Signet 3350 User manual

Signet 3350/3550 Ultrasonic Flowmeter

3-3350.090 Rev. A 11/05 English

3-3350.090

1. Description

The Signet 3350/3550 Ultrasonic Flowmeter uses transit-time technology to deliver

accurate flow rate and totalizer information with no direct fluid contact.

Originally used for temporary installations and periodic flow rate validation, today these

ruggedized instruments are perfectly suited to applications where pipes cannot be

penetrated, or where the fluid medium is hazardous or easily contaminated.

The clamp-on sensors are easy to install, without interrupting the process stream. Simply

enter the pipe parameters and the application preferences; the 3550 will provide stable and accurate data that is tailored

by you, for your unique requirements.

The Ultrasonic Flowmeter is programmable via the front panel keypad. Select display menu instructions in English,

French, Spanish, German or Japanese on a 2-line, backlit LCD.

ENT

ESC

Signet Ultrasonic Flowmeter

123.456 GPM

12345678 Gal

Caution: High Voltage

Turn off power before opening unit

Contents Page

Description Front cover

Specifications 2

Features and Functions 3

Installation and Quick Start Guide 4

Pipe Parameters 8

Factory settings 12

Parameter Protection 14

Measure setup mode 15

Configuring the Display 17

Set the 4-20 mA Range (FLOW SPAN-1) 17

Set Dual 4-20 mA Ranges (FLOW SPAN-2) 18

Set Pulse Output and Totalizer functions 19

Start, Stop and Reset the Totalizer 20

Set Relay Outputs (DO1 and DO2) 21

Adjust the 4-20 mA Span 22

Calibrate the 4-20 mA Output 23

Set Serial Communication parameters 25

TROUBLESHOOTING AND MAINTENANCE 27

Piping data: Acoustic Velocity in Solids 33

Acoustic Velocity of Water (Listed at varying temperatures) 33

Acoustic Velocity in Fluids 34

Pipe Dimensions: PVC 41

Pipe Dimensions: Steel 43

Pipe Dimensions: Welded Steel, Aluminum, and Copper 44

Pipe Dimensions: Galvanized Steel Tubing and Pipe 45

Pipe Dimensions: Iron 47

Ordering Information Back Cover

2

Scaled for footer

Signet 3350/3550 Ultrasonic Flowmeter

General

Flow rate range: 0.3 to 10 m/s (1 to 33 ft/s)

Low flow cut off : 0 to 5 m/s configurable

Suitable pipe materials:

• Plastic (PVC, PVDF, CPVC, PP, PE, PEEK, etc.)

• Metals (carbon steel, SS, copper, aluminum, iron)

Pipe Size Range

• Plastic pipes:

• 3550-100: DN25 to DN100 (1 in. to 4 in.)

• 3550-200: DN50 to DN225 (2 in. to 9 in.)

• Metal pipes:

• 3550-100: DN50 to DN100 (2 in. to 4 in.)

• 3550-200: DN50 to DN225 (2 in. to 9 in.)

Application: Clean liquids, no aeration or particles

Accuracy

Pipe size Over 2 m/s

(6 ft/s)

Under 2 m/s

(6 ft/s)

DN25 to DN40

(1 to 1½ in.)

±3% of rate ±0.06 m/s

DN50 to DN225

(2 to 9 in.)

±2% of rate ±0.04 m/s

Display: LCD w/back light 2x16 characters

• Sensor signal quality LED - Normal: green, Error: red

• User selectable language:

English, French, German, Spanish, Japanese

Display resolution:

• Flow rate: 00.0000 min to 9999999 max

• Totalizer: 00000.00 min to 99999999 max

Totalizer Error condition:

Hold last good value or Continue Count

Error Time delay 0 to 100 s

Damping: 0 to 100s Averaging function for 4 to 20 mA

output and Flow Rate display

Response time: 200 ms

Material

Flowmeter: ABS

Sensors: PBT

Sensor frame: 304 SS

Electrical

• 3-3350-1: 100-120 VAC ±10%, 50/60Hz, 15VA max

• 3-3350-2: 200-240 VAC ±10%, 50/60Hz, 15VA max

Signal cable: RF coaxial cable, 5 m std (Avail to 30 m)

Output Specifications

4 to 20 mA output

• Max. load resistance: 600Ω

4 to 20 mA Error condition (Burnout): User selectable

• Hold last good value • Over-scale (22.6 mA)

• Under-scale (3.8 mA) • Zero (4 mA)

Bi-directional or Autoscale dual ranges

• User Selectable

• Hysteresis: 0 to 10% of flow rate range

• Flow range applicable to digital output

Output Specifications (continued)

Relay output (DO2)

• Capacity: 220V AC /30V DC, 1A (resistive load)

• Mechanical SPDT relay contact: (replaceable)

• Mechanical life expectancy: > 2 x 107 operations

• Relay Pulse width: User selectable 50, 100 or 200 ms

Open collector output (DO1)

• Capacity: 30V DC, 0.1A

• Total pulse: Programmable, 1 pps to 1 pulse per day

• Open Collector Pulse width:

User selectable 5, 10, 50, 100 or 200 ms

Digital output Logic

ACTIVE ON: Relay DO2 Normally OFF (de-energized)

Open Collector DO1 normally open

ACTIVE OFF: Relay DO2 Normally ON (de-energized)

Open Collector DO1 normally closed

Programmable functions

• Cutoff limit (common to DO1 and DO2)

• NOT USED

• TOTAL SWITCH Operation

• +TOTAL PULSE: Proportional to +Flow rate

• –TOTAL PULSE: Proportional to -Flow rate

• FLOW SPAN-2:

Select a contact output at SPAN-2 measurement status

(forward automatic 2 ranges, forward/reverse automatic

2 ranges).

• ALARM Operation

- HARDWARE: Contact output at EEPROM error.

- PROCESS: Contact output when signal is bad

FLOW SWITCH Operation

• UPPER SWITCH: HIGH Flow Alarm

• LOWER SWITCH: LOW Flow Alarm

• TOTAL SWITCH: Volumetric Pulse

Flow requirements

• Well-developed turbulent or laminar flow

• Maximum air in liquid volume:

0.2% @ 1 m/s (inversely proportional to velocity)

Weight

• Flowmeter: 0.8 kg

• Sensor: 3-3550-100: 0.3 kg

3-3550-200: 0.4 kg

Environmental

NEMA4/IP65 enclosure for both flowmeter and flow sensor

Process temperature:

• With silicone rubber acoustic couplant

-40°C to +180°C (-40°F to 356°F)

• With silicone-free grease acoustic couplant

0°C to 60°C (32°F to 140°F)

Ambient temperature:

• 3-3350-X: -20° to 50°C (-4° to 122°F)

• 3-3550-XXX: -20° to 60°C (-4° to 140°F)

Short-term thermal stability: 140ºC, 30 min

Relative Humidity: 90% (non-condensing)

