Sigenergy EVAC 7 4G T2 WH User manual

Sigen EV AC Charger

Installation Guide

Sigen EVAC (7, 11, 22) 4G T2 WH

Sigen EVAC (7, 11, 22) 4G T2SH WH

Version: 02

Release date: 2024-01-25

1

1 Introduction

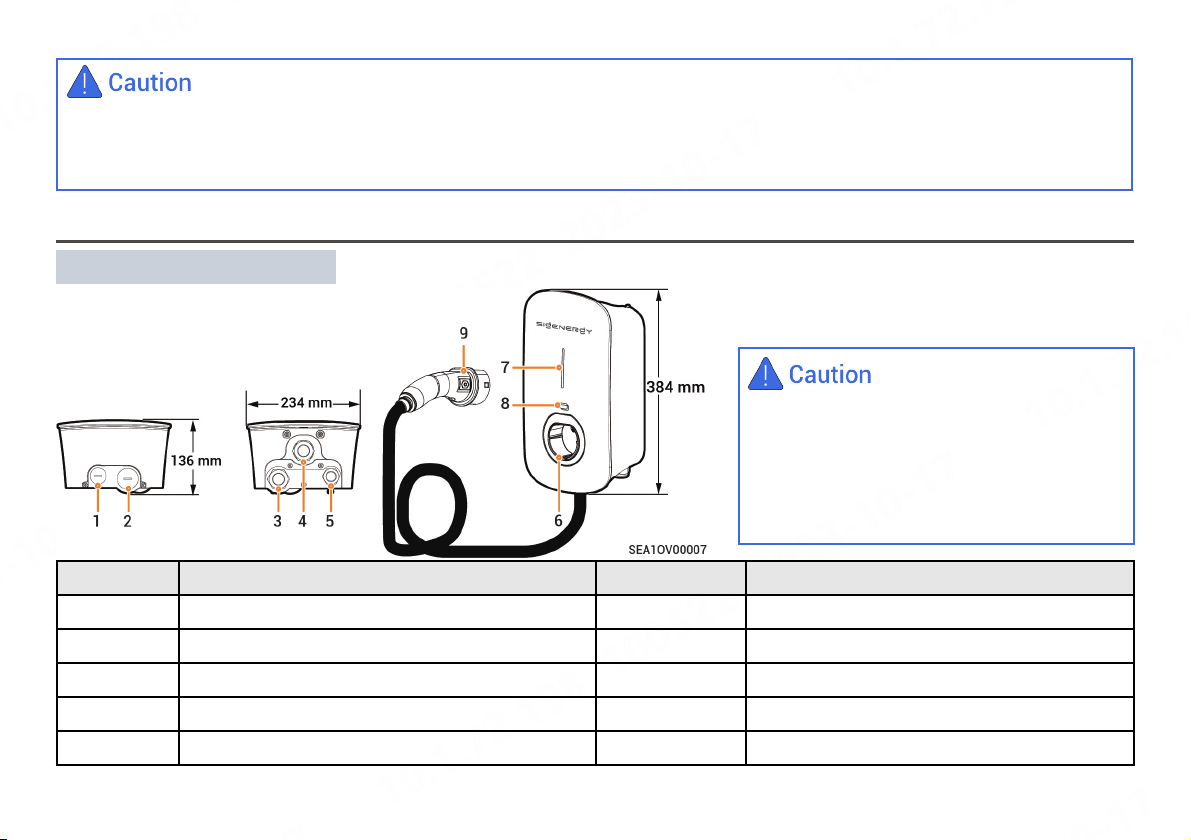

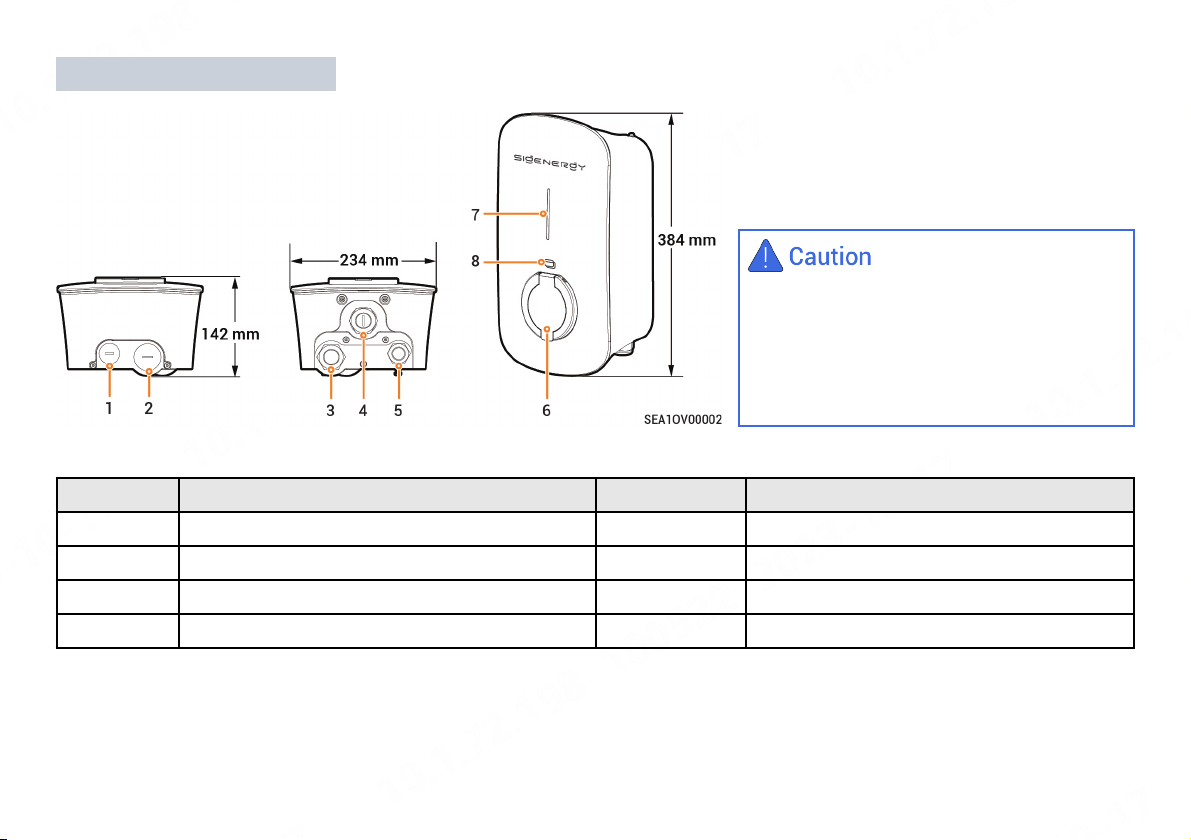

No. Description No. Description

1Top routing hole for communication cable 2Top routing hole for AC input cable

3Bottom routing hole for AC input cable 4Bottom routing hole for charging cable

5Bottom routing hole for communication cable 6Type 2 charging connector holder

7Indicator 8RFID card reading area

9Charging connector - -

•You are advised to connect cables through

bottom routing holes (holes 3 and 5).

