Siesta AHQ71AV1 User manual

INSTALLATION

MANUAL

IM-5CEY-0711(0)-SIESTA

Part No.: R08019036905

Models

AHQ71AV1

AHQ100AV1

AHQ125AV1

AHQ140AV1

Installation Manual

Split Type Unit

Manuel D’installation

Type d’unité Split

Installationshandbuch

Split Typ Einheit

Installatiehandleiding

Werdelen Drukletter Eenheid

Manual De Instalación

Escisión tipos Unidades

Руководство по установке

Блок Раздельного Типа

Kurulum kılavuzu

Ayrılma Tipi Üniteleri

Εγχειρίδιο Εγκατάστασης

Διαίρεση Τύπος Μονάδα

Manual De Instalação

Split Tipo Unidades

English

Français

Deutsch

Nederlands

Español

Русский

Türkçe

Ελληνικά

Português

1-1

English

Indoor Unit AHQ71AV1

Original Instruction

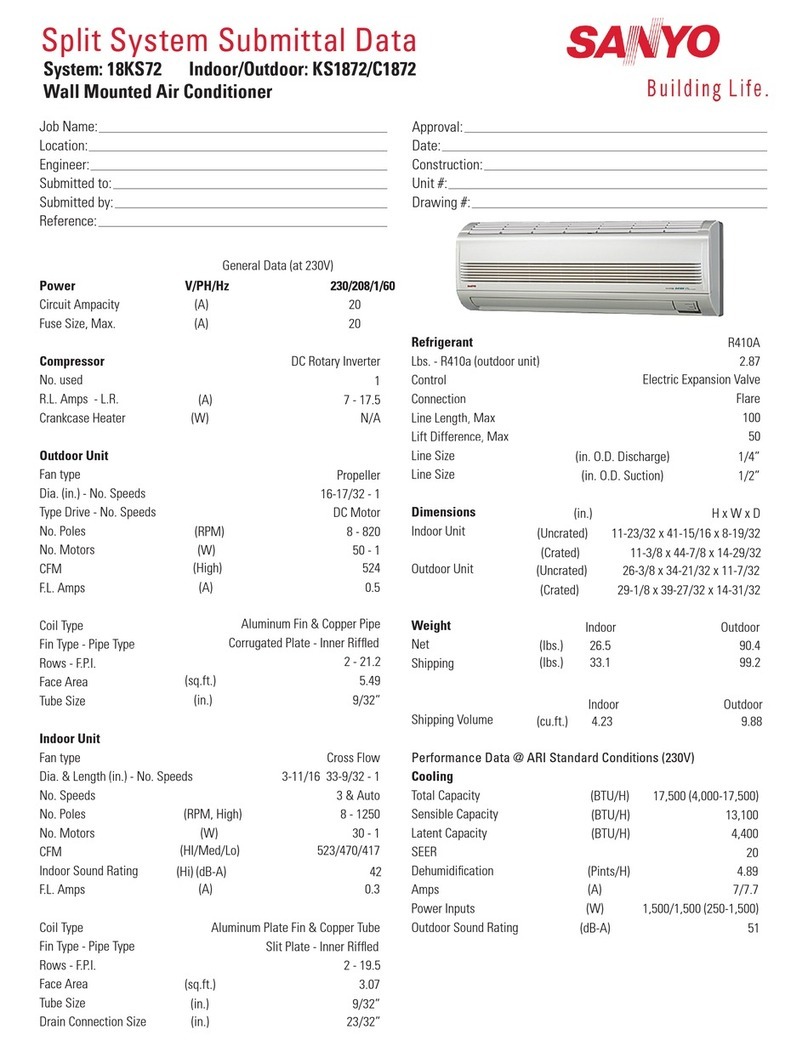

OUTLINE AND DIMENSIONS

All dimensions are in mm

G

B

DE

C

F

A

Dimension

Model A B C D E F G

AHQ71AV1 1080 65 630 400 230 218 928

Indoor Unit AHQ100/125AV1

All dimensions are in mm

A

B

E

C

D

F

G

Dimension

Model A B C D E F G

AHQ100AV1 1490 1308 74 1538 268 635 259

AHQ125AV1 1738 1556 74 1786 268 635 259

1-2

Indoor Unit AHQ140AV1

All dimensions are in mm

Dimension

Model A B C D E F G H I J K L

AHQ140AV1 1750 40 36 1903 1830 680 352 292 285 140 1880 250

D

B

CC

CC

B

A

J

I

G

F

H

L

E

C

K

1-3

English

SAFETY PRECAUTIONS

!WARNING !CAUTION

Installation and maintenance should be performed by qualiÞed

persons who are familiar with local code and regulation, and

experienced with this type of appliance.

