SIFCO ASC TechnoPlate Power Pack 6015A20V User manual

SIFCOTechnoPlate Power Pack_2019-05-06_V1.5_e.doc 1/68

Strictly confidential! No unauthorized circulation of content.

© All rights reserved by plating electronic GmbH. Modification and reproduction only by authorized persons!

Documentation type: Operating manual

Author: J. Schumann

Last modification by: Johannes Schumann Print date: 2019-06-28

Last saving date: 2019-06-28

Last modification: ..\History_SIFCO TechnoPlate_001.xlsx V1.5

Comment:

plating electronic GmbH - Rheinstraße 4 - D-79350 Sexau - Germany

Tel.: +49 (0)7641 / 93500-0 - Fax.: +49 (0) 7641 / 93500-999 E-Mail: info@plating.de

Operating Manual for

SIFCO ASC TechnoPlate Power Pack

with detachable control unit

Read this operating manual completely before installation.

Not following installation and operation procedures will void the warranty. It also

could result in serious injury or death.

SIFCOTechnoPlate Power Pack_2019-05-06_V1.5_e.doc 2/68

plating electronic GmbH - Rheinstraße 4 - D-79350 Sexau - Germany

Tel.: +49 (0)7641 / 93500-0 - Fax.: +49 (0) 7641 / 93500-999 E-Mail: info@plating.de

SIFCOTechnoPlate Power Pack_2019-05-06_V1.5_e.doc 3/68

plating electronic GmbH - Rheinstraße 4 - D-79350 Sexau - Germany

Tel.: +49 (0)7641 / 93500-0 - Fax.: +49 (0) 7641 / 93500-999 E-Mail: info@plating.de

List of Contents:

1EU declaration of conformity ----------------------------------------------------------------- 5

2General security information ----------------------------------------------------------------- 6

2.1 Class-A device---------------------------------------------------------------------- 6

2.2 Security ------------------------------------------------------------------------------- 6

2.3 Installation of the DC power supply modules-------------------------------- 8

2.4 Operation conditions--------------------------------------------------------------- 8

3After transportation ----------------------------------------------------------------------------- 9

3.1 Transportation locking devices-------------------------------------------------- 9

4Storage -------------------------------------------------------------------------------------------- 9

4.1 Environmental conditions for storage------------------------------------------ 9

5General description----------------------------------------------------------------------------10

5.1 Two housing sizes ----------------------------------------------------------------10

5.2 Switch mode technology---------------------------------------------------------11

5.3 Intended purpose------------------------------------------------------------------11

6Detachable control unit -----------------------------------------------------------------------12

6.1 Assembling after transportation------------------------------------------------12

6.2 Transport lock for the control unit ---------------------------------------------13

6.3 Protective cover--------------------------------------------------------------------14

6.4 Control unit with stand -----------------------------------------------------------15

7Devices 15 A / 20 V and 30 A / 20 V------------------------------------------------------16

8DC-output connection-------------------------------------------------------------------------17

9The RS485 BUS connection ----------------------------------------------------------------18

9.1 Bus - terminator--------------------------------------------------------------------19

9.2 Specification of the BUS cable-------------------------------------------------19

10 Mains supply ------------------------------------------------------------------------------------20

10.1 single-phase devices-------------------------------------------------------------20

10.1.1 Power cord plug single-phase type -------------------------------------------21

10.1.2 PFC technology--------------------------------------------------------------------21

10.2 3~phase devices ------------------------------------------------------------------22

10.2.1 Power cord plug three-phase type --------------------------------------------22

11 Back plane---------------------------------------------------------------------------------------24

12 Operation ----------------------------------------------------------------------------------------25

12.1 Main switch -------------------------------------------------------------------------25

13 Function overview of the software ---------------------------------------------------------26

14 Manual pole changer--------------------------------------------------------------------------26

15 Ampere-Hour Counter and Reset function-----------------------------------------------27

15.1 A/H value setting (A/H PRESET)----------------------------------------------27

15.2 A/H RESET function--------------------------------------------------------------27

16 Potentiometer control and step function--------------------------------------------------28

17 Potentiometers control for voltage and current -----------------------------------------29

17.1 Control function--------------------------------------------------------------------30

17.1.1 Function 1 “Counting” ------------------------------------------------------------31

17.1.2 Function 2 “Jumping” -------------------------------------------------------------32

17.1.3 Function 3 “Counting and Jumping” ------------------------------------------33

17.1.4 Function 4 “Digit reset”-----------------------------------------------------------34

18 Step function ------------------------------------------------------------------------------------35

18.1 STEP and NEXT STEP keys---------------------------------------------------36

18.2 STORE key -------------------------------------------------------------------------37

18.3 STEP RESET key-----------------------------------------------------------------37

SIFCOTechnoPlate Power Pack_2019-05-06_V1.5_e.doc 4/68

plating electronic GmbH - Rheinstraße 4 - D-79350 Sexau - Germany

Tel.: +49 (0)7641 / 93500-0 - Fax.: +49 (0) 7641 / 93500-999 E-Mail: info@plating.de

