SIG CAP 231EX User manual

CAP 231EX ARF ASSEMBLY MANUAL

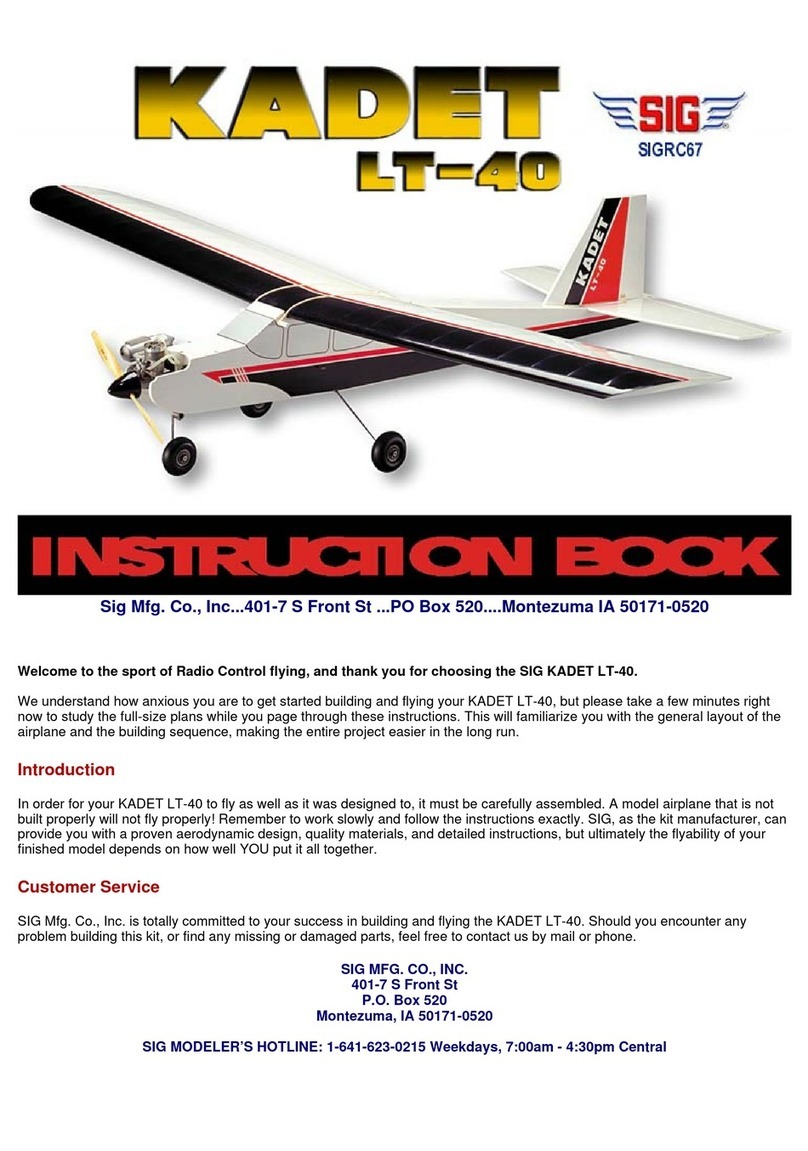

INTRODUCTION:

Congratulations on the purchase of your SIG CAP231EX ARF kit!

Properly assembled, powered and flown, this SIG ARF kit will

surely become one of your favorite models. Since the general con-

struction, sanding and covering have already been done at the fac-

tory, the only remaining tasks are those of assembly and radio and

engine installations. Note that due to the large number of

useable engines for this model, we simply cannot cover every

possible installation. However, the volume provided inside the

large cowl should be helpful when mounting any engine within the

suggested size range.

The SIG CAP231EX ARF contains some of the lightest, best-

engineered construction of any ARF on the market. This is one of

the reasons it flies as well as it does, using the recommended

engine sizes. You will find that the CAP has superb take-off and

landing characteristics combined with remarkable aerobatic

capabilities. The airframe has been specifically designed to

provide you with a "zeroed out" model. This is to say that the wings

and horizontal stabilizer sit at 0° in relationship to the

thrustline. In turn, this provides you with a model that is

completely "honest" in any attitude. We will cover more set-up

information in the course of the following assembly instructions.

For those of you who are interested in 3-D work, we have

provided the CAP with double beveled rudder and elevator hinge

lines. This means that the flying surfaces can be driven to throws

in excess of 45° for 3-D maneuvers!

We urge you to follow these assembly instructions closely to

produce the model as it is intended to be. Modifications are the

very nature of modelers and we're sure that many of you will be

tempted. Simply be aware that certain assembly procedures for

this airplane must be followed. We will make a point of telling you

what these are as we proceed.

REQUIRED EQUIPMENT,TOOLS AND SUPPLIES

FOR ASSEMBLY:

RADIO EQUIPMENT

We highly recommend the use of one of the modern

programmable computer radios, such as the excellent Airtronics™

RD-6000 system, used during our development of this design.

Such radio systems allow you to easily set and adjust every

function and additionally pre-program various flight functions to

suit your individual style of flying. Four channels are required to fly

your CAP231EX; rudder, elevator, ailerons, and throttle.

However, you will require a total of six servos; ailerons-2,

elevators-2, rudder-1, and throttle-1.

Since your CAP 231EX is a large, highly aerobatic airplane and

because the control surfaces are also large, we urge you to use

appropriate servos on all flight surfaces (ailerons, elevator, and

rudder). This model should not be flown with “standard” 40 - 50

inch/ounce output servos! The CAP is big enough to impart very

large air loads and standard servos will quickly fail, resulting in loss

of control. You should use heavy-duty ball-bearing servos with at

least 65 inch/ounces of torque or more to drive the ailerons,

elevator, and rudder. If available, use a servo with metal gears

instead of plastic. Specifically in our prototype models, we used

Airtronics™ #94731 servos for the ailerons, elevators, and rudder.

This is a dual ball-bearing servo, rated at 80 inch/ounces of torque.

Another good choice is the Hitec™ #605MG servo (77

inch/ounces) or Hitec™ #615MG servo (107 inch/ounces). These

servos or equivalent from other manufacturers, can be relied upon

to work well thoughout the CAP’s flight envelope.

A “standard” servo is adequate for the throttle.

We also suggest that you consider using after-market reinforced

plastic servo output arms, such as the Du-Bro "Super Strength"

products. These output arms are available to fit any servo. They

are very strong and work well with this model. We highly

recommend their use with the pull-pull rudder system used in this

CAP. Using typical plastic servo output arms with the braided steel

cables for rudder control, may cause problems due to the

potential of wearing of the plastic by the cables over extended use.

The Du-Bro output arms are molded from considerably tougher

material and these have held up extremely well in our CAP

prototypes.

In addition to the servos, switch harness, receiver, etc., used in

normal airborne radio installations, you will also need two (2) 12"

aileron servo extensions, one (1) aileron Y-harness cable for the

two aileron servos, and a Y-harness splitter cable for the two

elevator servos. Note that the elevatorY-harness cable is used to

electronically connect both elevator servos to a single connector

going into the receiver. Normally, this requires reversing one of the

elevator servos, making it the "mirror image" of the opposite one,

mounted on the opposite fuselage side. However, we found a

great product that not only acts as an elevator Y-harness

cable/extension, it electronically reverses one of the elevator

servos and has a centering adjustment pot. This feature lets you

dial in the elevators exactly to a neutral relationship with each

other. This product is called the "Miracle Y™", sold by MAXX

PRODUCTS, Lake Zurich, Illinois. It can be ordered with any radio

manufacturer's connectors you specify. We have thoroughly

tested this product and found it to be reliable, easy to use and very

reasonably priced. In addition, it is a total of 24" in length - 12" of

elevator extension cables and a 12" cable lead to the receiver.

Perfect for the CAP! Please refer to the Manufacturer's Index for

further contact information.

Finally, since you will be using a total of six servos to fly this

airplane, we strongly suggest you use a large capacity battery

pack for use in this model. We have used both 1000 Mah and 1200

Mah packs with very good results. Using the light 1000 Mah pack,

we have been able to safely fly five or six flights during any given

flying session, a reasonable amount of flying time for most

modelers. Naturally, a larger pack provides more flight time but

1

R

remember that larger can also equate to heavier. We also suggest

that you routinely use an Expanded Scale Voltmeter (ESV) at the

field to check the charge condition of your batteries. This common

piece of field equipment can save your model!

