7

material and ashes from the heater and start a new

fire. The fire should be allowed to go out.

DO NOT attempt to remove hot live coals.

Each installation will vary slightly. Therefore, only

with experience can the best firing procedure be

determined.

Opening the Fill Door

Making sure smoke outlet damper is FULL OPEN,

open the door ½ inch for 15 seconds before

opening it completely. This provides a slow

combustion of the accumulated gases above the

fire rather that a sudden burst of flame caused by

the introductions of oxygen. This will also allow

smoke to move out of the heater more completely.

D. Ash Control and Removal

For best results, shake down ashes until live coals

start to fall. Remove the ashes when the fir is low

prior to adding fuel. This should be done daily or

as often as required to avoid ash buildup.

DO NOT allow ashes to build up to the grate level

as this will cause intense heat on the grate and

cause it to warp and have a short life. Inspect the

area around the ash pan and clean out as required.

For disposal of ashes, places ashes in metal

container with a tight fitting lid. The closed

container of ashes should be placed on an

incombustible floor or on the ground, well away

from all combustible materials, pending final

disposal. If ashes are disposed of by burial in the

soil or otherwise locally dispersed, they should be

retained in the closed container until all cinders

have thoroughly cooled.

DO NOT USE A PAPER BAG OR BOX.

E. Creosote & Soot Formation and Removal

When coal is burned, products of combustion

combine with moisture to form a soot residue

which accumulates on the flue lining. When

ignited, this soot makes an extremely hot fire.

When wood is burned slowly, it produces tar and

other organic vapors which combine with expelled

moisture to form creosote. The creosote vapors

condense in the relatively cool chimney flue of a

slow burning fire. As a result, creosote residue

accumulates on the flue lining, the connector pipe

and within the heater. When ignited, this creosote

makes an extremely hot fire.

If this happens, the fire department should be

called immediately. Extinguish the fire in the heater

by dumping a large quantity of coarse salt on the

fire, or by using a dry powder to keep air from

entering the chimney. If possible, do not use water

to extinguish a chimney fire because it could

damage the flue liner. If there is a major creosote

problem, have the chimney, stove pipe and heater

cleaned and inspected before firing the heater

again.

In addition to being a fire hazard, the presence of

creosote will affect the performance by reducing

the draft. This may cause smoking from the fill

door or cause the inability to hold a fire.

The chimney connector and chimney should be

inspected at least once every two months during

the heating season to determine if a soot buildup

has occurred.

To reduce Creosote Problem:

1. Use dry wood.

2. Burn a hot fire for approximately 30 minutes

daily.

3. Keep stack temperature above 250 degrees

Fahrenheit. Below 250 degrees Fahrenheit

produces black liquid creosote.

4. Rather than burn the heater extensively at a

low setting during the mild temperatures of 50

degrees and above, build a small hot fire for a

short period of time.

