SIGRIST PhaseGuard C User manual

Document number: 11026E

Version: 4

Valid from: Software Vx26

INSTRUCTION MANUAL

PhaseGuard C/T/HT

In-line Interface Monitor

Copyright© SIGRIST-PHOTOMETER AG, subject to changes without notice 9/2016

SIGRIST-PHOTOMETER AG

Hofurlistrasse 1

CH-6373 Ennetbürgen

Switzerland

Tel. +41 41 624 54 54

Fax +41 41 624 54 55

info@photometer.com

www.photometer.com

Instruction Manual PhaseGuard C/ T/ HT

11026E/4 i

Content

1. Notes to the user...........................................................................................................1

1.1. General information..............................................................................................1

1.2. Explanation of symbols .........................................................................................2

2. Instrument description ...................................................................................................3

2.1. General information about the PhaseGuard ..........................................................3

2.2. Technical data.......................................................................................................8

3. General safety pointers................................................................................................10

3.1. Behavior in emergency........................................................................................10

3.2. Dangers when using properly..............................................................................11

3.3. Residual risk ........................................................................................................12

3.4. Warning and danger symbols on the instrument.................................................12

4. Mechanical mounting..................................................................................................13

5. Electrical installation ....................................................................................................14

5.1. Safety pointers for the electrical installation ........................................................14

5.2. Installation of the PhaseGuard ............................................................................15

5.3. Installation of the SICON control unit, field bus...................................................16

6. Initial start-up ..............................................................................................................17

6.1. Commissioning procedure ..................................................................................17

6.2. Perform zero calibration......................................................................................19

7. Operation ....................................................................................................................20

8. Servicing......................................................................................................................21

8.1. Servicing schedule...............................................................................................21

8.2. Replacing the desiccant.......................................................................................22

8.3. Cleaning the sensor head....................................................................................23

8.4. Replacing gasket of the in-line housing and blanking plate .................................25

9. Troubleshooting ..........................................................................................................27

10. Customer service information ......................................................................................27

11. Decommissioning & storage ........................................................................................28

12. Packaging & transport .................................................................................................29

13. Disposal.......................................................................................................................30

14. Spare parts ..................................................................................................................31

15. Appendix.....................................................................................................................32

15.1. Dimension sheet PhaseGuard-MB .......................................................................32

15.2. Overview of gaskets on the PhaseGuard .............................................................33

15.3. PhaseGuard connection diagram.........................................................................34

16. Index ...........................................................................................................................35