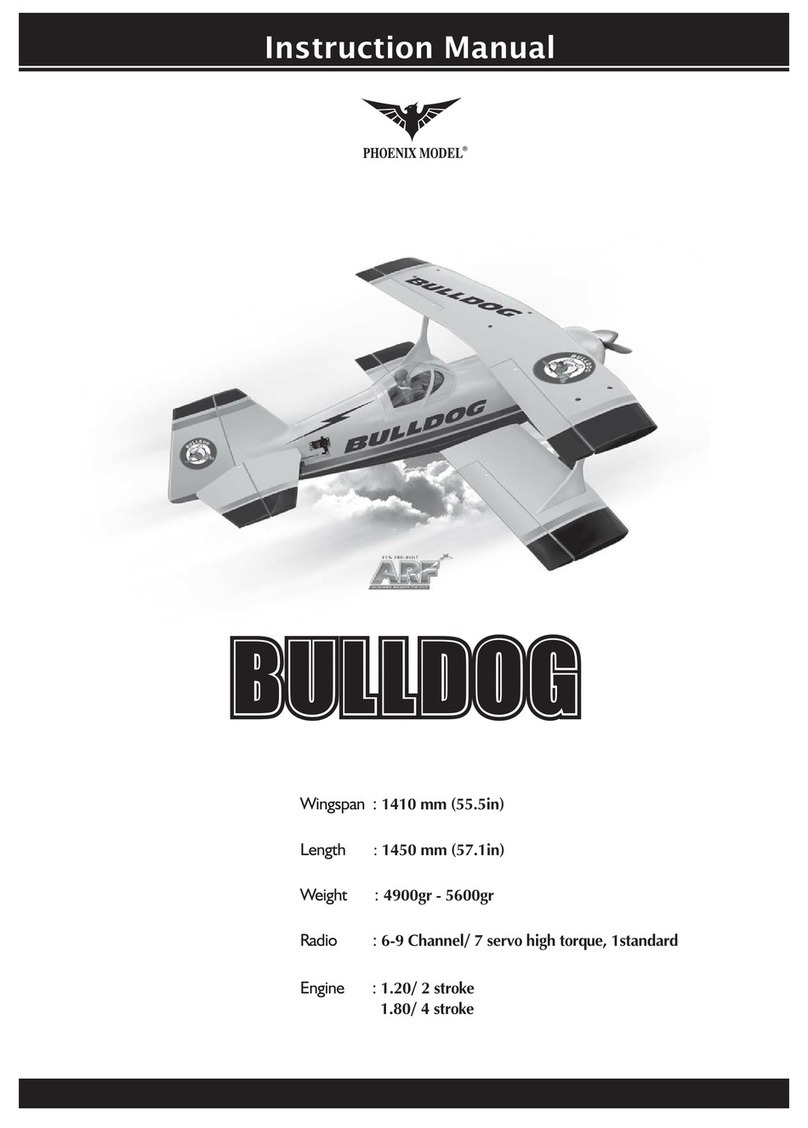

ENGINE SELECTION

The SIG CAP 231EX ARF has been flown with a variety of 2 and

4-stroke engines. As everyone knows, there is no substitute for

power and the engines recommended for this model all provide

good power margins. Naturally, the larger engines in this range

make more power and will fly the CAP with more authority than the

smaller engines. It is simply a matter of how you want to fly this

airplane. We can tell you that our testing with both the Irvine 1.20

and 1.50 2-stroke engines was very good. Both engines make

great power and are easy to install and operate. In the case of the

1.50, we use a 16 x 8 APC prop and find the power sufficient to

achieve excellent vertical performance, with power to spare. When

using a 2-stroke engine, mufflers are always a problem. But not in

this case! SIG stocks a special in-cowl muffler for use with the

CAP and either the Irvine 1.20 or 1.50 engines. This muffler is very

effective, fits perfectly and was expressly designed for use in the

CAP. It is SIG part number IRV120150M. In the 4-stroke range,

good engine choices might be the YS 1.20 or 1.40 and

others such as the Saito 1.20, 1.50, or the newer 1.80.

We have done no testing of gasoline engines for this model and

cannot recommend any one particular engine over another.

However, should you decide to power your CAP with a gasoline

engine, be very sure to use gasoline compatible fuel tubing and a

fuel tank meant for gasoline.

TOOLS AND SUPPLIES

The CAP ARF requires a variety of typical hobby tools and

supplies found in most workshops. For example, you will need a

power drill, a selection of drill bits, a Dremel®Tool, screwdrivers

(both slotted and phillips), a soldering iron and solder, pliers, a

hobby knife with a selection of blades, a ruler, a tape measure,

masking tape, wax paper, petroleum jelly, threadlocking

compound, such as Loctite®, etc.

You will also need a variety adhesives. We suggest you have both

thin and thick SIG CA glues handy, as well as both 5 and

30-minute epoxy glues. For ease of mounting the elevator splitter

cables, we found that clear silicon adhesive works great. These

assembly instructions will be specific regarding adhesives. While

we all have our own preferences, we would urge you to give

careful consideration to these suggestions.

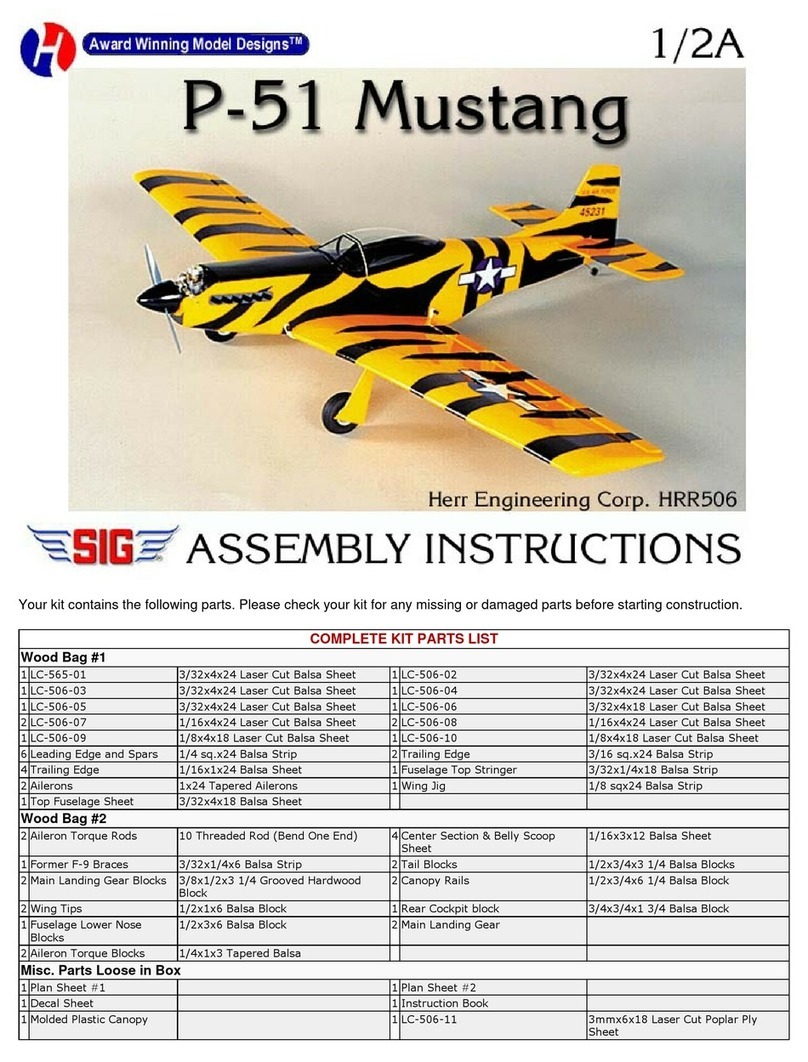

KIT CONTENTS

The following is a complete list of every part included with your

CAP 231EX ARF kit. This kit was packed and inspected at the SIG

factory. Each part has been individually inspected and packed by

SIG employees. We urge you to be as careful as we have been,

using the check-off blocks to inventory your kit before beginning

assembly.

❑1 Fuselage, covered

❑1 Wing Set, covered

❑1 Aileron Set, covered

❑1 Aileron Servo Hatch Cover Set, covered

❑1 Wing Bolt Plate, covered

❑1 Vertical Fin, covered

❑1 Rudder, covered

❑1 Horizontal Stabilizer, covered

❑1 Elevator Set, covered

❑1 Fiberglass Cowl, painted

❑1 Molded Plastic Canopy Base, painted

❑1 Molded Plastic Tail Fairing, painted

❑1 Fiberglass Wheel Pant set, painted

❑1 Canopy, clear plastic

❑1 Tailwheel Assembly, complete

❑1 2-3/4" dia. Spinner Assembly, complete

❑1 500cc Fuel Tank Set

❑1 .021x72" Rudder Pull-Pull cable

❑4 3/32"O.D.x1/2" Alum. Pull-Pull Crimps

❑2 4-40 Threaded Rigging Couplers

❑1 1/8"dia.x2" Heat Shrink Tubing

❑1 Pre-Cut Wood Parts Package:

4 Aileron Servo Mounts - 13/16" sq. x 3/8"

2 Rudder Servo Mounts - 3/8"x 9/16"x1"

1 Throttle Tube Mount - D/C 1/8" plywood

1 Wing Joiner - laminated plywood

1 Front Wing Dowels - 5/16" dia.x1-9/16"

10 Mounting Pads - 1/8"x3/4"sq. plywood

❑1 2-56 Solder Clevis - Throttle

❑14 4-40 Blind Mounting Nuts

❑2 4-40 J-Bolts - Tank Mounting

❑4 4-40 Solder Clevises - Aileron/Elevators

❑7 4-40 Threaded R/C Links

❑2 4-40 x 2/34" Threaded Pushrods - Ailerons

❑2 4-40 x 2-1/8" Threaded Pushrods - Elevators

❑4 4-40 x 3/8" Slotted Bolts - Wheel Pants

❑6 4-40 Hex Nuts - Jam Nuts For Clevises

❑10 4-40 x1/2" Nylon Bolts - Canopy/Cowl Mounts

❑4 10-32 x 1" Socket Head Bolts - Motor Mounts

❑4 10-32 Blind Mounting Nuts - Motor Mounts

❑2 M5.5x35mm Nylon Wing Bolts

❑3 M4x25mm Landing Gear Bolts

❑12 #4x3/8" Sheet Metal Screws - Control Horns

❑1 Main Landing Gear, .190 hardened aluminum

❑2 3-3/16" dia. Main Wheels

❑1 1-1/4" dia. Tailwheel

❑2 Wheel Axles, hardened steel

❑2 Lock Nuts for wheel axles

❑4 Wheel Collars & Set Screws for wheel axles

❑8 #2 Wood Screws for aileron servo hatches

❑1 Motor Mount Set, glass-filled nylon

❑1 Pushrod Connector Assembly - Throttle

❑17 Nylon Double X Hinges

❑17 Steel Hinge Pins

❑3 Nylon Control Horns/RIGHT-Ail., Elev. & Rud.