All Þeld wiring must be installed in accordance with the national

wiring regulation.

Ensure that the rated voltage of the unit corresponds to that of

the name plate before commencing wiring work according to

the wiring diagram.

The unit must be GROUNDED to prevent possible hazard due

to insulation failure.

All electrical wiring must not touch the refrigerant piping, or

any moving parts of the fan motors.

ConÞrm that the unit has been switched OFF before installing

or servicing the unit.

Disconnect from the main power supply before servicing the

air conditioner unit.

DO NOT pull out the power cord when the power is ON. This

may cause serious electrical shocks which may result in Þre

hazards.

Keep the indoor and outdoor units, power cable and transmission

wiring, at least 1m from TVs and radios, to prevent distorted

pictures and static. {Depending on the type and source of the

electrical waves, static may be heard even when more than 1m

away}.

•

•

•

•

•

•

•

•

•

Please take note of the following important points when installing.

Do not install the unit where leakage of ßammable gas may occur.

If gas leaks and accumulates around the unit, it may cause

Þre ignition.

Ensure that drainage piping is connected properly.

If the drainage piping is not connected properly, it may

cause water leakage which will dampen the furniture.

Do not overcharge the unit.

This unit is factory pre-charged.

Overcharge will cause over-current or damage to the

compressor.

Ensure that the unit’s panel is closed after service or

installation.

Unsecured panels will cause the unit to operate noisily.

Sharp edges and coil surfaces are potential locations which

may cause injury hazards.

Avoid from being in contact with these places.

Before turning off the power supply, set the remote

controller’s ON/OFF switch to the “OFF” position to prevent

the nuisance tripping of the unit. If this is not done, the unit’s

fans will start turning automatically when power resumes, posing

a hazard to service personnel or the user.

Do not operate any heating apparatus too close to the air

conditioner unit. This may cause the plastic panel to melt or

deform as a result of the excessive heat.

Do not install the units at or near doorway.

Do not operate any heating apparatus too close to the air

conditioner unit or use in room where mineral oil, oil vapour

or oil steam exist, this may cause plastic part to melt or

deform as a result of excessive heat or chemical reaction.

When the unit is used in kitchen, keep ßour away from going

into suction of the unit.

This unit is not suitable for factory used where cutting oil

mist or iron powder exist or voltage ßuctuates greatly.

Do not install the units at area like hot spring or oil reÞnery

plant where sulphide gas exists.

Ensure the color of wires of the outdoor unit and the terminal

markings are same to the indoors respectively.

IMPORTANT: DO NOT INSTALL OR USE THE AIR

CONDITIONER UNIT IN A LAUNDRY ROOM.

Don’t use joined and twisted wires for incoming power supply.

Avoid direct contact of any coil treatment cleaners on plastic part. This

may cause plastic part to deform as a result of chemical reaction.

For any enquiries on spare parts please contact your

authorized dealer.

The equipment is not intended for use in a potentially

explosive atmosphere.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

This manual provides the procedures of installation to ensure a safe and good standard of operation for the air conditioner unit.

Special adjustment may be necessary to suit local requirements.

Before using your air conditioner, please read this instruction manual carefully and keep it for future reference.

This appliance is intended to be used by expert or trained users in shops, in light industry and on farms, or for commercial use by lay persons.

This appliance is not intended for use by persons, including children, with reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

INSTALLATION MANUAL

NOTICE

Disposal requirements

Your air conditioning product is marked with this symbol. This means that electrical and electronic products shall not be mixed with unsorted

household waste.

Do not try to dismantle the system yourself: the dismantling of the air conditioning system, treatment of the refrigerant, of oil and of other

parts must be done by a qualiÞed installer in accordance with relevant local and national legislation.

Air conditioners must be treated at a specialized treatment facility for re-use, recycling and recovery. By ensuring this product is disposed

of correctly, you will help to prevent potential negative consequences for the environment and human health. Please contact the installer or

local authority for more information.

Batteries must be removed from the remote controller and disposed of separately in accordance with relevant local and national legislation.

1-4

Air Filters

(Inside Air Intake Grille)

TO OUTDOR UNIT

Wrap the Insulated pipe with the

Þnishing tape from bottom to top

Air Discharge Louver

Air Intake Grille

INSTALLATION DIAGRAM (AHQ71AV1)

Top Panel

Bottom Panel

Figure A

Preliminary Site Survey

Voltage supply ßuctuation must not exceed ±10% of the

rated voltage. Electricity supply lines must be independent

of welding transformers which can cause high supply

ßuctuation.