Notes to the user Instruction Manual PhaseGuard C/ T/ HT

11026E/4 1

1. Notes to the user

1.1. General information

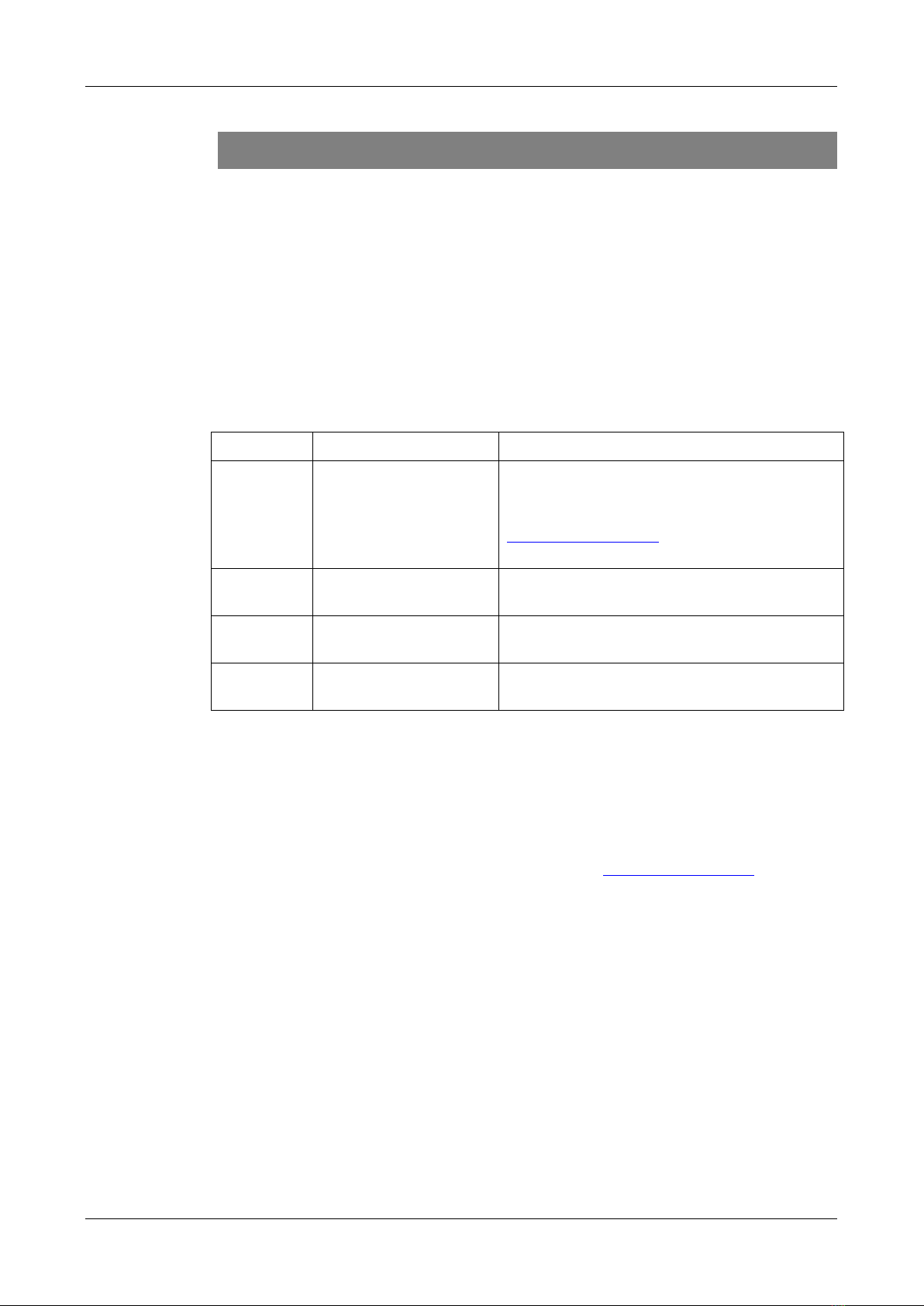

This Instruction Manual provides the user with the most important information up to and in-

cluding commissioning. Information such as operation, servicing, troubleshooting and more

are described in greater detail in the Reference Manual.

The Instruction Manual is intended for all persons who are responsible for mounting,

installing and commissioning the instrument.

DOC. NO.

TITLE

CONTENT

11027E

Reference Manual

More sophisticated menu functions and work-

steps for advanced users.

This document can be downloaded from

www.photometer.com (first time registration re-

quired).

11018E

Data sheet

Descriptions and technical data about the pho-

tometer.

11052E

Service Manual

Repair and conversion instructions for service

engineers.

11050DEF

Declaration of conformity

Compliance with the underlying directives and

standards.

This Instruction Manual has been written by SIGRIST PHOTOMETER AG. Copying or modify-

ing the content or giving this document to third parties is permitted only with express writ-

ten consent.

The Instruction Manual is a component of the product and should always be close at hand.

Registered uses can download the latest version (color) at www.photometer.com.

It can also be ordered from our representative in your country. Section 10

Purpose of the

Instruction Manual

Target group

Additional

documentation

Copyright regulations

Storage location of

the Instruction

Manual

Instruction Manual PhaseGuard C/ T/ HT Notes to the user

2 11026E/4

1.2. Explanation of symbols

Below is a description of all danger symbols that occur in this Instruction Manual.

Danger due to electrical shock that may result in serious bodily injury or

death.

Non-observance of this danger warning may lead to electrical shocks and death.

Danger due to explosion that may result in serious bodily injury or death.

Non-observance of this notice may cause explosions resulting in serious material damage and

death.

Warning about bodily injury or hazards to health with long-term effects.

Non-observance of this warning may lead to injuries with possible long-term effects.

Notice about possible material damage.

Non-observance of this notice may cause material damage to the instrument and its periph-

erals.

Below is an explanation of all pictograms that occur in this Instruction Manual.

Additional information about the current topic.

Practical procedures when working with the photometer and control unit.

Work on the PC.

Danger symbols

DANGER!

EXPLOSION

HAZARD!

WARNING!

CAUTION!

Pictograms

Instrument description Instruction Manual PhaseGuard C/ T/ HT

11026E/4 3

2. Instrument description

2.1. General information about the PhaseGuard

2.1.1. View of a measuring station

Figure 1: Overview of PhaseGuard C/ T/ HT

Photometer PhaseGuard

USB interface for configuring the

instrument

Connection cable between the

instrument and the customer-side

control system

Customer-side control system

Varivent® in-line housing or

compatible (optional)

Sample line

2.1.2. Proper use

The PhaseGuard and its peripherals are designed to detect phase transitions in liquids.

Possible areas of application:

Food and beverage industry

Milk processing industry

Chemical and pharmaceutical industry

2.1.3. User requirements

The instrument may be operated only by trained technical personnel.

The instrument may be operated only by persons who are familiar with the content of

the Instruction Manual and Reference Manual.

Instruction Manual PhaseGuard C/ T/ HT Instrument description

4 11026E/4

2.1.4. Conformity

Current technological principles were followed in designing and manufacturing the photom-

eter. They comply with the usual guidelines concerning duty to take due care and safety.