18.4 LABEL key --------------------------------------------------------------------------38

18.5 Creating a preset at STEP 1----------------------------------------------------40

19 Examples how to adjust set values--------------------------------------------------------42

19.1 Example 1: Adjust voltage set value to 24 V -------------------------------42

19.2 Example 2: Adjust voltage set value to 24.53 V ---------------------------43

19.3 Adjust existing preset values and store new values ----------------------44

19.4 Adjust preset value temporary -------------------------------------------------44

20 Settings in main menu ------------------------------------------------------------------------45

20.1 General description ---------------------------------------------------------------45

20.2 The SETTINGS functions -------------------------------------------------------46

20.3 Configuration of BUS interface-------------------------------------------------47

20.4 Total counter------------------------------------------------------------------------49

20.5 Preset counter----------------------------------------------------------------------50

20.5.1 Configuration of the preset counter -------------------------------------------51

20.6 Pole changer -----------------------------------------------------------------------54

20.6.1 Configuration of the pole changer---------------------------------------------54

20.7 Overload detection----------------------------------------------------------------56

20.7.1 Configuration of the Overload detection -------------------------------------57

20.8 The STEP menu-------------------------------------------------------------------58

20.9 Set label -----------------------------------------------------------------------------58

21 Technical data ----------------------------------------------------------------------------------59

21.1 General specifications------------------------------------------------------------59

21.2 Individual specifications----------------------------------------------------------60

21.2.1 Type 6015A20V--------------------------------------------------------------------60

21.2.2 Type 6030A20V--------------------------------------------------------------------60

21.2.3 Type 6015A50V--------------------------------------------------------------------60

21.2.4 Type 6060A20V--------------------------------------------------------------------61

21.2.5 Type 3750 W -1 coming year 2020 ------------------------------------------61

21.2.6 Type 3750 W -2 coming year 2020 ------------------------------------------61

22 Dimensions--------------------------------------------------------------------------------------62

23 Checking calibration---------------------------------------------------------------------------65

23.1 Voltage calibration ----------------------------------------------------------------65

23.2 Current calibration-----------------------------------------------------------------66

24 Service and maintenance--------------------------------------------------------------------67

25 Spare parts list----------------------------------------------------------------------------------68

26 Warranty and Repair Information ----------------------------------------------------------68

Packing list:

- Rectifier unit “SIFCO ASC TechnoPlate” (type: see

package labeling, and rating plate)

- Control unit SIFCO ASC (for type 15A / 20 V and 30 A / 20 V: integrated

control panel)

- Three types of mains power cord (individual plugs) for

single-phase devices

- Operating manual

SIFCOTechnoPlate Power Pack_2019-05-06_V1.5_e.doc 5/68

plating electronic GmbH - Rheinstraße 4 - D-79350 Sexau - Germany

Tel.: +49 (0)7641 / 93500-0 - Fax.: +49 (0) 7641 / 93500-999 E-Mail: info@plating.de

1 EU declaration of conformity

Conformity declaration of the European community corresponding to the EMV-

guidelines 2014/30/EU about the electromagnetic compatibility and the low-voltage

guidelines 2014/35/EU.

We

Manufacturer: plating electronic GmbH

Ust.-Id No.: DE 141938869

Address: Rheinstraße 4

79350 Sexau / Deutschland

declare that the product, listed below, is corresponding to the following standards

resp. normative documents:

DIN EN 61000-6-2: 2005 (German Language Version)

Corrigendum to DIN EN 61000-6-2 (VDE0839-6-2): 2006;

German version CENELEC-Cor.: 2005 to EN 61000-6-2: 2005.

DIN EN 61000-6-2 Corrigendum 1: 2011; VDE0839-2 Corrigendum 1: 2011

Electromagnetic compatibility (EMC) Part 6-2: Generic standards -

Immunity for industrial environments (IEC 61000-6-2:2005)

DIN EN 61000-6-4: 2011; VDE 0839-6-4: 2011

German version: Electromagnetic compatibility (EMC) part 6-4: Generic standards -

Emission standard for industrial environments (IEC 61000-6-4: 2006 + A1: 2010)

German version EN 61000-6-4: 2007 + A1: 2011

DIN EN 55011: 2011; VDE 0875-11: 2011

(German version) Class A, Group 1

German version: Industrial, scientific and medical equipment -

Radio-frequency disturbance characteristics –

Limits and methods of measurement (IEC/CISPR 11: 2009, modified)

+ A1: 2010); German version EN 55011: 2009 + A1: 2010

DIN EN 50178: 1998 (VDE 0160: 1998)

Electronic equipment for use in power installations

German version EN 50178: 1997

RoHS-conform to guideline 2011/65/EU per June 8th 2011

Sexau, 24.04.2017 ___________________________

Place / date Karl Rieder (Managing Director)

Product, to which the above declaration refers:

Installation: electroplating DC power supply type

SIFCO TechnoPlate POWER PACK

air cooled, with integrated pole changer

with preset counter, with RS485-BUS interface

Serial No.: see rating plate

SIFCOTechnoPlate Power Pack_2019-05-06_V1.5_e.doc 6/68

plating electronic GmbH - Rheinstraße 4 - D-79350 Sexau - Germany

Tel.: +49 (0)7641 / 93500-0 - Fax.: +49 (0) 7641 / 93500-999 E-Mail: info@plating.de

2 General security information

2.1 Class-A device

This device is defined as a class-A-device.

