6

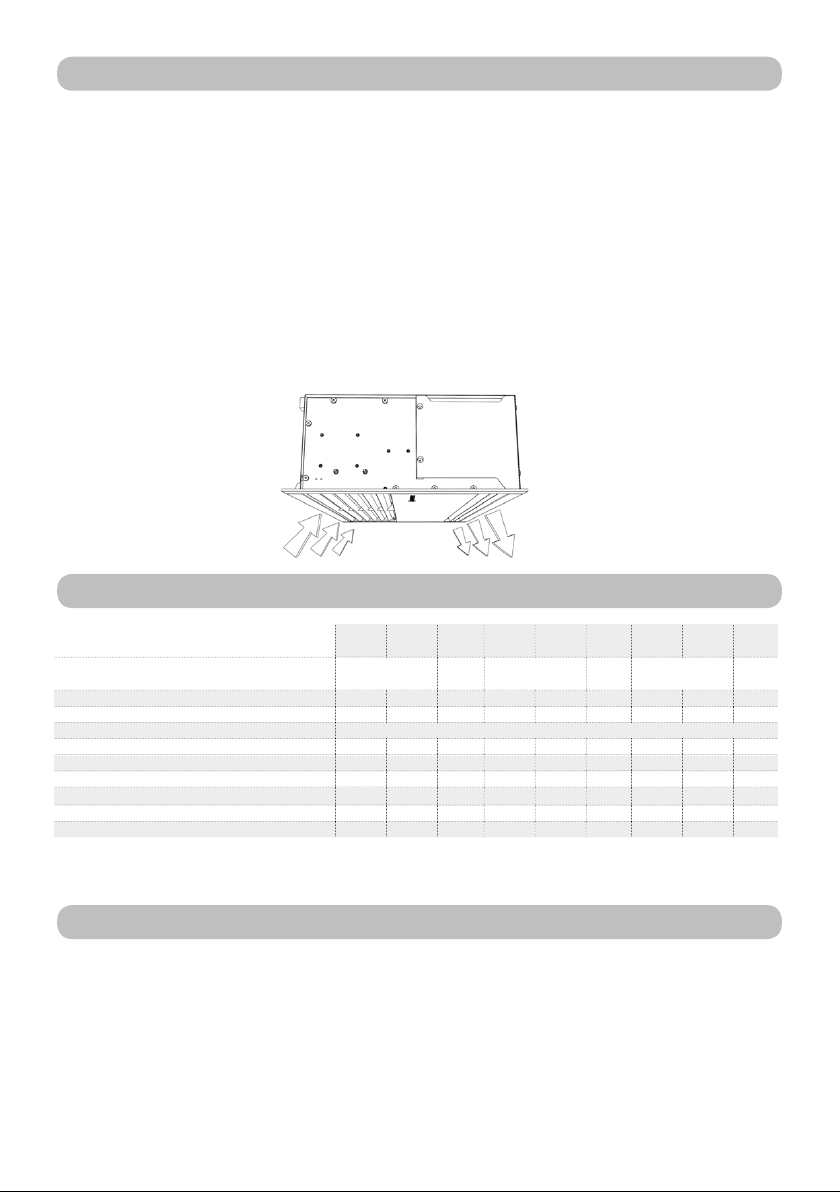

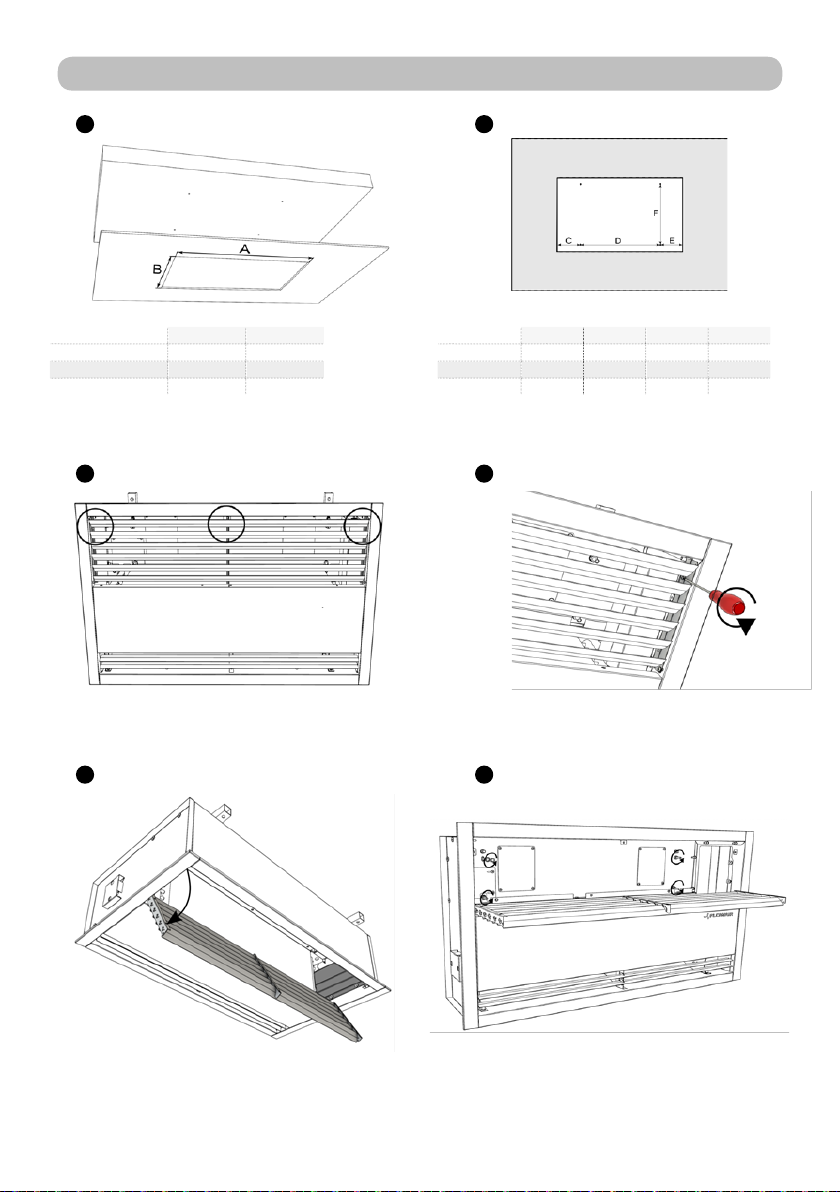

3.2. SOLANO CEILING-W-150

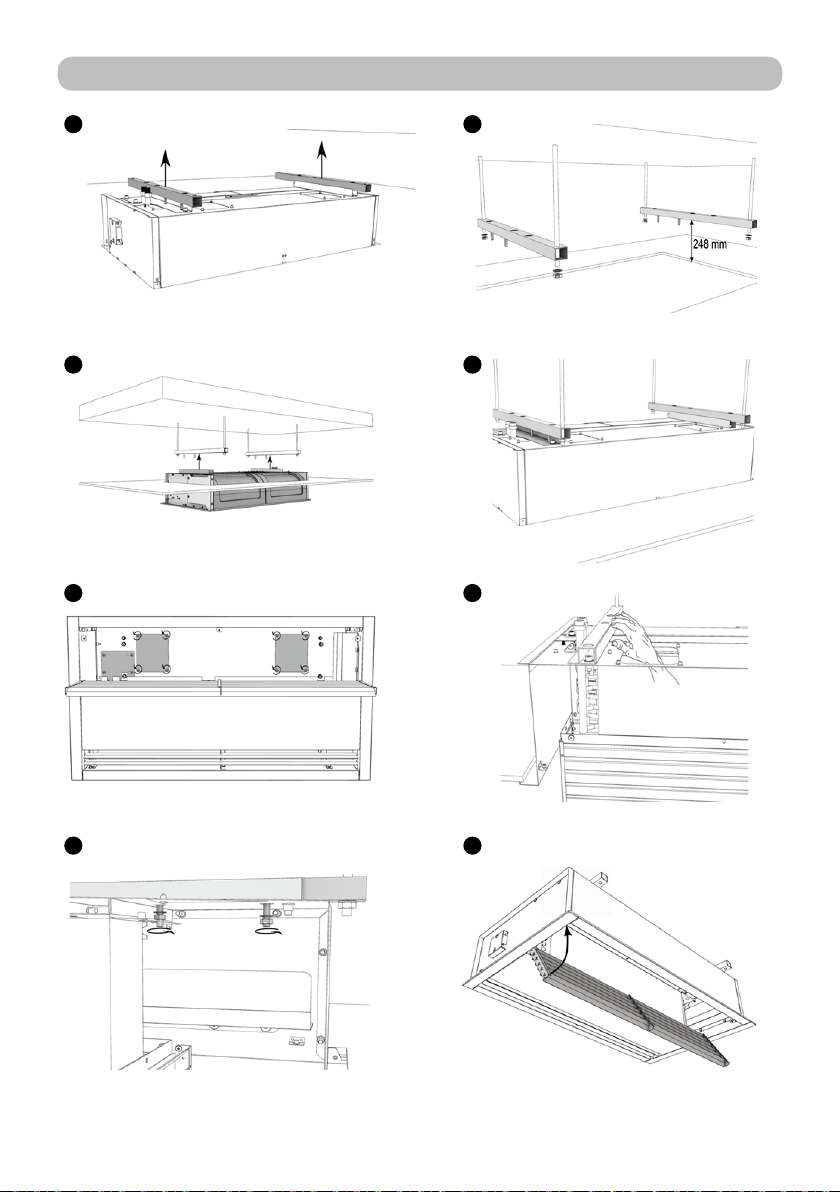

3.3. SOLANO CEILING-W-200

PT Qw ∆pw Tp2 PT Qw ∆pw Tp2

Tp1 V kW I / h kPa °C kW I / h kPa °C

°C m3/h Tw1 / Tw2 = 90/70oC Tw1 / Tw2 = 80/60oC

0

3200/3500/4000

20,9/21,9/23,5 923/968/1039 5,9/6,5/7,4 19,6/18,5/17,5 17,8/18,7/20,0 783/821/881 4,5/4,9/5,6 16,5/16,0/15,0

519,6/20,5/22,0 863/905/972 5,3/5,6/6,6 23,0/22,5/21,5 16,4/17,3/18,5 722/758/813 3,9/4,3/4,9 20,0/19,5/18,5

10 18,2/19,1/20,5 803/842/904 4,6/5,0/5,7 27,0/26,0/25,0 15,0/15,8/17,0 662/694/745 3,3/3,6/4,1 24,0/23,0/22,5

