Sign HTM-LCB4-I-LF User manual

HEAT TRANSFERRING

We are looking for distributor, please ask us for better offer!

Samples are available.

Sign-in-China.com

Online Wholesale for AD & Signage Products

User Manual for Pneumatic Heat Press

HTM-LCB5-III

Operation Manual (CE)

This machine is designed not for

minors to use or food processing

Please read this manual carefully before operation

Learn More >>

Add: Room 17-20, F-3M, Building 1, Community 3, Hanwei International Plaza,

No.186, Western Road of South 4th Ring Road, Fengtai District, Beijing, China. 100070

Cell Phone: +86 138 012 487 14

Sign-in-China.com

Online Wholesale for AD & Signage Products

Learn More >>

-2-

Congratulations on your purchase of the Air Operated Automatic digital heat press machine!

This heat press machine has many ex - citing features, all of which are meant to help make

your heat transfer pressing endeavors as successful and easy as possible. Please take the

time now to thoroughly read through this manual to become acquaint -ed with them. It will

explain some key features, concepts and methods that will save much time and effort in

using this press and in your heat pressing applications.

Throughout this manual, many areas and components of this machine will be referred to by

specific names. Please refer to the illustrations below in order to become familiar with some

of the terminology used in this manual.

I. Applications

This large format T-shirt heat press machine is widely used for transfer image for T shirts,

cloth, cushion covers, rock photos, tiles, backpack school bag, jigsaw puzzle, etc.