❑3 Nylon Control Horns/LEFT - Ail., Elev. & Rud.

❑1 1/8"O.D.x18" Nylon Throttle P/R Tubing

2

❑1 18" Steel Cable Throttle Pushrod

❑1 #64 Rubber Band - Fuel Tank Retainer

❑1 Set, Special CAP 231EX Decal Sheets:

2 #DKM277A

1 #DKM277B

❑2 3/4"x18" Yellow Covering Material Strips

❑1 Assembly Manual

COVERING MATERIAL

Your SIG CAP 231EX ARF kit has been expertly covered with #819

Dark Yellow Carl Goldberg Models ULTRACOTE®. Before

leaving the factory, all covered parts were inspected and cleaned

before being packed. Upon opening your kit you may find that the

covering has relaxed in some areas, requiring reshrinking. This is

perfectly normal and has nothing to do with the covering material

or how it was applied. It has to do with the wood beneath the

covering. Wood takes on or loses ambient humidity. Your CAP

ARF was manufactured in a relatively humid region of the world.

The wood was therefore holding humidity at the time the parts

were covered and bagged. Once the parts are removed from their

bags and subjected to drier conditions, the wood quickly loses

moisture and the covering may appear loose. This also explains

why most iron-on coverings stay tight in the summer only to loosen

a little in drier winter conditions.

We suggest you use a heat gun and/or a cloth-covered iron to

completely go over the various covered parts of your CAP, making

sure the covering is drum tight and that every seam is well

adhered. Be sure to follow Goldberg's suggested heat settings for

ULTRACOTE®to avoid damaging the covering.

INSTALLING HINGES

As mentioned, the CAP 231EX is a large airplane with large,

powerful flying surfaces. This means that the hinges used to attach

these flying surfaces must be up to the task. For this

reason, we have included SIG's famous Double X Pinned Nylon

Hinges for use with this model. Properly installed, these hinges

are extremely smooth in action and very strong. The effort involved

in mounting these hinges will be more than compensated by the

close fit, smooth action and the peace of mind you have when

flying this airplane.

The hinging procedure is the same for all flying surfaces - ailerons,

elevators and rudder. This manual will tell you when to hinge

the various surfaces - DO NOT hinge surfaces ahead of time,

unless instructed to do so. Note that each flying surface and its

corresponding installation point have been pre-slotted at the

factory for your convenience. Ailerons require four (4) hinges

each, elevator halves require three (3) hinges each, and the

rudder uses three (3) hinges, for a total of 17 hinges and hinge

pins. These are provided in a separate bag in your kit.

Begin by using a hobby knife to completely open up and clear each

pre-slotted hinge openings. These slots need to be 1" wide to

accept the width of the hinges and about 5/8" deep on each side.

Next use a short length of thin saw blade material (such as a piece

of Dremel®saw blade) to open the width of the slots even further

to accept the thickness of the nylon hinges.

Assemble the hinges by inserting a hinge pin through the center

holes of both interlocking halves. Once the hinges are pinned, use

a pair of needle nose pliers to bend the sharp end of the pin

90°, as close to the hinge joint as possible, without binding it.

Pre-assemble all hinges in this manner.

Next, use a sharp #11 blade in your hobby knife to countersink the

round "knuckles" of one of the hinges into the beveled edge of the

flight surface (ailerons, elevators and rudder). Simply insert a

hinge into the flight surface until it bottoms out on the edge of the

bevel. Use your hobby knife to then cut a slot on each side of the

hinge knuckle to a depth equal to the knuckle (about 1/8").

Remove the hinge half and use your knife to cut the rest of the

balsa and covering away from the hinge slot, allowing the hinge

knuckle to recess into the flying surface. Repeat this process for

each hinge slot location on each flying surface.

3

MODELER S TIP: One of the most common problems

associated with shrinking any covering film is controlling the

heat around seams. Heat applied close to or directly onto

seams re-heats the covering adhesive and the seam will often

"crawl". This is easy to control. Just tear a few paper towels

into strips and soak them in cool tap water. ay the wet strips

over any covering seam and use your heat gun or iron as you

normally would. The wet strips keep the seam cool while the

covering immediately next to it shrinks. This tip works great

with any iron-on covering.

IMPORTANT NOTE: There are left and right ailerons. You

can easily tell which aileron belongs with the proper wing

by the fit and noting the plywood hardpoint plate for the

aileron horns on the bottom of each aileron. The outline of

this plate is easy to spot through the covering. It lines up with

the aileron servo hatch on the bottom of each wing panel.

The elevator halves are symmetrical and each has a

plywood hardpoint plate on both sides, allowing them to be

mounted on either the right or left side of the horizontal

stabilizer.

The flight surface can now be hinged in place. Begin by using a

scrap wood stick to apply a coat of petroleum jelly, such as

Vaseline®, to both sides of the hinge knuckle, as well as each end

of the knuckle. Do not get this material on the hinge ends to be

glued! Petroleum jelly keeps epoxy from sticking to the hinge

joints. Hinges should be installed, starting with the flying surface

side first. We also suggest using slow cure 30-minute type epoxy

for hinging because of the longer working time and strength. Apply

epoxy glue to one side of the hinge, liberally coating each side and

filling the "double X" cutouts. Insert the hinge into its slot, along

with the sharp end of the pin. Slide the hinge in place into

the previously cut recess. The free, unglued side of the hinge half

should be even with the front, beveled edge of the flying surface

when flexed 90°. Use a clean cloth and alcohol to carefully

remove any excess glue and move to the next hinge. Once the

hinges are in place in the flying surface, apply epoxy to each side

of the remaining hinge halves and insert them into the

corresponding slots in the wing, stab or fin. You want the beveled

leading edge of the flying surface to be as close to the mating part

as possible while still having full left and right or up and down

movement ability. Again use alcohol and a cloth to carefully

remove all excess glue. Flex the flying surface to be sure it moves

freely. Tape the part in place and move to the next surface to be

hinged.

WING ASSEMBLY

The wing panels have been carefully built, sanded and covered at

the factory. The dihedral angle has been already built into the root

ribs of these two panels and should require no further adjustment.

However, before assembly, install the plywood laminate wing

joiner into one of the panels and slip the opposite panel in place.

Check the fit for alignment and that both root ribs come into firm,

straight contact with each other. If the wing joiner requires a little

trimming to achieve this fit, do so now. These instructions assume

a good fit.

❑1) Prepare the two wing panels for assembly by first using

your hobby knife to remove the covering from the forward

wing dowel mounting holes, the top round holes for the

servo cable exits and the rear wing bolt mounting holes.

❑2) From the kit contents, locate the two (2) pre-covered aileron

hatch covers and eight (8) #2 x 3/8" screws. Trial fit the

hatch covers into the aileron servo openings to determine

which cover goes in the right wing and which goes in the left

wing. Position and tape the hatch covers in place, aligning

their servo arm cutouts with the ones in the wing opening.

4

Drill a 1/16" dia. hole near each corner of the hatch covers.

Drill completely thru the hatch cover and into the hardwood

mounting beams that are in the wing.

❑3) Remove the hatch covers. Redrill the holes in each corner

of the covers with a 1/8" dia. drill bit to allow clearance for

the screws.

❑4) The aileron servos are mounted to the back, uncovered

sides of the servo hatch covers. From the kit contents,

locate the four (4) 13/16" sq. x 3/8" aileron servo mounts.

You will also need the servo mounting grommets, screws,

etc., supplied by the radio manufacturer for this step.

Remove the servo output arm/wheel and lay the servo flat

on its side. Position two of the mounting blocks beneath the

servo’s mounting arms, also flat on the same surface as the

servo. Use a bit to drill the servo mounting holes into the

wood mounting blocks. Use the screws that came with your

radio system to now mount the servos to the two mounting

blocks.

❑5) Attach the output arm back onto the aileron servo. Place

the servo/mounting block assembly onto the back side of

the servo hatch, aligning the output arm with the half slot

opening. The servo output arm must be able to move freely

back and forth without touching the slot’s edge - about 1/32"

clearance is adequate. With the servo now in this position,

use a sharp pencil to mark the hatch with the locations of

the servo mounting blocks. Remove the servo from the

hatch and apply thick CA or 5-minute epoxy the to bottoms

of the servo blocks and glue them in place to the hatch,

again checking for output arm clearance. Place a weight

onto this assembly and allow it to dry. Repeat this step with

the opposite servo hatch cover.