15 16,8/17,6/19,0 742/779/835 4,0/4,4/5,0 30,5/30,0/30,0 13,7/14,3/15,4 601/630/676 2,8/3,0/3,5 27,5/27,0/26,5

20 15,5/16,2/17,4 682/715/767 3,4/3,7/4,2 34,0/33,5/32,5 12,3/12,9/13,8 539/566/607 2,3/2,5/2,8 31,0/30,5/30,0

Tw1 / Tw2 = 70/50oC Tw1 / Tw2 = 70/40oC

0

3200/3500/4000

14,7/15,4/16,5 642/674/723 3,3/3,6/4,0 13,5/13,0/12,5 11,5/12,1/13,0 335/352/378 1,0/1,1/1,3 10,5/10,0/9,6

513,3/13,9/15,0 581/610/655 2,7/3,0/3,4 17,5/16,5/16,0 10,1/10,5/11,3 293/307/330 0,8/0,9/1,0 14,5/14,0/13,5

10 11,9/12,5/13,4 520/546/585 2,2/2,4/2,8 21,0/20,5/20,0 8,6/9,0/9,7 249/262/281 0,6/0,7/0,8 18,0/17,5/17,0

15 10,5/11,0/11,78 458/481/516 1,8/1,9/2,2 24,5/24,0/23,5 7,0/7,3/7,9 202/213/230 0,4/0,5/0,5 21,5/21,0/20,5

20 9,0/9,5/10,2 395/415/445 1,4/1,5/1,7 28,0/27,5/27,5 5,1/5,4/6,0 147/158/173 0,2/0,3/0,3 24,5/24,5/24,0

Tw1 / Tw2 = 60/40oC Tw1 / Tw2 = 50/40oC

0

3200/3500/4000

11,5/12,0/13,0 500/525/563 2,2/2,4/2,7 10,5/10,0/9,5 11,5/12,0/13,0 1001/1050/1128 7,7/8,4/9,5 10,5/10,0/9,5

510,1/10,5/11,5 438/460/494 1,7/1,9/2,1 14,5/14,0/13,5 10,1/10,6/11,4 878/922/990 6,1/6,6/7,5 14,5/14,0/13,5

10 8,6/9,0/9,7 375/394/423 1,3/1,4/1,6 18,0/17,5/17,0 8,7/9,1/9,8 755/793/851 4,6/5,0/5,7 18,0/17,5/17,0