The system meets the requirements applicable within the European Union (EU) for electro-

magnetic compatibility (EMC) and low voltage directives (LVD) and has the CE mark.

Please refer to the separate declaration of conformity for details (document 11050DEF).

2.1.5. Use restrictions

Explosion hazard during operation in an inappropriate environment.

Use in explosion hazardous areas may cause explosions that could be lethal to persons in the

vicinity.

It is not permitted to operate the instrument in explosion hazardous areas

or rooms.

It is not permitted to use the instrument with explosive media.

Danger during operation with inappropriate media.

The use of too hot or aggressive media may cause leakage that could be lethal to persons in

the vicinity.

It is not permitted to use the measuring instrument for applications in which the medium

can attack it. Parts which contact the media: stainless steel, sapphire, gaskets.

2.1.6. Dangers when not used properly

Operation when not used properly.

Improper use can cause injuries to persons, process-related consequential damage and dam-

age to the instrument itself and its peripherals.

In the following cases the manufacturer cannot guarantee the protection of persons and the

instrument and therefore assumes no legal responsibility:

The instrument is used in a way not included in the described area of application.

The instrument is not properly mounted.

The instrument is not installed and operated in accordance with the Instruction Man-

ual.

If the instrument has been operated with accessories which SIGRIST-PHOTOMETER AG

has not expressly recommended.

Improper changes to the instrument have been performed.

The instrument has not been operated within the specifications, in particular concern-

ing pressure and temperature.

EXPLOSION

HAZARD!

DANGER!

DANGER!

Instrument description Instruction Manual PhaseGuard C/ T/ HT

11026E/4 5

2.1.7. Identification of the PhaseGuard

The photometer displays the following rating plate:

Figure 2: PhaseGuard rating plate

Manufacturer

Country of origin

Product name

Serial number

Date of manufacture

Service voltage

Frequency range

Power

Observe the Instruction Manual.