❑6) Before installing the aileron servos and hatch covers into

the wing panels, use your radio system to 1) center both

servos and 2) to check travel. Install the correct servo

output arms onto each servo, being sure they are upright at

90¡ to the servo and that they are long enough to clear the

wing’s surface during extremes of travel. Once this has

been checked, attach the 12" servo cable extensions to

both aileron servos. We would suggest that you also use

tape to secure these connections. Feed the servo

extension cable into the wing servo hatch opening, through

the holes in the ribs and finally out through the round holes

provided at the center of each wing panel. Tape the

connector to the wing’s top surface. Install the aileron

servo/servo hatch in place into the wing and use the

#2 x 3/8" washer head screws to secure the hatch. Did you

remember to install the output arm screws in each servo?

5

❑7) Using the hinging instructions provided, install and glue the

four required hinges into each aileron. Hinge each aileron

to it's appropriate wing panel - remember that the inset ply

aileron horn mounting pad is located on the bottom side of

each aileron. Carefully clean any excess epoxy with a

clean cloth and alcohol.

❑8) Use 30-minute epoxy to liberally coat the inside of each

wing joiner pocket in both wing panel roots. Liberally apply

epoxy glue to the exposed wood center ribs of each wing

panel and apply glue to the laminated plywood wing joiner

itself. Insert the wing joiner into one wing panel pocket and

slide the other panel in place over the exposed joiner end,

joining the two panels at the center. Press the panels

together and use alcohol and a cloth to remove all excess

glue. Firmly tape the front and trailing edge joints to align

and secure them. Place a clean rag on the floor next to a

wall. Stand the wing upright, with one wingtip on the cloth,

as vertical as possible, leaning against the wall. Place a

weight on the upper wing tip and allow this assembly to fully

cure.

❑9) Use slow cure 30-minute epoxy to install the two front

locating dowels into the front wing plate, leave 1/2" of dowel

exposed to engage the corresponding fuselage mounting

holes. Use plenty of glue and a stick to get it into the two

holes before inserting the dowels. Visually be sure these

dowels are straight in the wings and not at angles. With the

dowels in place, stand the wing up on its leading edge and

allow the glue to cure.

❑10) Use the 3/4" x 18" lengths of ULTRACOTE®supplied with

your kit and a heat iron to carefully cover the center wing

glue joint. Cover the bottom seam first, followed by the top

seam.

❑11) The wing is now fitted to the fuselage. First engage the two

forward dowel ends in the wing into the two dowel holes in

the forward, bottom fuselage former. Because of slight

differences in the manufacturing process, it may be

necessary to adjust one of these holes slightly to receive

the wing dowels. If this is the case, only adjust one of the

holes. This is easiest to do with a #11 blade in your hobby

knife, opening the hole to either the right or left, allowing the

wing dowel to pass. Once the wing engages into the front

of the fuselage, press it in place into the wing saddle.

❑12) From the kit contents, locate the covered plywood wing bolt

plate. The bolt plate has two holes that will line up with the

6

wing bolt holes already drilled in the rear center section of

each wing panel. Use your hobby knife to remove the

covering over the two wing bolt holes in the wing panels

and the bolt plate. Place the plate in position over the

trailing edge of the wing, aligning its rear edge with the

fuselage bottom and its two bolt holes with the bolt holes in

the wing panels. In this position, press the bolt plate to the

wing and use a pencil to draw the outline of the bolt plate

onto the wing. Remove the wing from the fuselage. Use a

hobby knife to remove the covering material on the wing,

about 1/8" inside the bolt plate outline. Glue the bolt plate

to the wing - aligning its bolt holes with those in the wing -

with thick CA glue. Hold or clamp the plate firmly to the

wing, allowing the glue to set.

❑13) From the kit contents, locate the two M5.5 x 35mm nylon

wing bolts. Mount the wing in place to the fuselage and

insert the two nylon wing bolts into the two holes. Thread

the bolts into the blind mounting nuts and use a

screwdriver to tighten them and the wing in place onto the

fuselage. Do not over tighten the bolts. Remove the bolts

and the wing from the fuselage.

❑14) Connect aileron servoY-harness to your receiver and servo

leads to the Y-harness. Turn on your transmitter and plug

your airborne batteries into your receiver. You should now

be able to operate your aileron servos.

•Center servos with trims and/or through the radio's

computer.

•Carefully center servo output arms to exactly 90°upright

when at neutral.

•Test the action of the servos, making sure the output

arms move freely and that they move in the correct

directions for left and right aileron action.

•Turn off the radio system, disconnect the servos from the

Y-harness.

❑15) From the kit hardware provided, locate one left and one

right nylon control horn and four #4 x 3/8" sheet metal

screws. Tape the ailerons in neutral and lay the wing

upside down on your bench. Position one of the ailerons

horns in place on the bottom, leading edge of the aileron,

lined up with the servo output arm. Mark the horns hole

locations onto the aileron with a pointed marker pen. Drill

two 3/32" dia. guide holes into the aileron at the marks just

made. Mount the horn in place, using two #4 x 3/8 sheet

metal screws. Repeat this process on the opposite aileron.

❑16) Make the aileron pushrods by first soldering a 4-40 solder

clevis to the unthreaded ends of the two 4-40 x 2-3/4" steel

pushrods. Thread a 4-40 hex nut onto the threaded end of

the pushrod, followed by a threaded clevis. Connect the

solder clevis end of the pushrod to the aileron servo output

arm. Holding the pushrod in place to the aileron horn,

adjust threaded clevis as needed to match its connecting

pin to the middle hole in the horn - snap the threaded clevis

in place to the horn. Repeat this process on the opposite

wing panel. Remove the tape holding the ailerons in

neutral to the wing panels.

❑17) Check the aileron servo action with your transmitter by

connecting the servos to your receiver. Final adjustments

of all flying surfaces will be done after assembly is

complete. This completes the wing assembly.

ENGINE MOUNTING

It is assumed that most modelers will side mount their engines,

with the head in the right cowl cheek. The CAP has a relatively

large amount of area for this type of engine mounting and it is

highly recommended. Realistically, the engine could be mounted

in any position, including upright or inverted, as long as it is

understood that the cowl must be cut to clear it. These instructions

assume that your engine will be mounted on its side with the head

in the right cowl cheek. Accurate horizontal and vertical engine

centerline marks are on the firewall. These marks must be used in

order to position your engine accurately to the intended

thrustline and to accurately mount the cowling. The round hole in

the firewall accepts the front of the fuel tank and is purposely

offset to allow fuel line clearance when installing most engine

types. The supplied motor mounts are generic. They will accept

many engines but not all. Check your engine for fit to these mounts

before using them. Other after-market mounts are available and

will work on this airplane if you choose.

❑1) Use a straightedge and pencil to highlight the horizontal and

vertical centerline marks on the firewall.

❑2) Measure the width of your engine's case, at the mounting

lugs. (example: an Irvine 1.50 2-stroke has a case width of

2.03" (2-1/32") between the mounting lugs and a Saito 1.50

measures almost exactly 1.80" between the mounting

lugs.). Divide the case width measurement by 2 and place

a mark on each side of the vertical centerline on the firewall.

7

These marks become the inside locator marks for the two

motor mounts.

❑3) The motor mounts have a centerline "tick" mark at their

mounting ends. Line this mark up with the vertical

centerline, with the inside edge aligned with the case width

marks just made. This is the position the mount needs to

be, in order to fit your engine. Mark the mount's bolt hole

locations onto the firewall with a pencil or a little shot of

paint from a spray can - remove the mount. Repeat this

procedure for the opposite mount arm.

❑4) Use a 3/16" dia. bit to drill the four required holes in the

firewall for the two motor mount arms, being careful to

center them as exactly as possible. Once all four holes are

drilled, change drill bits to a 1/4" dia. and redrill the four

holes to allow clearance for the 10-32 blind nuts.

❑5) Apply epoxy glue to the four 10-32 blind nuts, keeping glue

away from the threads. Install the nuts from the inside of

the fuselage, pressing them firmly in place. Use a motor

mount arm and a 10-32 x 1" socket head bolt to pull the

blind nuts firmly into place in the back of the firewall.

Remove the bolt after each nut is secured. When all four

nuts are in place, use a cloth and a little alcohol to remove

excess glue from the inside back face of the firewall.

❑6) Bolt the two motor mounts to the firewall. Place your engine

on the mounts. Move the engine on the mounts until it

measures exactly 6" from the front face of the prop drive

flange, back to the firewall. This is the distance your engine

needs to be from the firewall for cowl mounting and prop

clearance purposes. Mark your engine's mounting lug bolt

hole locations onto the motor mount arms and remove the

engine.

❑7) Note that we have supplied you with most of the hardware

needed to assemble this kit, with the exception of engine

mounting bolts. These you will need to obtain yourself. We

have used and strongly recommend, steel hex head bolts at

least 1-1/4" - 1-1/2" long, with washers and lock nuts. For

example, 8-32 bolts will fit and work with both the Saito and

Irvine 1.50 engines -

DO NOT USE SELF-TAPPING OR WOOD SCREWS

FOR MOUNTING YOUR ENGINE ON THE SUPPLIED

MOTOR MOUNTS!