15 7,1/7,5/8,1 311/327/351 0,9/1,0/1,1 21,5/21,0/21,0 7,3/7,6/8,2 631/662/711 3,3/3,6/4,1 21,5/21,5/21,0

20 5,6/5,9/6,3 243/256/276 0,6/0,7/0,7 25,0/24,5/24,5 5,8/6,1/6,5 505/530/568 2,2/2,4/2,8 25,5/25,0/24,5

PT Qw ∆pw Tp2 PT Qw ∆pw Tp2

Tp1 V kW I / h kPa °C kW I / h kPa °C

°C m3/h Tw1 / Tw2 = 90/70oC Tw1 / Tw2 = 80/60oC

0

4000/4300/5200

27,6/28,7/31,8 1217/1266/1402 11,4/12,2/14,7

20,5/19,5/18,0

23,6/24,6/27,7 1038/1080/1195 8,7/9,4/11,3 17,5/17,0/15,5

525,8/26,9/29,7 1140/1186/1312 10,0/10,8/13,0

24,0/23,5/22,0

21,9/22,7/25,2 961/999/1106 7,6/8,2/9,8 21,1/20,5/19,5

10 24,0/25,0/27,7 1063/1105/1223 8,9/9,5/11,5

27,5/27,0/25,7

20,1/20,9/23,1 883/918/1016 6,5/7,0/8,4 25,0/24,5/22,5

15 22,3/23,2/25,7 985/1024/1133 7,7/8,3/10,0

32,5/30,5/29,5

18,3/19,0/21,0 804/836/925 5,5/5,9/7,1 28,5/28,0/27,0

20 20,5/21,4/23,6 907/943/1043 6,6/7,1/8,8

35,0/34,5/33,0

16,5/17,2/19,0 725/754/834 4,6/4,9/5,9 32,0/31,5/30,5

Tw1 / Tw2 = 70/50oC Tw1 / Tw2 = 70/40oC

0

4000/4300/5200

19,7/20,5/22,5 860/894/990 6,4/6,9/8,3

14,5/14,0/13,0

16,1/16,7/18,5 468/487/538 2,2/2,3/2,8 12,0/11,5/10,5

517,9/18,6/20,5 782/813/900 5,4/5,8/6,9

18,0/17,5/17,0

14,3/14,8/16,4 414/431/477 1,8/1,9/2,3 15,5/15,0/14,5

10 16,1/16,7/18,5 703/731/809 4,5/4,7/5,7

21,5/21,5/20,5

12,4/12,9/14,2 360/374/414 1,4/1,5/1,8 19,0/19,0/18,0

15 14,5/14,8/16,4 624/649/717 3,6/3,8/4,6

25,5/25,0/24,5

10,4/10,9/12,0 304/316/350 1,0/1,1/1,3 22,5/22,5/21,5

20 12,4/12,9/14,3 544/565/625 2,8/3,0/3,6

29,0/28,5/28,0

8,4/8,8/9,6 245/256/284 0,7/0,7/0,9 26,0/26,0/25,5

Tw1 / Tw2 = 60/40oC Tw1 / Tw2 = 50/40oC

0

4000/4300/5200

15,6/16,3/18,0 681/708/784 4,6/4,7/5,6

11,5/11,0/10,5

15,3/15,9/17,6 1327/1380/1529 14,8/15,9/19,2 11,5/11,0/10,0

513,8/14,4/15,9 602/626/693 3,5/3,7/4,5

15,0/15,0/14,0

13,5/14,0/15,5 1170/1217/1348 11,8/12,7/15,2 15,0/14,5/13,5

10 12,0/12,5/13,8 522/543/601 2,7/2,9/3,5

18,5/18,5/18,0

11,6/12,1/13,4 1012/1052/1165 9,1/9,7/11,7 18,5/18,5/17,5

15 10,1/10,5/11,6 441/458/507 2,0/2,1/2,6

22,5/22,0/21,5

9,8/10,2/11,3 852/886/981 6,6/7,1/8,6 22,5/22,0/21,5

20 8,2/8,5/9,5 357/372/412 1,4/1,5/1,8

26,0/25,5/25,0

7,9/8,3/9,1 690/718/794 4,6/4,9/5,6 25,5/25,5/25,0

V – air flow

PT – heating capacity

Tp1 – inlet air temperature

Tp2 – outlet air temperature

Tw1 – inlet water temperature

Tw2 – outlet water temperature

Qw – heating water stream

∆pw – water pressure