•If cables are connected through top routing

holes (holes 1 and 2), please install the

equipment in a sheltered location to prevent

water ingress after prolonged water

accumulation on the top.

•Trained or experienced electrical personnel are required to operate the equipment.

•Operators should be familiar with national/regional laws, regulations and standards, the structure and working principle of relevant systems.

•Please read carefully the operating requirements and precautions in this document and Important Notice before operating. Failure to do so may

result in damage to the equipment that is not covered by the warranty.

Sigen EVAC 7/11/22 4G T2 WH

2

No. Description No. Description

1Top routing hole for communication cable 2Top routing hole for AC input cable

3Bottom routing hole for AC input cable 4(Reserved) Bottom routing hole

5Bottom routing hole for communication cable 6Type 2 charger socket with protective door

7Indicator 8RFID card reading area

•You are advised to connect cables through

bottom routing holes (holes 3 and 5).

•If cables are connected through top routing

holes (holes 1 and 2), please install the

equipment in a sheltered location to prevent

water ingress after prolonged water

accumulation on the top.

Sigen EVAC 7/11/22 4G T2SH WH

3

Digital torque

open-end wrench

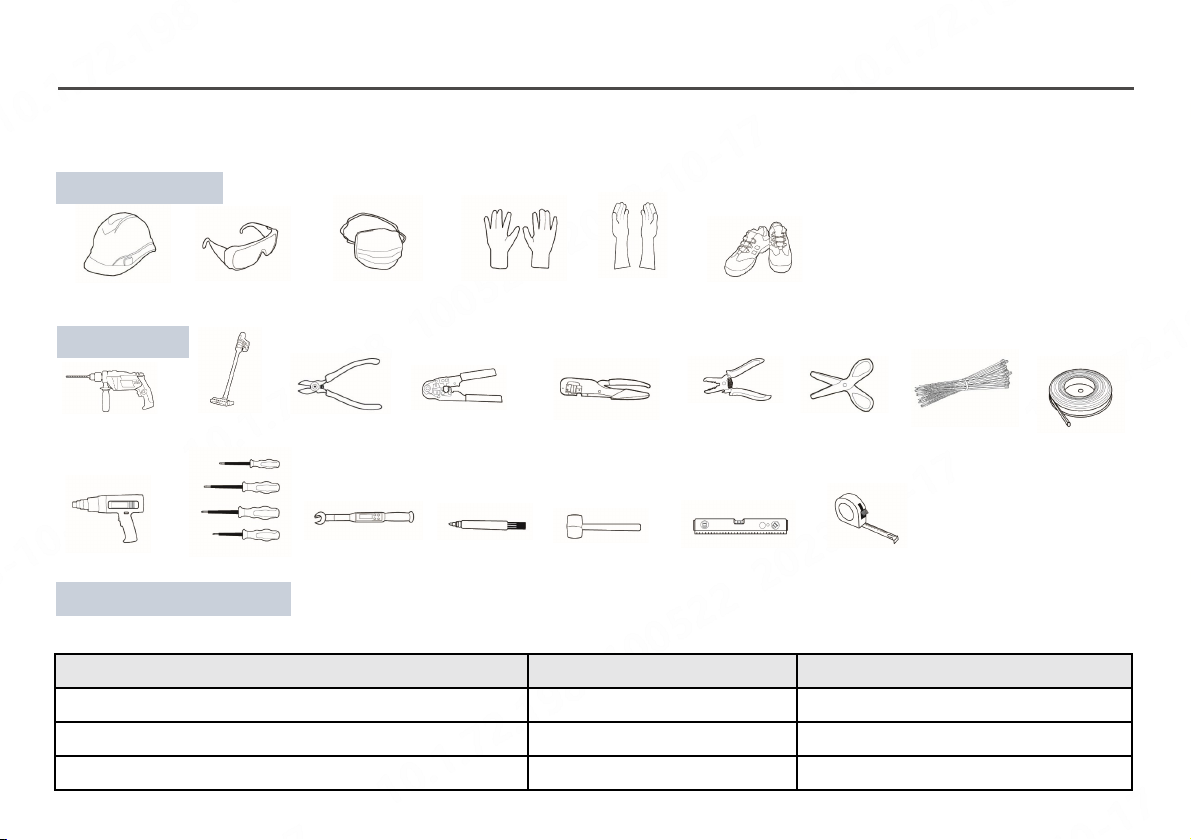

2 Pre-installation Check

•According to the packing list, check whether the components are complete and in good appearance. If any abnormality occurs, contact your

sales agent in time.

•Check personal protective equipment and installation tools to ensure that they are complete; If not, please make them up.

•Check the customer-provided cable to ensure that the quantity and specifications are correct; if not, prepare again.

Installation tool

Protective equipment

Safety hat Safety glasses Dust mask Protective gloves Insulating gloves Insulating shoes

Power

drill

Crimp tool Crimping pliers Wire stripperWire cutter Cable tieScissorsVacuum

cleaner Heat shrinkable

sleeve

Heat gun Insulation

screwdriver set Rubber malletMarker Level Tape measure

Self-supplied pre-AC switch

Users should prepare type B MCB compliant with IEC/EN 60898 with recommended specifications shown below. Users can omit this requirement if

they have installed compliant AC switches.