Disposal information Section 13

Instruction Manual PhaseGuard C/ T/ HT Instrument description

6 11026E/4

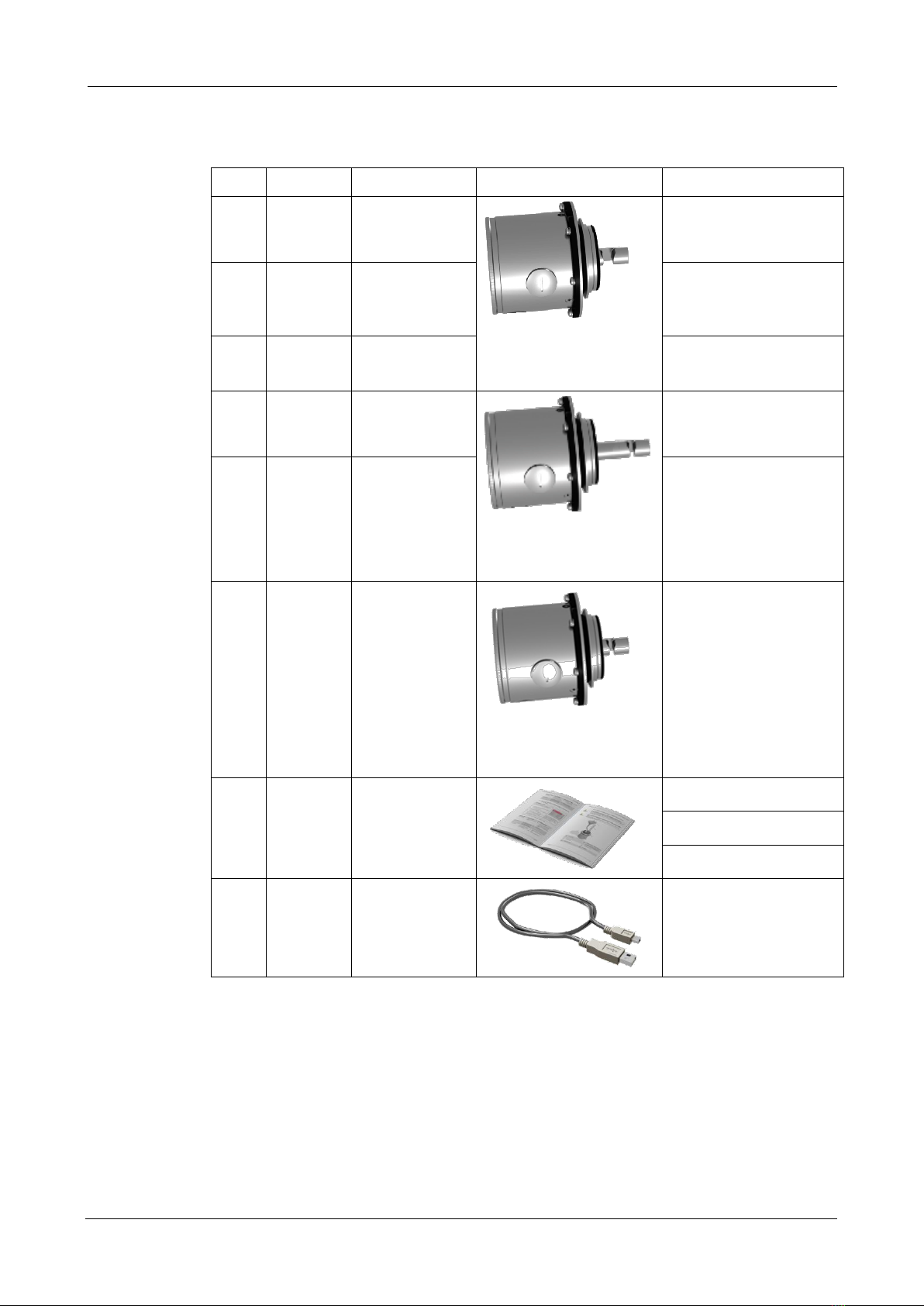

2.1.8. Scope of delivery and accessories

PCS.

ART. NO.

NAME

VIEW

VARIANT

1

118676

PhaseGuard C

Length of sensor head:

33 mm

Path length: 10 mm

Detection of phase tran-

sitions based on color

change

1

118677

PhaseGuard T

Detection of phase tran-

sitions in media with

mid-range turbidities

1

119788

PhaseGuard T

Sensor head made of

Hastelloy

1

118678

PhaseGuard HT

Length of sensor head:

56.5 mm

Path length: 5 mm

Detection of phase tran-

sitions with high turbidi-

ties

1

119123

PhaseGuard HC

For liquids with high ab-

sorption levels

1

119675

PhaseGuard HT

< DN65

Length of sensor head:

28 mm

Path length: 5 mm

Detection of phase tran-

sitions at high turbidities

for Varivent® housing <

DN65

1

20012

Instruction

Manual

11026D German

11026E English

11026F French

1

118730

USB cable

Scope of delivery

Instrument description Instruction Manual PhaseGuard C/ T/ HT

11026E/4 7

PCS.

ART. NO.

NAME

VIEW

VARIANT

1

118695

PhaseGuard

with integrated

field bus inter-

face recogniza-

ble by the larger

housing, the

two cable pene-

trations and

M12 connector

Profibus DP

118696

RTU Modbus

1

118342

SICON control

unit

1

119040

SICON M

Multichannel

control unit

1

120444

Device cable, 8-

pole, 10 m with

connector

1

Various

Varivent® in-

line housing

Various nominal widths

1

118740

Uncoated

blanking plate

1

20012

Reference Man-

ual as PDF

11027D German

11027E English

Optional accessories:

Instruction Manual PhaseGuard C/ T/ HT Instrument description

8 11026E/4

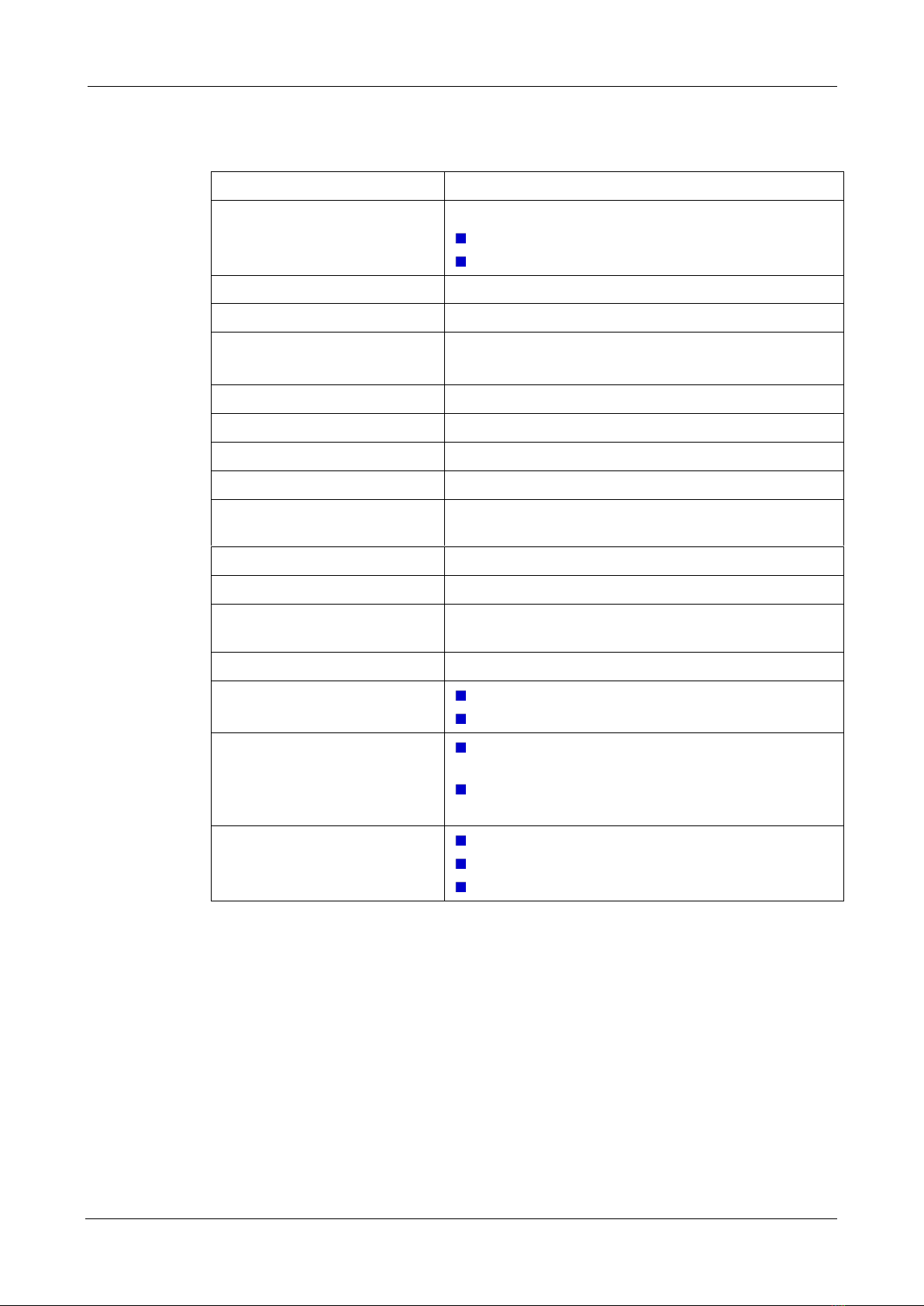

2.2. Technical data

TURBIDITY MEASUREMENT

VALUES

Measuring principle

Absorption

at 880 nm (T/HT)

at 430 nm (C/HC)

Measurement span

0 .. 100% absorption

Measuring range

0 .. 100% absorption

Sample temperature

-10 .. +100°C

120°C max. 2 hr

Ambient temperature

-10 .. +50°C

Pressure

1 MPa (10 bar) / 100°C

Resolution

0.5% absorption

Warm-up time

< 3 min

Repeatability (2 measurements

with 1 instrument)

0.5% absorption

Linearity

0.5% absorption

Temperature stability

±0.05%/K (full scale)

Reaction time

< 0.3 s at 0 seconds integration time (step response

limit switch)

Ambient humidity

0 .. 100% relative humidity

Path lengths

10 mm (T/C)

5 mm (HC/HT)

Outputs

1 x 4 .. 20 mA, galvanically separated up to max.

35 VDC relative to ground and max. 500 Ω burden

2 x switching transistor with open collector

UEXT 3 .. 30 VDC, ILmax. 8 mA

Interfaces

USB (for configuration via text file)

Modbus RTU / Profibus DP (both optional)

To optional SICON control unit

Instrument description Instruction Manual PhaseGuard C/ T/ HT

11026E/4 9

PHOTOMETER

VALUES

Service voltage

9 .. 30 VDC, 2 W (3 W with Profibus DP)

Material

Housing: stainless steel 1.4301 or 1.4307

Sensor head stainless steel 1.4404 or better

Hastelloy for PhaseGuard T (optional)

Window

Sapphire

Weight

Approx. 2.1 kg

Approx. 2.5 kg (PhaseGuard with interface card)

Dimensions

Ø 120 x 143 mm for instrument types T and C

Ø 120 x 164.5 mm with interface card

Ø 120 x 166.5 mm for instrument type HT

Ø 120 x 188 mm with interface card

Detailed dimension drawing PHASEGUARD-MB

Pipe connections

Minimum DN 40 for instrument types T and C with

Varivent® or compatible connections

Minimum DN 65 for instrument type HT with

Varivent® or compatible connections

Protection type

IP66

Instruction Manual PhaseGuard C/ T/ HT Instrument description

10 11026E/4

3. General safety pointers

3.1. Behavior in emergency

Behavior in emergency:

SIGRIST-PHOTOMETER AG instruments have no on/off switch. This is installed customer-side.

Before commissioning, clarify the following points:

Position of the on/off switch and the way it works.

Where and how the sample supply can be stopped.

Who the responsible authorities are.

MEASURE

NOTES

1.

Interrupt the service voltage to the

measuring station.

2.

Interrupt sample supply.

3.

Secure emergency location.

4.

Notify responsible institution.

CAUTION!

PROCEDURE IN

AN

EMERGENCY!

Instrument description Instruction Manual PhaseGuard C/ T/ HT

11026E/4 11

3.2. Dangers when using properly

Electrical shock due to damaged instrument or cabling.

Touching damaged cables may lead to electrical shocks with lethal consequences.