Warning: This device is provided to be used only in industrial

environment! In other environments, a sufficient electromagnetic

tolerance could not be assured without additional installation measures.

2.2 Security

Attention!

There are components inside the casing carrying a live-endangering

voltage for up to 5 minutes after turning off the power supply.

Without casing, the DC power supply has protecting grade IP00. It is

dangerous to open the casing because of the possibility touching

voltage-carrying parts. Therefore, it is not permitted to use the DC power

supply without bottom or cover plate or with side or front / back panels

removed.

- Installation, repairing and maintenance only by qualified personnel!

- Supply sufficient cooling air for the DC power supply!

- Customer and operator are responsible for the proper installation and

handling of the DC power supply!

- Do not remove protection covers and do not modify the unit in any

way!

- Do not use DC connectors and cables to lift or move the device!

Attention!

Do not operate any DC-power-supply with one or more loose internal

cable connectors!

If during operation one or more plugs are pulled out of the boards inside

the modules, electronic parts and the power unit could be destroyed!

SIFCOTechnoPlate Power Pack_2019-05-06_V1.5_e.doc 7/68

plating electronic GmbH - Rheinstraße 4 - D-79350 Sexau - Germany

Tel.: +49 (0)7641 / 93500-0 - Fax.: +49 (0) 7641 / 93500-999 E-Mail: info@plating.de

This DC power supply was delivered after a thorough function- and

safety-check. Only qualified staff shall connect the device and put it into

operation. Service and maintenance is only to be performed by qualified

personnel.

Unauthorized modification or repairing is life endangering. Observe all

instructions of the manufacturer; else, the warranty for DC power

supplies and accessories will expire.

Parts carrying a life-endangering voltage potential are installed inside the

casing. These are marked with warning labels.

Any manipulation of the electrical parts is life endangering and, by doing

so, including improper operation, cancels the guarantee.

This DC power supply was constructed in consideration of the threat

analysis and the relevant safety regulations. Further, all relevant

technical specifications are respected. Therefore, this technology is

state-of-the-art and guarantees a maximum of safety and functionality.

The safety and functionality can only be kept if the all relevant

arrangements are done.

The operator of the installation is responsible for the adherence of safety

rules.

The operator has to ensure that

- the DC power supply is only to be used for the application released

by the manufacturer

Active loads such as batteries or generators must never be

connected to the DC generator (danger of destruction)!

- the installation is only to be put into operation if it is in an accurate

condition and all safety devices are checked regularly.

- all requested individual protective equipment for operator and

maintenance personnel is available and is be used.

- The operating manual must be available at the operating place. The

operating manual must be complete and in a good condition.

- Mounting, repairing, electrical installation, adjusting and

maintenance are only to be done by qualified personnel!

SIFCOTechnoPlate Power Pack_2019-05-06_V1.5_e.doc 8/68

plating electronic GmbH - Rheinstraße 4 - D-79350 Sexau - Germany

Tel.: +49 (0)7641 / 93500-0 - Fax.: +49 (0) 7641 / 93500-999 E-Mail: info@plating.de

Security advice:

The DC-power-supplies of the SIFCO TechnoPlate POWER PACK series

are designed as desktop units.

The DC power supplies are only to be operated in the permissible ranges

of current, voltage, environmental temperature and atmospheric humidity

according to the rating plate and the operating manual.

The devices are only to be used in plating systems. The use of the

device for other applications must be released by the manufacturer.

The safety precautions must be done according to all local and federal

regulations.

2.3 Installation of the DC power supply modules

While mounting the module and the DC connectors, observe especially

the following:

- Don‘t tighten screws with a lever, don’t bent any rails or panels.

- The device must be operated as desktop unit.

- If mounting the device near the plating tanks or similar installations

is necessary, one has to make sure that it is protected against

chemical vapor, dust and dropping particles.

- Ensure an unhindered airflow at the air input and air output.

- Observe the installation instructions of the electrical installation.

2.4 Operation conditions

Plating DC power supplies are not to be operated in an explosive

environment. Ensure a sufficient airflow to avoid an internal overheating.

The cooling air must be free from any chemical contamination and free

from particles, steam and dust.

The unit must be protected from dropping particles, dripping water and

splash water.

If contaminated air is getting into the device, the electronic

components could be damaged.

SIFCOTechnoPlate Power Pack_2019-05-06_V1.5_e.doc 9/68

plating electronic GmbH - Rheinstraße 4 - D-79350 Sexau - Germany

Tel.: +49 (0)7641 / 93500-0 - Fax.: +49 (0) 7641 / 93500-999 E-Mail: info@plating.de

3 After transportation

Check the device and the packaging and transportation material for

damages caused by transportation! Never put a device into operation if

there are visible or hidden transportation damages!

Attention:

After transportation, all electrical connections accessible by the customer

must be checked! Vibrations during transportation may loosen the screws

of clamps.

Check mains wiring and output connections as well as control cables.

Loose cable connections may cause overheating of clamps and cables

and will lead to destruction of the installation.

3.1 Transportation locking devices

Make sure no transportation locking material is left at the device before

putting into operation.

Remove labels and stickers that are not necessary for safe operation.

4 Storage

Aluminum electrolytic capacitors are built into TechnoPlate Power Pack

series and into their control components to ensure correct operation.