Specifications

3

Scaled for footer

Signet 3350/3550 Ultrasonic Flowmeter

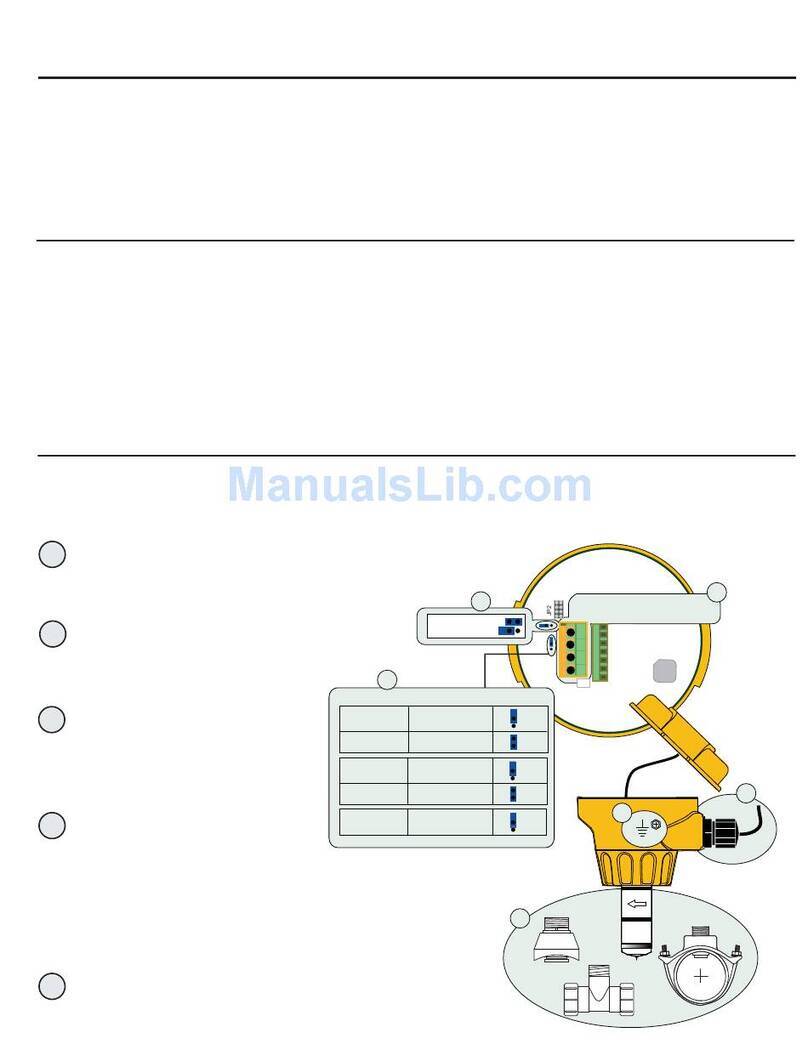

Features and Functions

Signet Ultrasonic Flowmeter

2

1

5

4

3

8

6

7

14

9

11 10

15

12

13

No. Name Description

1. Cable ports, PG 13.5 For power cable, Output Cable

2. Cable ports, PG 9 For signal cables only

3. Flow signal LED Green = Normal operation, Red = Error condition

4. Escape key Moves back one menu level or cancels changes not yet ENTERED

5. UP key Selects items, scrolls active numeric values and symbols

6. Shift key Advances blinking cursor, selects decimal position

7. Enter key ENTERS (saves to memory) new settings and selections

8. Liquid Crystal Display Displays flow rate and menu information

9. Power terminals Connect AC or DC power

10. Input/Output Cables Sensor coaxial cables, Relay output and 4-20 mA output cables

11. Fuse and Fuse holder 250 V, 0.5 A for AC models, or 250 V, 1 A for DC models

12. Communication board terminals Wiring for optional Comm board for serial data output

13. Communication board RS-232 (3-3350.403) or RS-485 (3-3350.404) Optional

14. Arrester board Optional arc supressors for relay outputs

15. Relay DO2 Dry Contact, 1 A 220 VAC or 30 VDC resistive load

16. Scale Used to measure proper spacing for TX-RX sensors

17. Locking hole Sensors lock in place at these openings

18. Transmit and Receive Signal Cables BLACK = Downstream, RED = Upstream

19. Sensor Frame Mounting apparatus for Sensor units

20. Sensors Ultrasonic TX-RX sensors

21. Mounting straps for Frame Stainless steel belts (3-3550.393)

22. Spring tightener Removes slack from steel mounting straps after mounting

Spacing illustrated: 34

19

17

16

18 & 20

18 & 20

21 &22

4

Scaled for footer

Signet 3350/3550 Ultrasonic Flowmeter

Installation and Quick Start Guide

The electronics may be mounted on a wall or on a pipe

stand.

• For wall mounting, use two M8 bolts. Drill holes based

on the dimensions illustrated here.

• For pipe mounting, use the two U-bolts supplied with

the unit.

Mounting hole

130 mm (5.1 in.)

70 mm (2.75 in.)

140 mm (5.5 in.)

170 mm (6.7 in.)

197 mm (7.75 in.)

Mounting

plate

1. Select a mounting location and method for the 3350 electronics.

The installation and startup of this flowmeter is divided into

seven steps. They are organized in the sequence they

should be completed:

1. Select a mounting location and method for the 3350

electronics.

2. Select a location and mount the 3550 strap-on sensor

assembly onto the pipe.

3. Connect the sensor cables and 24 VDC power to the

electronics terminals.

4. Navigate to the MEASURE SETUP menu and enter

the information for your pipe and fluid.

5. Position the two ultrasonic transducers at the spacing

indicated by the PIPE PARAMETER and secure them

in the frame.

6. Review the system troubleshooting information and the

initial values of the output parameters in this manual to

determine if it is safe to start the flowmater.

7. Program the 3350 flowmeter electronics to reflect the

remaining application requirements.

ENT

ESC

Signet Ultrasonic Flowmeter

123.456 GPM

12345678 Gal

Caution: High Voltage

Turn off power before opening unit

5

Scaled for footer

Signet 3350/3550 Ultrasonic Flowmeter

Air tends to accumulate May not completely be filled with liquid

May not

completely be

filled with liquid Good

Good

Pump

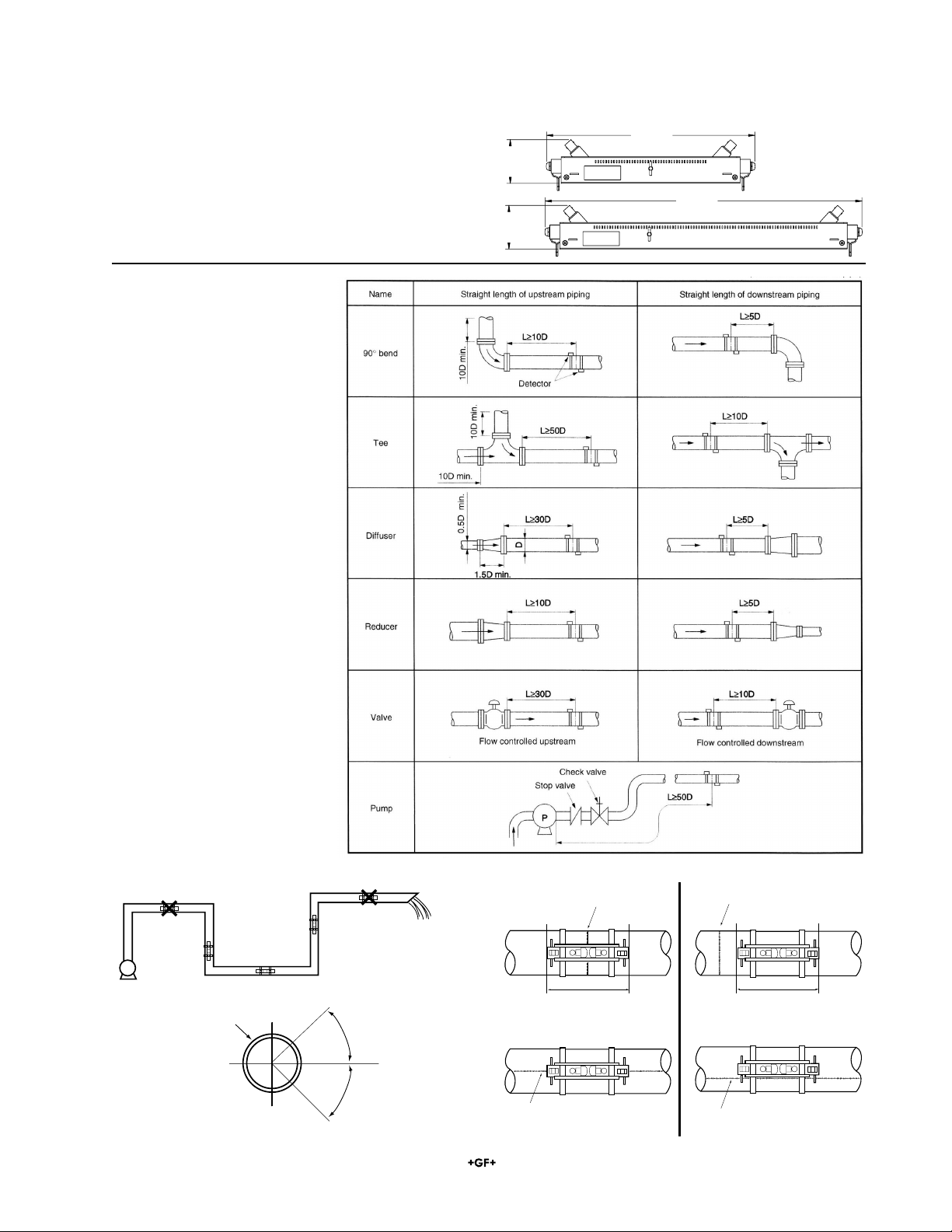

The length of upstream and downstream straight pipe of

the ultrasonic detector should be long enough to ensure

accurate measurements.

2A. Select a location for the 3550 strap-on sensor assembly.

The sensor can be installed at any

position around the pipe when

attention is given to the following

requirements:

• The pipe must be completely

filled with fluid.

• IOn horizontal pipes, mount

the sensors at ±45° from the

horizontal plane to avoid air

pockets and debris that may

accumulate at the top and

bottom of the pipe.

• The pipe surface must be free

of pits and distortions. Use

thinner, sandpaper, etc., to

remove and surface corrosive,

rust, etc, and to remove any

rust, pitch, or other materials

from the pipe surface.

• Do not mount the sensors on a

section of pipe that is visibly out-

of-round, or straddling a flange

or weld seam.

Pipe

Horizontal

45°

45°

Weld seam Weld seam

Sensor straddles weld seam Sensor is clear of weld seam

Sensor is clear of weld seam.

Sensor is on top of weld seam

No Yes

50.8 mm

(2.0 in.)

240 mm

(9.45 in.)

3-3550.100

50.8 mm

(2.0 in.)

360.6 mm

(14.2 in.)