The instrument may be operated only when the cables are undamaged.

The instrument may be operated only if it has been properly installed or repaired.

Dangerous voltage inside the instrument due to galvanically separated current

output.

Touching the galvanically isolated current output may lead to electrical shocks with lethal

consequences.

The instrument must never be operated when the housing is removed.

The instrument may be opened only by trained personnel.

Bodily injury due to escaping sample liquid.

Contact with the medium may lead to burns, caustic irritations or poisoning with lethal con-

sequences.

The instrument must never be connected to leaking sample lines and operated.

The local clothing regulations must be observed during operation.

The local safety precautions must be observed during operation.

Damage due to incorrect power supply.

If the instrument is connected to an incorrect service voltage, it can be damaged.

The instrument may be connected only to voltage sources as specified on the rating plate.

Damage to the instrument caused by humidity or condensation entering the in-

strument when it is opened:

If moisture enters the instrument, it can be damaged.

Work on the inside of the instrument may be performed only in a dry room and at

room temperature. The instrument should be warm from operation or at room tem-

perature. (Condensation on optical and electrical surfaces must be avoided.)

The instrument may be opened only under these conditions (e.g. removing cover to

the usb interface).

Use of aggressive chemicals.

The use of aggressive cleaning agents can destroy surfaces on the instrument that are rele-

vant to measurement.

Do not use aggressive chemicals or cleaning agents when cleaning.

Thoroughly clean the instrument with a neutral cleaning agent if it has come into con-

tact with aggressive chemicals.

If the instrument changes hands, always include the Instruction Manual.

If the Instruction Manual is lost, you can request a replacement.

Registered users can download the current version at www.photometer.com.

DANGER!

DANGER!

DANGER!

WARNING!

CAUTION!

CAUTION!

CAUTION!

Instruction Manual PhaseGuard C/ T/ HT Instrument description

12 11026E/4

3.3. Residual risk

During operation with hot or dangerous media, the possibility of leakage cannot be

completely excluded.

Contact with the medium may lead to burns, caustic irritations or poisoning with lethal con-

sequences.

The operator is responsible for using the instrument for this purpose.

The operator must ensure that additional protection measures such as safety clothing

and similar items are available and are put to use.

To avoid faulty measurement values as much as possible, the maintenance duties

must be carried out according to the servicing schedule.

Evaluate digital output warnings and error messages to recognize them.

3.4. Warning and danger symbols on the

instrument

There are no warning or danger symbols on the PhaseGuard.

Users must ensure that they observe the safety measures as specified in the Instruction Man-

ual when working with the photometer and its peripheral equipment at all times.

Important to note:

Sections 1.2 and 3.2.

Observe local safety pointers when performing the described procedures.

DANGER!

CAUTION!

