INSTALLATION

1. When hydrants are received, they should be handled

carefully to avoid breakage and damage to flanges. Keep

hydrants closed until they are installed. Protect stored

hydrants from the elements if possible.

2. Before installation of hydrant, clean piping, base and

drain ring of hydrant of any foreign material. Check for

loose bolts at base, groundline and cover. Tighten if

necessary.

3. Hydrants shall be located as shown or as directed and

in a manner to provide complete accessibility, and also

in such a manner that the possibility of damage from

vehicles or injury to pedestrians will be minimized.

When placed behind the curb, the hydrant barrel shall

be set so that no portion of the Pumper or Hose Nozzle

Cap will be less than 6 inches, nor no more than 12

inches from the gutter face of the curb. When set in the

lawn space between the curb and the sidewalk, or

between the sidewalk and the property line, no portion

of the hydrant or nozzle cap shall be within 6 inches of

the sidewalk.

4. All hydrants shall stand plumb and shall have their

nozzles parallel with or at right angles to the curb, with

the Pumper Nozzle facing the curb. Hydrants shall be set

to the established grade, with nozzles at least 20 inches

above the ground, as shown or as directed by the

engineer.

5. It is recommended practice to install an auxiliary or

secondary gate main in the lateral between the hydrant

and the main to permit inspection and repair of the

hydrant without shutting down mains.

6. On traffic hydrants, be sure the earth is firmly

compacted around the barrel to support the lower

barrel against side loading. If the soil is too sandy and

will not support the loads, pour a concrete pad around

the barrel at or near the groundline at least 6 inches

thick and 36 inches in diameter for barrel support.

7. Whenever a hydrant is set in soil that is pervious,

drainage shall be provided at the base of the hydrant by

placing coarse gravel or crushed stone mixed with

coarse sand, from the bottom of the trench to at least 6

inches above the drain opening in the hydrant and to a

distance of 12 inches around the elbow. It is recom-

mended to place plastic or mesh sheathing above the

crushed stone and wrapped around the standpipe to

prevent soil from settling.

8. Whenever a hydrant is set in clay or other impervious

soil, a drainage pit 24 inches in diameter and 36 inches

deep shall be excavated below each hydrant and filled

compactly with coarse gravel or crushed stone mixed

with coarse sand under and around the elbow of the

hydrant and to a level of 6 inches above the drain

opening.

9. Restrain hydrant movement with appropriate thrust

blocking or restrained joint to prevent pipe joint

separaon.

10. When first installed, the hydrant should be operated

from full closed to full open posion and back to make

sure no obstrucons are present.

11. Aer the line as well as the hydrant have been

hydrostacally tested, the hydrant should be flushed

and then checked for proper drainage.

IMPORTANT - Inial installaon of hydrant MUST BE

MADE PROPERLY so the Sigelock Safety Flange will

funcon properly. Hydrant should be blocked at ground

line and around shoe using concrete or similar

substance to prevent ground from giving way when

hydrant is struck.

For addional informaon on hydrant anchorage,

blocking, and drainage, see AWWA Standard C600 and

Manual M17.

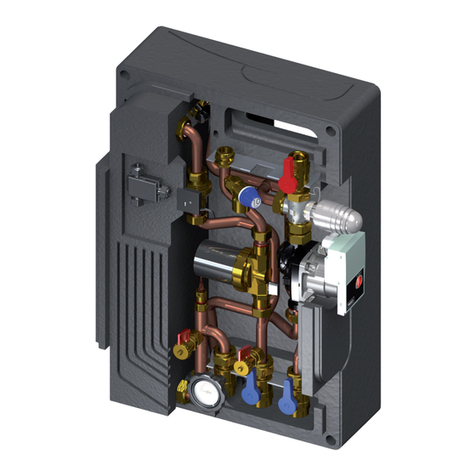

14.5" - 20.5"

20"

25.5

"

OF TRENCH

DEPTH

6" - 12"

CINDER BLOCKS

CRUSHED STONE

OR COARSE GRAVEL

PLASTIC OR

MESH SHEETING

GROUND LINE

BACKFILL

DONUT FOR SOFT

GROUND CONDITIONS

FACE OF CURB

ROAD SURFACE

EARTH FILL

SUPPLY BRANCH

SIGELOCK SYSTEMS, LLCSPARTAN 5 1/4 FIRE HYDRANT 8

Do NOT use chains to lift

hydrant! Use cloth

straps. Do NOT pour rock

over bare hydrant!

Cover hydrant with

heavy plastic to avoid

paint damage during

installation.

SUGGESTED 36” DIA.

X 6” THICK CONCRETE

CAUTION:

Do NOT use chains to lift hydrant! Use cloth straps.

Do NOT pour rock over bare hydrant! Cover hydrant with heavy

plastic to avoid paint damage during installation.