31" x 39" Pneumatic Single Station Flat Heat Press Machine with Drawer

Sign-in-China.com

Online Wholesale for AD & Signage Products

Learn More >>

-3-

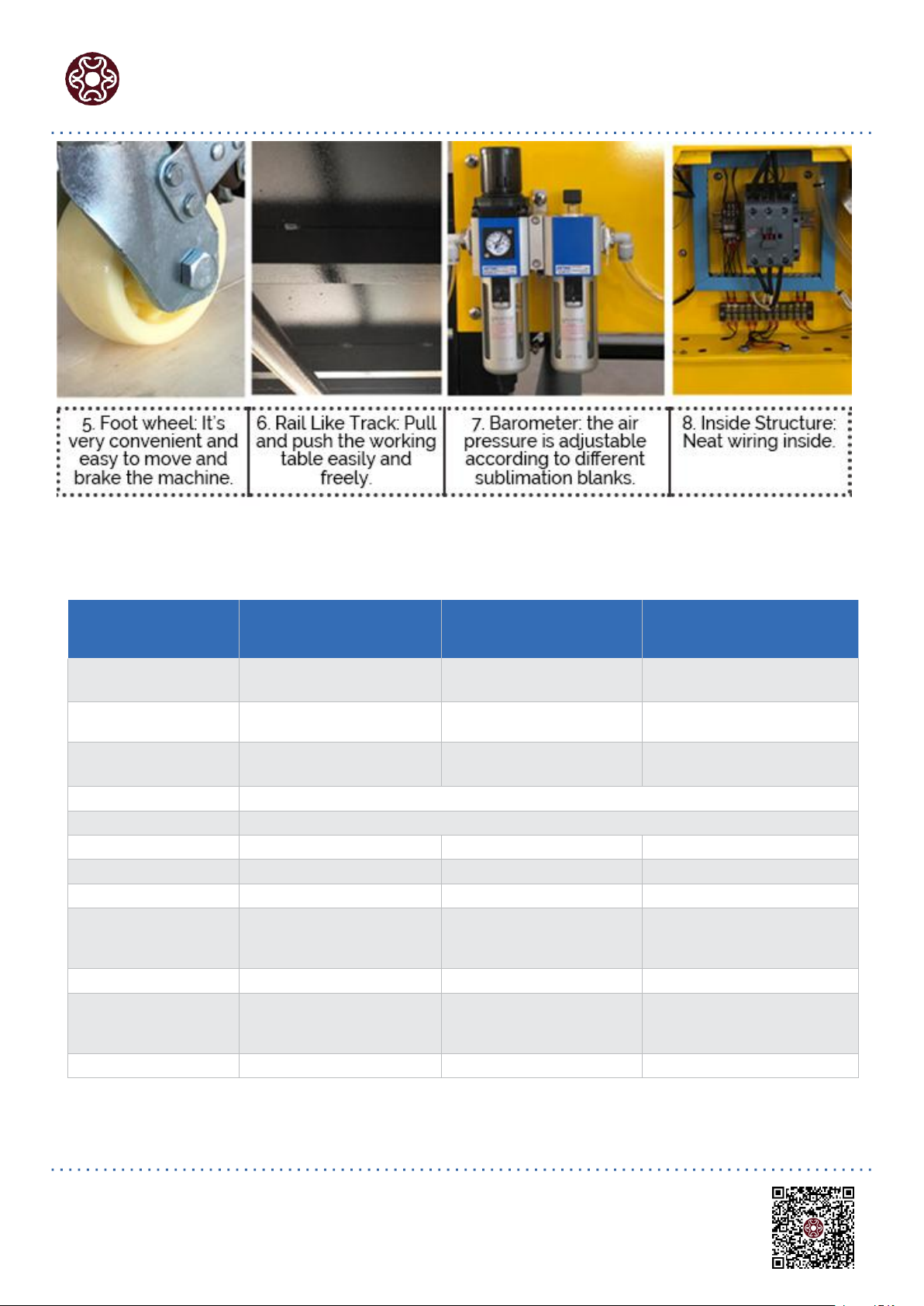

II. Heat Press Components

1Power Switch

2Temp / Time Gauge

3Pressure Meter

4Pressure Adjustment Knob

5Emergency-stop Button

6Start Button

Sign-in-China.com

Online Wholesale for AD & Signage Products

Learn More >>

-4-

III. Specifications

Model

HTM-LCB4-I-LF

HTM-LCB4-II-LF

HTM-LCB4-III-LF

Voltage

110V, 60Hz, 1P, 41A

220V, 60Hz,3P, 50A

380V, 60Hz, 3P, 27A

220V, 60hz, 3P, 60A

380V, 60Hz, 3P, 36A

Power

4500W

9000W + 1500W Air

Compressor

12000W + 1500W Air

compressor

Size

600mm x 800mm (24in x

31in)

800mm x 1000mm (31in

x 39in)

1000mm x 1200mm (39in x

47in)

Temperature Range

0°C - 250°C (32℉- 482℉)

Time Range

0-999sec

Air Cylinder

One

Two

Two

Cylinder Distance

125cm (49.2in)

125cm (49.2in)

125cm (49.2in)

Largest Pressure

8kg / cm2

8kg / cm2

8kg / cm2

Machine Size

1200mm x 2400mm x

1650mm

(47in x 95in x 65in)

1420mm x 3060mm x

1650mm

(56in x 120in x 65in)

1620mm x 3660mm x

1650mm

(64in x 144in x 65in)

Machine Weight

827lbs (375kg)

1135lbs (515kg)

1408lbs (639kg)

Packing Size

1200mm x 1550mm x

900mm

47in x 61in x 35in

1400mm x 1550mm x

1150mm

55in x 61in x 45in

1620mm x 1550mm x

1260mm

64in x 61in x 50in

Gross Weight

866lb (393kg)

1190lb (540kg)

1486lbs (674kg)

Sign-in-China.com

Online Wholesale for AD & Signage Products

Learn More >>

-5-

Warm Tips:

1. LCB4-I has only one air cylinder, other two bigger size machines with two cylinders.

2.The heat press machine uses electricity about 41A/50A/60 Amps, we suggest you

prepare thicker cables for safety reason.

3.You need to prepare one air compressor. And the suggested specification is that power

greater than 1.5KW, capacity about 30L, pressure more than 1MPa.

Heat Platen Test:

Each Single Copper sheathed heating rod is tested before it is cast in an aluminum alloy or

Mica Sheet. These heating rods are comparable to those found in industrial ovens that heat

up quickly, work efficiently and last many years.

Finished Machine Test:

1.

Turn on the machine, let it heating up to 200℃(392℉).

2.

Keep the temperature stay at 200℃(392℉) for at least half an hour.

IV. Installation

4.1 installation precautions

1. Before unpacking, carefully check if there is damage for the packing and machine during

transportation.

2. After unpacking, check if the service parts are correct as the packing list.

3. The installing place should be provided enough space for operating and free of dust,

novapor, no corrosive gas, no combustible or explosive substance around. Keep the

machine away from wind blowing place, otherwise will affect the roller temperature which

might bring the laminating quality.

4. After installation, adjust each caster to reach level ground. The casters only be used on

even ground for short distance movement.

Not ice: Please move carefully since it is heavy equipment.

Sign-in-China.com

Online Wholesale for AD & Signage Products

Learn More >>

-6-

4.2 The Machine Assembly

1)

Take out the machine from the packing.

Place the heat press on a stable flat surface with good ventilation. Don’t put much staff around the

machine to avoid the necessary problem. The power cord not allow to put on ground nor

with object on top.