Mechanical mounting Instruction Manual PhaseGuard C/ T/ HT

11026E/4 13

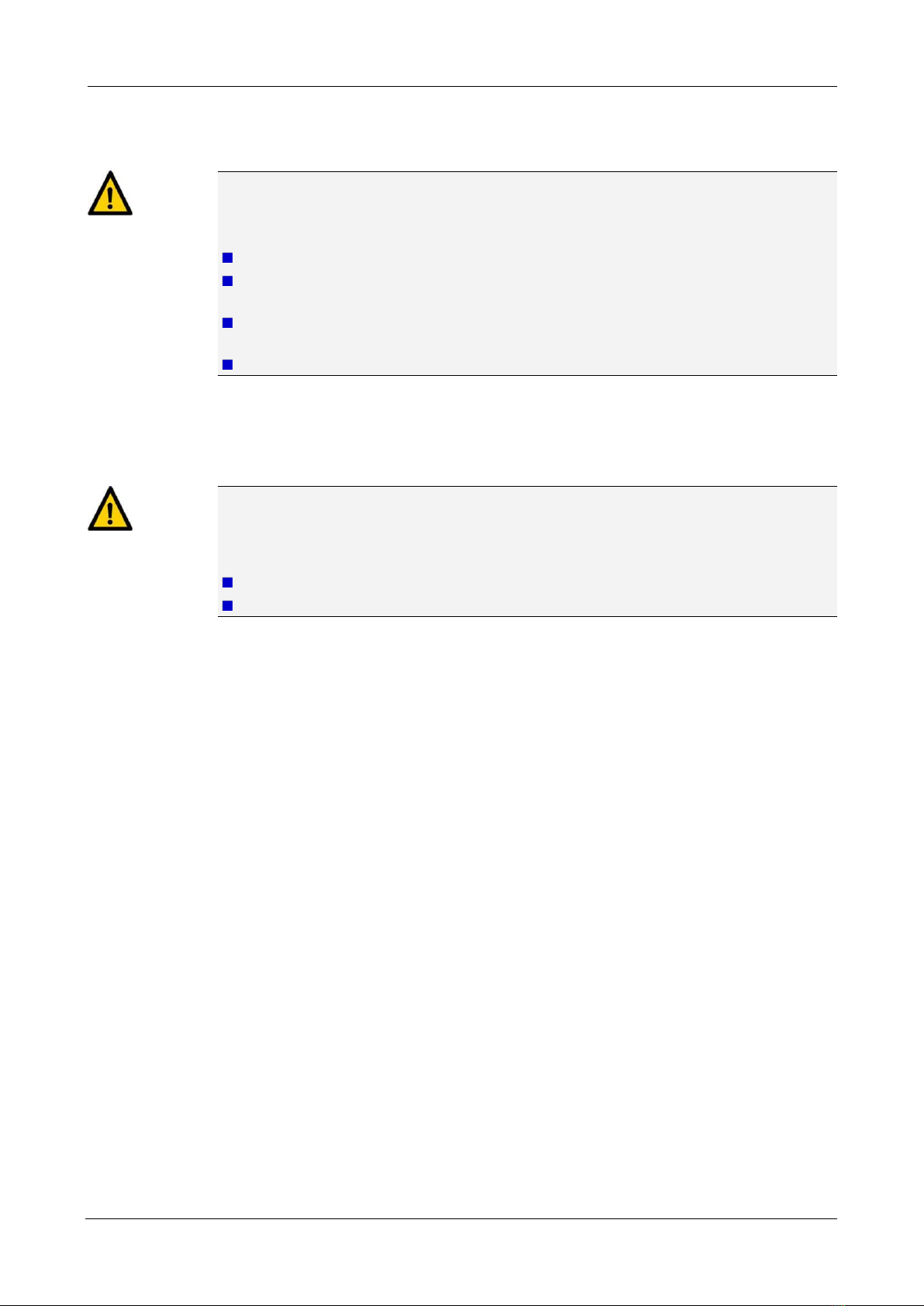

4. Mechanical mounting

The instrument can be installed in horizontal or vertical sample lines using the standards-

compliant in-line housing. Figure 4

The mounting dimensional drawing (PHASEGUARD-MB) provides detailed information about

the dimensions.

Figure 3: Position of the sensor in horizontal mounting

Photometer

Centering pin on the instrument

Sensor with measurement opening

pointing downward

Varivent® sample line

The photometer must be mounted in the line at least 0.5 m away from sight glasses

and other unwanted light sources.

In the vertical mounting position, the centering pin (2, Figure 3) must point upward

(X, Figure 4).

In the horizontal mounting position, the centering pin (2, Figure 3) must point to the

right (Y, Figure 4).

Basics of mounting

the photometer

Instruction Manual PhaseGuard C/ T/ HT Mechanical mounting

14 11026E/4

Figure 4: Correct installation in the vertical or horizontal sample lines

Figure 5: Incorrect

mounting position

5. Electrical installation

5.1. Safety pointers for the electrical installation

Dangerous voltage inside the instrument:

Connecting electrical lines can be life threatening. Parts of the system can also be damaged.

Local regulations for electrical installations must be observed at all times.

Further, the following basic principles must be observed:

The power supply 9 .. 30 VDC is to be provided by the customer. It must be stable,

low noise voltage.

Only voltages complying with the local regulations for low voltage may be used as

power supply and on the galvanically separated current output.

Because the unit has no main switch, a suitable disconnection device (switch, plug)

must be installed near the power supply.

If faults cannot be remedied, the unit must be put out of operation and protected

against inadvertent operation.

Mounting position of

the photometer

DANGER!