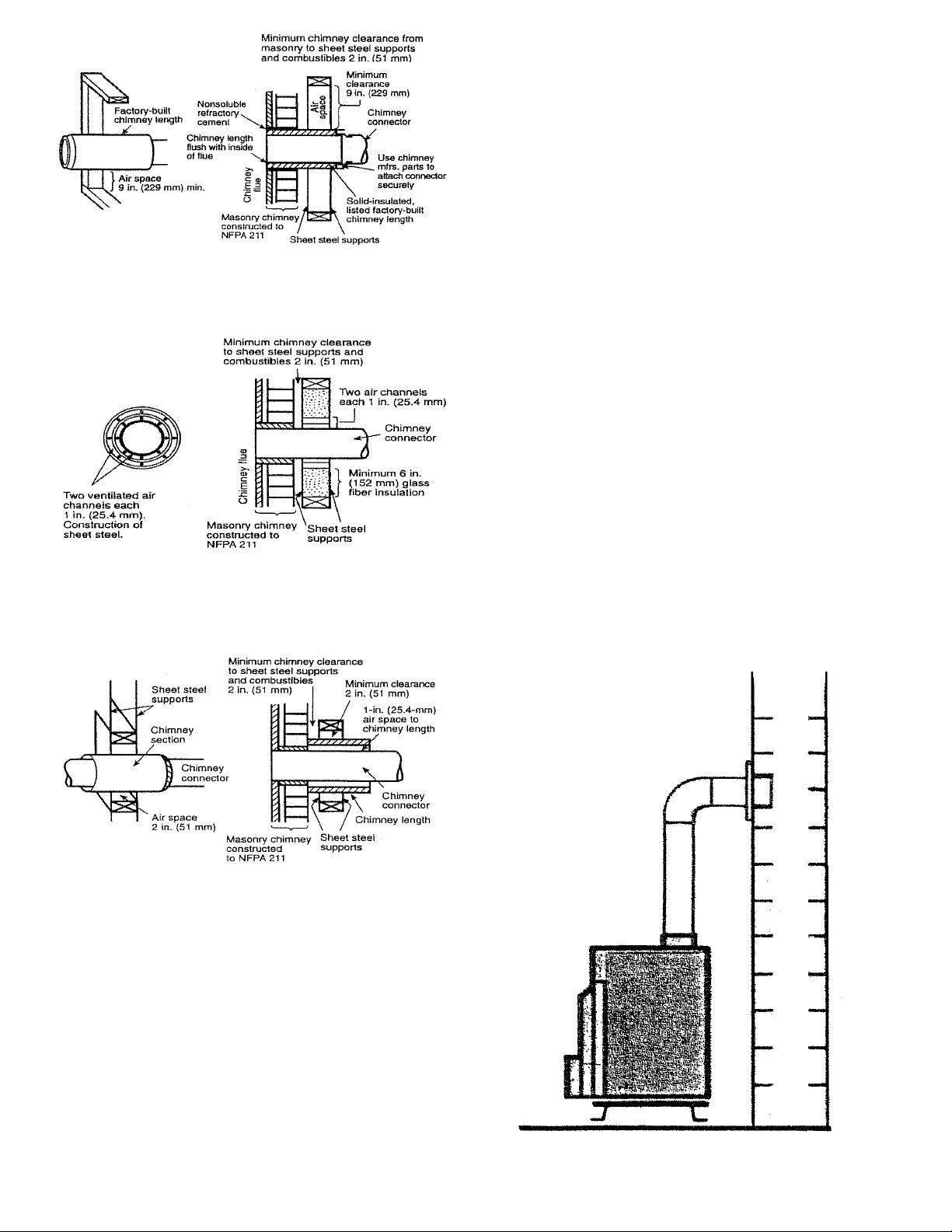

5. Install the heater with the connector pipes as

short as possible.

Chimney inspection and cleaning

The chimney and heater should be inspected for

creosote buildup every two weeks during the

heating season. Creosote is recognizable as a

black oily or flaky deposit on the walls of the

heater and flue. If creosote has accumulated, it

should be removed to reduce the risk of a chimney

fire.

PERFORMANCE TIPS

A. If your heater SMOKES, has LOW HEAT

OUTPUT, or CANNOT MAINTAIN A FIRE, review

the following:

1. The chimney draft must be at least .04" W.C.

with .06" W.C. the recommended draft.

2. Clean creosote deposits from the chimney and

connector pipe.