2)

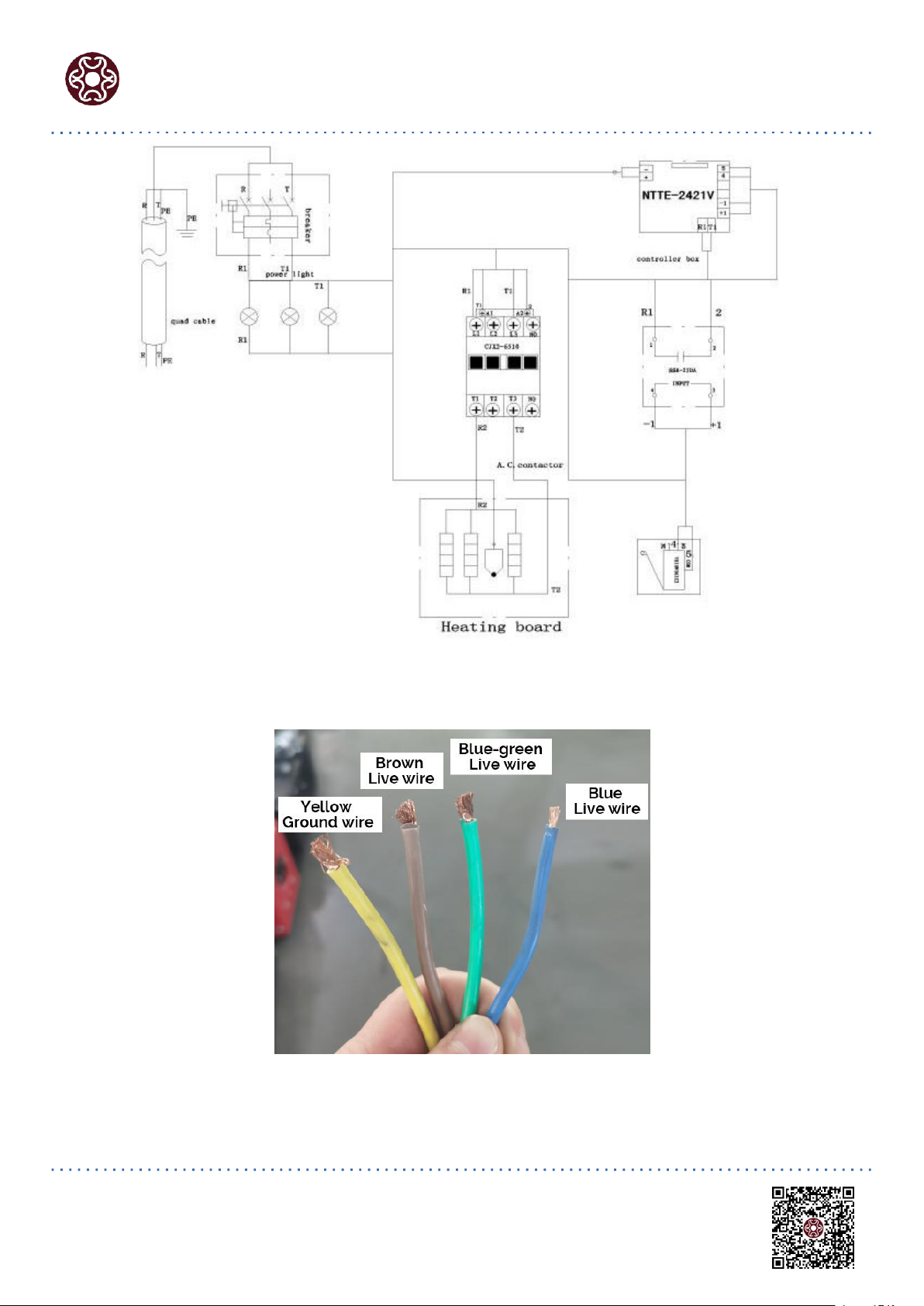

Wiring Diagram

It was installed the standard power supply plug, before plug in, please check your power supply

voltage is same as the machine's rated operating voltage, also should verify the access to the

socket is in requirements, and have a good grounding,and the capacity is large enough.

HTM-LCB4-I-LF Model heat press machine, 1 phase power, circuit diagram

Sign-in-China.com

Online Wholesale for AD & Signage Products

Learn More >>

-7-

HTM-LCB4-II-LF and HTM-LCB4-III-LF Model heat press machine, 3 phase power, circuit

diagram

Sign-in-China.com

Online Wholesale for AD & Signage Products

Learn More >>

-8-

3)

Turn on power switch①and connect air compressor, place the material on working

table.

4)

Adjust the pressure with pressure adjustment knob④, lift this knob up and rotate it for

adjusting pressure of air compressor. Clockwise for adding pressure, anticlockwise for

decreasing pressure (we advise 0.3-0.6)

Sign-in-China.com

Online Wholesale for AD & Signage Products

Learn More >>

-9-

5)

Set temperature & time with temp/time gauge ②

Sign-in-China.com

Online Wholesale for AD & Signage Products

Learn More >>

-10 -

1The temperature for heating plate will start to rise up, when it reaches the

temperature you have set, place the material on the working table.

