2 Siemens-Elema AB E382 EH81E 061 01 03 02

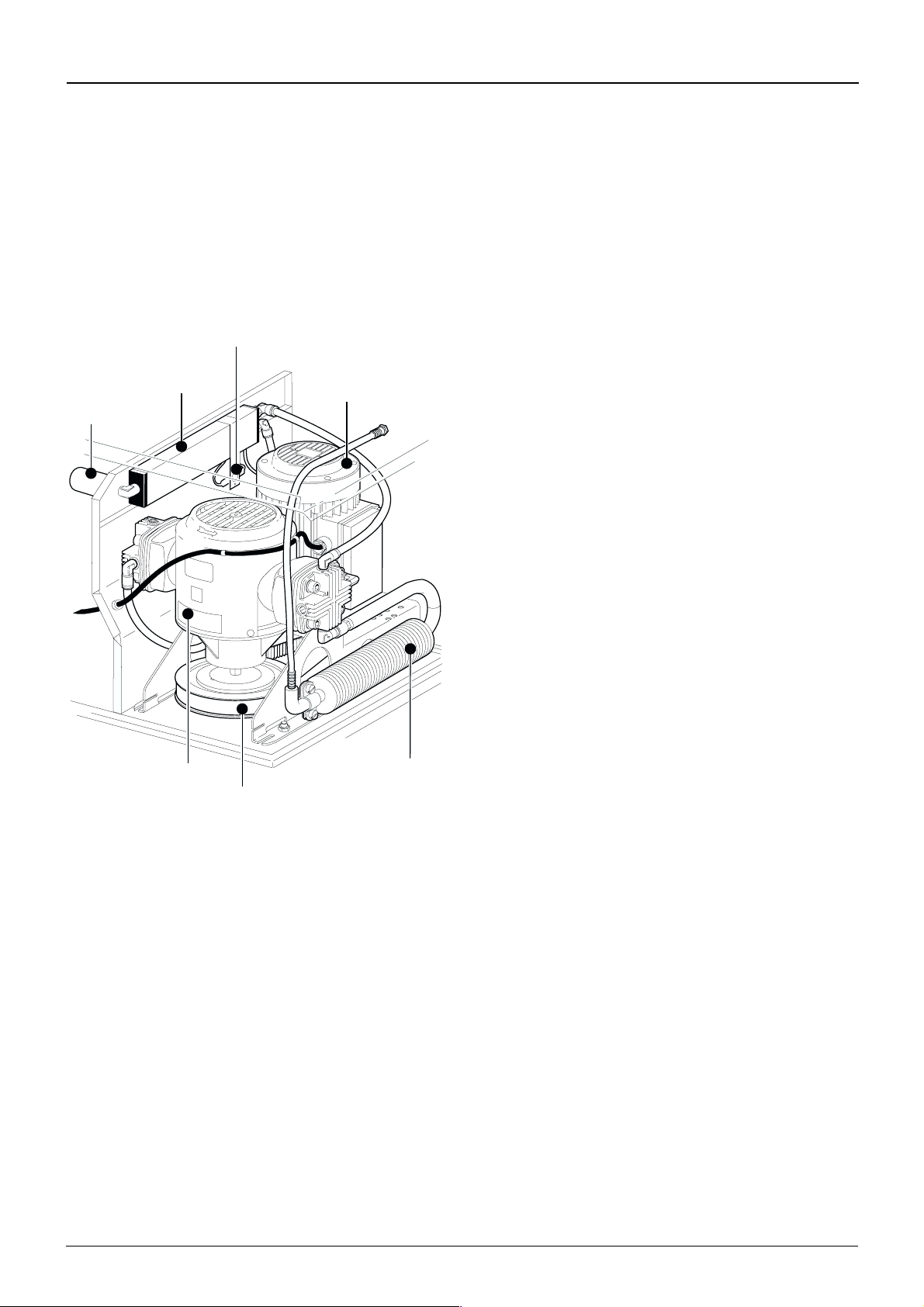

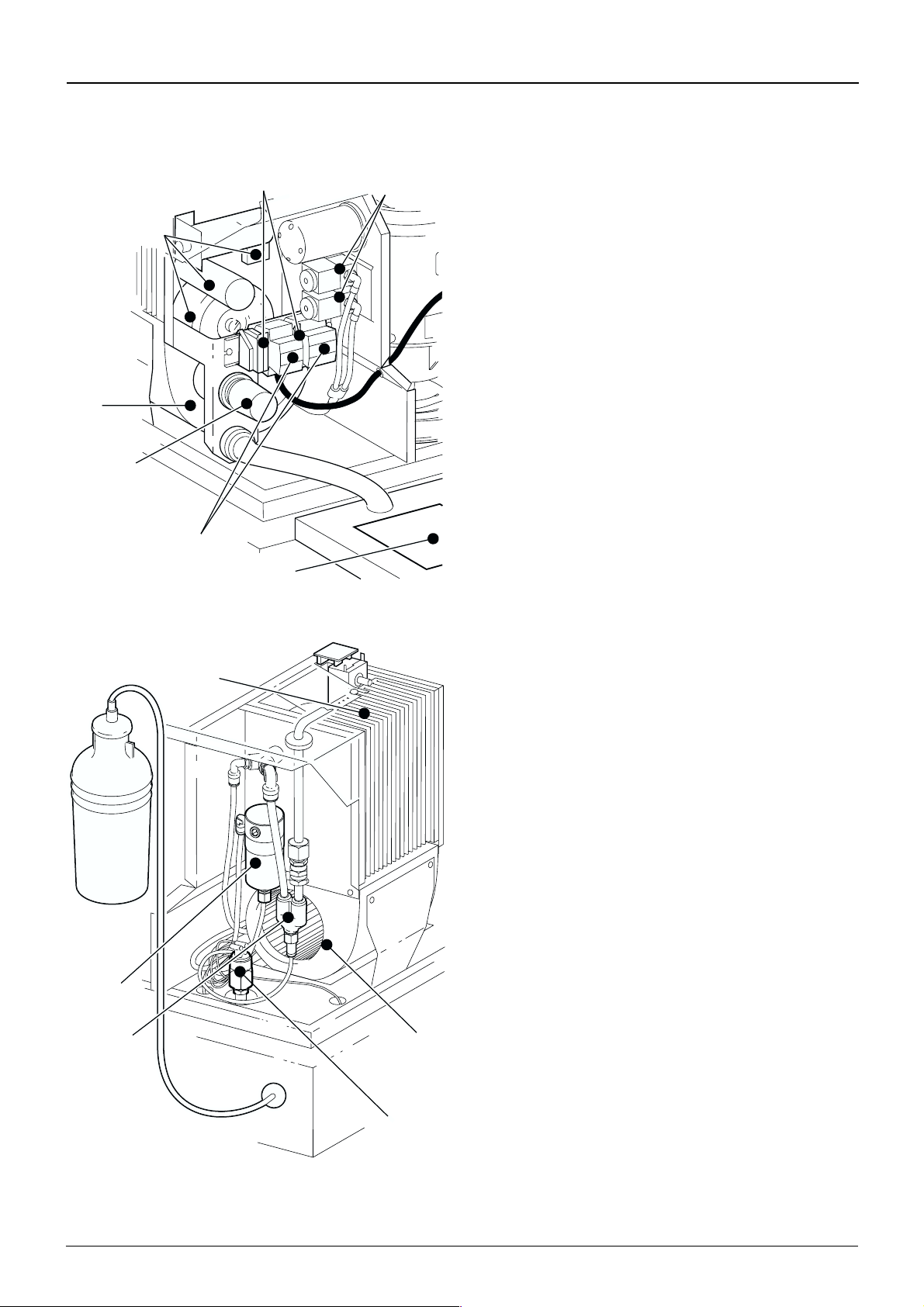

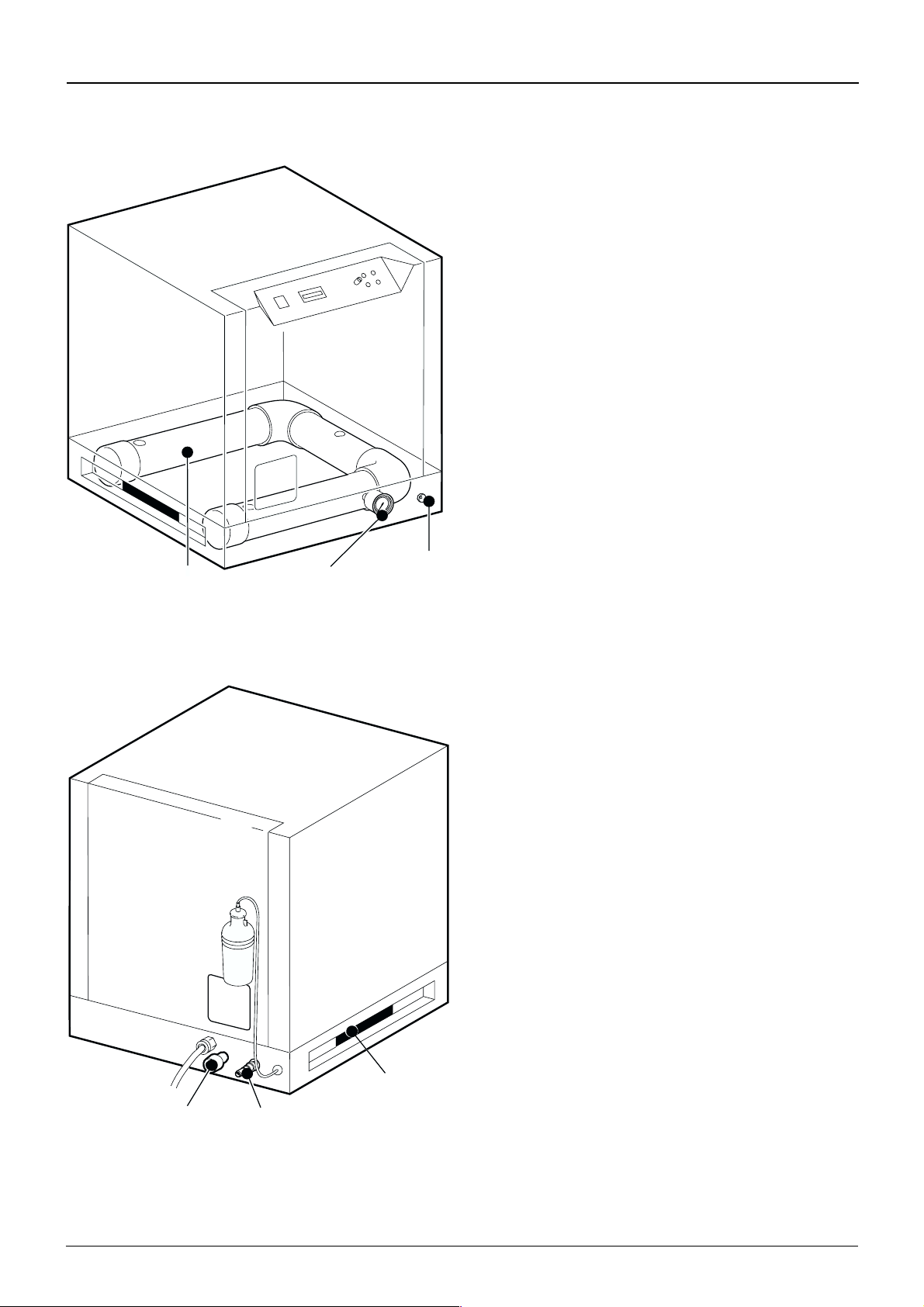

Compressor Compact

Important

Important

General information

The documentation for the Compressor Compact

consists of:

• Operating Manual

• Service Manual

• Spare Parts List

For proper servicing, the Operating Manual and

the Spare Parts List are indispensable

complements to this Service Manual

Data on pressures in the Compressor Compact

are given in Pa (bar):

1 kPa = 10 mbar 1 mbar = 0 1 kPa

1 kPa = 0 01 bar 1 bar = 100 kPa

1 kPa ≈ 10 cm H2O 1 cm H2O ≈ 0 1 kPa

1 kPa ≈ 0 01 at 1 at ≈ 100 kPa

1 kPa ≈ 0 01 kgf/cm21 kgf/cm2 ≈ 100 kPa

1 kPa ≈ 0 01 kp/cm21 kp/cm2 ≈ 100 kPa

1 kPa ≈ 0 145 psi 1 psi ≈ 6 9 kPa

In addition to the Important information given

here, always pay attention to applicable national

regulations

If not stated otherwise in this manual:

• The 100 V/50 Hz, 100 V/60 Hz and 115 V/60 Hz

versions are refered to as the 115 V version

• The 230 V/50 Hz and 240 V/60 Hz versions are