Model Number of Poles, MCB Rated Current, MCB

Sigen EVAC 7 4G T2 WH, Sigen EVAC 7 4G T2SH WH 1P+N 40 A

Sigen EVAC 11 4G T2 WH, Sigen EVAC 11 4G T2SH WH 3P+N 20 A

Sigen EVAC 22 4G T2 WH, Sigen EVAC 22 4G T2SH WH 3P+N 40 A

4

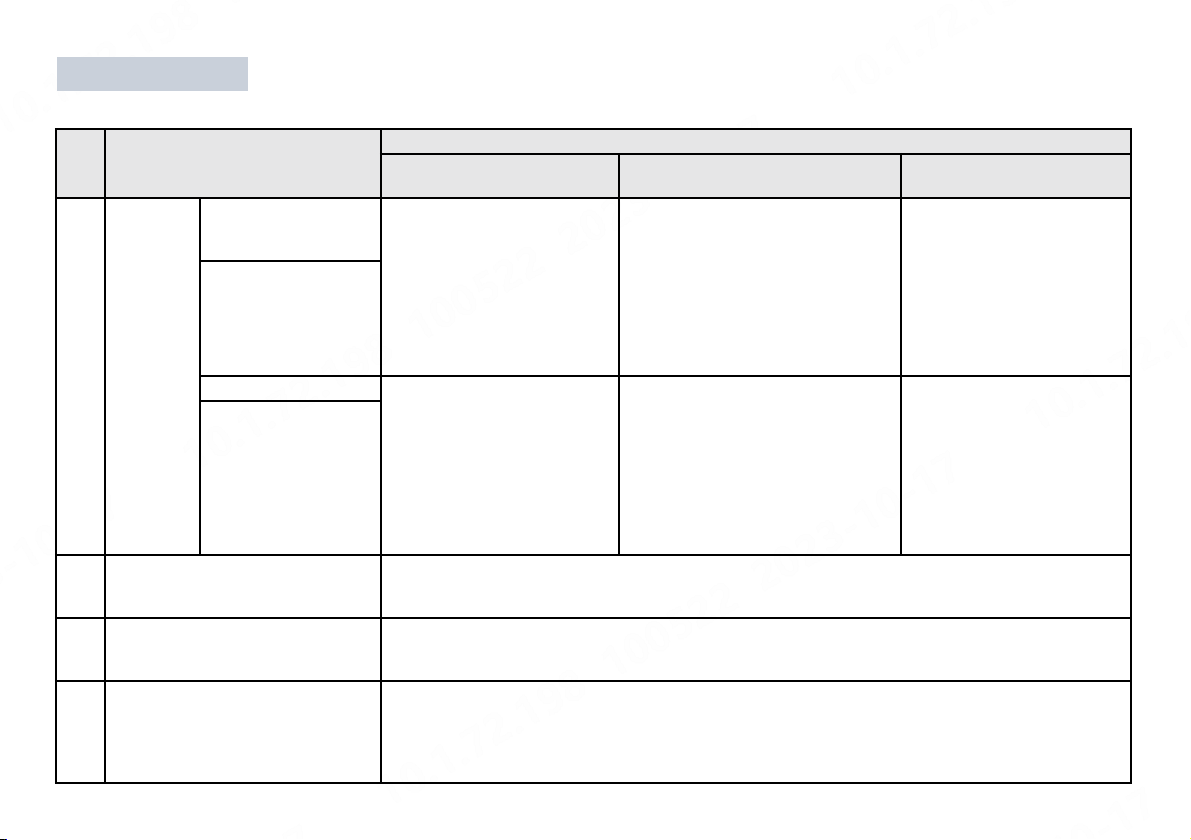

Self-supplied Cables

The grid power options include TT, TN-S, TN-C-S, and IT. Users can prepare cables according to their local grid power mode.

No. Cable Name Recommended Specification

Sigen EVAC 7 4G T2 WH

Sigen EVAC 7 4G T2SH WH

Sigen EVAC 11 4G T2 WH

Sigen EVAC 11 4G T2SH WH

Sigen EVAC 22 4G T2 WH

Sigen EVAC 22 4G T2SH WH

1AC input

cable

Three-phase five-wire

system

(L1/L2/L3/N/PE)

-Five-core/four-core copper core

cables for outdoor use

•Cable temperature resistance: ≥

90°C

•Outer diameter: 13 mm to 20 mm

•Current: 16 A

•Cross-sectional area of conductor:

2.5 mm² to 4 mm²

Five-core/four-core copper

core cables for outdoor use

•Cable temperature

resistance: ≥ 90°C

•Outer diameter: 13 mm to

20 mm

•Current: 32 A

•Cross-sectional area of

conductor: 6 mm²

Three-phase four-wire

system (L1/L2/L3/PE)

Two phases (L1/L2/PE) Three-core copper core cables

for outdoor use

•Cable temperature

resistance: ≥ 90°C

•Outer diameter: 13 mm to

20 mm

•Current: 32 A

•Cross-sectional area of

conductor: 6 mm²

- -

Single phase (L/N/PE)

2RS485 signal cable/DO signal

cable/Linky smart meter signal cable

Cables or two-core shielded twisted pair for outdoor use

•Conductor cross-sectional area: 0.2 mm² to 1.5 mm²

•Outer diameter: 5 mm to 7 mm

3RJ45 network cable Shielded twisted pair for outdoor use

•Conductor cross-sectional area: 0.129 mm² to 0.205 mm²

•Outer diameter: 5 mm to 7 mm

4(Optional) PEN control line (only

applicable to the UK)

Two-core copper core cables for outdoor use

•Cable temperature resistance: ≥ 90°C

•Voltage requirement: ≥ 300 V/500 V

•Cross-sectional area of conductor: 0.75 mm² to 1.5 mm²

•Outer diameter: 5 mm to 7 mm

3 Equipment Installation

5

Installation environment

Installation position

Mounting surface

•Do not install the equipment in smoky, flammable, explosive, or corrosive

environments.

•Avoid exposing the equipment to direct sunlight, rain, standing water, snow, or

dust. Install the equipment in a sheltered place. Take preventive measures in

operating areas prone to natural disasters such as floods, mudslides,

earthquakes, and typhoons.

•Do not install the equipment in an environment with strong electromagnetic

interference.

•Ensure that the temperature and humidity of the installation environment

comply with the equipment's requirements.

•The equipment should be installed in an area that is at least 500 m away from

corrosion sources that may result in salt damage or acid damage (corrosion

sources include but are not limited to seaside, thermal power plants, chemical

plants, smelters, coal plants, rubber plants, and electroplating plants).

•Do not tilt or overturn the equipment to ensure that it is installed horizontally.

•Do not install the equipment in a place easily touched by children.

•Do not install the equipment in mobile scenarios such as RVS, cruise ships,

and trains.

•You are advised to install the equipment in a position that is easy to operate,

maintain, and view indicator status.

•When installing the equipment in the garage, do not install the equipment in

the position where the vehicle passes through to avoid collision.

