RECEIVING AND INSPECTION

Upon receiving the product, check to make sure all

items are accounted for by referencing the Bill of

Lading to ensure all items were received. Inspect

each carton for shipping damage before accepting

delivery. Notify the freight carrier if any damage is

noticed. The carrier will make notification on the

delivery receipt acknowledging any damage to the

product. All damage should be noted on all copies of

the Bill of Lading which is countersigned by the

delivering carrier. A Carrier Inspection Report

should be filled out by the carrier upon arrival

damaged upon arrival, file a claim immediately with

the carrier. Any physical damage to the unit after

acceptance is not the responsibility of Mars Air

Systems.

UNPACKING

Verify that all parts, components and accessories,

and the correct quantities of each have been

received. If any items are missing, report shortages

to Mars Air Systems directly to arrange for obtaining

the missing items. Again, verify quantities received

against those on the Bill of Lading only, as multiple

shipments may be involved.

INSTALLATION

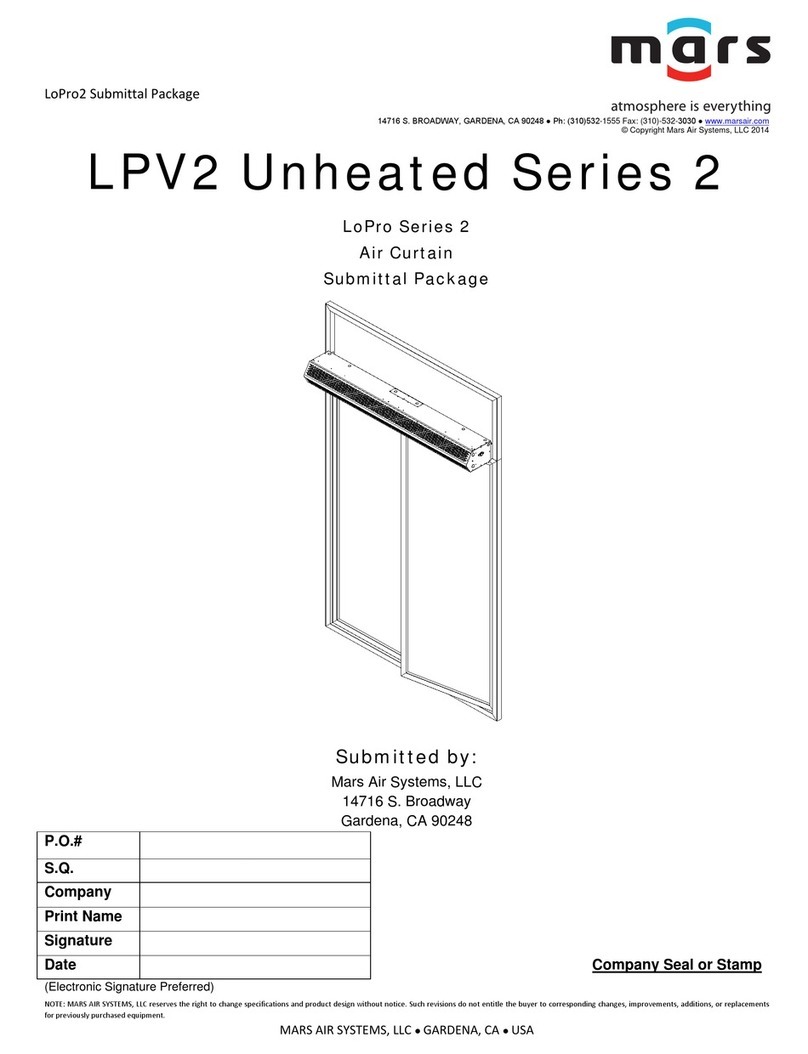

Typical Mounting – Wall or Ceiling Mounted

Horizontally Above the Door Opening

1. Overhead installation is recommended to

prevent the possibility of the unit falling if the wall

to which the unit is mounted is hit by a truck or

material handling device. If, however, wall or

bracket mounting is preferred, additional holes

may be drilled in the side panels of the housing.

Note: Bracket/Support mounting is not generally

recommended for Air Curtains equipped with

steam or hot water coils. Overhead installation

using threaded rods with independent

suspension of coils is recommended.

2. Center the unit over the opening. The air curtain

shall be equal to or greater than the width of the

opening.

3. Four pre-punched 1/2” mounting holes on the top

of the unit are provided for your convenience.

These holes must be utilized to secure the

product overhead. All hardware is field provided

by others.

4. Mount the product such that the discharge is 1”

above the opening and all obstacles. (FIG. 1)

Note: If the product is installed higher than the

recommended 1” above the opening, then it

must be moved 3/8” away from the wall for every

1” that it is moved up. Any void between the wall

and the product must be sealed, by others, to

optimize performance.

FIG. 1

5. Use four (4) threaded rods for overhead

installation or four (4) threaded bolts for wall

installation. All hardware is field provided by

others. (FIG. 1)

6. If applicable, for tandem installation or products

mounted side by side, allow no more than 6”

between the two products. For overhead

installation using threaded rods, the products

may require a beam, by others, to span the full

distance of the mounting length. (Reference

Accessory Installation Supplement)

7. All wires must be connected to the external

junction box(s) of the unit.

8. The unit must be wired per NEC and local codes.

Electrical Field Wiring

The unit and any optional accessories must be wired

with the proper voltage to the junction box per the

wiring diagram. (FIG. 2, unheated products only)

Precaution should be taken in explosive atmospheres.