Drill the four required mounting holes in the motor mount

arms, being very careful to drill them perpendicular to the

mount arm at 90°angles, using the hole locations just

made. These must be clearance holes, which allow the

bolts to slip through. In the case of 8-32 bolts, an 11/64"

dia. drill bit will provide clearance holes. With the engine's

muffler and needle valve removed, mount the engine in

place to the motor mount arms.

❑8) You will of course need to mount a muffler to your engine

and in turn, the muffler must be considered when mounting

the cowl in the next assembly step. If you are using either

the Irvine 1.20 or 1.50 2-stroke engines to power your CAP,

SIG has a muffler available for these engines that is not only

light in weight but fits perfectly within the cowl. This muffler

is SIG part number IRV120150M and is available

separately.

8

MOUNTING THE COWL

Before mounting the cowl, carefully inspect its inside rear edges.

Use sandpaper to smooth the inside rear surface of the cowl,

making it free of any bumps or ragged edges that may scratch or

dent the fuselage when pressed in place. Also, make sure the four

mounting holes are open and free of any debris.

❑1) Carefully fit the fiberglass cowl in place over the engine and

back onto the fuselage. The head of your engine will likely

fit inside the cowl. If it does not, you will now need to open

the cowl cheek, allowing clearance of the head, rocker arm

cover or whatever else may be contacting the inside of the

cowl. This is largely a matter of carefully observing where

the engine part is contacting the cowl and then marking that

location on the cowl with a felt marker. Remove the cowl,

and use a Dremel®Tool to make a small hole in the cowl

at the point of contact. Refit the cowl, checking the hole

location and size, adjust as needed and again use the

Dremel®Tool to work on the opening. This method is

referred to as "sneaking up" on the opening, making a

perfect clearance hole. A handy tool for this job is a small

penlight. The penlight can be used from the inside or

outside of the cowl to highlight and spot required hole

locations. We suggest using a clearance distance rule of

thumb of at least 3/16" from the cowl to any engine part.

❑2) Once the cowl is in place without any part of the engine

contacting it, push the cowl back onto the fuselage until the

engine prop mounting flange emerges from the front

spinner ring. This flange must clear the front of the cowl by

at least 1/16".

❑3) Slip the spinner backplate in place over the engine prop

shaft, pushing it all the way back to the prop mounting

flange. Mount a prop or prop stub "dummy" in place on the

drive shaft, followed by the thrust washer and retaining nut.

Tighten this assembly sufficiently to bring the spinner

backplate firmly in place against the prop mounting flange.

❑4) We suggest mounting the cowl with a 1/16" space between

the back of the spinner and the cowl. This allows for small

thrust adjustments, if desired. Use scrap pieces of 1/16"

plywood to space the cowl behind the back surface of the

spinner backplate. Center the spinner backplate to the cowl

and use masking tape to hold it securely in this position.

Use masking tape to secure the back of the cowl to the

fuselage, leaving the four pre-drilled mounting holes

uncovered. With the cowl securely in place, it is in position

for mounting to the fuselage.

❑5) Use a 7/64" dia. drill bit to drill holes through the fuselage,

centered in each of the four holes in the cowl (1 hole on

each upper right and left sides of the cowl and 1 hole on

each bottom right and left sides of the cowl). From your

parts bag, locate two (2) 1/8" x 3/4" sq. plywood plates, four

(4) 4-40 x 1/2" nylon bolts and four (4) 4-40 blind mounting

nuts. The two 1/8" x 3/4" sq. ply plates will be glued to the

inside of the fuselage at the upper right and left hole

locations, directly over the holes just drilled. Hold one of the

ply plates in place, flat against one of the upper inside cowl

mounting holes and use a sharp pencil, from the outside, to

make a mark on the plate. Remove the plate and use a

5/32" dia. bit to drill a hole through the plate at the mark just

made. Apply epoxy glue to one of the 4-40 blind nuts and

insert it into the plate, pressing it firmly in place - wipe off

any excess glue. Apply glue to the face of the ply plate and

hold it in place inside the fuselage. Before pressing the

plate in place, run one of the 4-40 nylon bolts through the

cowl and into the fuselage. Engage the bolt into the threads

of the blind nut, mounted in the ply plate. Thread the bolt in

place, tightening it until the plate is firmly in place against

the inside of the fuselage. Repeat this procedure to secure

the opposite side of the cowl with a nylon bolt, plate and

blind nut.

❑6) The two bottom cowl holes are handled in a similar manner

but without using plywood plates. Apply epoxy glue to one

of the 4-40 blind nuts and insert it into one of the bottom

inside cowl hole locations. With the fuselage flat against

your workbench, use pressure to seat the nut firmly into the

plywood. Wipe off any excess glue and repeat the process

with the remaining blind nut and cowl mounting hole.

❑7) Use the four nylon 4-40 x 1/2" bolts supplied in your kit to

secure the cowl to the fuselage from the outside. Remove

all masking tape, the 1/16" plywood spinner/cowl spacer,

the retaining nut, prop and spinner backplate. Check your

work and remove the cowl from the fuselage.

❑8) An opening must now be made in the bottom of the cowl.

This opening is absolutely necessary to allow incoming air

to properly flow through and exit the cowl. Without this

opening, your engine will overheat and quit. If you are

using a 2-stroke engine, such as the Irvine 1.20 or 1.50 or

a 4-stroke, such as the Saito 1.20, 1.50 or the 1.80, we

suggest using an opening, which measures 4-1/8" wide by

7" deep. This size opening allows the exhaust pipes on

the recommended SIG muffler for the Irvine engines to

clear the cowl with plenty of additional air exit area, as well

as allowing plenty of air for 4-stroke engines. This opening

may certainly be "customized" for your particular

engine/muffler set-up, as long as there is sufficient air exit

area.

Stand the cowl upright on its rear edge, nose up, with the

bottom side facing you. You will need a ruler, a 90°triangle

and a fine point non-permanent felt marker pen to mark the

cowl for cutting. The approximate width of the bottom rear

edge of the cowl is 6-1/2". Make a mark at the center of the

9

cowl, approximately 3-1/4" in from the outer edge. Stand

the triangle up against the bottom edge of the cowl, aligned

with the mark just made. Use the felt marker to draw a

vertical line up toward the nose about 8" long. Measuring

from this centerline, make a mark at 2-1/16" to the left of the

centerline and another at 2-1/16" to the right of the

centerline. Again using the triangle and the marks just

made, draw a straight vertical lines on the cowl from the

bottom edge up towards the nose, again about 8" long.

These two outer lines should parallel the centerline.

Measure 7" up from the back edge of the cowl, making

a mark at one of the outer vertical lines. Repeat this

measurement and mark on the other outer vertical line. Use

a straightedge and marker pen to connect these two marks.

This gives you the area to be cut out from the bottom of the

cowl. To avoid sharp corners and for a better look, we

suggest using a circle guide to round the two upper corners

of this cut out area.

The fiberglass can be cut from the cowl easily, using a

Dremel®Tool and a large cut-off wheel. Before cutting out

the cowl opening be sure to wear safety glasses and a

mask of some kind to avoid inhaling any fiberglass dust.

Carefully cut the fiberglass, using the lines previously

drawn. If you are careful, you will find that you can get

fairly close to the lines with the cut-off wheel. The goal is to

remove most of the material within the lines. Once the

piece is cut and removed, exchange the cut-off wheel for a

sanding drum bit in your Dremel®Tool. Use the drum

sander bit to round the upper two corners and to lightly

clean up any jagged edges. Use 220 sandpaper to clean

up the edges of the cutout, without sanding the paint. Make

sure the edges are uniform and free of any loose glass.

Remove all fiberglass dust from the cowl with alcohol and a

clean cloth.

❑9) Mount the now trimmed cowl back onto the fuselage, over

your engine. In this step you will determine the location for

the hole required for your engine's needle valve to exit the

cowl. This is easiest done using the penlight mentioned

earlier in step #1 and fine line marker pen. First find the

approximate location of where the needle valve will exit by

looking carefully at your engine's carburetor. Mark that

location onto the cowl.

Now look a little closer and use the penlight to adjust the

mark just made from the outside of the cowl. Reposition the

mark as required to get as close as possible to the actual

exit location. Use the Dremel®Tool and a small tipped

grinding bit to make a small hole (maybe 1/16" in diameter)

in the cowl, at the exit mark just made. Chances are that

you were quite close to the actual exit point. Stick a piece

of music wire into the hole, down to the needle valve hole in

the carburetor. Carefully observe if the hole needs to be

repositioned to straighten up the wire, as if it were the

needle valve. Make another mark on the cowl and again

use the Dremel®Tool to open the hole just a little towards

the correct position. In this manner, continue checking and

adjusting the exit hole until it aligns perfectly with the

carburetor/needle valve position. Use the Dremel®Tool

and tapered bit to open the hole enough to insert and install

the needle valve in the carb. Be sure the hole has at least

3/32" clearance around the needle valve to avoid contact.