3-3550.200

6

Scaled for footer

Signet 3350/3550 Ultrasonic Flowmeter

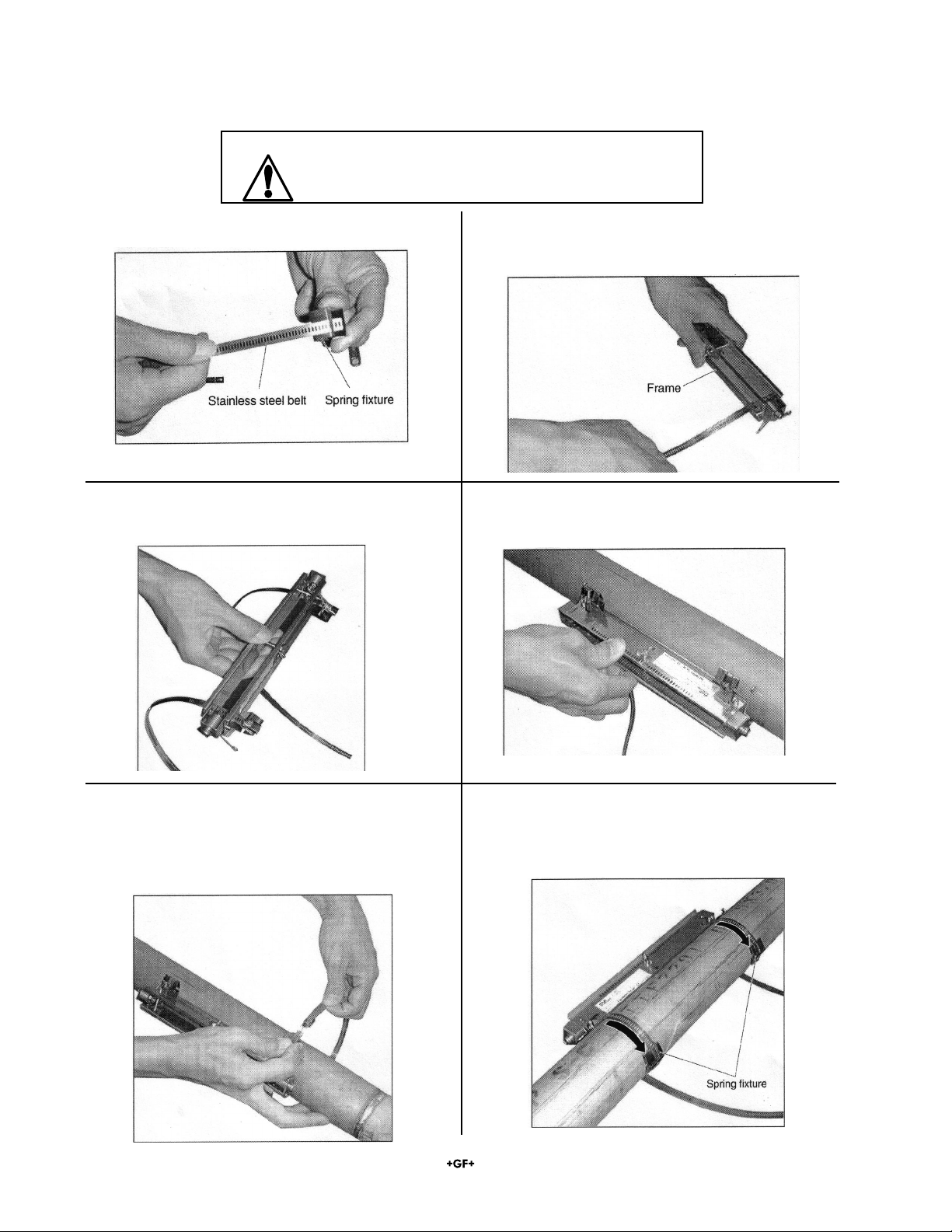

3. Place the frame on a pipe smooth, clean section sub-

jected to a surface treatment.

4. Temporarily tighten the first stainless steel belt on the

pipe.

5. Adjust the frame so it is parallel with the pipe, put the

spring fixture to the side of the frame and tighten the

stainless steel belt so that the frame will tightly be fitted.

Mounting on pipe whose diameter is DN150 (6 in.) or

larger, connect 2 stainless steel belts.

6. After tightening both stainless steel belts, slide the

spring fixture to the opposite to the frame.

Note: Frame must be relocated, use new stainless steel

belts.

1. Slide the spring fixture onto the stainless steel belt. 2. Pass the stainless steel belt through 2 belt holes on the

frame.

Handle the steel mounting belts carefully to avoid injury.

2b. Mount the 3550 strap-on sensor assembly onto the pipe

WARNING! CAUTION

7

Scaled for footer

Signet 3350/3550 Ultrasonic Flowmeter

Connect the signal line with BNC connectors to the sensor

units. Engage the red BNC connector upstream, and the

black BNC connector downstream.

Before mounting the sensor unit into the frame, Apply

silicone (or silicone-free grease) over the transmission

surface of the sensor unit. Do not leave any bubbles.

When using silicon-free grease, do not exceed the fluid

temperature range:

• Silicon rubber: 20 to 100°C

• Silicon-free grease: 0 to 60°C

Silicon-free grease should be reapplied approximately once

every 6 months. (Silicon rubber need not be reapplied.)

Insert the sensor unit into the frame. The UPSTREAM and

DOWNSTREAM sensors must be spaced according to the

PIPE PARAMETER results. Do not lock the sensors yet.

They will need to be adjusted in step 5.

Mount both sensor units so as to be roughly symmetrical

with respect to the frame.

2b. Mount the 3550 strap-on sensor assembly onto the pipe (continued)