Ensure that the installation location is convenient for wiring

and piping.

•

•

Standard Mounting

Ensure that the overhead supports are strong enough to hold

the weight of the unit. Position the hanger rods (wall mounting

bracket for ßoor standing), and check for its alignment with

the unit as shown in Figure A. Also, check that the hangers

are secured and the base of the fan coil unit is leveled in both

horizontal directions, taking into account

the gradient for

drainage ßow as recommended in Figure B.

A

BC

H G

E D

F

Figure B

10mm or more

All dimensions are in mm

INSTALLATION OF THE INDOOR UNIT (AHQ71AV1)

Thermal insulation

Dimension

Model A B C D E F G H

AHQ71AV1 1073 534 268 135 336 630 145 485

1-5

English

Please ensure that the following steps are taken:

Unit installation should be tilted at least 10mm as recommended in Figure B.

The drain pipe slope shall be kept at least 1:100.

Provide clearance for easy servicing and optimal air ßow as shown in Figure C.

The indoor unit must be installed such that there is no short circuit of the cool discharge air with the warm return air.

Do not install the indoor unit where there is direct sunlight shining on the unit. The location should be suitable for piping

and drainage installation. The unit must be a large distance away from the door.

•

•

•

•

•

400mm

or more

250mm or more

1m or more

Floor Standing Type

250mm or more

Utensils, furnitures or built-in

architectural features must not

protrude more than 250mm

Drainage Pipe

250mm or less

300mm

(Min.)

500mm or more

10mm

Indoor Unit

Hanger Bracket

Nut

Washer

Washer

Nut

Floor

2300mm or more

Ceiling

Figure C

1-6

Install the Suspension Bolts

Install the suspension bolts so that it can support the indoor unit.

Adjust distance to ceiling before installation.

Refer to the dimension given to install the unit.

Install the Indoor Units

Insert the suspension bolts into the Þttings of the hanger bracket.

Set the nuts and washer on the both side of the metal Þttings.

Secure it with nuts.

Attach the hanger cover (4 pcs) to the units.

1.

2.

3.

1.

2.

3.

4.

Suspension Bolt

Hanger Cover

Hanger Cover

Suspension Bolt

Hanger Rod

Installation Floor Standing Type

28mm

479mm 547mm or more Mounting Bracket

509mm

458mm

301mm or more

759mm or more

Rear Piping Hole

Floor

123mm

78mm

40mm

307mm

Installation Ceiling Type

UNDER CEILING INSTALLATION (AHQ71AV1)

1-7

English

Refer to the dimension as illustrated when installing the mounting bracket.

When installing the rear piping, determine the pipe hose position. Drill the pipe hole at the slight downward slant to the

outdoor side.

1.

2.

Mounting Bracket

Wall

Piping and Drain Hose Installation (Under Ceiling Type)

The piping direction can be 2 ways as illustrated.

The drain hose is only 1 way.

1.

2.

Rear Piping and Drain Hose Rear Piping Hose

Upper Piping

OR

Hook the unit on the

mounting bracket

Piping and Drain Hose Installation (Floor Standing Type)

Wall

OR

Piping and Drain Hose

Wall

Piping and Drain Hose

How to Install the Drain Hose

Remove the two screws and the drain pipe holder.

Cut a slit for the drain hose hole.

1.

2.

Place the drain hose on the v-shape area and secure it with

drain pipe holder and two screws.

3.

Slit for Drain Hose Hole

Screws

Drain Pipe Holder

1-8

How to Remove Air Inlet Grille

Remove the air inlet grille by both hands as the direction

shown.

Loosen the screw for Þxing the panel arm (3 screw, left,

right and center). Do not remove the screw at this time.

1.

2.

Air Inlet Grille

Axis of the Front Panel

Rib

Grille Holder (Center)

(Optional)

Screw

Air Inlet Grille Holder

Grille Holder (Center)

Grille Holder (L/R)

Move the air inlet grille upward, and then turn it backwards.

(Do not use too much force).

Remove the grille holder (both left and right side). After

that, remove the air intake grille.

Remove the grille holder (center) from the panel.

3.

4.

5.

How to Install the Air Filter

(A) (A)

(B) (B)

Snap in the Þlter in order to secure it

Install the Þlter to the panel in the (A) direction

follow by (B) to secure the Þlter.