❑10) You must be able to fuel and de-fuel your CAP

conveniently. There are several commercially available

fueling systems that would work with this model. We have

used and highly recommend the Du-Bro #334 Kwik-Fill

Fueling Valve for glow engines. In this optional step, we will

explain how we mounted our fuel valve. All that's required

is to make a simple aluminum bracket, mount it to the

firewall area and make a small hole in the cowl to accept the

fuel probe. We mounted our filler bracket on the inside face

of the left hardwood protrusion on the left edge of the

firewall. In order to meet the cowl as closely as possible but

10

not contact it, we bent the bracket to match the

fuselage/cowl side when viewed from the front. Our

bracket was made from K&S 1/16“aluminum sheet. Drill

the bottom end of the bracket with a 3/8" dia. hole to accept

the fuel valve body and drill two 7/64" dia. holes at the top

end, allowing it to be mounted in place with two #4 sheet

metal screws (not supplied).

A small hole in the cowl, directly over the fuel valve, must

now be made to allow the fuel probe to be inserted into the

valve. Place your penlight behind the bracket, at the hole

for the filler valve. You can now clearly see exactly where

the hole must be on the outside of the cowl. Mark this

location with a marker pen, remove the cowl and use the

Dremel®Tool and a tapered bit to open up a hole about

5/16" in diameter at the mark made earlier. Put the cowl

back on and check your work. Adjust the hole as needed to

allow easy insertion and removal of the fuel probe.

With the engine and cowl mounted in place, the spinner can

now be fitted to the engine. This spinner is a high quality

SIG unit that has been molded to accept APC propellers up

to 16 x 8 in size. The shaft hole in the base of the spinner

must be made to fit your particular engine. If required, shaft

spacers are included. If your engine shaft is larger than the

hole size in the spinner, it can be drilled to fit. This should

be done using a drill press. Slip the base plate onto the

shaft. Slip the propeller onto the shaft and secure it with

your engine's nut and washer. Snap the spinner nose cone

in place into the base plate channels and use the four

mounting screws supplied with the spinner to mount it to the

base plate. Don't over-tighten the screws but bring them up

snug.

GENERAL FUSELAGE AND TAIL GROUP ASSEMBLY

❑1) From the kit contents, locate the bag containing the

tailwheel assembly. Lay the fuselage upside down on your

bench. Note that the tailwheel assembly will be mounted

directly to the fuselage at the rearmost location. Hold one

of the two tailwheel leaf springs in place on the fuselage,

lined up with its centerline. Use a fine tip felt marker to mark

the locations of the two mounting holes in the spring, onto

the fuselage. Remove the spring and use a 5/32" dia. drill

bit to drill two holes through the fuselage bottom at the hole

locations just made.

❑2) Turn the fuselage over, exposing the inside rear of the

fuselage. Apply epoxy glue to the front surfaces of the two

4-40 blind nuts and insert them into the two holes just

drilled. Press them into the wood and wipe off any excess

glue, keeping glue out of the threads.

11

❑3) As shown, assemble the nylon bearing bracket to the

longer of the two leaf springs with two 4-40 x 3/8" bolts and

two 4-40 locknuts. Slip a #2 washer over the top of the

tailwheel wire, sliding it down to the top bend in the wire.

Solder the washer in place to the wire as shown. Slip

another #2 washer over the axle end of the tailwheel wire,

sliding it back to the first bend - solder the washer in place.

Insert the top end of the tailwheel wire into the plastic

bearing bracket, up to the soldered washer. Insert the

wheel collar into the bottom of the steering arm, aligning its

threaded hole with the arm's clearance hole. Install the

4-40 x 3/16" bolt through the steering arm hole, threading it

into the wheel collar. Slip the steering arm in place over the

exposed top end of the tailwheel wire, with the set screw

facing the rear. Leave clearance for free movement and

tighten the set screw in place to the wire.

❑4) Place the 1-1/4" dia. tailwheel onto the axle end of the wire.

If the wheel is a tight fit, use a 7/64" dia. drill bit to open the

axle hole a little. The remaining #2 washer will be soldered

in place to retain the tailwheel. To protect the plastic wheel

hub, use a scrap piece of 1/32" plywood over the axle and

against the wheel. Slide the washer in place against the

plywood and solder it in place - remove the plywood

spacer. The completed tailwheel assembly is now bolted in

place to the fuselage, using two 4-40 x 1" bolts. Use

non-permanent Loctite®on the bolt threads to prevent them

from loosening.

❑5) Use a sharp #11 blade to open up the two elevator servo

cutouts, beneath the stabilizer saddle at the top rear of the

fuselage. Use a trim seal iron to tack the loose covering

around into these cutouts. Trim and remove the excess

covering material.

❑6) Assemble the fuel tank as shown. Be sure to label the

"vent" and "carb" lines for later identification.

❑7) Trial fit the tank in place into the front of the fuselage to

familiarize yourself with how it mounts. The front fits into

the hole in the firewall and the end of the tank requires

support. For this you will need to now install two J-hooks,

12

one on either side of the tank. With these in place, a #64

rubber band is hooked to one J-hook, pulled around the

tank and hooked to the opposite J-hook. With the tank in

place, use a pencil to mark the J-hook locations - remove

the tank. Glue two 1/8" x 3/4" plywood mounting pads over

the hook location marks. Use a twist drill with a 5/64" bit to

drill guide holes through the pads and fuselage supports.

Thread the hooks in place.

❑8) Apply a bead of silicon adhesive around the neck of the

tank, where it contacts the inside of the firewall. Fit the tank

in place into the fuselage, pressing it firmly against the

firewall. Support the rear of the tank to the fuselage with a

#64 rubber band, using the J-hooks.

❑9) Two throttle servo locations are provided, one on each side

of the fuselage. Choose the side that corresponds with the

throttle arm on your engine. Attach the grommets supplied

with your radio system to the servo mounting lugs and use

the mounting screws, also supplied with your system, to

mount the throttle servo.

❑10) From your kit, locate the 1/8" OD x 18" nylon throttle tubing,

the 18" length of steel throttle cable, the die-cut 1/8"

plywood throttle tube support (small part with one rounded

end with a hole for the tube), the pushrod connector

assembly (3/16" hex brass body, nylon retainer and

4-40 x 1/8" socket head cap screw) and the 2-56 solder

clevis. Drill a 1/8" dia. hole through the firewall, aligned with

your engine's carburetor throttle arm. From the front, insert

the 1/8" nylon tube through the firewall and into the

fuselage, leaving 3" exposed in front of the firewall (typical

when using a 1.20 or 1.50 2-stroke engine). With the tube

in place, turn the fuselage over and note the location of the

tube in relationship to the throttle servo. You want to

position the tube directly in front of the servo's output arm.

Assemble the pushrod connector to the servo output arm.

Slip the die-cut 1/8" plywood throttle tube support part over

the end of the tube, back to the forward fuselage former

location. Glue the support in place to the inside front of the

former, locating the tube directly in front of the throttle servo

output arm. Use a razor blade to trim the tube to a length

of 1" behind the die-cut tube support. Remove the tube

and sand its surface with 220 sandpaper to rough it a little.

Reinstall the tube and glue it in place to the firewall and the

die-cut tube support with thick CA glue.

❑11) The steel throttle cable is now prepared for installation.

Solder the provided 2-56 solder link to one end of the cable

13

- this is the carburetor end. Install the brass pushrod

assembly to the output arm on the throttle servo and press

the output arm in place onto the servo. From the firewall,

insert the bare end of the cable through the throttle tube,

connecting the solder link to your engine's throttle arm.

The cable is now cut to length, leaving about 2" of extra

length behind the brass pushrod connector. The extra

length will be useful when setting up the throttle later on.

❑12) From your kit contents, locate the two 3/8" x 9/16" x 1"

hardwood rudder servo mounting blocks. As shown, the

rudder servo is mounted in the center servo cutout, directly

beneath the canopy base. In order to mount the servo, the

two hardwood blocks must be glued in place at the front and

rear edges of the cutout. Test-fit the servo first. If the

opening needs enlargement, do this now until a good fit is

achieved. Epoxy the mounting blocks in place. As shown,

we drilled a small diameter hole in front of the servo,

redirecting the connector back into the fuselage. Use the

grommets and screws provided with your radio system to

securely mount the rudder servo in place onto the blocks.

❑13) Use a ruler to find the exact center of the stabilizer, marking

the location with a felt pen. Use a triangle to draw a 90°

centerline directly onto the stab at this location. Place the

stabilizer into the fuselage, centering it visually. Holding the

stabilizer in place, use the felt pen to mark the stab bottom,

where it meets the fuselage on each side. Remove the

stabilizer and use a #11 blade to carefully remove the

covering material just inside of these two lines, including

where it contacts the fuselage at its leading and trailing

edges.

❑14) In this step you will prepare the horizontal stabilizer for

mounting by first checking it's alignment with the wing and

fuselage. Start by using the three M4 x 25mm bolts

provided to mount the landing gear to the fuselage. Bolt the

wing in place. Attach a Robart Incidence Meter tool to the

inboard leading and trailing edge of the wing and prop the

rear of the fuselage up until it is level according to the

meter. In this position, the wing incidence should read 0°.

Place the stabilizer into its saddle in the fuselage and use

weights to secure it. With the stab in this position, remove

the Incidence Meter from the wing and attach it to the

leading and trailing edge of the stabilizer. Ideally the meter

will again read 0°. If it does not, then the saddle in the

fuselage must be adjusted to seat the stab at 0°. Use

sandpaper or a #11 blade to adjust the stab saddle as

needed. Remove the stab from the fuselage.

