrachloride Wet C B B B A C C C

Carbon Water Slurries C B A A A A A A

Cesium, 260°F(127°C) C A A A A C C

Chlorine, Anhydrous A A A A A C C C

Chlorine Water C C C A A A A C C

Chloroacetic Acid C C C C A C C

Chlorobenzene C A A A A C A B

Chloroform B A A A A C A C

Chlorosulfonic Acid C B B B A C C C B

Choline Chloride A A A A

Chromic Acid to l5O°F(66°C) C B B B A C A

Citric Acid C B B A A A A A A

Copper Chloride C C C C A A A A A

Copper Fluoride C B B B A A

19

Corrosive Agent Steel 304 SS 316 SS C-20 Teflon PVC Viton Buna-N Fluoraz

Copper Nitrate C B A A A A A A A

Copper Sulfate B A A A A A A A A

Cottonseed Oil A A A A A A A A

Creosols A A A A A C C C A

Cyclohexane B A A A A C A C A

Cyclohexanone B A A A A C C C B

Dichlorethane, Dry A A A A A C C C

Diethanolamine A A A A A C C A

Diethyl Benzene A A A A A C

Diethyl Ether A A A A A C C

Diethyl Sulfate C B B A A

Diethylene Glycol B A A A A A A A

Dimethyl Amine A A A A A C

Dimethyl Phthalate A A A A A C C B

Ether A A A A A C C C

Ethyl Acetate A A A A A C C C C

Ethyl Alcohol A A A A A A C A

Ethyl Benzene A A A A A A C

Ethyl Bromide C C C C A C

Ethyl Chloride C A A A A C A C A

Ethyl Mercaptan B A A A A C A C

Ethylene(Liquefied) A A A A A

Ethylene Dichioride C A A A A B C A

Ethylene Glycol B A A A A A A A A

Ethylene Oxide C A A A A C C C C

Fatty Acids C A A A A A A A

Ferric Chloride C C C C A A A A A

Ferric Nitrate C B B A A A A A

Ferric Sulfate C C B C A A A A A

Ferrous Chloride C C C C A A A A

Ferrous Sulfate C C C C A A A A

Filter Aid Slurries B AAAAAAA

Fluosilicic Acid C C C B A A A A

Copper Fluoride C B B B A A

Copper Nitrate C B A A A A A A A

Copper Sulfate B A A A A A A A A

Cottonseed Oil A A A A A A A A

Creosols A A A A A C C C A

Cyclohexane B A A A A C A C A

Cyclohexanone B A A A A C C C B

Dichlorethane, Dry A A A A A C C C

Diethanolamine A A A A A C C A

Diethyl Benzene A A A A A C

Diethyl Ether A A A A A C C

Diethyl Sulfate C B B A A

Diethylene Glycol B A A A A A A A

Dimethyl Amine A A A A A C

Dimethyl Phthalate A A A A A C C B

Ether A A A A A C C C

Ethyl Acetate A A A A A C C C C

Ethyl Alcohol A A A A A A C A

Ethyl Benzene A A A A A A C

Ethyl Bromide C C C C A C

Ethyl Chloride C A A A A C A C A

Ethyl Mercaptan B A A A A C A C

Ethylene(Liquefied) A A A A A

Ethylene Dichioride C A A A A B C A

Ethylene Glycol B A A A A A A A A

Ethylene Oxide C A A A A C C C C

Fatty Acids C A A A A A A A

Ferric Chloride C C C C A A A A A

Ferric Nitrate C B B A A A A A

Ferric Sulfate C C B C A A A A A

Ferrous Chloride C C C C A A A A

Ferrous Sulfate C C C C A A A A

Filter Aid Slurries B AAAAAAA

Fluosilicic Acid C C C B A A A A

Formaldehyde,80°F(27°C),Rm.

Temp

B B A A A B A A C

Formic Acid,80°F(27°C) C B A A A B B C A

CHEMICAL COMPATIBILITY CHART (continued)

Key to Rating: A - Substantial Resistance, B - Moderate Resistance, C - Severe Effect, Blank - No Data

Table of contents

Other SIA Water Pump manuals

Popular Water Pump manuals by other brands

EINHELL

EINHELL RG-GP 1355 NM Original operating instructions

Richter

Richter MNK Series Installation and operating manual

Wilo

Wilo CronoLine-IL Installation and operating instructions

Hydro-Force

Hydro-Force V115 manual

Everbilt

Everbilt LTS250A Use and care guide

Grundfos

Grundfos APG Series Installation and operating instructions

Draper

Draper SWP220A Instructions for use

Graf

Graf 202561 Instructions for installation

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 62 1/2A1-CH13 Series Installation, operation, and maintenance manual with parts list

Grundfos

Grundfos SCALA1 Installation and operating instructions

Everbilt

Everbilt UTA02510 quick start guide

Torrent

Torrent AP265 Installation and operating instructions