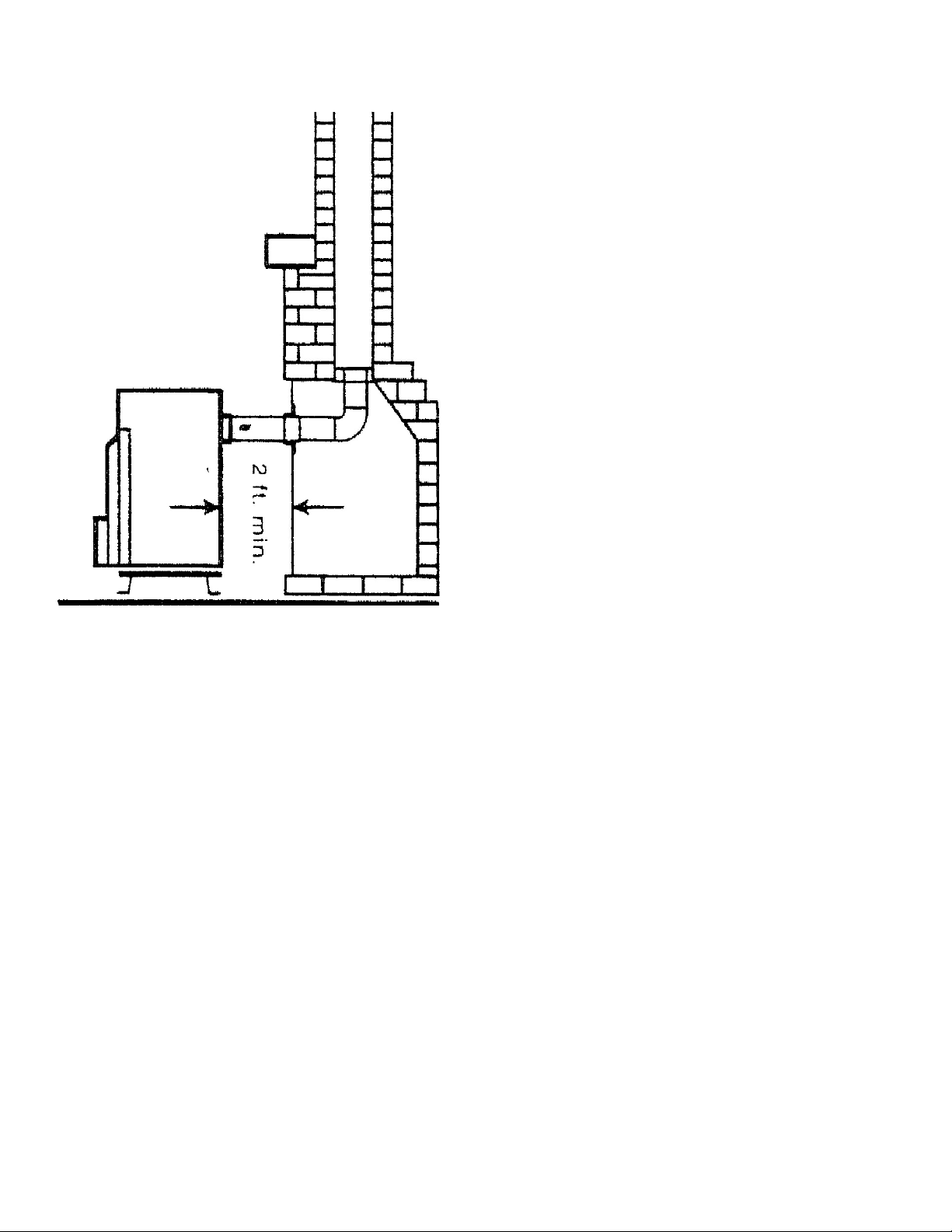

3. The connector pipe from the heater to the

chimney may be too long. Reposition the

heater, if possible, for minimum clearances.

4. Do not have more than two 90 degree elbows

in the connector pipe.

5. Horizontal connector pipe must have 1/4" rise

per linear foot.

6. Use a chimney cap to reduce down drafts in

the chimney.

7. More than one heating appliance connected to

the same chimney flue can affect the draft.

8. Ash clean out at the chimney base must be

sealed with the door closed tightly.

9. Remove tree limbs that are too close to

chimney.

10. The chimney height may not be adequate for

proper draft. Increase height if necessary.

11. Burn small hot fires instead of heavily loaded

smoldering fires in mild weather.

12. Sufficient combustion air may not be available

to the heater. This can occur in some newly

constructed highly insulated “light” houses.

Open a window I the room in which the heater

is located., If this helps, then outside air must

be piped to the damper area of the heater.

Consult your dealer for assistance.