8

Scaled for footer

Signet 3350/3550 Ultrasonic Flowmeter

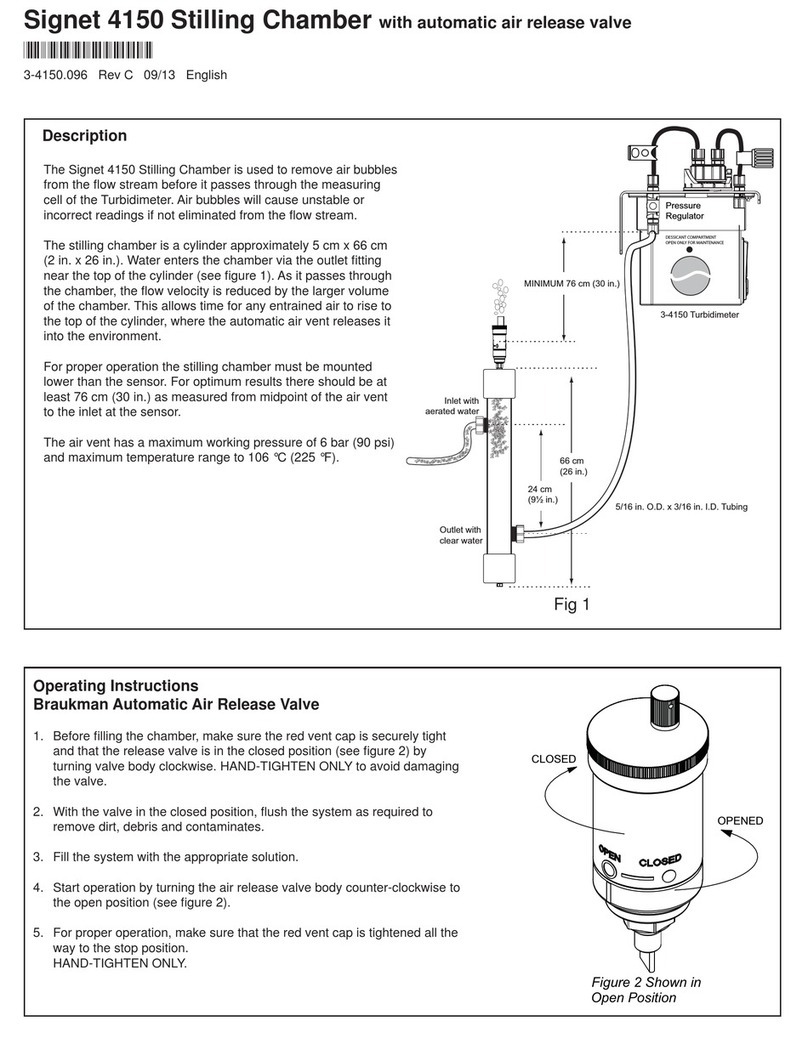

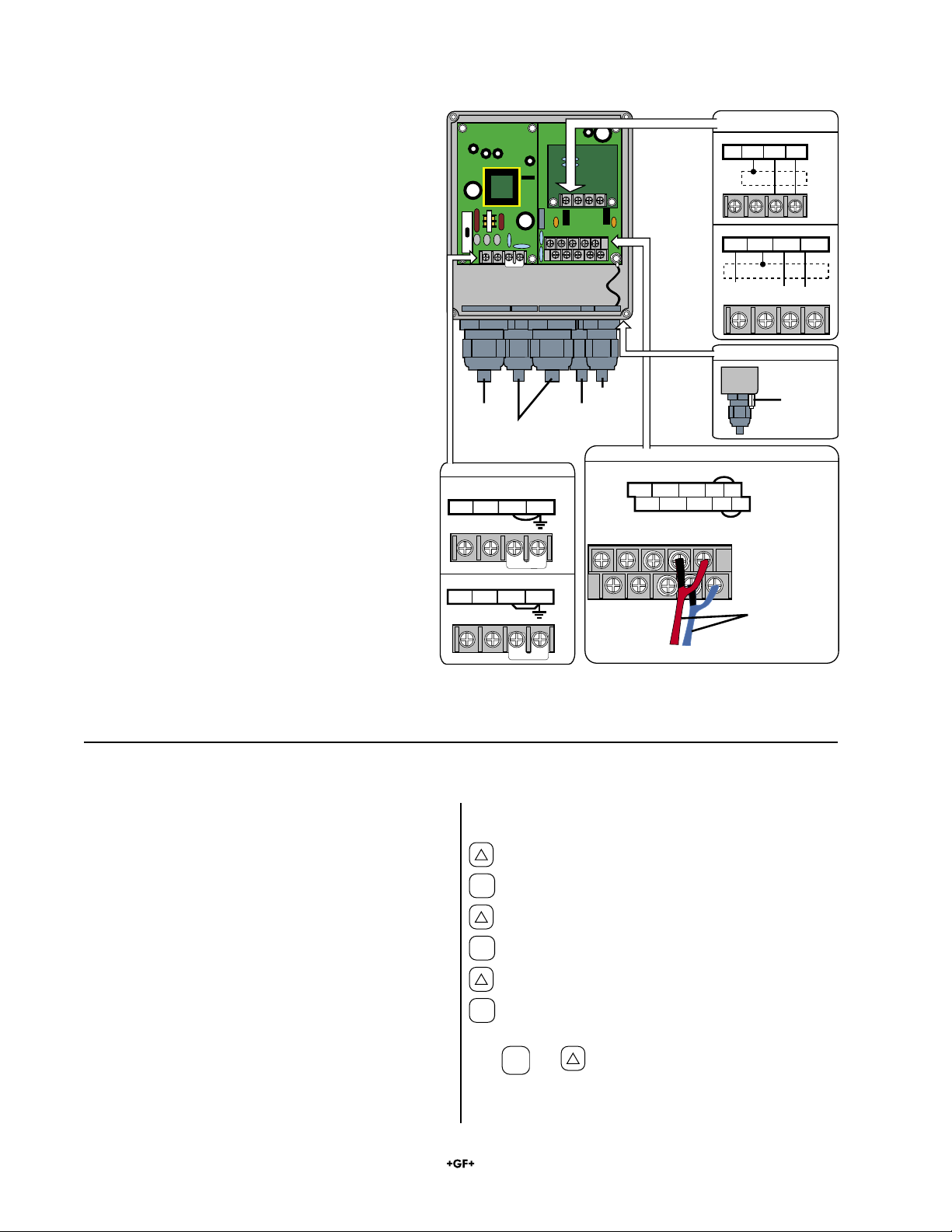

3. Wiring

Main Board Terminal Block

Power Board Terminal Block

Upstream

sensor cable

Downstream

sensor cable

Power cable

Output signal cable

(analog output, DO1, DO2,

communication synchronization)

AC power source: 100 to 120 or 200 to

240 V AC, 50/60 Hz

Notes:

1.All screws are M3 on the terminal block. Use crimp-style terminals for M3 whose outer diameter is

5.8 mm (¼ in.) or smaller.

2. Connect the power board ground terminal block or the external ground terminal to earth ground.

3. Use only cables supplied with sensors.

Red (upstream sensor)

Coaxial signal cables

DC power source: 20 to 30V DC

L N GND GND

GND GND

Communication Board

Terminal Block (Option)

External Ground Terminal

RS-232C

NC GND RXD TXD

RS-485 and synchronization

SYNC SHILD TXCR2 TXDR1

Synchronization

RS-485

Ground terminal

Iout(+) DO1(+) DO2(+) GND HF1

Iout(-) DO1(-) DO2(-) GND

Upstream sensor

Downstream sensor

HF2

+-

Blue (downstream sensor)

Connect the power source and the two sensor

cables as shown here.

4. PIPE PARAMETERS

Press: Display shows:

x 4 “MAINTENANCE MODE”.

ENT

“CURRENT CALIBRATION”.

x7 “LANGUAGE”.

ENT

2nd line begins blinking.

Scroll to the language required.

ENT

New selection is stored.

Use

ESC

and keys to resume measurement mode.

Display language

Before proceeding to the next step, the 3350 can be set to

display the menus in several languages. The procedure to

change from the ENGLISH selection is provided here.

The languages available are listed in the order in which

they appear in the menu.

• English

• Japanese

• German

• French

• Spanish

9

Scaled for footer

Signet 3350/3550 Ultrasonic Flowmeter

Press: Display shows:

3x. 1st line: “MEASURE SETUP”

ENT

1st line: “SYSTEM UNIT”

3x. 1st line: PIPE PARAMETER”

ENT

1st line: “OUTER DIAMETER”. 2nd line: “60.00 mm”

ENT

Cursor blinks on 2nd line.

and Input the outer diameter. (Pipe data is located in section 3.2.)

ENT

“COMPLETE” is indicated for about 1 second on 2nd line.

1st line: “PIPE MATERIAL”. 2nd line: “PVC” (As currently selected)

ENT

Cursor blinks on 2nd line.

Select the pipe material from menus. If the pipe material is not listed, select “PIPE SV” and

input the sound velocity of the pipe material at the end of its, See piping data in section 3.2.

ENT

“COMPLETE” is indicated for about 1 second on 2nd line.

1st line: “WALL THICKNESS”. 2nd line: “4.50mm” * (or as currently selected)

ENT

Cursor blinks on 2nd line.

and Input the wall thickness of a measurement pipe.See piping data in section 3.2.

ENT

“COMPLETE” is indicated for about 1 second on 2nd line.

The PIPE PARAMETER section of the Measure Setup menu calculates the correct spacing between the two Ultrasonic

electrodes. This must be done before the installation can be completed The following pages will guide the user through

each step.

If the parameter protection is set at “PROTECTION ON”, change it to “PROTECTION OFF”.

The ID NO. must be entered if it is active.

4. PIPE PARAMETER (continued)

10

Scaled for footer

Signet 3350/3550 Ultrasonic Flowmeter

Press: Display shows:

1st line: “LINING MATERIAL”. 2nd line: “NO LINING”

ENT

Cursor blinks on 2nd line.

Select the lining material. If the material is not listed, select “Lining S.V.” and input the sound

velocity of the lining material. Sound Velocity data is located in section 6.6.

ENT

“COMPLETE” is indicated for about 1 second on 2nd line.

1st line: “LINING THICKNESS”. 2nd line: “2.00 mm”. (Not present if “No Lining” is selected)

ENT

Cursor blinks on 2nd line.

and Input the lining thickness.

ENT

“COMPLETE” is indicated for about 1 second on 2nd line.

1st line: “KIND OF FLUID”. 2nd line: “WATER”.

ENT

Cursor blinks on 2nd line.

Select “WATER” or “SEA WATER”. If the fluid is not listed, input the sound velocity of fluid.

Sound Velocity (acoustic velocity) data is located at the back of this manual.

ENT

“COMPLETE” is indicated about 1 second on 2nd line.

1st line: “KINEMATIC VISCO”. 2nd line: “1.0038E-6m2/s”. Kinematic viscosity of water or Sea

Water is factory set. If fluid to be measured is other than water, input the kinematic viscosity

referring to piping data at the back of this manual.

ENT

Cursor blinks on 2nd line.

and Input the kinematic viscosity.

ENT

“COMPLETE” is indicated about 1 second on 2nd line.

First line: “SENSOR MOUNTING” Second line: “V”

(Do not change this setting. The “Z” option is not available for this system)

1st line: “SENSOR TYPE”. 2nd line: “3-3350-100”.

ENT

Cursor blinks on 2nd line.

Select “3-3350-100” or “3-3350-200”.

ENT

“**COMPLETE**” is indicated about 1 second on 2nd line.

ESC

1st line: “PIPE PARAMETER”. 2nd line: “S= 16 (48mm)”

Use this value to secure the two sensors at the correct spacing.

ESC

1st line: “MEASURE SETUP”

2x. Measurement mode is resumed.

4. PIPE PARAMETER (continued)

11

Scaled for footer

Signet 3350/3550 Ultrasonic Flowmeter

5. Position the two ultrasonic sensors at the spacing indicated by the PIPE PARAMETER

and secure them in the frame.

Spacing illustrated: 34

6. System Troubleshooting

If everything has been completed according to the instructions, the system is ready to begin working.

All of the remaining settings and menus enable the output functions to be tailored to suit a specific application. Review

the next two pages and identify the functions that must be modified for the application.

About 10 seconds after connecting the signal line, the red LED on the flow transmitter should turn green, indicating the

received signal is normal.

If the LED remains red, the Flowmeter is not receiving a good signal from the 3350 sensor.

The problem is most probably caused by the sensor installation.

Check these conditions:

Sensor spacing: Are the sensors the correct distance apart?

Sensor orientation: Are both sensors facing outward from each end of the frame?

Lock mechanism: Are both lock mechanisms securely latched into the frame?

Lubricant: Have the two sensors been coated liberally with silicone grease or a similar filler?

Parameter settings: Is the information in the PARAMETER SETTINGS menu correct?

Full pipe: Is the pipe filled with fluid?

Closeup of the center mark on the sensor and the spacing

scale on the frame.