These components are subject to natural ageing processes.

Aluminum electrolyte capacitors containing liquid electrolyte age over

time due to the electrolyte slowly drying out, depending on temperature.

As a result, these devices should not be stored for longer than six

months. If you keep replacement devices in storage, they should be

integrated into systems after six months at the latest. If not, they should

be connected to the power supply in non-operational mode for at least an

hour before they are installed and also at least once a year to recondition

the electrolyte capacitors.

Important

Condensate may form on the external surfaces of devices if air humidity

is high.

This condensation may cause the external casing to corrode. It is

therefore recommended to store these devices in a dry and/or air-

conditioned room with adequate ventilation to prevent such corrosion.

Ensure that the ventilation openings are not covered when you mount the

devices. Each device should be left to adjust to room temperature for a

couple of hours after installation before it is put into operation.

4.1 Environmental conditions for storage

Ambient temperature: 0 °C to +50 °C (for storage only)

Air humidity: 15 to 95 %, non-condensing

SIFCOTechnoPlate Power Pack_2019-05-06_V1.5_e.doc 10/68

plating electronic GmbH - Rheinstraße 4 - D-79350 Sexau - Germany

Tel.: +49 (0)7641 / 93500-0 - Fax.: +49 (0) 7641 / 93500-999 E-Mail: info@plating.de

5 General description

The DC-power supply type SIFCO ASC TechnoPlate Power Pack is

a sophisticated switch mode type rectifier, designed for the selective

electroplating industry. It is designed as a desktop unit.

5.1 Two housing sizes

The control of the output parameters is done by keys and rotary buttons

in the front panel of the unit, or by RS485 BUS interface.

The electronic regulation guarantees correct output parameters during

the operation, even with variable loads at the DC output.

The pole changer can be programmed individually, according to your

application.

The pole changer can be operated in MANUAL or AUTO pole changer

mode.

The preset counter can be individually configured. The preset counter

can be used to switch the DC power supply off after a certain current

rate.

The A/H RESET key is used to start the preset counter manually (or to

enable auto-start) if the plating process is running.

Over temperature protection

The device is temperature protected. If the interior temperature is

exceeding the limit the device decreases the output current

automatically and, after a cooling phase, increases it.

There is an auto-switch-off function in case of overheating.

Attention!

Auto-power-up after cooling down!

Do not run the power supply at higher environmental temperatures

than 40 °C and lower environmental temperatures than 5 °C!

Size 2:

15 A / 20 V and

30 A / 20 V,

control panel integrated

Size 1: air cooled by fans,

detachable control unit,

protective cover

SIFCOTechnoPlate Power Pack_2019-05-06_V1.5_e.doc 11/68

plating electronic GmbH - Rheinstraße 4 - D-79350 Sexau - Germany

Tel.: +49 (0)7641 / 93500-0 - Fax.: +49 (0) 7641 / 93500-999 E-Mail: info@plating.de

5.2 Switch mode technology

This device was designed as switch mode type DC power supply. The

advantages of the switch mode technology are:

- very compact design

- maximum regulation accuracy

- very low ripple

- high efficiency; optimized power factor (0.95, correlated to nominal

DC values)

5.3 Intended purpose

Device for industrial application

According to the norms

DIN EN 61000-3-12 (VDE 0838-12):2012-06

EN 61000-3-12:2011

this device is only to be used for industrial applications. Offering and

selling the device to the general public is not provided.

This device was designed to be used for selective electroplating

processes in plating systems only.

All other use must be clarified with the technical support of the

manufacturer. Otherwise, the installation or other connected devices

could be damaged.

SIFCOTechnoPlate Power Pack_2019-05-06_V1.5_e.doc 12/68

plating electronic GmbH - Rheinstraße 4 - D-79350 Sexau - Germany

Tel.: +49 (0)7641 / 93500-0 - Fax.: +49 (0) 7641 / 93500-999 E-Mail: info@plating.de