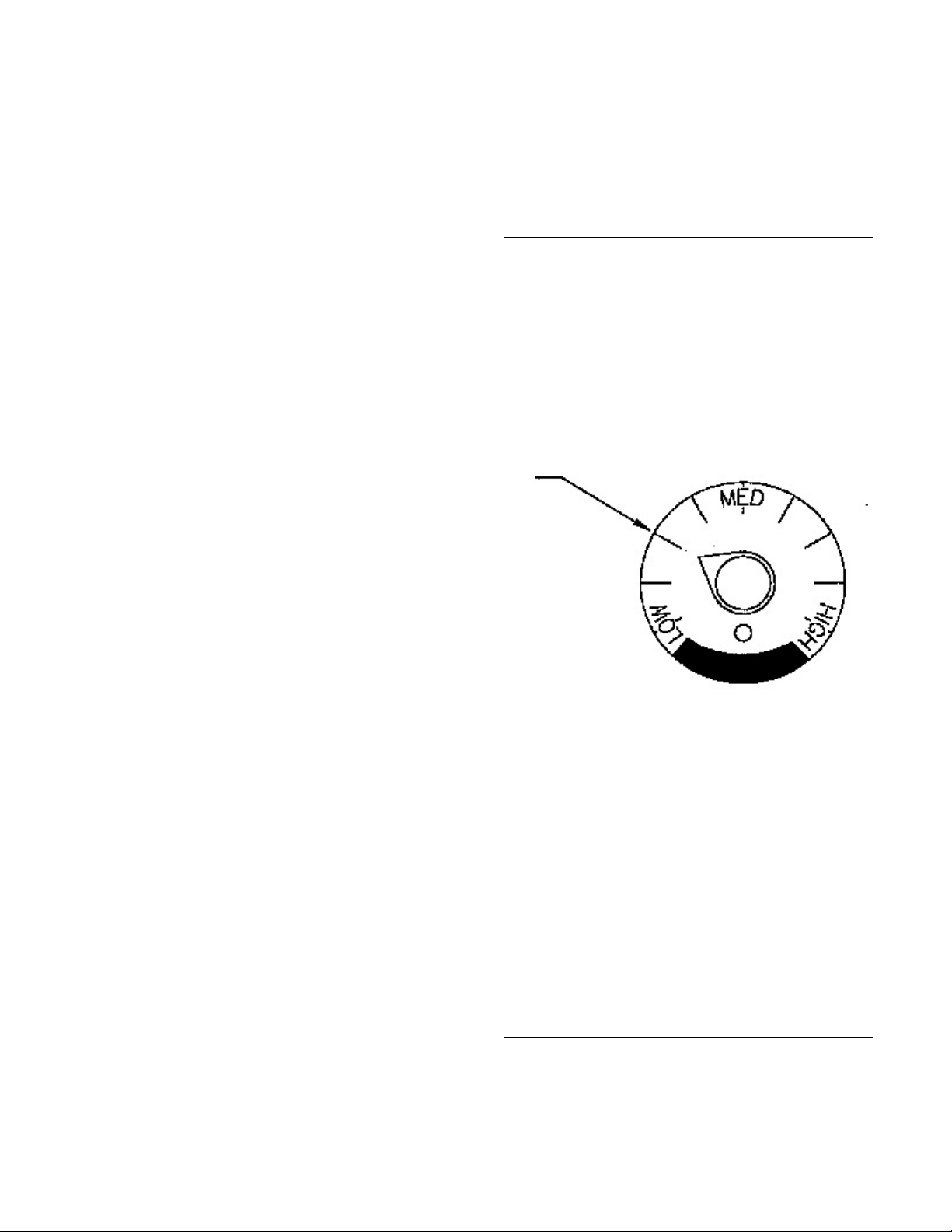

B. Fire Burns Too Hot or Too Fast

1. Check door gasket for proper seal.

2. Be sure knob is set to LOW setting.

3. Check combustion air damper. Be sure it is not

sticking open. (See section B under Operating

instructions)

4. For wood burning, allow ashes to build up on

grate.

5. Check chimney draft - .07" W.C. maximum.

6. High winds or prevailing winds may cause

excessive draft.

7. Install a barometric damper in pipe to reduce

drat.

8. Contact dealer for assistance.

C. Coal Fire Goes Out

1. Check chimney draft. Should be no less than

.04" W.C. but .06" is recommended.

2. Shake down ashes more frequently.