12

Scaled for footer

Signet 3350/3550 Ultrasonic Flowmeter

Factory settings

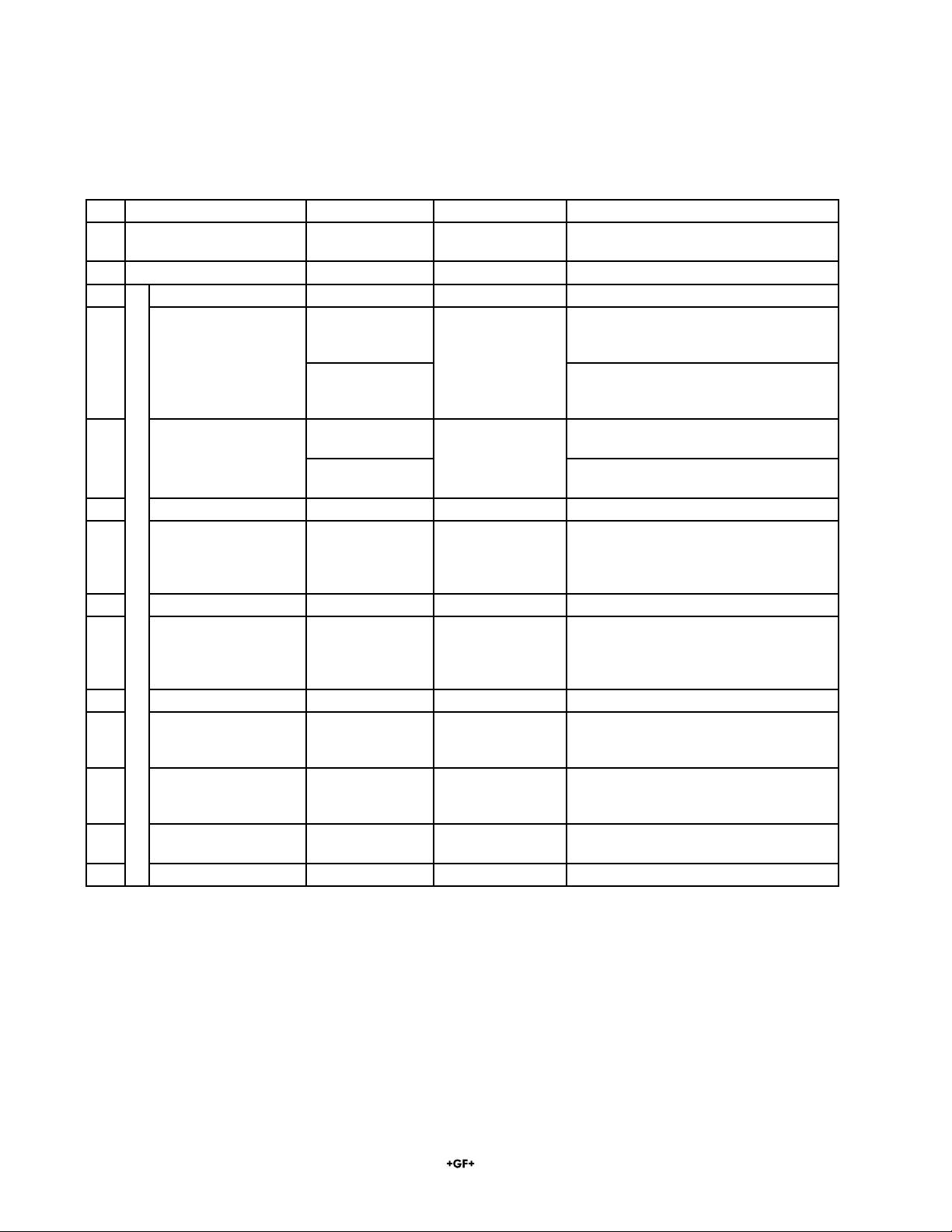

No. Setting Item Setting Range Initial Value Settable Value

1 Parameter protection 2 menus PROTECTION ON PROTECTION ON,

PROTECTION OFF

2 ID No. 0000 TO 9999 0000

3 Unit system 2 menus Metric Metric (metric system)

4 Flow rate unit 12 menus

(Menus system)

L/s l/s, L/min L/h ML/d m3/s m3/min

m3/h Mm3/d BBL/s BBL/min

BBL/h MBBL/d

12 menus

(Inch system)

gal/s gal/min gal/h Mgal/d ft3/s

ft3/min ft3/h Mft3/d BBL/s BBL/min

BBL/h MBBL/d

5 Total unit 8 menus

(Metric system)

mL mL L m3 km3 Mm3 mBBL BBL

kBBL

10 menus

(Inch system)

gal kgal ft3 kft3 Mft3 mBBL

BBL kBBL ACRE-in ACRE-ft

6 Pipe outer diameter 10.00 to 300mm 60.00mm [mm, in]

7 Pipe material 10 menus

Sound velocity;

1000

to 3700 m/s

PVC PVC, PVDF, PEEK, PP, CARBON

STEEL, STAINLESS STEEL, COPPER,

other (sound velocity:__[m/s, ft/s])

8 Wall thickness 0.1 to 50.00mm 4.50mm [mm,in]

9 Lining material 7 menus

Sound velocity:

1000

to 3700m/s

No lining No lining, tar epoxy, mortar, rubber,

Teflon, Pyrexglass, other (sound veloc-

ity:___[m/s, ft/s])

10 Lining thickness 0.01 to 50.00 [mm, in]

11 Fluid type 3 menus

Sound velocity:

500 to 2500m/s

Water Water, sea water, other (Sound velocity:

[m/s, ft/s])

12 Kinematic viscosity 0.0001 to

999.9999 x 10-

6m2/s

1.0038 x 10-6m2/s [x10-6m2/s, ft2/s]

13 Sensor mounting

method

2 menus V V,Z

14 Sensor type 2 menus 3-3350-100 3-3350-100, 3-3350-200

Measurement conditions

The tables below list each setting in the 3350 Magmeter menus, all of the available options, and the factory settings that

will be found in a new instrument.

13

Scaled for footer

Signet 3350/3550 Ultrasonic Flowmeter

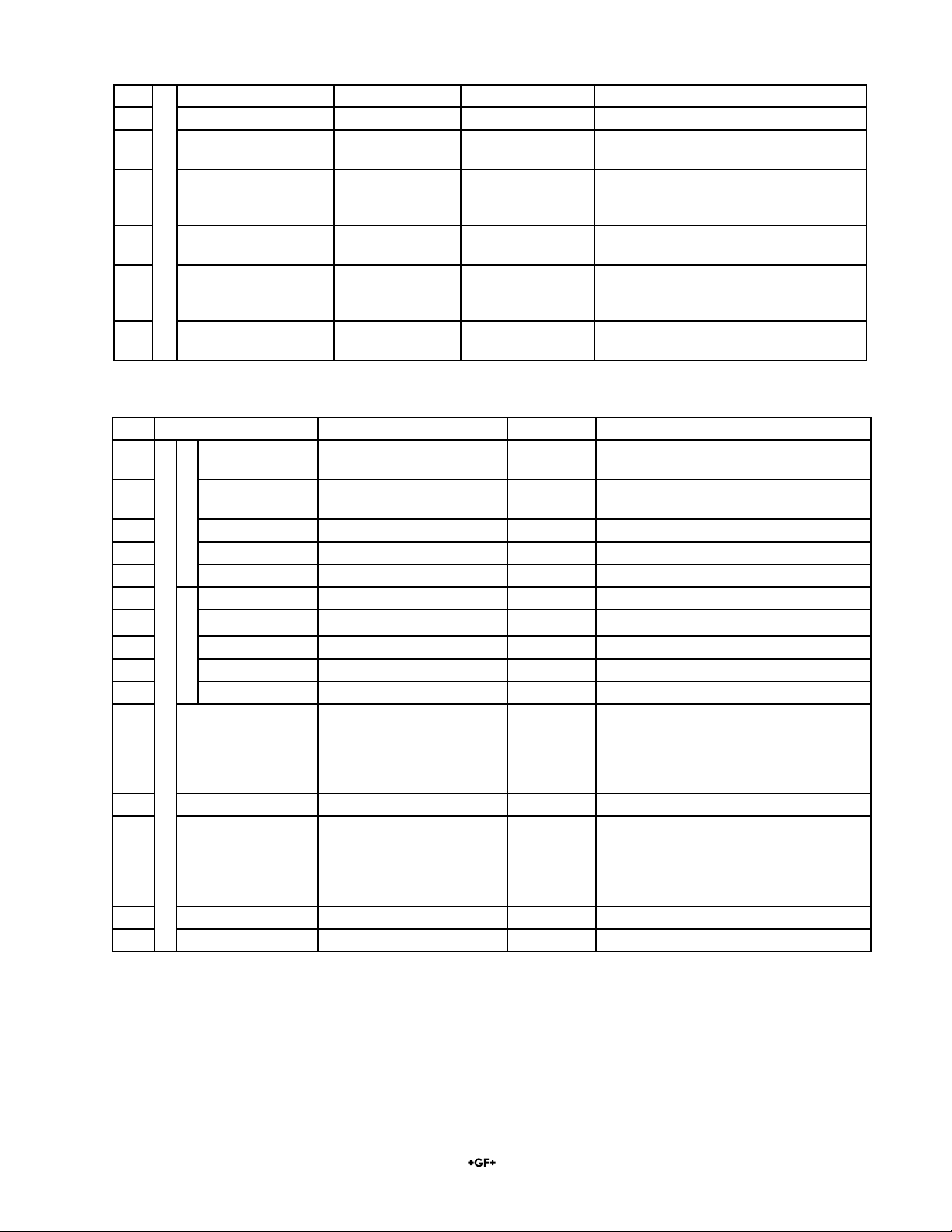

No. Setting Item Settable Range Initial Value Settable Value

22 Flow span-1 0.3 to 10m/s in terms of flow

velocity

10.0000L/s Units are based on FLOW RATE UNIT.