•Do not install the equipment on a flammable carrier.

•The installation carrier must meet load-bearing requirements. Solid brick-

concrete structure, concrete walls are recommended.

•The surface of the installation carrier must be smooth and the installation

area must meet the installation space requirements.

•No water or electricity is routed inside the carrier to prevent drilling hazards

during equipment installation.

The warranty applies when the equipment has been installed properly for its intended use and in accordance with the operating instructions.

6

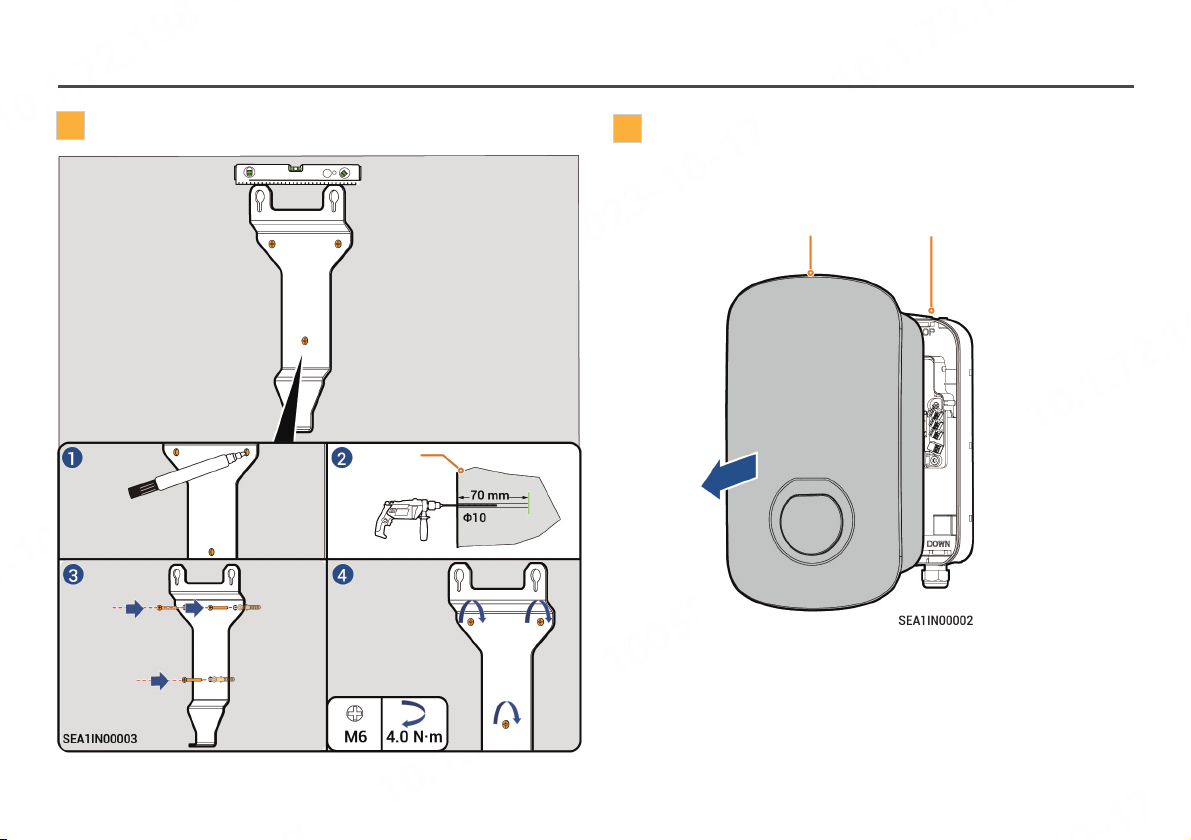

