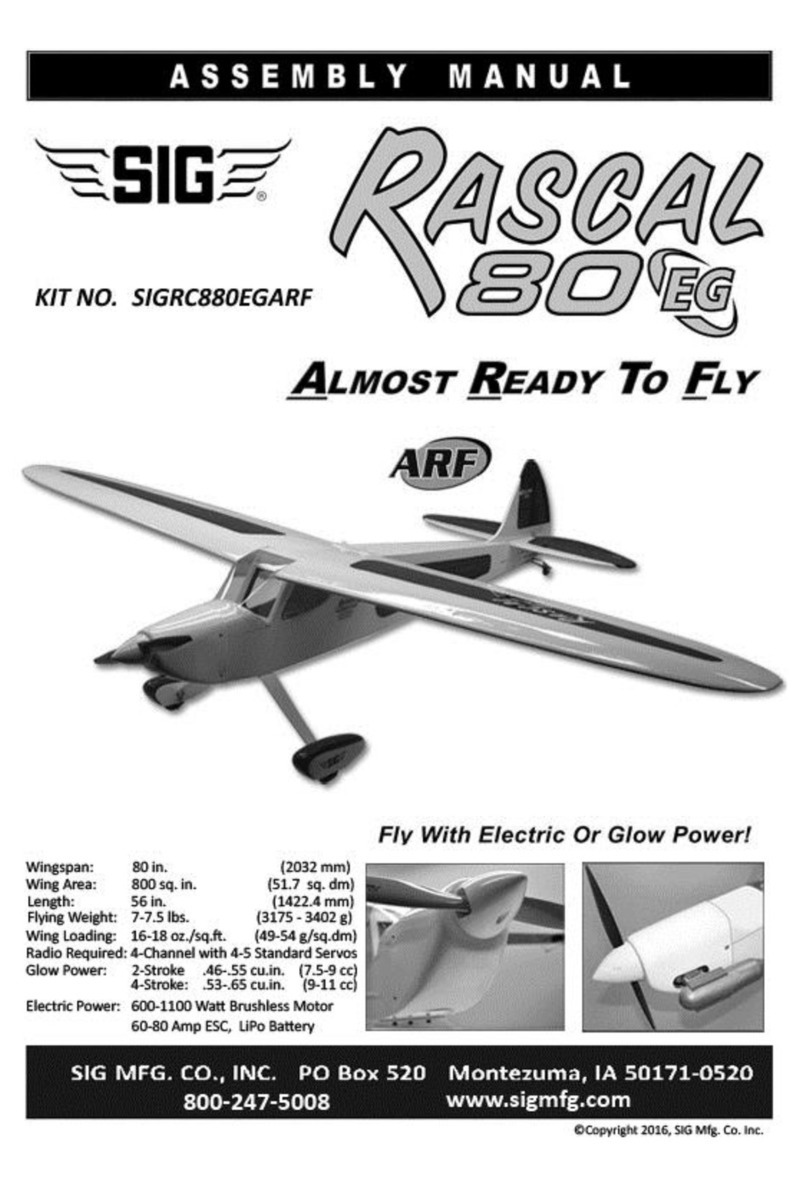

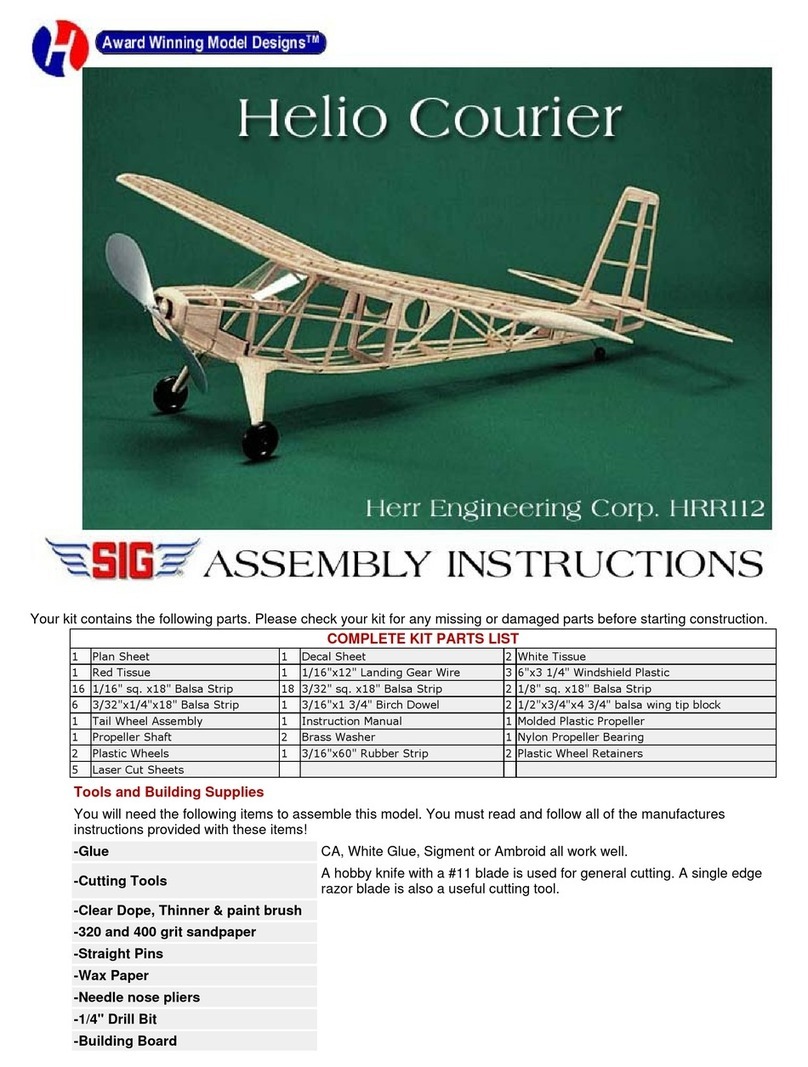

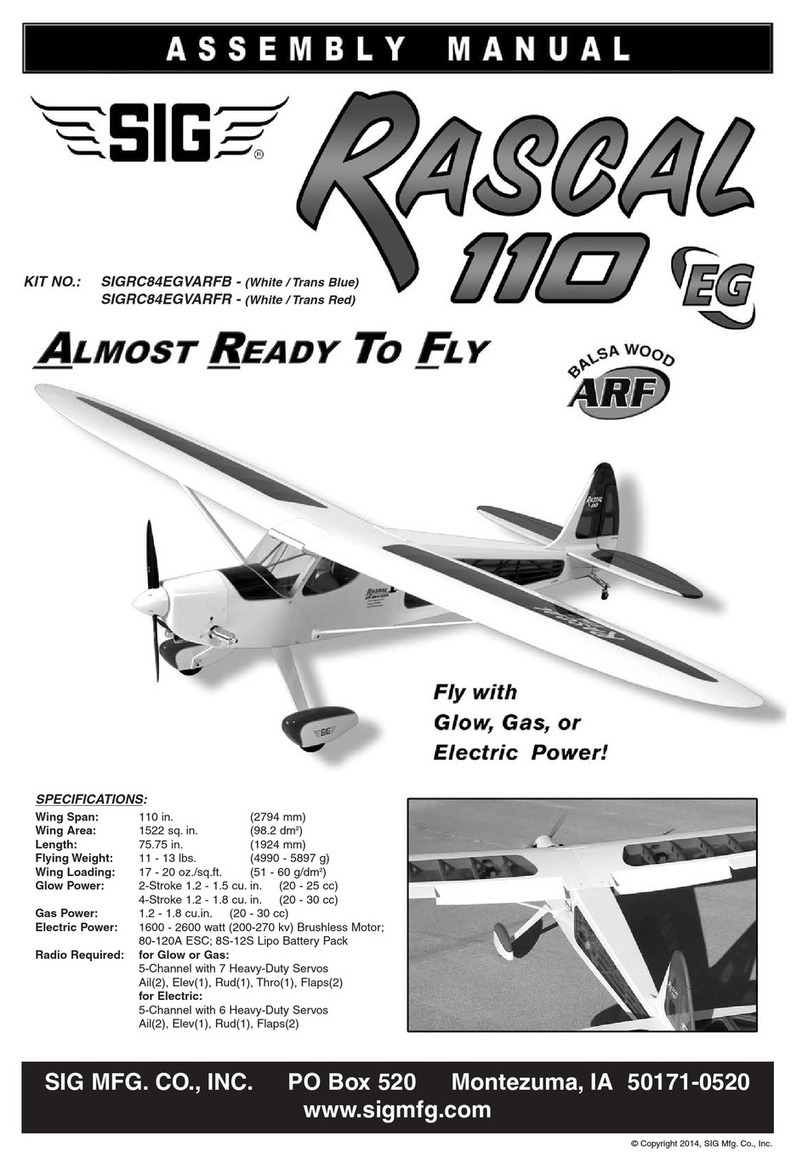

RASCAL 110 ARF ASSEMBLY MANUAL

INTRODUCTION:

SIG's RASCAL 110 ARF represents one of the largest, best built

R/C model aircraft ever offered to modelers. The distinctive and

classic lines of the Rascal are reminiscent of the beautiful personal

aircraft designs of the thirties and post WWII periods. The elegant

good looks of the Rascal design seem to bridge the gap between

modern small aircraft and airplanes from the golden age of flight.