6 Detachable control unit

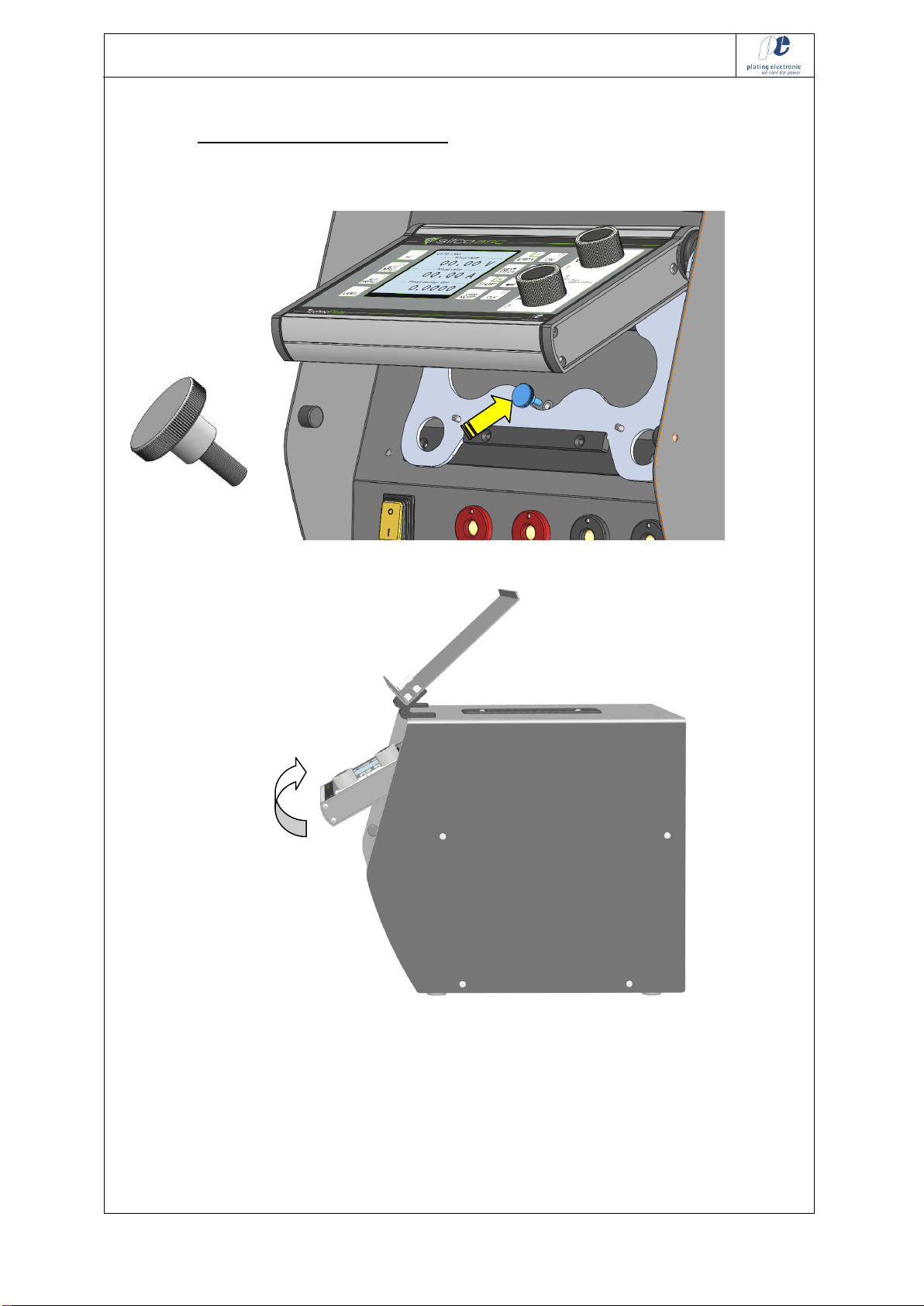

6.1 Assembling after transportation

For transportation, make sure the control unit is properly latched, and the

protective cover is closed.

Using an extension control cable, the control unit could be unlocked from

rectifier unit and placed nearby. Use the fold-out stand at the back plane

of the control unit to move it in an ergonomic position for your work.

To unlatch the control unit, push it upwards and take it out.

Latch the control unit to

the rectifier unit

Plug the control cable to

the socket at the control

unit

SIFCOTechnoPlate Power Pack_2019-05-06_V1.5_e.doc 13/68

plating electronic GmbH - Rheinstraße 4 - D-79350 Sexau - Germany

Tel.: +49 (0)7641 / 93500-0 - Fax.: +49 (0) 7641 / 93500-999 E-Mail: info@plating.de

6.2 Transport lock for the control unit

Use the delivered screw to fix the control unit during transportation:

You can swing the control unit to adjust the angle of view.

SIFCOTechnoPlate Power Pack_2019-05-06_V1.5_e.doc 14/68

plating electronic GmbH - Rheinstraße 4 - D-79350 Sexau - Germany

Tel.: +49 (0)7641 / 93500-0 - Fax.: +49 (0) 7641 / 93500-999 E-Mail: info@plating.de