To Adjust the Vane Direction

Adjust the vane linkage as the direction shown to get the required

vane direction

Dimension of the fresh air intake hole

70mm

Ø 3mm

70mm

Ø 64mm

1-9

English

Knock out the fresh air intake hole at the top panel.

Assemble the axial fan, fresh air adapter, Þlter and dust hose as shown in Þgure below.

1.

2.

2" DUCT HOSE

ASSY. FRESH AIR ADAPTER

FILTER FRESH AIR INTAKE

TOP PANEL

INSTALLATION OF FRESH AIR INTAKE (AHQ71AV1)

1-10

INSTALLATION DIAGRAM (AHQ100/125AVI)

Preliminary Site Survey

Voltage supply ßuctuation must not exceed ±10% of rated

voltage. Electricity supply lines must be independent

of welding transformer which can cause high supply

ßuctuations.

Ensure that the location is convenient for wiring, piping

and drainage.

•

•

Standard Mounting

Ensure that the overhead supports are strong enough to hold

the weight of the unit. Position the hanger rods (wall mounting

bracket for ßoor standing), and check for its alignment with

the unit as shown in Figure D. Also, check that the hangers

are secured and the base of the fan coil unit is leveled in both

horizontal directions, taking into account the gradient for

drainage ßow as recommended in Figure E.

Figure D

All dimensions are in mm

A

E

B

CD

F

G

H

INSTALLATION OF THE INDOOR UNIT (AHQ100/125AV1)

Dimension

Model A B C D E F G H

AHQ100AV1 1538 635 255 134 1440 49 148 120

AHQ125AV1 1538 635 255 134 1688 49 148 120

TO OUTDOOR UNIT

Air Discharge Louver

Signal Receiver

Indicator Light

Air Intake Grille

Wrap the Insulated pipe with the

Þnishing tape from bottom to top

Air Filters

(Inside Air Intake Grille)

1-11

English

Figure E

10.0mm or less

Please ensure that the following steps are taken:

Unit installation should be tilted at least 10mm as recommended in Figure E.

The drain pipe slope shall be kept at least 1:100.

Provide clearance for easy servicing and optimal air ßow as shown in Figure F.

The indoor unit must be installed such that there is no short circuit of the cool discharge air with the warm return air.

Do not install the indoor unit where there is direct sunlight shining on the unit. The location should be suitable for piping

and drainage installation. The unit must be a large distance away from the door.

•

•

•

•

•

10.0mm or more

Figure F

1m or more

400mm or more

Floor Standing Type

Utensils, furnitures or built-in

architectural features must not

protrude more than 250mm

Drainage Pipe

250mm or less

300mm

(Min.)

500mm or more

10mm

Indoor Unit

Hanger Bracket

Nut

Washer

Washer

Nut

Floor

2300mm or more

Ceiling

1-12

UNDER CEILING INSTALLATION (AHQ100/125AV1)

10mm

300mm or more

300mm or more

635mm

10mm

or more

Ceiling

10mm or more

Install Suspension Bolts

Install the suspension bolts so that it can support the

indoor unit.

Adjust distance to ceiling before installation.

Refer to dimension given to install the unit.

1.

2.

3.

Installation Ceiling Type

Installation Floor Type

Wall

Wall

Figure G

Figure H

Install Indoor Units

Insert the suspension bolts into the Þttings of the hanger

bracket.

Set the nuts and washer on both side of the metal

Þttings.

Secure it with nuts.

1.

2.

3.

1-13

English

Installation - Ceiling Exposed Type

Step 1

Remove air intake grille, side panel and hanger bracket from the unit. Please refer to Figure J.

Step 2

Position the hanger rod as shown in Figure K and install the hanger bracket.

Figure J

Figure K

Step 3

Hang up the unit and tighten the bolts after installation of piping and drain pipe. Please refer to Figure L.

Lastly install the intake grille and side panel to the correct position. Please refer to Figure M.

Figure L

Hanger Bracket Side Panel

Intake grille

1-14

Figure M

Piping and Drain Hose Installation

Steps to open intake grille

Unlock the screw attached to block lock grille with screwdriver.

Remove block lock grille and unlock grille lock.

Please refer to Figure P for reference.

1.

2.

3.

