3

Building Technologies

A6V10362122_a_en_--

Fire Safety & Security Products 12.2011

Installation

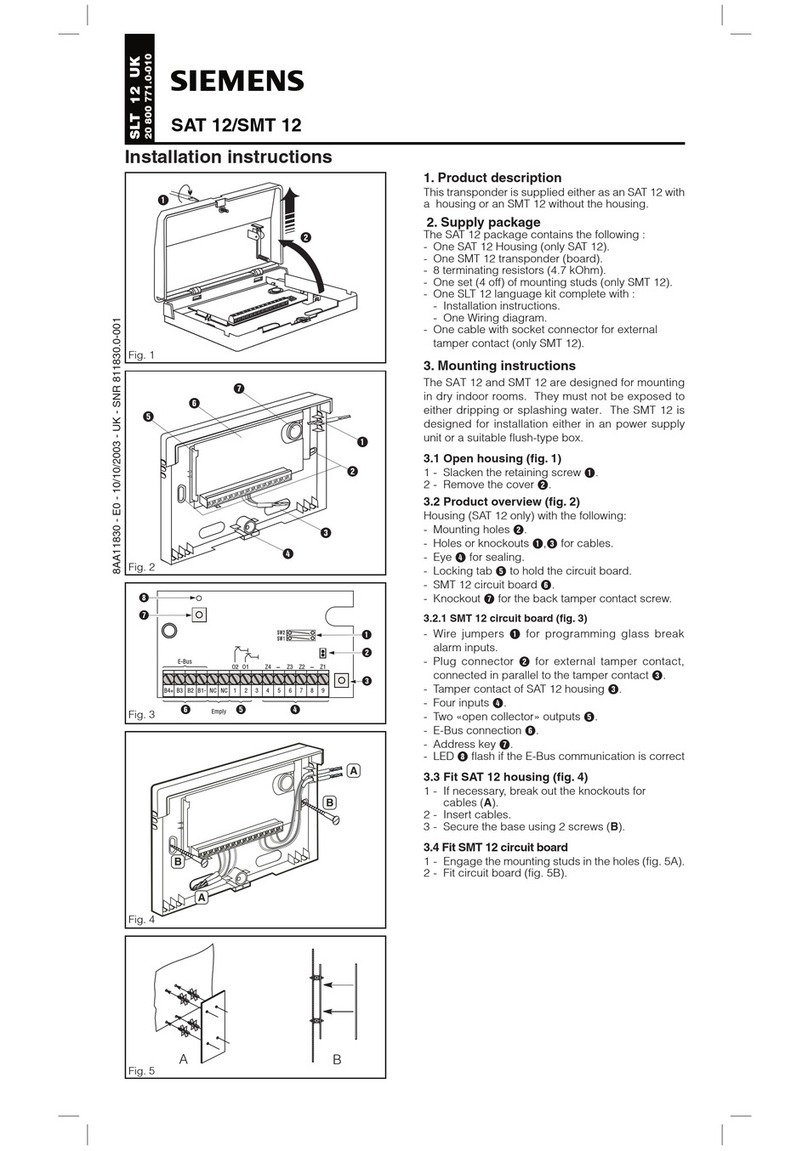

Fig. 2

Fig. 3

Fig. 4

Fig. 8 Detection line connection

Fig. 9 Detector line with safety barrier

(

the earth fault monitoring must be switched off)

Preparation

Voltage!

No power supply during installation.

1. Determine type of installation:

– Installation outside a switching cabinet or a control unit:

use FDCH221 housing (Fig. 3) .

– Installation directly in a switching cabinet or a control

unit: mount the module on an even surface (Fig. 2) .

Procedure with installation on an even surface

1. Put the transponder on an even surface.

2. Fix it with two M4 screws (Fig. 2). Distance between

installation holes:

118.0

±

1.0mm

。

Procedure with installation in the housing

1. Open the housing (Fig. 6).

2.

Determine the cable entries in the housing and break them

out.

3. Mount the housing on an even surface with two M4

(Fig. 4). Distance between holes: 182.0

±

1.0mm.

4. Insert the cables and fix the cables in the housing (Fig. 5).

5. Insert the seal and fix the lid additionally with four screws

(Fig. 6). (only this way is IP65 protection guaranteed)

Electric connection

Input voltage should not be less than 18VDC.

Mind the positive and negative polar when connecting the

diodes.

Connect only

one

wire per terminal.

1. Connect the cables to the terminals according to the

connection diagram (Fig. 7, Fig. 8, Fig. 9).

2. Connect the line terminators (EOL). These must be

connected to the end of the line (Fig. 8 /Fig. 9).

3. Connect the cables to the module with cable ties (max.

width 2.6 mm).

+

I/O

FDCI183

1.5KE20CA