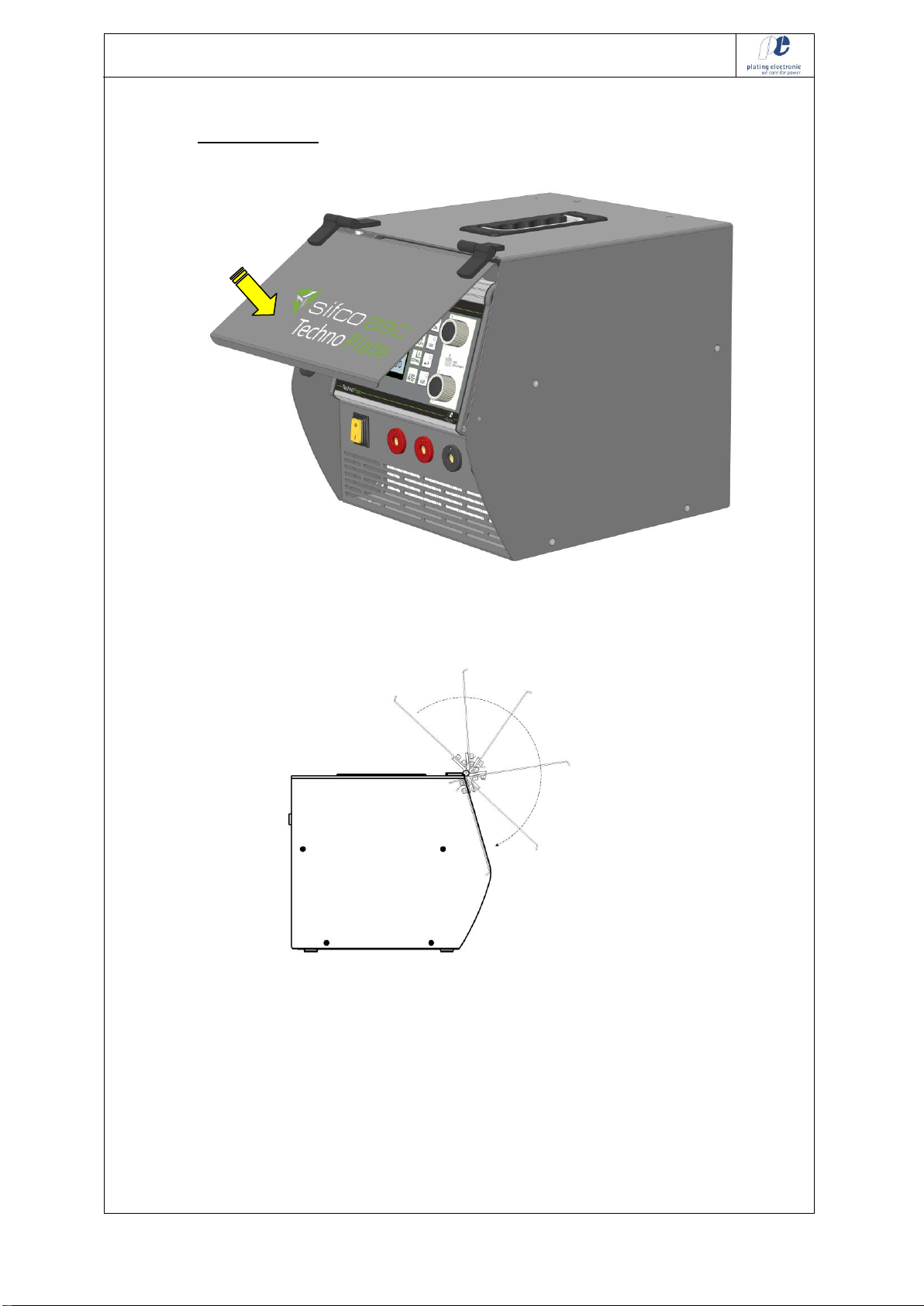

6.3 Protective cover

The protective cover plate is used to protect the control unit during

transportation. It should be closed if the device is not in use.

If the cover is opened, it could be used as a stand for manuals or process

instructions.

SIFCOTechnoPlate Power Pack_2019-05-06_V1.5_e.doc 15/68

plating electronic GmbH - Rheinstraße 4 - D-79350 Sexau - Germany

Tel.: +49 (0)7641 / 93500-0 - Fax.: +49 (0) 7641 / 93500-999 E-Mail: info@plating.de