23 Flow span-2 0.3 to 10m/s in terms of flow

velocity

0.0000L/s Units are based on FLOW RATE UNIT.

24 Hysteresis 0 to 10% 5.00% %

25 Burnout 4 menus Hold Hold, upper limit, lower limit, sero

26 Burnout timer 0 to 100sec 10sec sec

27 Total action 3 menus Start Start, stop, reset

28 Pulse value 0.00001 to 999999 1mL Units are based on TOTAL UNITS

29 Total pulse width 5 menus 5msec 5,10,50, 100, 200msec

30 Burnout 2 menus Hold Hold, count

31 Burnout timer 0 to 100sec 10sec sec

32 DO1 output type 5 output contents menus

3 alarm menus

Flow switch range 0 to 10

m/s. Total switch range:

0.00001 to 99999999

NOT USED NOT USED, Flow direction, Alarm [all,

hard, process], Flow switches, Upper limit,

Lower limit, Total switch.

(Units are based on FLOW RATE UNITS

and TOTAL UNITS selections.)

33 DO1 output action 2 menus ON, OFF

34 DO2 output type 5 output contents menus

3 alarm menus

Flow switch range 0 to 10

m/s. Total switch range:

0.00001 to 99999999

NOT USED NOT USED, Flow direction,Alarm [all,

hard, process],Flow switches, Upper limit,

Lower limit, Total switch

(Units are based on FLOW RATE UNITS

and TOTAL UNITS selections.)

35 DO output action 2 menus ON, OFF

36 Span calibration 0 to ±200% 100.0% %

Analog OutputTotal output

Output conditions

15 Zero adjustment 2 menus Clear (adjusted) Set zero, clear (factory set at clear)

16 Damping 0 to 100sec 5 sec sec

17 Low flow rate cut off 0 to 5 m/s in terms

of flow velocity

0.001 L/s Units are based on FLOW RATE UNIT.

18 Display 1st line con-

tents

7 menus Flow velocity (m/s) Flow velocity, flow rate (ACTUAL), flow

rate (%), forward total, reverse total, for-

ward total pulse, recerse total pulse

19 Display 1st line deci-

mal point position

00000.000 ���������

Mark the decimal position

20 Display 2nd line con-

tents

7 menus Flow rate (L/s) Flow velocity, flow rate (ACTUAL), flow

rate (%), forward total, reverse total, for-

ward total pulse, reverse total pulse

21 Display 2nd line deci-

mal point position

00000.000 ���������

Mark the decimal position

Output conditions

14

Scaled for footer

Signet 3350/3550 Ultrasonic Flowmeter

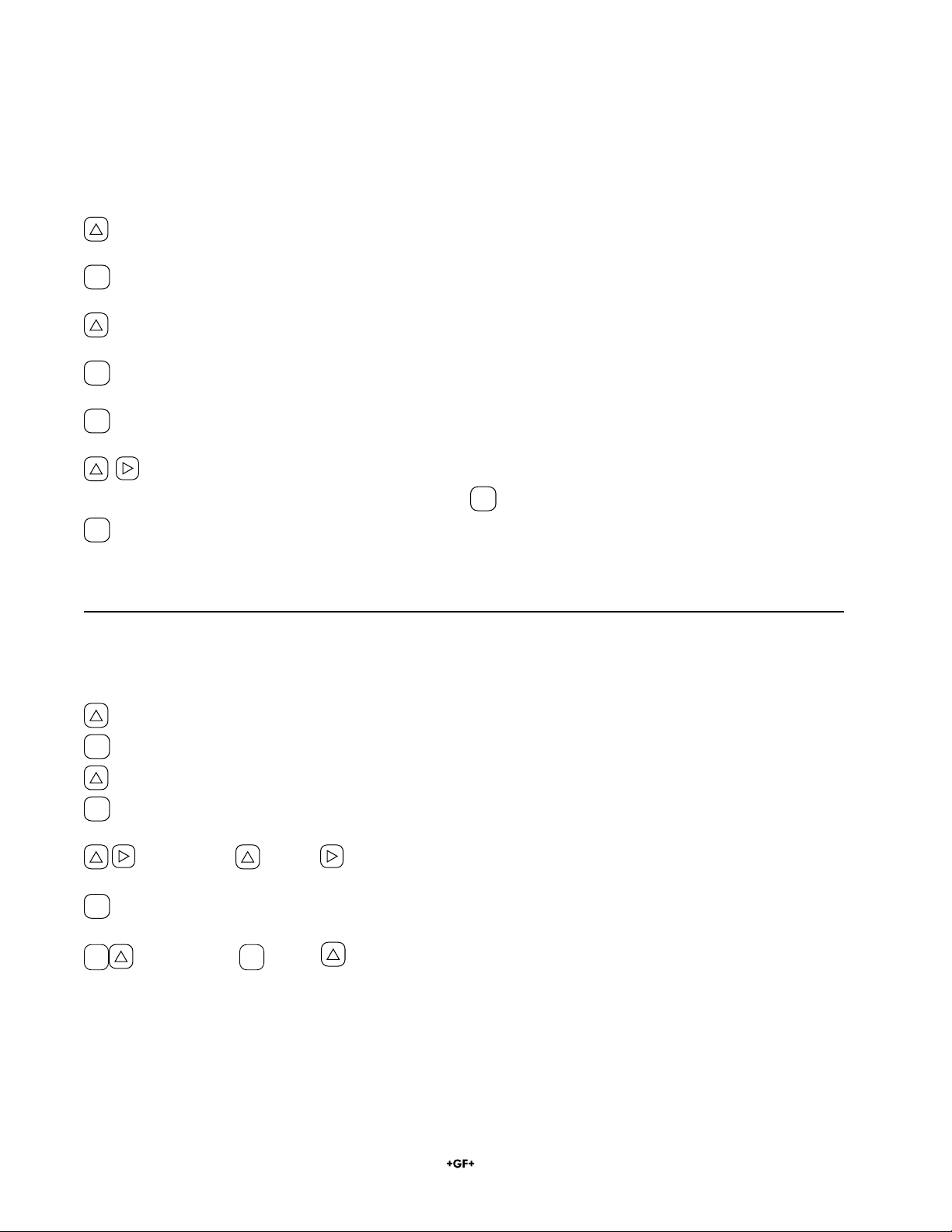

Parameter Protection

Parameter Protection serves to protect the flow meter settings from unauthorized changes.

• The 3350 uses an Identification number (ID No.) to enable authorized changes.

• The ID number is factory set at 0000 and the Parameter Protection is turned ON.

• To change the ID number, the parameter protection must first be turned OFF:

Press: Display shows:

First line: “PAR. PROTECTION” Second line: “PROTECTION ON”

ENT

2nd line of display begins blinking.

“PROTECTION OFF”.

ENT

“INPUT ID NO.”.

ENT

“0000” with first zero blinking.

Use UP and RIGHT buttons to set the ID No. into the display

Note: If ID No. is “0000” (factory set), press

ENT

key to set the parameter protection to OFF.

ENT

First line: “PAR. PROTECTION” Second line: “PROTECTION OFF”

* If “INPUT ERROR!” appears, the ID No. is incorrect. The display returns to the previous step.

Identification (ID) number

Press: Display shows:

4x “MAINTENANCE MODE”.

ENT

“CURRENT CALIBRATION”.

8x “REGISTER ID NO.”

ENT

2x 2nd line blinks

Press key and key to compose a new ID number.

ENT

“COMPLETE” is indicated about 1 second on 2nd line.

ESC

Using

ESC

key and key to resume the measurement mode.

Note: To enable the new ID number, set the parameter protection to “PROTECTION ON”.