❑15) To prepare the fin for mounting to the fuselage, first,

pre-hinge the rudder, gluing the hinges into the rudder, but

not into the fin. Remove the covering material from the

sides of the fin tailpost that fits into the fuselage. Draw a

centerline onto the fuselage fin mounting base, to assist you

in aligning the fin. Using slow-cure epoxy, apply glue to the

bottom of the fin and to the tailpost sides, where it contacts

the fuselage. Slide the fin in place into the fuselage and

onto the fin mounting base. Align the leading edge of the

fin with the centerline and use tape to hold the fin in place.

With the fin in this position, view the airplane from the front

and rear to be sure that the fin is absolutely 90°upright to

14

the fuselage and aligned with the centerline of the fuselage.

Wipe off any excess glue with alcohol. Adjust as needed

and tape securely. Remove the wing and allow the glue to

cure completely.

❑16) Install a right and left rudder horn to the bottom of the

rudder using #4 x 3/8" sheet metal screws. The rudder has

inset plywood mounting pads on each side for this purpose.

The two rudder horns directly oppose one another and

should be lined up with the pull-pull exits at the bottom rear

of the fuselage. The rudder is now hinged to the fin using

epoxy glue on the hinges - remember to protect the hinge

knuckles with petroleum jelly. Clean off any excess glue

and allow to cure.

❑17) The rudder pull-pull system is now installed. Begin by using

your radio system to accurately center the rudder servo.

Install the output arm onto the rudder servo. From your kit

contents, locate the package containing the coil of .021

braided steel cable, rigging couplers, heat shrink tubing

and aluminum crimps. You will also need two 4-40

threaded R/C links and two 4-40 hex nuts. Cut the braided

cable into two equal 36" lengths (a carbide cut-off wheel

works great) and cut the heat shrink tubing into four

1/2" lengths.

Place one 1/2" length of heat shrink tubing onto one end of

the cable, followed by one of the 1/2" aluminum tubes.

Thread the end of the cable through the small hole in the

end of the threaded rigging coupler, giving yourself about

4" - 5" to work with. Make a half loop around the rigging

coupler hole and run the short end of the cable through the

aluminum tube. Pull the tube up to the rigging coupler,

about 1/2" away from it. Take the short end of the cable and

loop it back around and through the aluminum tubing,

pulling it tight. Use a pliers or a crimping tool to squeeze the

aluminum tube tightly over the cable in two places, locking

it in place. Cut off the excess short end of the cable. Press

the heat shrink tubing in place over the aluminum tube and

use heat to shrink it in place. Thread a 4-40 hex nut

completely onto the rigging coupler, followed by a 4-40 R/C

link. Center the link approximately onto the rigging coupler

threads. Repeat this process on the remaining length of

cable. These two prepared ends will be located at the

rudder.

Feed the bare end of the cables into the pull-pull exits at the

bottom rear of the fuselage and up to the rudder servo

location. Use masking tape to hold the rudder in neutral

with the fin. Connect the R/C links to the rudder horns using

the same hole locations on each horn. Turn the fuselage

upside down on your bench and make the cable

connections to your servo output arm. Start by placing a

1/2" length of heat shrink tubing onto the cable, followed by

a 1/2" aluminum tube. Thread the bare cable end through

a hole in your output arm with a half loop back into and

through the aluminum tubing. Pull the cable to remove any

slack - not tight - and slide the aluminum tube up to the

output arm, about 1/2" away. Re-loop the bare cable end

through the aluminum tubing and pull it tight. Crimp the

tubing in two places and cut off the excess cable. Press the

heat shrink tubing in place over the aluminum tube and use

heat to shrink it tight. Repeat this process with the

remaining cable on the opposite side of the output arm.

With the rudder still taped in neutral, adjust the R/C links at

15

PULL-PULL GEOMETRY: In order to make this or any

pull-pull system work correctly, without binding or placing

undue stress on the servo, the connections must have the

proper geometry. This is simply a matter of making the

spacing of the two required connections at the rudder horns

and those at the servo output arm, the same distance apart.

Using the after-market DuBro Super Strength output arms, we

used the two outer holes, which have a spacing of 2".

Therefore, at the rudder horns, we made our connections at

the center holes on each horn, providing 2" of spacing. Doing

this assures smooth, non-binding rudder action.

the rudder horns to approximately the same mild tension -

do not pull the cable tight. Remove the tape holding the

rudder in place, plug the rudder servo into your airborne

system, turn on the transmitter and test the movement

and centering of the rudder. Adjust as needed. Thread the

hex nuts back to the R/C links and tighten them to lock the

clevises in place. Be certain the output arm screw is in

place!

❑18) The two tailwheel centering springs are now attached to the

tailwheel tiller arm and the two rudder horns. Use needle

nose pliers to make a small "Z" bend at one end of each

spring. Install the "Z" bend ends to rudder horns. Apply a

small amount of tension to the spring and use the pliers to

make a 90°bend at the tailwheel tiller arm hole. Insert the

wire into the tiller arm and make another 90°bend, creating

a "Z" bend. Do not over stretch the springs when doing this.

The springs should center the tailwheel to the rudder when

it is at neutral.

❑19) The elevator servos are now installed. As mentioned

earlier, you will either need to electronically reverse one of

these servos and use a standard Y-harness with 12"

extensions or use the "Miracle Y™" elevator splitter to

obtain "mirror image" elevator action. Install the splitter

cables through the back of the canopy hatch opening, back

to the two elevator servo cutouts. To avoid a clutter of

cables and to keep them away from the pull-pull cables,

route the extensions through the upper rear fuselage.

Connect the servos to the extension cables, securing the

connectors with tape. Mount the servo grommets supplied

with your radio system to both servos. Insert one of the

servos in place and mark it's mounting hole locations onto

the fuselage side with a felt pen. Pre-drill guide holes

(typically 1/16" dia.) for the mounting screws and repeat this

procedure on the other side of the fuselage for the

opposing servo. Install the elevator servos, securing them

with mounting screws. Use your radio system to check the

action of these servos. Make any corrections required. We

used silicon adhesive to spot glue the extension cables in

place to the upper rear of the fuselage and to mount the

"Miracle Y™" control pot, just behind the canopy base.

❑20) Pre-hinge the elevator halves by gluing their hinges in place

and preparing the horizontal stabilizer to receive the

opposite hinge ends - do not hinge elevators to the

16

stabilizer yet.

❑21) Bolt the wing back in place to the fuselage. The horizontal

stabilizer is now glued in place. Use only slow-cure epoxy

for this step. First set the airplane on your flat work surface

and prop the tail up to about level. Apply glue to the

fuselage stab saddle and position the stab squarely in place

- use a weight to secure it. View the airplane from the top,

front and rear, making sure the stab is square, without

leaning one way or the other. Use a ruler to measure from

the outer trailing edge wingtip back to the stab's leading

edge tip and note the measurement and repeat this process

on the opposite side. The two measurements should be the

same. Make adjustments as needed. Tape and/or weight

the stab firmly in place to the fuselage, wipe off any excess

glue with alcohol and allow the glue to set. Remove the

wing from the fuselage.

❑22) Locate the molded plastic fuselage/fin fairing. Fit the fairing

in place onto the fuselage, over the stabilizer and around

the fin to check the fit. Trim as need to seat the fairing

squarely in place, in contact with the fuselage, top of the

stabilizer and the fin. Once satisfied with the fit, mark the

location of this fairing onto the fuselage, stab and fin with a

pencil - remove the fairing. Use a sharp #11 blade to cut

away the covering just inside of the outlines just made,

exposing the wood. Apply a coat of epoxy glue to the inside

of the fairing where it will contact these areas. Fit the

fairing, pressing it firmly in place to make sure it contacts all

gluing areas. Clean up any excess glue with alcohol and

use tape to secure the faring in place. Allow the glue to

cure.

❑23) Apply petroleum jelly to the elevator hinge knuckles and

apply epoxy to the exposed hinge halves. Attach the left

and right elevator halves to the stabilizer, wiping off any

excess glue from the hinge line. Tape the elevator halves

to the stabilizer in the neutral position and allow the glue to

cure.

❑24) From the kit contents, locate the two 4-40 x 2-1/8" elevator

control rods, two 4-40 solder clevises, two 4-40 threaded

R/C links and two 4-40 hex nuts. Make two elevator

pushrod assemblies by soldering a solder clevis onto the

unthreaded ends of the pushrods. Thread a hex nut onto

the threaded ends, followed by an R/C link.

❑25) From the kit contents, locate a right and left nylon elevator

horn and four #4 x 3/8" sheet metal screws. Remove the

wing from the airplane and turn the fuselage upside down

on your bench. The elevator horns are now installed onto

the bottoms of the elevator halves. As mentioned, there are

plywood mounting pads in the elevator halves, inset in their

forward, inboard leading edges. Hold the horn in place on

the elevator, lined up with the elevator servo output arm,

with the holes in the horn directly over the elevator/stab

hinge line. Mark the horn mounting holes with a felt pen.

Pre-drill the hole locations with a 3/32" dia. bit. Mount the

horn in place with two #4 x 3/8" screws. Repeat this

procedure on the opposite elevator half.