Block Lock Grille

Screw (M4)

Close

Open

Figure P

Drain Hose

Figure N

1-15

English

INSTALLATION DIAGRAM (AHQ140AV1)

Air Discharge Louver

Indicator Light

Air Discharge Grille

Air Intake Grille

Signal Receiver

Wrap the Insulated pipe with the

Þnishing tape from bottom to top

INSTALLATION OF THE INDOOR UNIT (AHQ140AV1)

Preliminary Site Survey

Voltage supply ßuctuation must not exceed ±10% of the rated voltage. Electricity supply lines must be independent of

welding transformers which can cause high supply ßuctuation.

Ensure that the installation location is convenient for wiring and drainage.

Standard Mounting

Ensure that the overhead supports are strong enough to hold the weight of the unit. Position the hanger rods, and check for its

alignment with the unit. Also, check that the hangers are secured.

•

•

Figure Q

10mm

20mm

Ceiling

Unit at level

Unit at level

TO OUTDOOR UNIT

Air Filters

(Inside Air Intake Grille)

1-16

10mm or less

UNDER CEILING INSTALLATION (AHQ140AV1)

Please ensure that the following steps are taken:

Unit installation should be tilted/slanted at least 10mm as recommended in Figure Q.

The drain pipe slope shall be kept at least 1:100.

Provide clearance for easy servicing and optimal air ßow as shown in Figure R.

The indoor unit must be installed such that there is no short circuit of the cool discharge air with the warm return air.

Do not install the indoor unit where there is direct sunlight shining on the unit. The location should be suitable for piping

and drainage installation. The unit must be a large distance away from the door.

•

•

•

•

•

Install Suspension Bolts

Install the suspension bolts so that it can support the indoor

unit.

Adjust distance to ceiling before installation.

Refer to dimension given by Figure S to install the unit.

1.

2.

3.

Figure S

Install Indoor Units

Insert the suspension bolts into the Þtting of the hanger.

bracket.

Set the nuts and washer on both side of the metal Þttings.

Secure it with nuts.

1.

2.

3.

Installation Ceiling Type

Top Panel Of Unit

Ceiling Board

10mm

145-155mm

10mm

300mm or more

10mm

621mm

Figure R

10mm or less

300mm or more

Utensils, furnitures or built-in

architectural features must not

protrude more than 250mm

Drainage Pipe

250mm or less

300mm

(Min.)

500mm or more

10mm

Indoor Unit

Hanger Bracket

Nut

Washer

Washer

Nut

Floor

2300mm or more

Ceiling

1-17

English

D

A

Piping Works And Flaring Technique

Do not use contaminated or damaged copper tubing. If any pipings, evaporator or condenser had been exposed or had been

opened for 15 seconds or more, the system must be vacuumed. Generally, do not remove plastic, rubber plugs and brass

nuts from the valves, Þttings, tubings and coils until it is ready to connect suction or liquid line into valves or Þttings.

If any brazing work is required, ensure that the nitrogen gas is passed through coil and joints while the brazing work is

being done. This will eliminate soot formation on the inside walls of the copper tubings.

Cut the pipe stage by stage, advancing the blade of the pipe cutter slowly. Extra force and deep cut will cause more distortion

on the pipe and thus extra burr. See Figure I.

•

•

•

Cutting Copper Tube

Figure II

Figure I

Remove Burr

Figure III

Copper Tube

Swaging Block

Spanar Torque Wrench

Indoor Piping Flare Nut

Flared Tube

Flare Joint

Figure IV

Ø Tube, D A (mm)

Inch mm Imperial

(Wing-nut Type)

Rigid

(Clutch Type)

1/4" 6.35 1.3 0.7

3/8" 9.52 1.6 1.0

1/2" 12.70 1.9 1.3

5/8" 15.88 2.2 1.7

3/4" 19.05 2.5 2.0

Pipe Size

(mm/in)

Torque

(Nm/ft-lb)

6.35 (1/4") 18 (13.3")

9.52 (3/8") 42 (31.0")

12.70 (1/2") 55 (40.6")

15.88 (5/8") 65 (48.0")

19.05 (3/4") 78 (57.6")

1/4t

Remove burrs from cut edges of the pipes with remover

as shown in Figure II. This will avoid unevenness on the

ßare faces which will cause gas leak. Hold the pipe on top

position and burr remover at lower position to prevent metal

chips from entering the pipe.

Insert the ßare nuts, mounted on the connection parts of

both the indoor unit and outdoor unit, into the copper

pipes.

The exact length of pipe protruding from the top surface

of the swaging block is determined by the ßaring tool.

Refer Figure III.

Fix the pipe Þrmly on the swaging block. Match the centers

of both the ßare die and the ßaring punch, and then tighten

the ßaring punch fully.