15

Scaled for footer

Signet 3350/3550 Ultrasonic Flowmeter

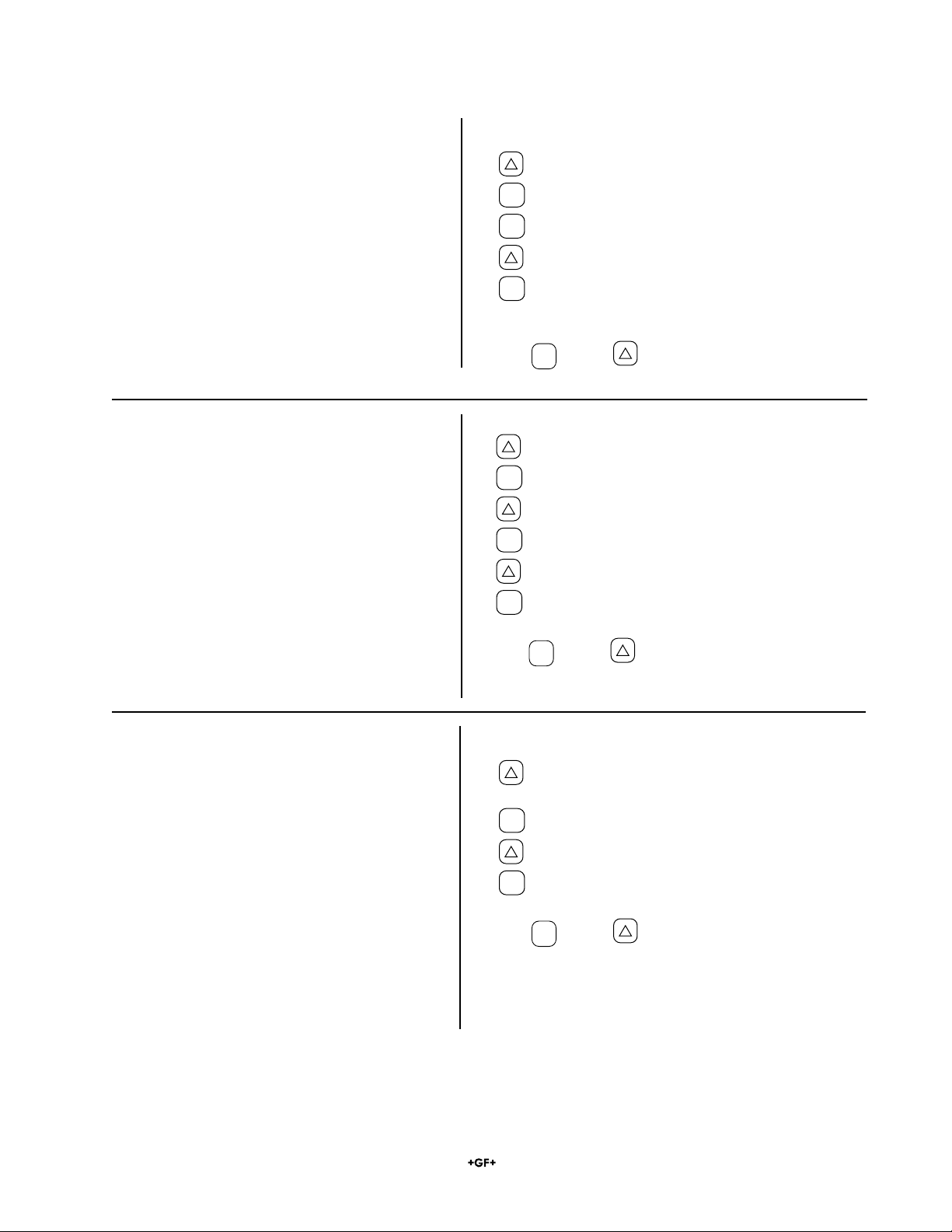

Measure setup mode

Press Display shows

3x “MEASURE SETUP”.

ENT

“SYSTEM UNIT”.

ENT

Cursor begins blinking

“METRIC”.

ENT

“COMPLETE” is indicated about 1

second on 2nd line.

Use

ESC

key and key to resume measurement mode.

Set the flow rate unit

Depending on the measurement selection above, the flow

rate can be set to measure in a variety of engineering units.

Select one

• Metric system

L/s (factory set) L/min L/h ML/d

m3/s m3/min m3/h Mm3/d

BBL/s BBL/min BBL/h MBBL/d

• Inch system

gal/s gal/min gal/h Mgal/d ft3/s

ft3/min ft3/h Mft3/d BBL/s BBL/min

BBL/h MBBL/d

Press: Display shows:

3x “MEASURE SETUP”.

ENT

“SYSTEM UNIT”.

“FLOW UNIT”.

ENT

“FLOW UNIT” blinks

6x “m3/h”.

ENT

Stores the new setting into memory

Use

ESC

key and key to resume measurement mode.

Press: Display shows:

1st line: [TOTAL UNIT]

2nd line: [mL]

ENT

2nd line blinks.

Repeatedly to select total unit.

ENT

Stores the new setting into memory

Use

ESC

key and key to resume measurement mode.

METRIC or ENGLISH

• Metric system (factory set)

Select to use the 3350 in a metric measurement

system (meters and liters)

• Inch system

Select to use the 3350 in an English measurement

system (inches and gallons)

Set the total unit

Select the unit of total volume.

• Metric system

mL (factory set) L

m3 km3 Mm3

mBBL BBL kBBL

• Inch system

gal kgal

ft3 kft3 Mft3 mBBL

BBL kBBL ACRE-in ACRE-ft

16

Scaled for footer

Signet 3350/3550 Ultrasonic Flowmeter

Adjust Zero point

The ZERO ADJUST allows the instrument to be set to

ignore any electrical background noise in the application.

There are two options:

• “SET ZERO” records the actual input as equal to zero.

• “CLEAR” sets the zero point to absolute “0”.

To set the instrument to zero, completely close the valves

upstream and downstream the flow meter so the sensors

are detecting still water in a FULL PIPE.

If there is no valve or if the fluid flow cannot be stopped,

select “CLEAR” instead of “ZERO ADJUST”.

Any electrical noise in the system will not be factored out of

the measurement when “CLEAR” is used.

Press: Display shows:

2x “OUTPUT SETUP”.

ENT

“ZERO ADJUST”

2nd line shows “SET ZERO”

ENT

“SET ZERO” blinks.

If “CLEAR” is blinking

press to go to “SET ZERO”.

ENT

The static signal being sensed in the

pipe will be set to represent zero flow.

Use

ESC

key and key to resume measurement mode.

Set the Damping

The DAMPING function attenuates any instability in the

flow measurement that may be present due to piping

limitations or flow profile disturbances.

Higher damping times result in smoother output.

A time constant is set (response time of about 63%).

Damping range: 0 to 100 sec in 1 sec increments.

Note: If Damping is set to 0 sec, the response time is:

System cycle: 0.2 sec

Dead time: less than 0.2 sec

Time constant: 0.1 sec

Press: Display shows:

x2 “OUTPUT SETUP”.

ENT

“ZERO ADJUST”.

“DAMPING”.

ENT

Cursor blinks

Press to set value from 0 to 100 seconds

ENT

Stores the new setting into memory

Use

ESC

key and key to resume measurement mode.

Set the Low Flow Rate Cutoff

The flow rate display, the analog output (4-20 mA) and the

totalizer can be disabled when the flow rate falls below this

setting. Use this function to prevent output response to

invalid input such as flow signals generated by vibration,

convection or electrical noise.

Set range: equivalent to 0 to 5 m/s in the selected

flow rate units. Factory set at 0.001 L/s

Press: Display shows:

x2 “OUTPUT SETUP”.

ENT

“ZERO ADJUST”.

x2 “CUTOFF”.

ENT

Cursor blinks

Press to set flow rate cutoff

ENT

Stores the new setting into memory

Use

ESC

key and key to resume measurement mode.

17

Scaled for footer

Signet 3350/3550 Ultrasonic Flowmeter

Configuring the Display

The 3350 display has two lines with 16 characters on each

line. Each line can be set to display a different value:

• VELOCITY

Display the linear velocity of the flow. Units are m/s for

METRIC systems or ft/s for ENGLISH systems.

• The decimal point position is fixed.

• FLOW RATE

Display the flow rate in the volumetric units selected

(GPM, L/m, BBL/DAY, etc.

• FLOW RATE (%)

Display the flow rate as a percentage of the flow range

setting.

• ±TOTAL (ACTUAL)

Display the totalizer value derived from the actual flow

rate. Select the total resulting from forward flow or from

reverse flow.

• ±TOTAL (PULSE)

Display the totalizer value that is derived from the pulse

output (DO1 or DO2)

Press: Display shows:

2x “OUTPUT SETUP”.

ENT

“ZERO ADJUST”.

3x “DISPLAY” “1ST ROW”

Press again to select “2ND ROW”.

ENT

“1ST ROW” and “FLOW RATE”

FLOW RATE is blinking

Use key and key to set new value.

ENT

“1ST ROW DIGIT” and “****.**”

Scroll to select decimal position.

ENT

“1ST ROW DIGIT” and “COMPLETE”

breifly, then

“1ST ROW DIGIT” and new display value

New display value is blinking.

Use

ESC

key and key to resume measurement mode.

Press: Display shows:

2x “OUTPUT SETUP”.

ENT

“ZERO ADJUST”.

“RANGE”.

ENT

Cursor blinks

ENT

Press again to select “FLOW SPAN-1”.

ENT

Cursor blinks

Use key and key to set maximum flow rate.

ENT

Stores the new setting into memory

Press to set FLOW-SPAN-2

or

Use

ESC

key and key to resume measurement mode.

Set the 4-20 mA Range (FLOW SPAN-1)

• The analog output (4-20 mA) corresponds to the range

setting.

• If “INPUT ERROR” appears, the setting is beyond the

operating range of the instrument.

• After changing the RANGE, adjust zero point.

• If “PIPING PARAMETERS” or “FLOW UNIT” are

changed, FLOW SPAN must be reset.