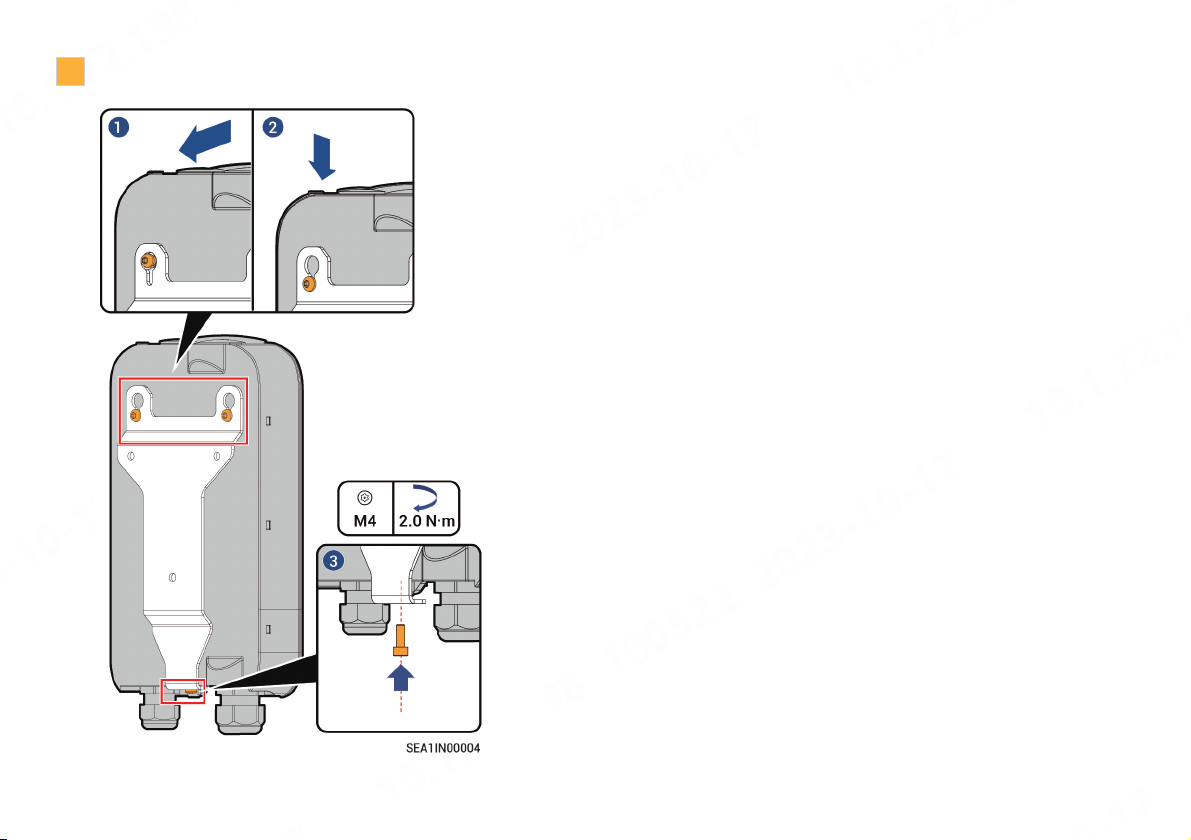

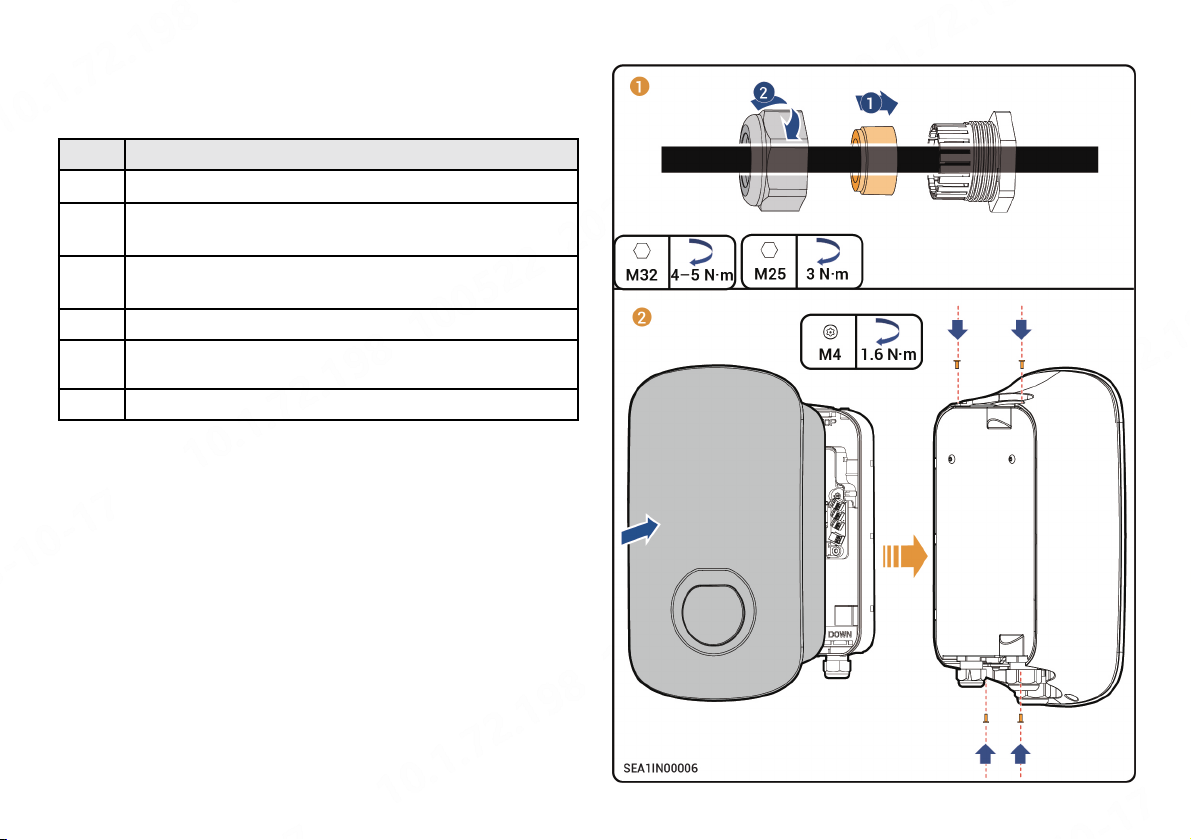

4 Installation

1Take the equipment from its package and disassemble it.

2

Install the wall mounting fittings.

Panel Terminal block

Wall

7

3Install and secure the terminal block.

8

5 Cable Connection

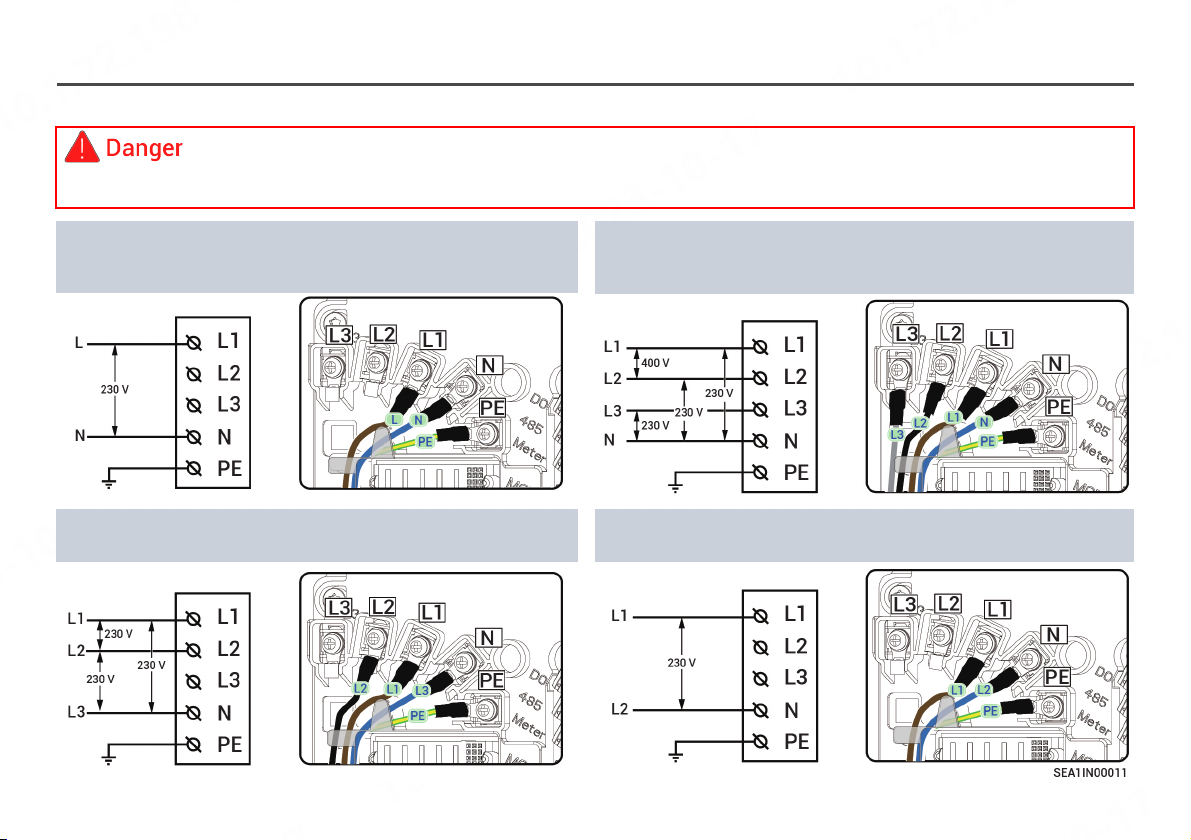

5.1 Description of Grid Power Supply Modes

Sigen EVAC supports the grid power supply methods shown in the diagram, please strictly refer to the diagram to connect the AC

cable. The device can not operate if the connection is wrong; safety hazard can be caused if the PE wire is wrongly connected.