Use your radio to center the elevator servos and then mount

17

X

X

the servo output arms in place at 90°upright. Attach the

solder clevis ends of the elevator pushrods to the servo

output arms. Adjust the threaded clevis ends to fit into the

middle hole in each elevator horn. Remove the tape

holding the elevators in neutral and test the movement

of the elevators with your radio. Adjust as required get

both elevators exactly at neutral - if you are using the

"MiracleY™" splitter cable, you can turn the pot adjustment

to achieve neutral very easily. Final surface throw

adjustments and locking the R/C links in place with the hex

nuts will be made later.

LANDING GEAR AND WHEEL PANT ASSEMBLY

From the kit contents, locate the two 3-3/16" dia.main wheels, two

main wheel axles, two axle lock nuts, four wheel collars with lock

screws, four 4-40 x 3/8" bolts, four 4-40 blind nuts and two

fiberglass wheel pants. You will also need the aluminum landing

gear and the three M4 x 25mm mounting bolts. We also suggest

that you use Loctite®threadlocking compound on all bolts used in

the assembly of the landing gear.

❑1) Install the axles into the large holes at the bottom of each

landing gear leg. Thread the large lock nuts onto the

threaded ends of the axles and tighten these securely in

place to the landing gear. Slide a wheel collar onto the axle

shaft, all the way to axle's hex nut. With the wheel collar set

screw pointing straight down, tighten the set screw to the

axle. Slide a main wheel onto the axle, followed by

another wheel collar. With the set screw pointing straight

down, tighten the set screw enough to temporarily retain the

wheel.

❑2) With the wheel pant slots facing inward, fit the pant in place

over the wheel - if necessary, loosen the wheel collars to

reposition the wheel to fit into the pant. The pant slot should

accept the axle hex nut. If not, rotate the hex nut with a

wrench until the pant slides in place. This is how the pants

fit to the landing gear.

❑3) Remove the loose wheel pants from the landing gear. Bolt

the landing gear in place to the bottom of the fuselage. Set

the fuselage on your flat workbench, with the tail supported

to approximately level. Place both wheel pants onto the

landing gear. Use a length of balsa stock (1" sq. shown) to

equally raise the rear of both wheel pants. Move the balsa

spacer to adjust the angle of the wheel pants until their

centerlines look parallel with fuselage. Hold the pant in this

position, against the landing gear. Use a 7/64" dia. drill bit,

through the two pant mounting holes, to mark the wheel

pant with the hole locations. Remove the wheel pants.

❑4) Use a 5/32" dia. drill bit to drill two mounting holes in the

wheel pant at the marks just made. Apply epoxy glue to the

face of two 4-40 blind mounting nuts and insert them in

place into the holes, from the inside of the wheel pant.

Wipe off any excess glue, keeping it out of the blind nut

threads.

❑5) Install the wheel pants to the landing gear and secure them

with the 4-40 x 3/8" bolts. Turn the landing gear assembly

upside down and use the two wheel collars to center

and space the main wheels to the pant openings. The

wheels should turn freely without obstruction. Mount the

18

completed landing gear to the fuselage.

CANOPY AND CANOPY BASE ATTACHMENT

The molded plastic canopy base has three (3) factory drilled holes

on each side. These accept the 4-40 x 1/2" nylon mounting

bolts, used to hold it in place. Begin by using masking tape to

accurately position and secure the base in place to the top of the

fuselage. Make sure the base is firmly in place and that its front

and rear mounting lips are over the fuselage. Use a fine point felt

marker pen to mark the position of each mounting hole on both

sides of the fuselage - remove the canopy base.

From your kit contents, locate six 1/8" x 3/4" sq. plywood

mounting pads, six 4-40 x 1/2" nylon slotted bolts and six 4-40

blind mounting nuts. Center one of the plywood mounting pads

directly behind one of the hole marks just made, holding the pad

firmly to the inside of the fuselage side. Use a 7/64" dia. drill bit to

drill through the fuselage side and the plywood pad - remove the

pad. Use a 5/32" dia. bit to enlarge the hole in the pad. Apply glue

to the face of a 4-40 blind nut and press it in place into the pad.

Apply glue to the face of the pad and press it in place to

the inside of the fuselage side, with the blind nut aligned with the

drilled hole. From the outside, thread a nylon bolt in place through

the hole and into the blind nut. Screw the bolt in place, bringing the

ply pad firmly in contact with the fuselage side. Wipe off any

excess glue. Repeat this procedure for the remaining five holes.

With all holes drilled and all pads and blind nuts in place, the nylon

bolts must now be trimmed in length to clear the inside surface of

the canopy base. Use a sharp, single-edge razor blade to cut 1/4"

off of the length of each bolt.

If desired, the canopy base can now be detailed. On our

prototypes, we used light gray art paper to line the bottom and

back of the canopy base, giving it depth and color. We measured

and cut the paper to fit and applied it to the base with a heavy coat

of spray cement. We used a commercially available instrument

panel - the Hanger 9™CAP 232 panel - mounting it with epoxy

glue. Last, we used a Hanger 9™1/4 -Scale Civilian pilot figure to

finish the cockpit. No matter what pilot figure you decide to use, be

sure to reinforce the bottom surface of the canopy base with a

piece of 1/32" plywood, epoxied in place. This stiffens the canopy

base and allows you to drill through the bottom of the base for

mounting screws to secure the pilot figure. We finished off the

overall look of our CAP cockpit using black twill tape to simulate

the shoulder harness restraint belts and a few pieces of light

aluminum sheet to simulate buckles and harnesses. Overall, it

looks believable and does not add much weight.

To mount the canopy, first wash it in warm sudsy water to remove

any hand oils, mold release agents, etc. Rinse and dry it

completely with a soft cloth and avoid handling the inside surface.

Use 220 sandpaper to lightly scuff the canopy base edge, where it

contacts the canopy itself. Wipe off excess dust with alcohol.

Mount the canopy base to the fuselage with the nylon bolts. Use

slow cure epoxy to mount the canopy. Mix a small amount of glue

and use a small stick to apply the glue only to the sanded edge of

the canopy base - apply a reasonable amount but not so much that

it oozes. Carefully place the canopy onto the canopy base,

easing it into position. Use alcohol and a paper towel to wipe off

19

any excess glue, while lightly pressing the canopy in place to the

base. Secure the canopy to the base with pieces of masking tape

and allow the glue to cure.

When the glue has cured, remove the masking tape. The

canopy/canopy base joint can now be covered using

ULTRACOTE®matching trim tape, available from Carl Goldberg

Models. This tape is called ULTRASTRIPE™and is available in a

variety of widths. We suggest using the wider tape, such as the

3/16" or 1/4".

RADIO INSTALLATION

With the servos now installed with the correct extensions in place

and secured, all that remains is the installation of the receiver,

battery pack and switch. Remember that the single heaviest unit

in this system is the battery pack. This means that you can, if

needed, locate the batteries wherever they are required to achieve

the correct CG. When mounting the receiver and battery pack, first

wrap them in foam and use rubber bands and/or tie-wraps to

secure them in the fuselage. This allows these units to be easily

accessed and repositioned if necessary. The switch can be

mounted onto the fuselage side or internally. We prefer an

internally mounted switch. We mounted ours onto the radio tray,

using a length of music wire to activate the switch from the outside.

This is simple to do. Just drill a small diameter hole in the switch

lever to fit a piece of .045 music wire. Drill an exit hole in the side

of the fuselage, lined up with the switch/wire location. Make a 90°

bend in one end of the wire and insert the short end into the hole

in the switch. Apply silicon glue to one side of the switch and insert

the wire through the hole in the fuselage, pressing the switch

firmly to the radio tray. Make another 90°bend in the wire outside

of the fuselage, giving you a small "handle" to pull and push when

activating the on/off switch. Besides looking neat, this method

provides protection to the switch from dirt, debris and exhaust.

When mounting the receiver, note that we have provided the CAP

with an internal antenna exit tube. When viewed from the wing

saddle (fuselage upside down) this tube is located on the right side

of the fuselage, extending from the radio tray back through the

fuselage, exiting just ahead of the tailwheel assembly on the

bottom. Thread your antenna through this tube when installing

your receiver.

All servo, switch, and battery connections to the receiver are now

made. The aileron Y-harness stays plugged into the receiver

aileron channel receptacle, with the two connecting ends hanging

loose for wing attachment. Turn the radio system on and check the

functions of the throttle, elevator and rudder servos. These should

all now be centered and working perfectly, without any binding.

Correct any such problems now. Plug your aileron servo

leads into the Y-harness connectors and mount the wing to the

fuselage. Test the action of the aileron servos, adjusting the

linkages as needed to center them. Make sure the ailerons are

traveling in the proper direction to provide left and right roll. With

everything checked and working, now is the time to set the initial

control movements.

CONTROL MOVEMENTS

This is an important section of this manual. After flying your

CAP231EX for awhile, getting used to its characteristics, you will

likely change the control throws to suit your style of flying. But you

have to start somewhere and this is where you begin. These

movements provide the CAP with very smooth control inputs

without the immediate need for expotential. We suggest starting

out with these movements as your low and high rates. Note that

we do not suggest full rudder throw initially. This is because the

rudder is very large and aerodynamically powerful. So powerful

that it can fly the airplane in knife-edge flight even at fairly low

throttle settings. At full throw, the rudder can also toss the CAP

very deeply into snap maneuvers, literally slowing it down. Rudder

throw is something you can easily play with after you are more

comfortable with the airplane, especially for 3-D type flying.

Last, after setting the controls for these surface movements, make