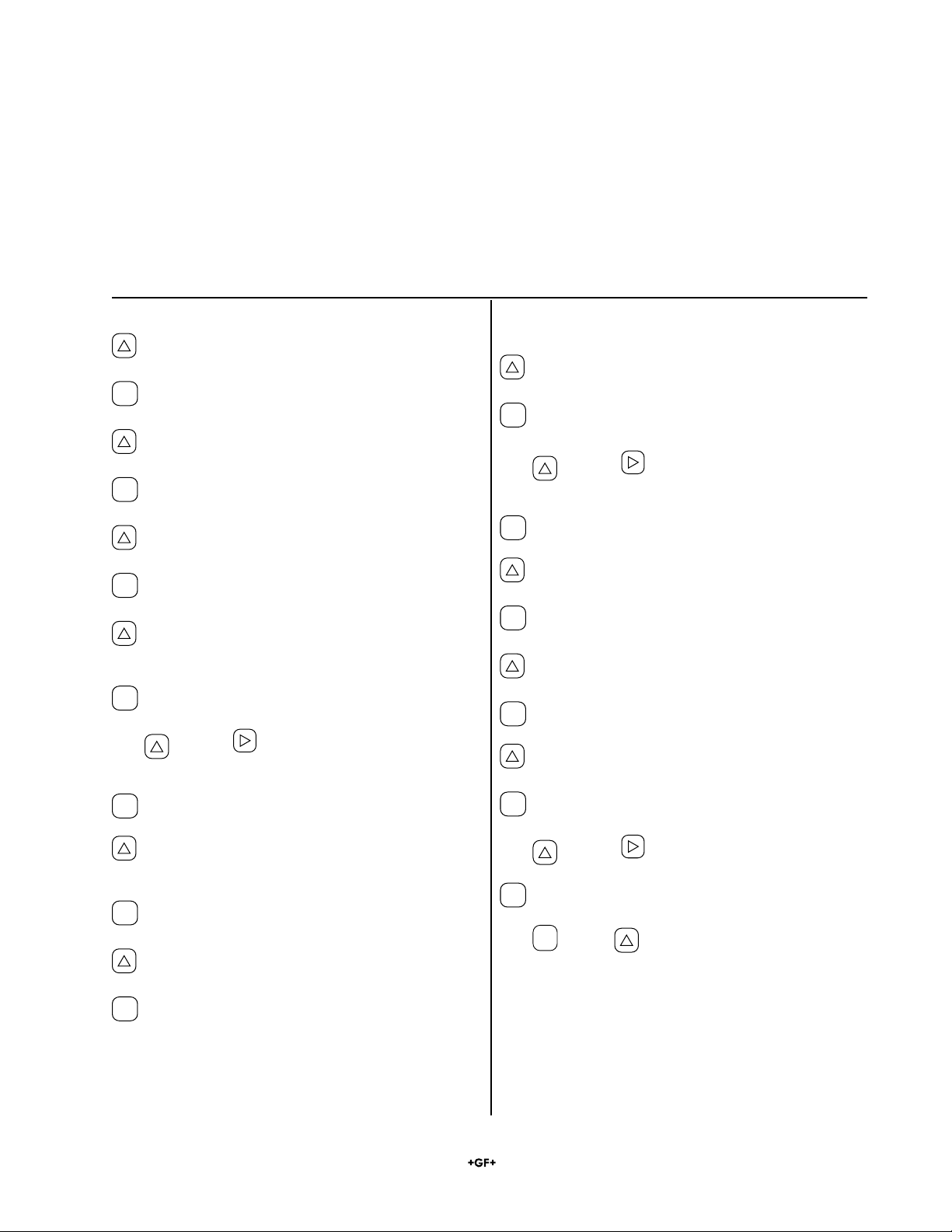

Flow rate

SPAN-1

4mA

20mA

100%0

18

Scaled for footer

Signet 3350/3550 Ultrasonic Flowmeter

Set Dual 4-20 mA Ranges (FLOW SPAN-2)

• Use FLOW SPAN-2 to set the 4-20 mA output to

automatically switch scales as the flow rate varies.

• If it is not used, set the range of FLOW SPAN-2 to 0.

• The HYSTERESIS can be set from 0 and 10% of the

smaller range.

• When the source of DO1 or DO2 is set to “FLOW

SPAN-2”, a contact outputs “SPAN-2” action. Select

[ACTIVE ON] or ACTIVE OFF separately.

• Always reset the ZERO ADJUST after changing the

range value.

• The dual ranges can be set to measure reverse flow.

Use the “-” sign in the first position when setting the

reverse flow range.

Hysteresis

SPAN-1

SPAN-2

4mA

20mA

0

Press: Display shows:

“FLOW SPAN-2”.

ENT

Cursor blinks

Use key and key to set maximum flow rate.

ENT

Stores the new setting into memory

“HYSTERESIS”.

ENT

Cursor blinks

Use key and key to set hysteresis.

ENT

Stores the new setting into memory

“BURNOUT”

ENT

Current selection blinks

Scroll to new setting.

ENT

Stores the new setting into memory

“BURNOUT TIMER” and “10 s”

ENT

Cursor blinks

Use key and key to set new time delay.

ENT

Stores the new setting into memory.

Use

ESC

key and key to resume measurement mode.

Set BURNOUT mode for the 4-20 mA output

BURNOUT is the error mode for the 4-20 mA output.

Specify how the 4-20 mA output will react during loss of signal, etc. due to hardware error, empty pipe or ingress of

bubbles.

The options are:

HOLD (factory set): Retain the last good value

OVER SCALE: Outputs 23.2 mA.

UNDER SCALE: Outputs 0.8 mA.

ZERO: Outputs 4 mA.

BURNOUT TIMER 0 to 100 seconds

(factory set at 10 sec).

(time delay from error detection to response)

19

Scaled for footer

Signet 3350/3550 Ultrasonic Flowmeter

Press: Display shows:

2x OUTPUT SETUP

ENT

ZERO ADJUST

4x “RANGE” and “FLOW RATE”

ENT

“FLOW RATE” blinks

“TOTAL” blinks

ENT

“TOTAL MODE” and “START”

“PULSE VALUE” and 1mL”

(or current selection)

ENT

Cursor blinks

Use key and key to set the volume represented

by each pulse.

ENT

Stores the PULSE VALUE into memory

PULSE WIDTH and 5.0 ms (or current

selection)

ENT

Cursor blinks on 2nd line.

Press to scroll to select pulse width value

ENT

Stores the new value into memory

Set Pulse Output and Totalizer functions

Set the pulse value, pulse width and preset value.

Then, reset the total value to a preset value (factory set at 0), and start a total.

BURNOUT(TOTAL)

Determines the behaviour of the totalizer when an error occurs due to an empty pipe interior or bubbles mixed in fluid

(common to total indication and total pulse output).

HOLD: Stops the total (as factory set).

COUNT: Continues the total according to a flow rate marked immediately before the error occurrence.BURNOUT TIMER

Sets the time from error occurrence to error processing.l Settable range: 0 to 100 sec (factory set at 10 sec).The

total continues until the burnout timer is actuated.

Press: Display shows:

TOTAL PRESET and 0 mL

ENT

Cursor blinks.

Use key and key to set the value where the

totalizer will start after a reset

ENT

Stores the new value into memory

BURNOUT (TOTAL) and HOLD

ENT

HOLD blinks.

Scroll to select BURNOUT action.

ENT

Stores the new setting into memory

“BURNOUT TIMER” and “10 s”

ENT

Cursor blinks

Use key and key to set new time delay.

ENT

Stores the new setting into memory.

Use

ESC

key and key to resume measurement mode.

20

Scaled for footer

Signet 3350/3550 Ultrasonic Flowmeter

Start, Stop and Reset the Totalizer

• The total is started, stopped or reset manually, from this menu.

START: Total output starts

STOP: Total output stops

RESET: Reset the total memory to the preset value.

This setting simultaneously resets both forward total memory and reverse total memory.

After performing a RESET the total function will remain STOPPED until “START” is executed.

Press: Display shows:

2x OUTPUT SETUP

ENT

ZERO ADJUST

4x “RANGE” and “FLOW RATE”

ENT

“FLOW RATE” blinks

“TOTAL” blinks

ENT

“TOTAL MODE” and “START”

ENT

“START” blinks

Scroll to select RESET or STOP.

ENT

START, STOP or RESET is implemented.

The TOTAL memory will be reset to the PRESET value

After resetting, the total operation automatically stops.

To resume a total, execute “START”:

ENT

“STOP” blinks

Scroll to select START.

ENT

START is implemented.

Use

ESC

key and key to resume measurement mode.

Total Count Reset Reset Reset Reset

Time

Preset Value

This manual suits for next models

1

Table of contents

Other Signet Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

ABB

ABB Aztec 600 manual

Ripley

Ripley MILLER VIS300 user guide

engelmann

engelmann microCLIMA DE-16-MI004-PTB025 Installation and operating instructions

METREL

METREL MI 3321 MultiservicerXA instruction manual

Precision Medical

Precision Medical 1MFA3001 user manual

Trend Micro

Trend Micro EdgelIPS Pro-2096 Quick setup guide

Endress+Hauser

Endress+Hauser Levelflex FMP50 operating instructions

Elenco Electronics

Elenco Electronics XK-700K Assembly and instruction manual

Vernier

Vernier Go Wireless GW-EHR manual

Grandway

Grandway FHP3P01 user guide

Master Meter

Master Meter Register Install & Remove

Flux

Flux FLUXTRONIC FMJ 100 Original attachment