Power grid Sigen EVAC Power grid Sigen EVAC

Power grid Sigen EVAC Power grid Sigen EVAC

Three-phase five-wire system (L1/L2/L3/N/PE)

Phase-tophase voltage (L-L): 400 V

Phase-to-neutral voltage (L-N): 230 V

Three-phase four-wire system (L1/L2/L3/PE)

Phase-tophase voltage (L-L): 230 V

Two phases (L1/L2/PE)

Phase-tophase voltage (L-L): 230 V

Single-phase three-wire system (L/N/PE)

Phase-to-neutral voltage (L-N): 230 V

9

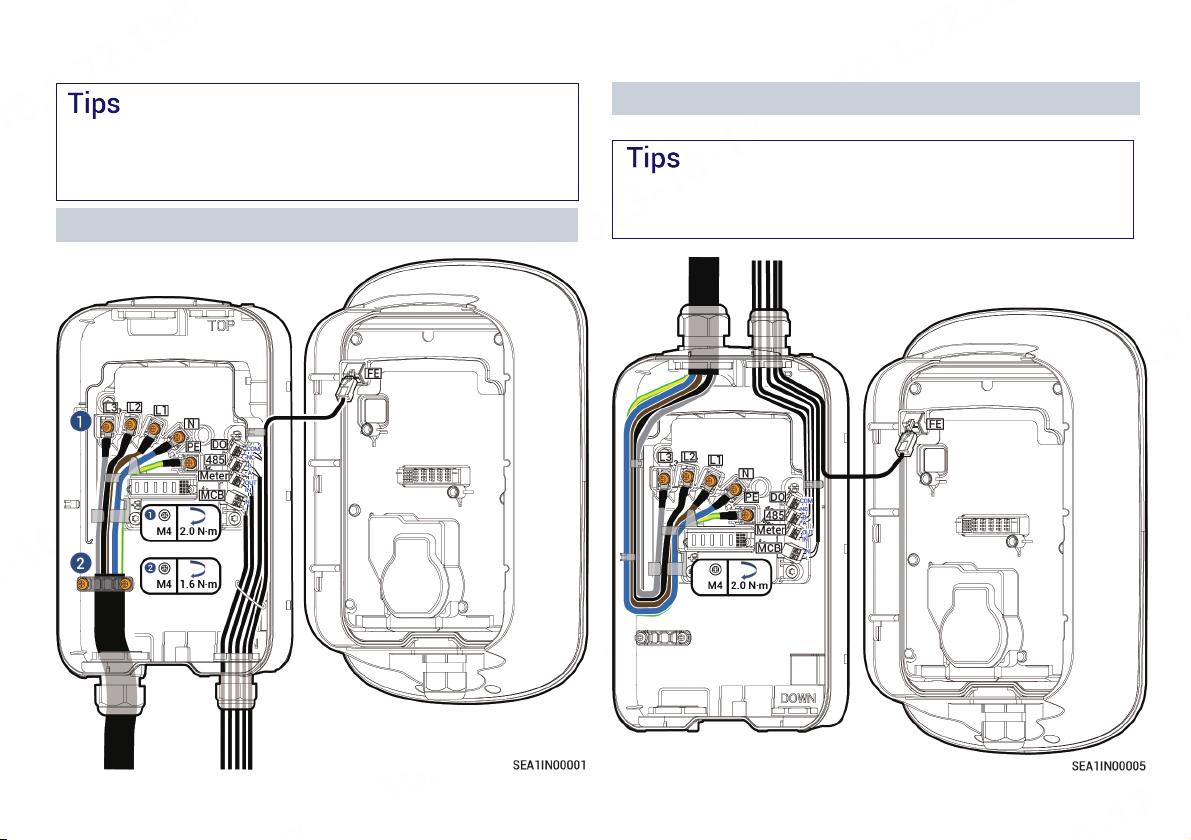

5.2 Routing

Bottom Routing (recommended)

•This section describes the routing method using the three-phase

five-wire system.

•You are recommended to place the PE core at the lowest layer

during routing.

Top Routing

When top routing is used, the equipment top should be adequately

protected to prevent water ingress caused by prolonged water

accumulation.

The stripping length (A) of cable insulation is determined

by the Sigen EVAC port to which cables are connected.

