i

mmmmm

Table of Contents

Table of Contents

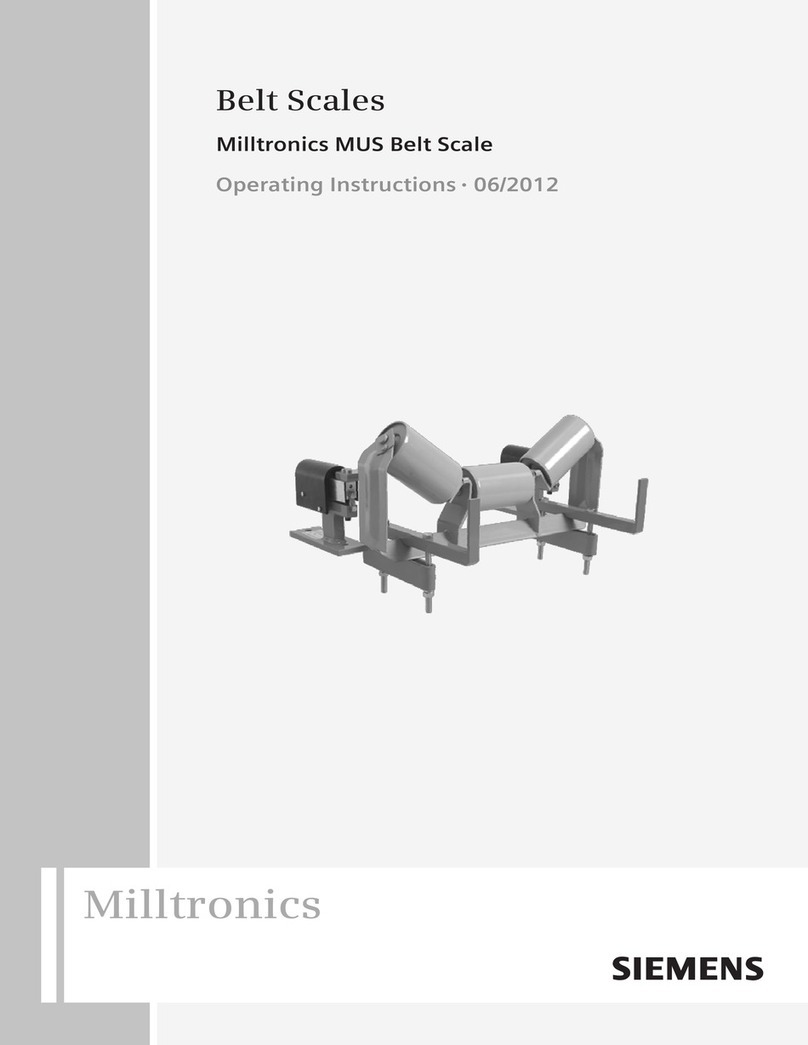

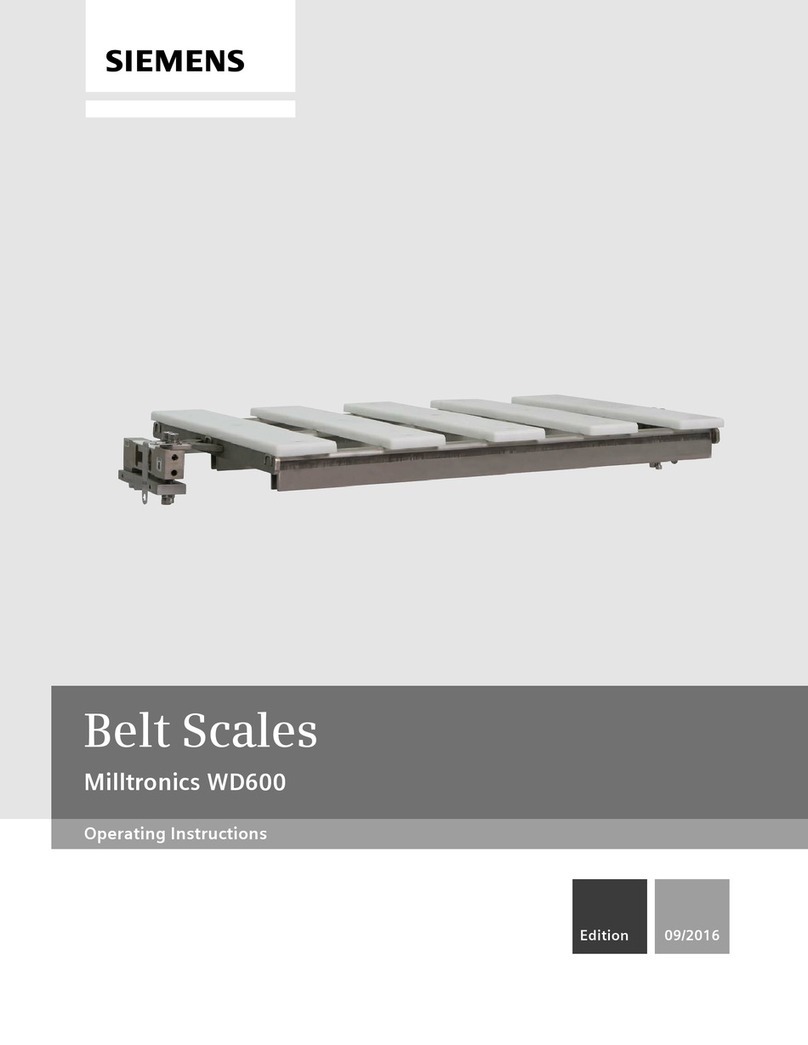

Milltronics MCS Belt Scale ..............................................................................................1

The Manual ...............................................................................................................................................1

Specifications ......................................................................................................................2

Operation ..............................................................................................................................4

Installation ...........................................................................................................................4

Outline Dimensions .................................................................................................................................5

Installation Precautions .........................................................................................................................6

Installation Location ...............................................................................................................................7

Installation Procedure ..........................................................................................................................12

Idler Alignment .......................................................................................................................................14

Wiring ..................................................................................................................................16

Calibration ..........................................................................................................................17

Balancing ................................................................................................................................................17

Test Load .................................................................................................................................................18

Final Calibration .....................................................................................................................................18

Material Test ...........................................................................................................................................19

Maintenance ......................................................................................................................19

Milltronics MCS Bandwaage .........................................................................................21

Die Betriebsanleitung ...........................................................................................................................21

Technische Daten .............................................................................................................22

Betrieb .................................................................................................................................24

Installation .........................................................................................................................24

Abmessungen ........................................................................................................................................25

Sicherheitsvorkehrungen bei der Installation ................................................................................26

Einbauort .................................................................................................................................................27

Vorgehen beim Einbau .........................................................................................................................32

Ausrichtung der Rollenstationen ......................................................................................................34

Anschluss ...........................................................................................................................36

Kalibrierung .......................................................................................................................37

Abgleich ...................................................................................................................................................37

Prüflast .....................................................................................................................................................38

Abschlusskalibrierung .........................................................................................................................38

Materialtest ............................................................................................................................................39

Wartung ..............................................................................................................................39

Báscula de banda transportadora Milltronics MCS ..................................................41

Acerca del manual ................................................................................................................................41