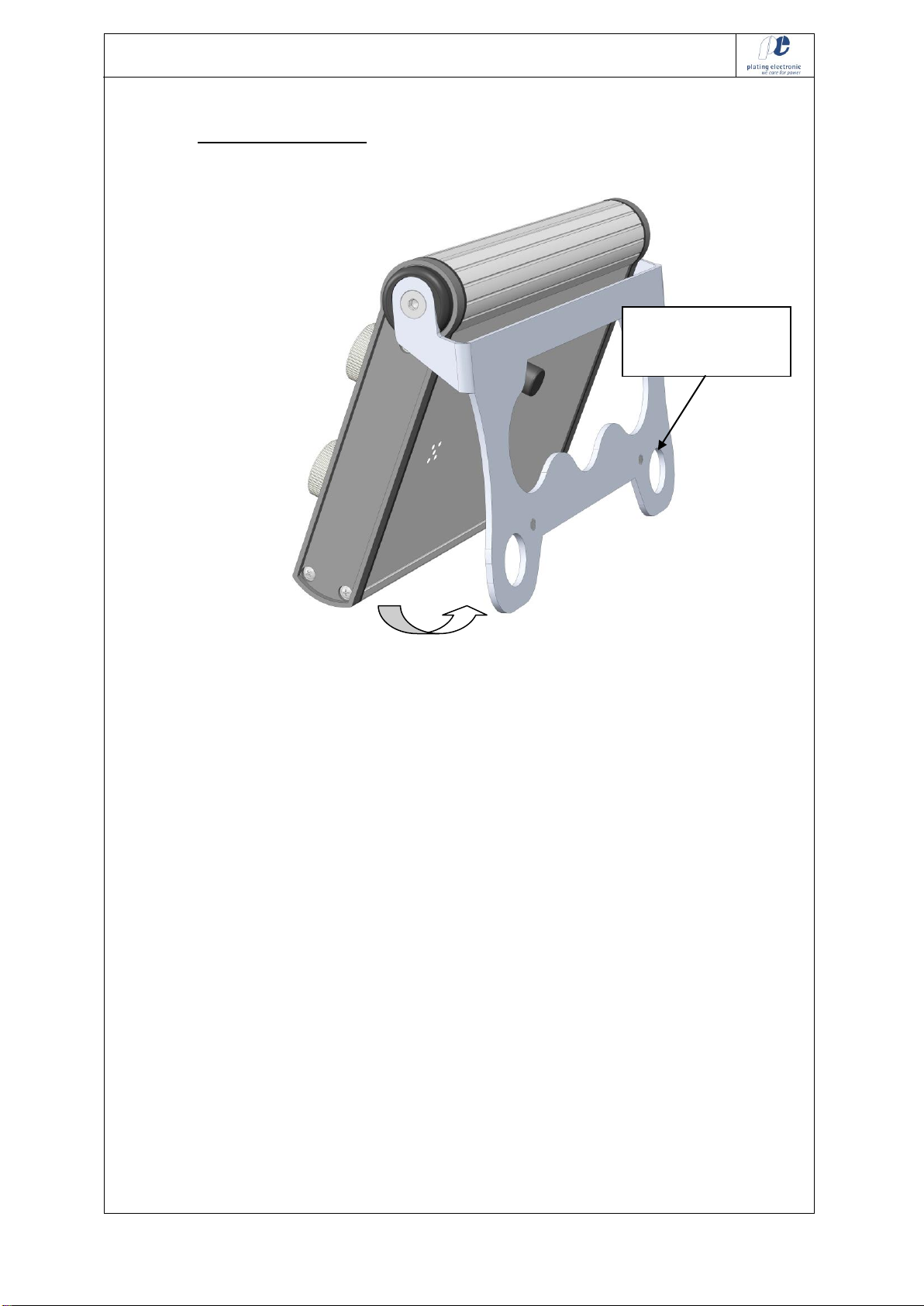

6.4 Control unit with stand

If unlatched, you can swing out the mounting plate of the control unit to

use it as a stand for desk top positioning (extension control cable

required, please order separately).

could also be hung

up (use holes in

plate)

SIFCOTechnoPlate Power Pack_2019-05-06_V1.5_e.doc 16/68

plating electronic GmbH - Rheinstraße 4 - D-79350 Sexau - Germany

Tel.: +49 (0)7641 / 93500-0 - Fax.: +49 (0) 7641 / 93500-999 E-Mail: info@plating.de

7 Devices 15 A / 20 V and 30 A / 20 V

The 15 A / 20 V type and the 30 A / 20 V type are the compact versions

of the TechnoPlate Power Pack.

The device 15 A / 20 V doesn’t require a fan or ventilation grille.

The control panel is firmly integrated.

The keypad, display and software functions are completely identical to

the larger rectifier version.

The two PLUS terminals have the same potential!

Type 6015A20V Type 6030A20V

Mains connection socket and RS485 BUS terminals are located in the

back panel.

SIFCOTechnoPlate Power Pack_2019-05-06_V1.5_e.doc 17/68

plating electronic GmbH - Rheinstraße 4 - D-79350 Sexau - Germany

Tel.: +49 (0)7641 / 93500-0 - Fax.: +49 (0) 7641 / 93500-999 E-Mail: info@plating.de

8 DC-output connection

Connect the DC-output connectors to the load. Check for right polarity

and contact.

Look for the DIN VDE 0298-4 / 2013-06

admitted cable cross section and the correct polarity.

Plug and turn for lock / unlock the connector.

The two PLUS terminals have the same potential!

The two MINUS terminals have the same potential!

The unit must be connected according to all applicable federal, state and

local electrical codes. The applicable phase current can be found on the

rectifier identification plate, located inside the unit.

Attention:

The connection of active loads such as batteries or DC-machines to the

DC-output-connectors will cause damages to the unit!

Please check:

Make sure that the mains supply cable is directly connected to your main

supply wall outlet.

Do not wire the power supply or the high-current cables into a roll or bind

the supply and the high-current wiring together with other wires.

Otherwise, overheating is possible.

+

+

SIFCOTechnoPlate Power Pack_2019-05-06_V1.5_e.doc 18/68

plating electronic GmbH - Rheinstraße 4 - D-79350 Sexau - Germany

Tel.: +49 (0)7641 / 93500-0 - Fax.: +49 (0) 7641 / 93500-999 E-Mail: info@plating.de