Designed specifically for modelers who have always wanted a

large, giant-scale airplane without all of the large airplane hassles,

the Rascal 110 ARF kit offers a perfect balance of size,

performance, looks, and versatility. From experience, we can tell

you that the Rascal 110 ARF will almost always draw a crowd of

admiring onlookers. But when the airplane takes to the air, the

smooth flight characteristics and sheer size make it even more

impressive.

You will have never flown an easier to handle airplane than the

Rascal 110 ARF. Take-offs and landings are spectacular in their

smoothness and when it comes to what goes on in the air, the

Rascal 110 is positively elegant. Despite it’s large size, the Rascal

110 can be easily flown at most typical R/C flying sites, either

grass or asphalt fields. Landings can be very slow and predictable

and the take-off runs are usually less than many .40-size trainers.

Powered with typical 1.20 4-stroke engines, the Rascal 110 is

capable of mild aerobatics, such as loops, lazy rolls, inverted flight,

etc. Power the airplane with larger engines and things can get a

bit more interesting. Our Rascal 110 models, powered with 1.50

or 1.80 4-stroke engines and 1.50 2-stroke engines, turned into

very capable aerobatic airplanes! Of course, the Rascal 110 ARF

is not a pure aerobatic machine and was never intended for IMAC

competition. None-the-less, with practice, it will deliver an

amazingly nice flight routine.

The Rascal 110 ARF is very well built, with attention paid to every

detail of its construction and finish. Even the functional aluminum

wing struts have been expertly built and factory painted, providing

just the right "look" to the model. The fiberglass cowl and wheel

pants are equally impressive, giving the airplane that "finished"

look, truly setting it apart from anything else available. The

airframe has been expertly covered with AeroKote™, employing a

trim scheme that is highly visible in flight and very attractive on the

ground. The kit includes all of the detailed decals seen on the box

art, allowing you to make the model very realistic. SIG has even

included a beautiful scale-like tailwheel assembly that fits the look

of this airplane almost perfectly!

Because of its size and lifting ability, the Rascal 110 ARF is a great

choice for use as a camera ship, either still or video. Properly

powered, it would also make a good glider tug and is also certainly

capable of towing banners. Properly modified, it could also be

used to drop candy or parachutes. Another potential use for this

versatile model is night flying. Because the trim scheme employs

the use of transparent covering material in the open areas of the

structure, lighting systems - such as those made and sold by Ram

Products - would be very effective!

Assembly of the Rascal 110 is easy, quick, and straightforward.

This assembly manual is fully illustrated and includes all detailed

instructions in the correct sequence. This allows you to get the

airplane from the box to the flying field in a very short amount of

time. We strongly suggest that you read through this manual first

to get familiar with the various parts and their assembly

sequences. The proper assembly and flying of this aircraft is your

responsibility. If you are new to the sport/hobby of radio control

model airplanes, we urge you to seek the assistance of a qualified

person to help you assemble this R/C model aircraft correctly. If

you do not understand a particular assembly step or sequence,

DO NOT guess - find qualified help and use it.

RADIO EQUIPMENT:

The Rascal 110 ARF requires a 4-channel radio system, with five

servos. Because of its size and the wide variety of engines that

can be used in this airplane, we highly recommend that you use

servos with at least 60 in/ounces of torque. Such servos are more

appropriate for a model of this size.

We use and can highly recommend either the Airtronics™

RD-6000 Sport system or the Hitec™ Flash 4X system for this

airplane. Both of these affordable and reliable computer radio

systems offer all the features you'll need for this and the many

other R/C aircraft in your future. For reference, this assembly

manual shows the installation of Hitec™ #HS-545BB servos for

aileron, rudder, and elevator controls. A Hitec™ #HS-300

standard servo is used for throttle control. We used a Hitec™

#23873 RCD 3800 Supreme Shift Select receiver and a Hitec™

#57215 Standard Switch Harness. We also used one Hitec™

#54606 36" servo extension for the elevator servo and two Hitec™

#57346 24" servo extensions for the aileron servos. A Hitec™

#57350 Y-Harness to connect the aileron servo leads to the

receiver. All of these items are available separately as after-

market equipment at very affordable prices. See your local hobby

shop for more information.

We like to use Du-Bro after-market servo output arms. These are

exceptionally strong and always seem to be the right shape and

geometry for most of our applications. Du-Bro makes their output

arms to fit any available servos, just use the right part number for

your particular brand of servos. Because our assembly manual

model is using Hitec™ servos, we chose the Du-Bro #675 set.

With an R/C model as large as the Rascal 110 - especially when

using five servos - we always suggest using airborne battery packs

with larger capacity than the typical battery packs supplied with

most radio systems. For example, we used an after-market

1400mAh four-cell battery pack in the model shown in this

assembly manual. Be sure you have a charger capable of properly

charging these larger battery packs.

1