Piping Connection To The Units

Align the center of the piping and tighten the ßare nut

sufÞciently with Þngers. Refer Figure IV.

Finally, tighten the ßare nut with the torque wrench until

the wrench clicks.

When tightening the ßare nut with the torque wrench,

ensure that the tightening direction follows the arrow

indicated on the wrench.

The refrigerant pipe connection are insulated by closed

cell polyurethane.

•

•

•

•

•

•

•

•

1-18

Attach insulation sleeve

Round crimp-style terminal Electric wire

Connect wires of the

same gauge to both side.

Do not connect wires of the

same gauge to one side.

Do not connect wires

of different gauges.

All wires must be Þrmly connected.

Make sure all the wire do not touch the refrigerant pipings, compressor or any moving parts.

The connecting wire between the indoor unit and the outdoor unit must be clamped by using provided cord anchorage.

The power supply cord must be equivalent to H07RN-F which is the minimum requirement.

Make sure no external pressure is applied to the terminal connectors and wires.

Make sure all the covers are properly Þxed to avoid any gap.

Use round crimp-style terminal for connecting wires to the power supply terminal block. Connect the wires by matching

to the indication on terminal block. (Refer to the wiring diagram attached on the unit).

•

•

•

•

•

•

•

Use the correct screwdriver for terminal screws tightening. Unsuitable screwdrivers can damage the screw head.

Over tightening can damage the terminal screw.

Do not connect wire of different gauge to same terminal.

Keep wiring in an orderly manner. Prevent the wiring from obstructing other parts and the terminal box cover.

•

•

•

•

R410A is a new HFC refrigerant which does not damage the

ozone layer. The working pressure of this new refrigerant is 1.6

times higher than conventional refrigerant (R22), thus proper

installation / servicing is essential.

Never use refrigerant other than R410Ain an air conditioner

which designed to operate with R410A.

POE or PVE oil is used as lubricant for R410A compressor,

which is different from the mineral oil used for R22

compressor. During installation or servicing, extra precaution

must be taken not to expose the R410A system too long

to moist air. Residual POE or PVE oil in the piping and

components can absorb moisture from the air.

To prevent mischarging, the diameter of the service port on

the ßare valve is different from that of R22.

•

•

•

Use tools and materials exclusively for refrigerant R410A.

Tools exclusively for R410A are manifold valve, charging

hose, pressure gauge, gas leak detector, ßare tools, torque

wrench, vacuum pump and refrigerant cylinder.

As an R410A air conditioner incurs higher pressure than

R22 units, it is essential to choose the copper pipes correctly.

Never use copper pipes thinner than 0.8mm even though

they are available in the market.

If the refrigerant gas leakage occurs during installation /

servicing, be sure to ventilate fully. If the refrigerant gas

comes into contact with Þre, a poisonous gas may occur.

When installing or removing an air conditioner, do not allow

air or moisture to remain in the refrigerant cycle.

•

•

•

•

SPECIAL PRECAUTIONS WHEN DEALING WITH R410A UNIT

Vacuuming is necessary to eliminate all moisture and air from the system.

Vacuuming The Piping And The Indoor Unit

The indoor unit and the refrigerant connection pipes must

be air-purged because the air containing moisture that

remains in the refrigerant cycle may cause malfunction of

the compressor.

Remove the caps from the valve and the service port.

Connect the center of the charging gauge to the vacuum

pump.

Connect the charging gauge to the service port of the 3-

way valve.

•

•

•

VACUUMING AND CHARGING

Start the vacuum pump. Evacuate for approximately

30 minutes. The evacuation time varies with different

vacuum pump capacity. ConÞrm that the charging gauge

needle has moved towards -760mmHg.

Caution

If the gauge needle does not move to -760mmHg, be sure to

check for gas leaks (using the refrigerant detector) at ßare

type connection of the indoor and outdoor unit and repair

the leak before proceeding to the next step.

Close the valve of the changing gauge and stop the vacuum

pump.

•

•

•

This manual suits for next models

3

Table of contents

Other Siesta Air Conditioner manuals

Popular Air Conditioner manuals by other brands

Mitsubishi Electric

Mitsubishi Electric PK-2.5FLD Technical & service manual

LG

LG MT11R owner's manual

Lasko

Lasko 2554 Important instructions & operating manual

Airwell

Airwell CD DCI Series Installation instruction

Unitary products group

Unitary products group H4TS024 Installation instruction

Sinclair

Sinclair MULTI VARIABLE SERIES Service manual