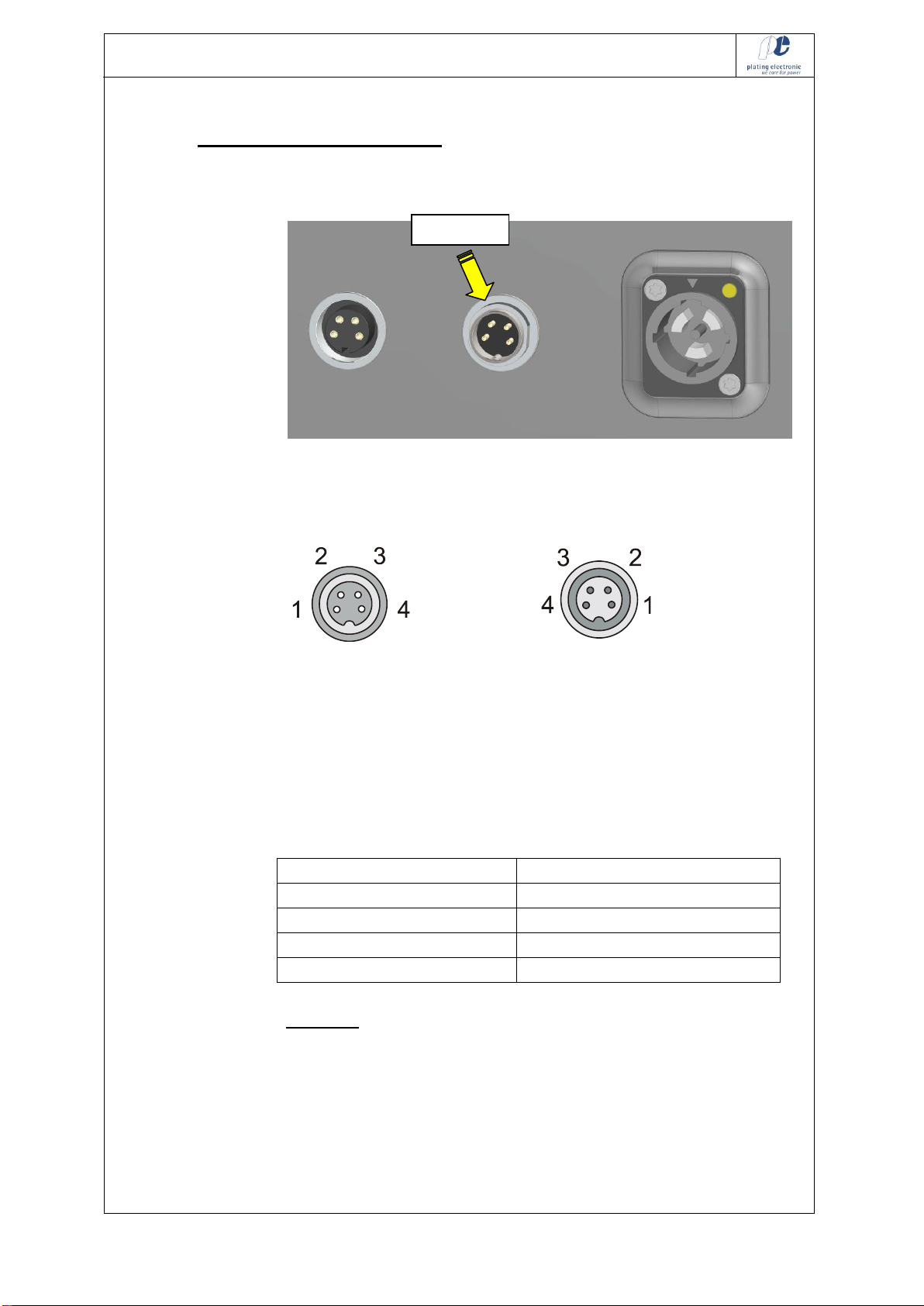

9 The RS485 BUS connection

There is a round four-pin socket located on the back plane of the device.

This is used for remote RS485 BUS control of the device.

Connect the RS485-BUS by the following scheme:

OUTPUT INPUT

BUS-output BUS-input

(„female“ socket) („male” socket)

The INPUT socket is used to connect the incoming BUS signal coming

from a BUS converter or a RS485 BUS interface.

The OUTPUT socket is used to connect the BUS terminator, if no

successive BUS device is looped into the RS485 BUS line.

Round 4-pin terminal

RS485 signal

1

+ VCC (only at BUS output)

2

BUS A

3

BUS B

4

GND (only at BUS output)

Attention! The 5 V DC signal that is used for the BUS terminator is

only available at the devices 15 A / 20 V and 30 A / 20 V!

BUS input

SIFCOTechnoPlate Power Pack_2019-05-06_V1.5_e.doc 19/68

plating electronic GmbH - Rheinstraße 4 - D-79350 Sexau - Germany

Tel.: +49 (0)7641 / 93500-0 - Fax.: +49 (0) 7641 / 93500-999 E-Mail: info@plating.de

9.1 Bus - terminator

4-pin female plug

The BUS terminator is to be installed at the BUS output socket of the last

participant within the RS485 BUS line.

9.2 Specification of the BUS cable

HELUKABEL type 2 x 2 x 0.22 mm2(AWG23)

2 pairs twisted, shielded; white, brown, green, yellow

SIFCOTechnoPlate Power Pack_2019-05-06_V1.5_e.doc 20/68

plating electronic GmbH - Rheinstraße 4 - D-79350 Sexau - Germany

Tel.: +49 (0)7641 / 93500-0 - Fax.: +49 (0) 7641 / 93500-999 E-Mail: info@plating.de

10 Mains supply

Supply voltage: see device type and specification list.

Use the delivered plug to connect the device to the corresponding mains

supply.

Respect the information on the rating plate, which is located on the right

side panel of the casing.

10.1 single-phase devices

Connecting scheme:

Outside view on the socket

N

PE

L

This manual suits for next models

5

Table of contents

Popular Power Supply manuals by other brands

DUNIWAY Stockroom

DUNIWAY Stockroom Terranova 752A instruction manual

BGS technic

BGS technic 3383 Safety and operating instructions

Honeywell

Honeywell 900P01 installation and replacement

SUNSLICE

SUNSLICE GRAVITY 432 instruction manual

Coolmax

Coolmax CUL-750B quick guide

M-system

M-system R3Y-SS16N instruction manual