refered to as the 230 V version

Hazard notices

The Compressor Compact operates from mains

power supply With power connected to the unit,

there are energized electrical components as well

as moving mechanical parts inside the equipment

All personnel must exercise extreme caution when

in the vicinity of this equipment if fault tracing or

adjustments are performed with mains power

supply connected and with the compressor cover

or front panel opened or removed

The Compressor Compact generates compressed

air at a pressure of 400 kPa (4 0 bar) Do not

attempt to connect or disconnect the compressed

air line or service the compressor section while

compressed air is being supplied Do not direct

the compressed air line toward the eyes or directly

onto unprotected skin surfaces

Classification

• Class I equipment

• according to IEC 601-1

Type B

Functional check

After any service intervention in the Compressor

Compact, perform a functional check according to

the instructions in the Operating Manual

Service

Your local Siemens representative supplies the

spare parts indicated in the Spare Parts List

When ordering spare parts, please state the serial

number of the unit

The Compressor Compact is oil free, and oil must

not be used when servicing the compressor

The Compressor Compact must be serviced at

regular intervals as follows:

• 2000 hour overhaul when replacing filters as

described in this Service Manual

• 8000 hour overhaul as described in this Service

Manual

To the responsible service personnel

The contents of this document are not binding If

any significant difference between the product and

this documentation is found, please contact your

local Siemens representative for further

information

We reserve the right to modify products without

amending this document or advising the user

We recommend that only Siemens authorized

personnel should be permitted to service or repair

the Compressor Compact, and that only Siemens-

Elema genuine spare parts should be used

Siemens does not otherwise assume responsibility

for the materials used, the work performed, or any

possible consequences of same