Mechanical mounting Instruction Manual PhaseGuard C/ T/ HT

11026E/4 15

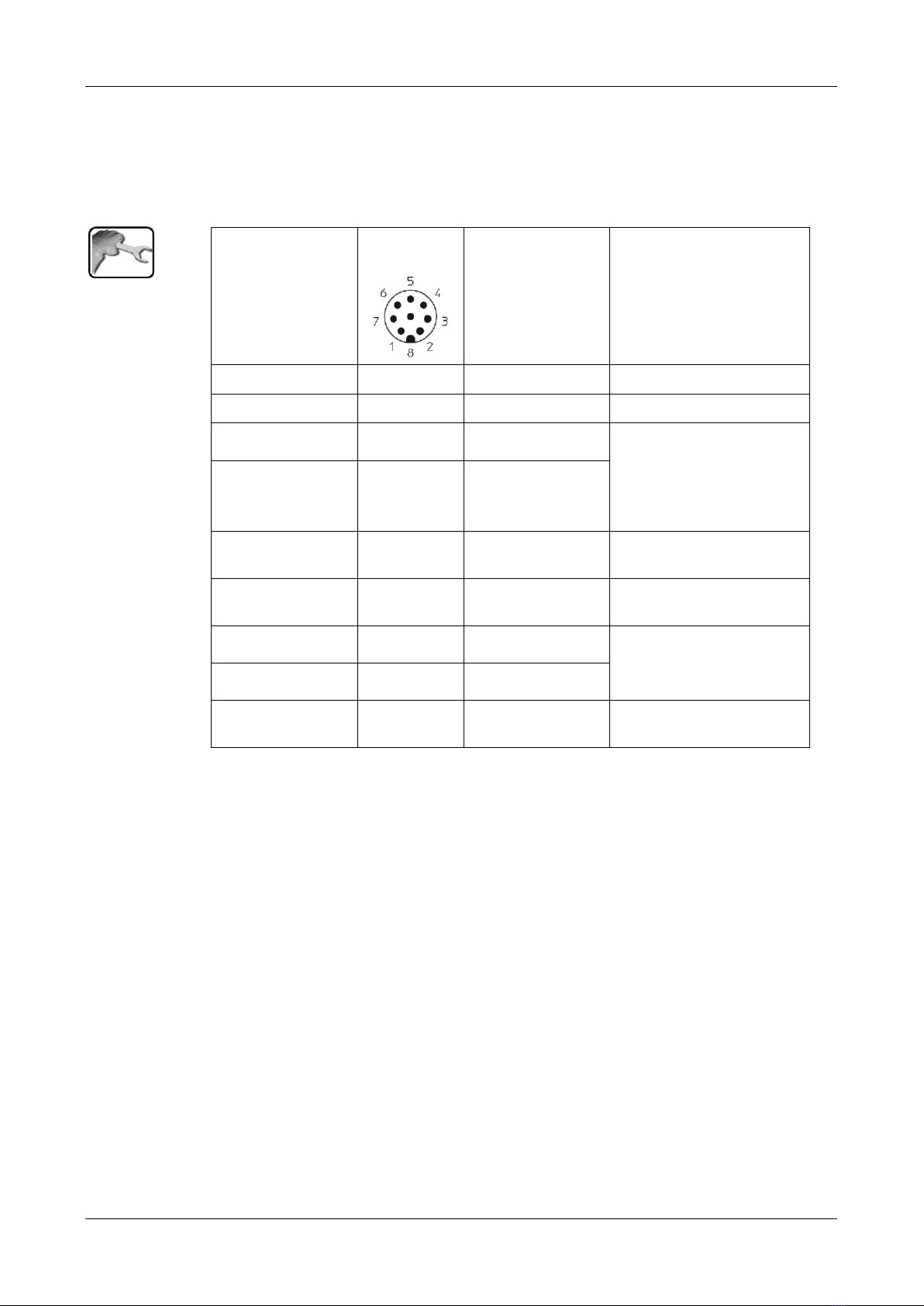

5.2. Installation of the PhaseGuard

An 8-pin connector of type M12x1 with A-coding is used. A screened device cable must be

used. The connector assignment looks like the following:

Description

Connector

pin (male)

Wire color for

device cable

(art. no. 120444)

Remarks

GND supply

1

white

Supply 9 .. 30 VDC

2

brown

RS 485 A

7

blue

Serial interface for SICON

(M)

Alternative: initiate zero

calibration

Reference Manual

RS 485 B

5

gray

Digital output 1

(alarm)

6

pink

Open collector to GND

Digital output 2

(limit)

4

yellow

Open collector to GND

Current output +

8

red

Max. 35 V to ground

Max. 500 Ω burden

Factory setting: 0 .. 100%

Current output -

3

green

Shielding

Screen

Must be connected to

ground

Connecting the

photometer

Instruction Manual PhaseGuard C/ T/ HT Mechanical mounting

16 11026E/4

The standard length of the connection cable is 10 m. For greater distances, a junction box

must be inserted between the instrument and a customer-side control system or, as shown

in the figure below, with a SICON.

Figure 6: Installation of the photometer with junction box

Photometer

Junction box

Customer-side control system or

SICON.

The maximum distance (X) between SICON or a customer-side system (3) and the junction

box (2) depends on the power supply and the cross-section in use:

CROSS-SECTION

MAX. DISTANCE

FOR 12 VDC

(WITH PROFIBUS)

MAX. DISTANCE

FOR 24 VDC

(WITH PROFIBUS)

REMARKS

[mm2]

[m]

[m]

0.14

40 (20)

150 (100)

0.20

60 (30)

250 (150)

Standard version

0.34

100 (50)

400 (250)

0.50

140 (70)

600 (350)

0.75

210 (110)

800 (500)

1.00

280 (140)

800 (700)

1.50

400 (200)

800 (800)

Paired cable, complete copper-braided shielding, impedance 100-165 Ω, capaci-

tance < 60 pF/m

5.3. Installation of the SICON control unit, field bus

Installation of the optional SICON control unit as well as installation and commissioning of

the field bus interfaces are described in the Reference Manual.

Cross section for

greater distances

Cross-section

specifications

Cable structure

This manual suits for next models

2

Table of contents

Other SIGRIST Industrial Equipment manuals