10

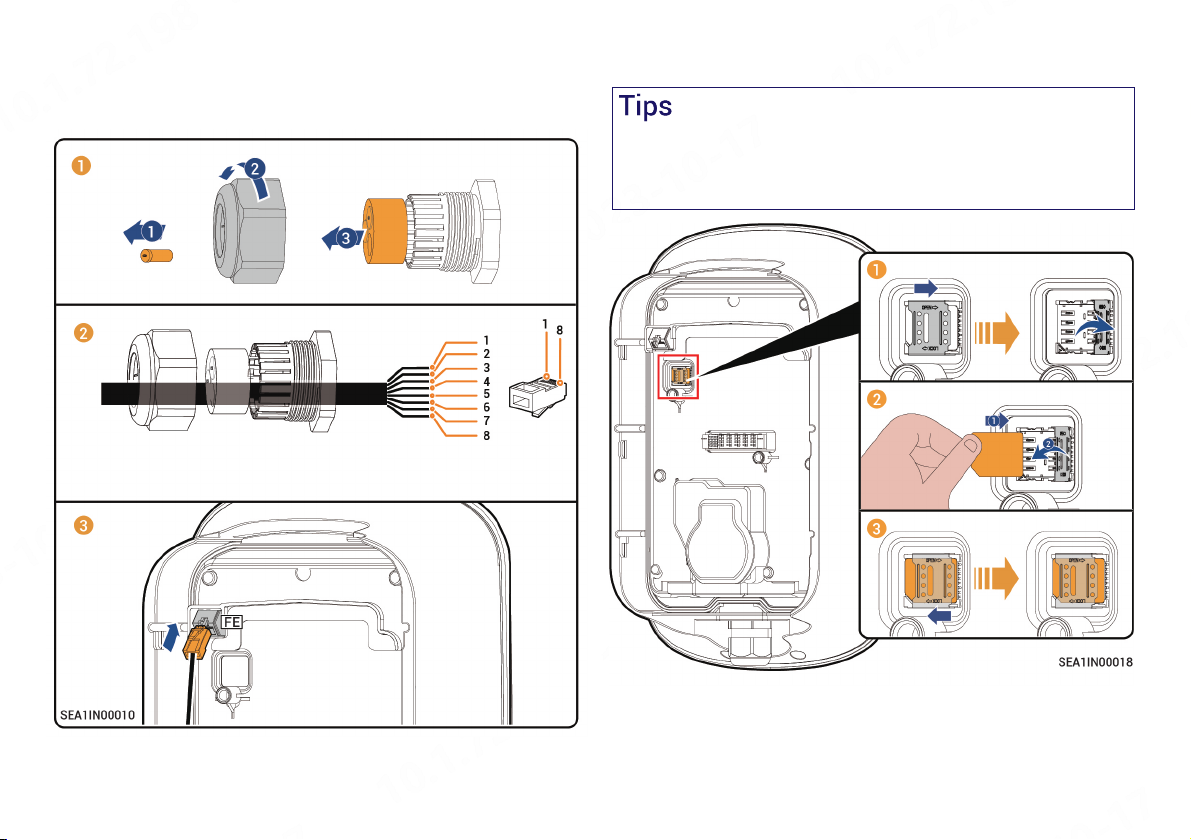

Top Routing 5.3 AC Input Cable Connection

This section will take three-phase five-wire system

as an example to introduce the connection procedure.

Install the water-proof connector at the bottom to the top before

connecting cables.

11

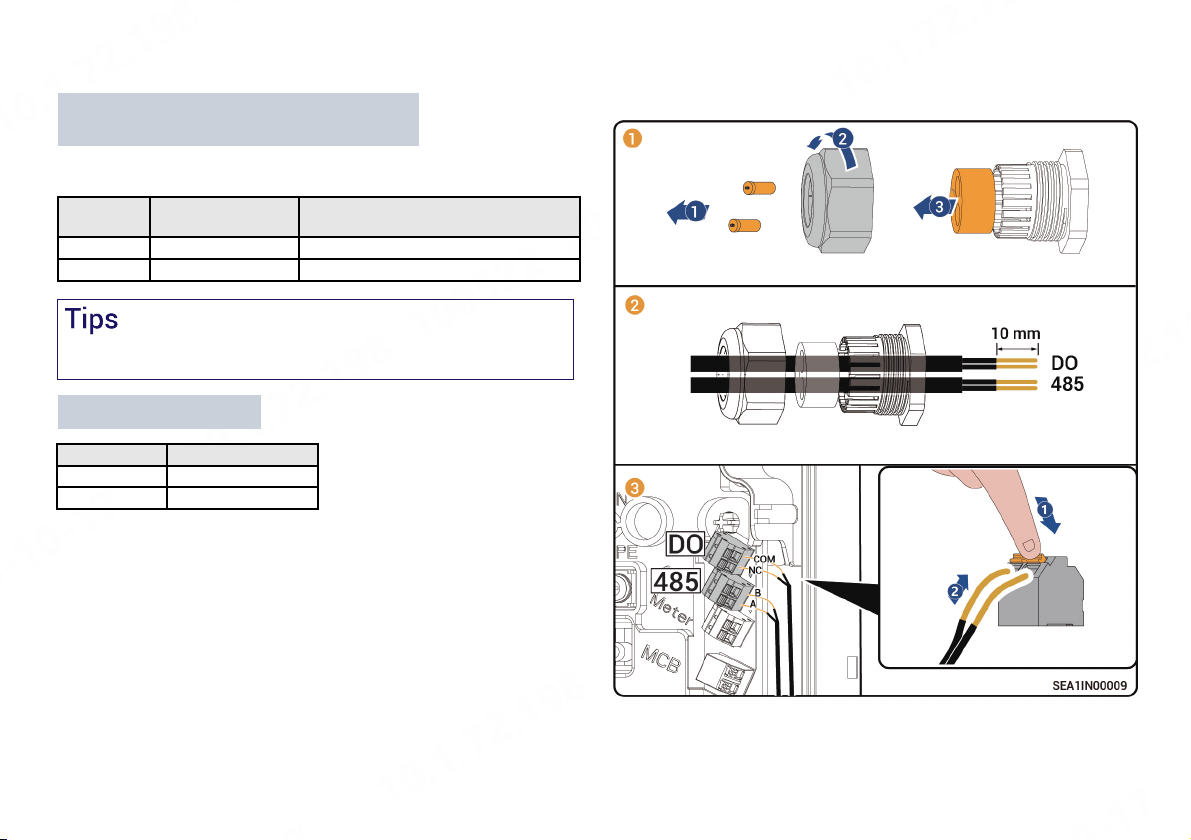

5.4 RS485/DO Signal Cable Connection

PIN Definitions Sigen Sensor TP-CT120-DH

(SDM630 MCT 40mA)

RS485_A RS485 signal_A+ 14

RS485_B RS485 signal_B-13

Definitions of RS485 Ports and Connection

Relationship with Power Sensor

Definitions of DO Ports

PIN Definitions

COM Output signal COM

NC Output signal NC

For appearance and connection details of the Power Sensor, refer to

the User Manual supplied with the product.

Connect one end of the RS485 signal cable to Sigen EVAC and the

other end to Power Sensor.

12

5.5 (Optional) Connection of PEN control lines

PIN Definitions Sigen EVAC Smart PEN Breaker[1]

NOutput N level Terminal C1

LOutput L level Terminal C2

Definitions of MCB Ports and Connection Relationship with Sigen

EVAC Smart PEN Breaker

Note [1]: The corresponding wiring terminal of the Sigen EVAC Smart

PEN Breaker

For information on the specific installation and wiring operation of the

Sigen EVAC Smart PEN Breaker, please refer to the user manual

supplied with the product.