2Push the working table inside, then press Start Button ⑥the heating plate will press

down.

3The heating plate will lift up automatic when the time you set is reached, pull out

the working table, and then take out the materia.

Note:

Because difference materials have different thickness, the temperature and time

required are different.

Pls try a small sample to get the right temperature and time needed before starting large

quantity printing.

Fabric requires the temperature about 180℃(356℉),Fabric clothing use with sublimation

paper: 30-50 sec, 100% cotton clothing use with transfer paper:15-20sec.

After using for a period of time, check whether there is water in the drainage cup. If

necessary, turn on the drain switch below. After the water is drained, tighten the switch.

Avoid contact with the heating plate during heating to avoid burns.

Successful transfer requires the correct time. The cooperation of temperature and

pressure, the thickness and material of the stamped object and the type of transfer paper

all affect the transfer effect.

Transfer paper must be approved for sample trial printing before mass production.

The function of the temperature control instrument is complicated, and extra adjustment

operation is not required except for setting the temperature value, otherwise it is easy to

cause the instrument program to be disordered and not to work properly !!!

Sign-in-China.com

Online Wholesale for AD & Signage Products

Learn More >>

-11 -

V. IProblems and Solutions

No.

Troubles

Reason

Solution

1

Picture burning

Heating time is too long or heating

temperature is too high.

Adjust time or temperature.

2

Fails to heat up, but display

well

Heating plate or relay broken

Check the heating plate or relay

3

Lack of color, faded image.

Insufficient temperature and / or

heating time.

Adjust the temperature and / or

increase the heating time.

4

Darkened, deep color;

blurred image.

Heating time is too long or heating

temperature is too high.

Adjust the temperature or heating

time.

5

Although the main is

plugged in and the power-

on button is pressed, the

LED does not light up.

The power plug is not well -

connected

Check the plug to ensure

connection.

The voltage of the main does not

adaptable to the required voltage.

Check the voltage of the main to

ensure its adaption to the machine.

Emergency stop is not switched on

Turn on the emergency stop.

The fuse link beside the power

cable is un-installed or damaged.

Check the fuse to ensure it is not

damage.

6

The actual heating

temperature exceeds the

setting temperature

Relay broken

Replace the relay

The cylinder does not move

When the heating plate cannot be pushed up and down, check

whether the pressure gauge on the air cylinder shows that there is

pressure, or observe whether the solenoid valve in the control box is

moved when the start button is pressed

VI. Maintenance

6.1 Notice

1) Only experienced operator could open the cabinet, be noted following measures;

2) Don’t use abrasive cleaner to clean the machine surface.

3) Check the rotation parts regularly and fill high-temperature grease to lubricate the

two bearings of heating rollers.

4)Do not wash the machine with water. This can damage the electrical circuits, cause

electrical shock or corrosion.

Sign-in-China.com

Online Wholesale for AD & Signage Products

Learn More >>

-12 -

5)During maintenance, don’t run the machine.

6)During maintenance, don't change, move and dismantle the safety parts. Make sure

the safety parts before using.

7) Cut the power supply before dismantling and assembly.

6.2 Cleaning

1) To extend the lifetime of the machines, please ensure the machine are clean.

2) Make sure environment clean and keep away from obstacles.

6.3 Checking

In order to ensure your safety, please check the safety of the machine regularly. If you find

failures in the check, please refer to the section of Trouble shooting and solution.

6.3.1 Visual Checking

Visual checking prior to maintenance.

1) Power supple cable undamaged.

2) Foot wheel is stable.

3) Any damage on machine

6.3.2 Safety Parts Checking

Emergency switch.

1) Turn on machine

2) press the emergency switch, machine stop or not

3) Turn on machine when emergency switch is on

4)Release the emergency switch, turn on and start to run machine.

WARRANTY CARD

Notes

i.

The warranty card should be filled by seller and kept by buyer. Alterations are prohibited.

ii.

The guarantee period is two years. The repair is free of charge within 6 months and will be charged

with material and labor cost after 6 months.

iii.

No free repair is available for any damages caused by the improperuse.

HEAT TRANSFERRING

We are looking for distributor, please ask us for better offer!

Samples are available.

Sign-in-China.com

Online Wholesale for AD & Signage Products

MODEL

LOT #

BUYER

DATE

SELLER

TEL

Learn More >>

Add: Room 17-20, F-3M, Building 1, Community 3, Hanwei International Plaza,

No.186, Western Road of South 4th Ring Road, Fengtai District, Beijing, China. 100070

Cell Phone: +86 138 012 487 14

This manual suits for next models

1

Table of contents