Sigen EVAC Smart PEN Breaker

Sigen EVAC

13

5.6 (Optional) Connection of Linky Smart Meter Signal Cable

Definitions of Meter Ports and Connection Relationship with Linky

Smart Meter

For information on the specific installation and wiring operation of the

Linky smart meter, please refer to the user manual supplied with the

product.

PIN TIC port of Linky Smart Meter

Meter_IN I1

Meter_OUT I2

14

5.7 FE Signal Cable Connection

Connect one end of the FE signal cable to Sigen EVAC and the other

end to a router.

①White orange ②Orange ③White green ④Blue

⑤White blue ⑥Green ⑦White brown ⑧Brown

5.8 Installation of SIM Card

•Install the SIM card when 4G communication is enabled.

•SIM cards are supplied by users and standard SIM cards are

recommended (size: 25 mm×15 mm, capacity ≥ 64 KB, traffic ≥

128 MB/month).

15

No. Check Item

1The equipment is securely installed.

2AC cables and signal cables are properly connected

without omission.

3Lock screws or terminals are installed in place without any

looseness.

4Cutouts of cable ties are free of burr or sharp edges.

5Unused ports are protected with water-proof covers or

plugs.

6No construction residue inside and outside the equipment.

Check the following items against the provided table, tighten routing

holes, and install the panel.

5.9 Installing Panel

16

5.10 Installing Cable Holder and Placing Charging Connector

1Install the cable holder.

Wall

This section applies only to Sigen EVAC 7/11/22 4G T2 WH.

2Place the charging connector.

17

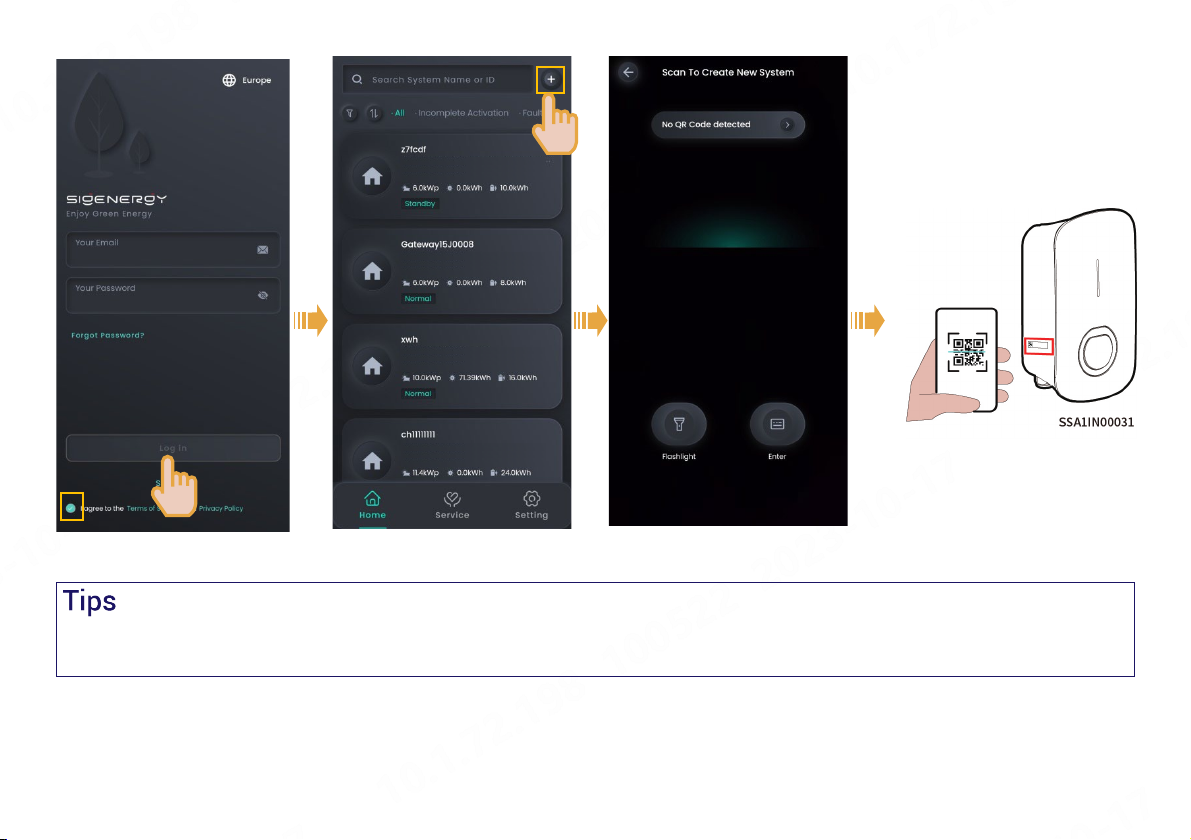

6 Power-on and New System Creation

1. Turn on the pre-AC switch.

2. Observe the indicator status on the front panel of Sigen EVAC to understand the operating conditions.

3. When the indicator turns green and is steady on or breathing blinking, create a new system in the mySigen app.

Illuminated Indicator Color Status Meaning

All Multicolored Steady on Starting, initializing configuration.

1Steady on In standby mode. Not connected to the internet, charging connector not

inserted into the vehicle.

1Breathing blink In standby mode. Connected to the internet, charging connector not inserted

into the vehicle.

All Steady on •RFID card not read. The charging connector is connected to the vehicle.

•Charging completed.

All Breathing blink You have registered the charging time, and the charging connector has

already been connected to your vehicle.

All Blink RFID card read. Get ready to charge vehicles.

All Flowing blink Charging.

None - - Not powered on or low voltage.

1Blink Equipment electrical leakage.

1Steady on Relays within the equipment getting stuck.

2Blink Overvoltage or undervoltage protection.

3Blink Overcurrent protection.

4Blink Overtemperature protection.

5Blink Grounding fault.

6Blink Communication failure between the equipment and the vehicle.

All Blink Other malfunctions.

19

The following steps are different when the equipment has already been connected or not connected to the internet (that is, FE and 4G communication

fault), as described below.

This manual suits for next models

5

Table of contents

Popular Batteries Charger manuals by other brands

WATSON

WATSON AC/DC Compact Charger owner's manual

Coleman

Coleman 6 Watt solar battery trickle charger user manual

Dynamite

Dynamite Passport UltraDuo DYN4300 instruction manual

Erbauer

Erbauer ERB607CHR Original instructions

Outback Power Systems

Outback Power Systems FX Series installation guide

ring

ring SmartCharge RSC701 instructions