SIL 107 Series User manual

MULTIPLIER

Type 107-12A

User Guide

Doc ref ud107-12a.vp Rev 3

WARNING!

It is important that this guide is read and fully understood before

attempting installation or commissioning of the instrument.

Instructions appearing in this document, and current safety

legislation, must be observed to ensure personal safety and to

prevent damage to the instrument or equipment connected to it.

The instrument should be installed, commissioned and operated

only by suitably qualified and authorised personnel.

Page 1

Safety and EMC information

Safety: EN61010 -1

Immunity: EN50082-1

Emissions: EN50081-1

CE certified

The specifications for the instrument must not be exceeded. If

the instrument is used in a manner not specified, the

protection provided by the instrument may be compromised.

The instrument must be installed in an enclosure that provides

adequate protection against electric shock.

Ensure that power to the instrument is switched off and signal

wiring isolated from hazardous voltages before carrying out

installation or maintenance.

The instrument is designed for installation in a clean, dry

environment (Pollution degree 1).

Stroud Instruments Ltd strongly recommends that repairs and

re-calibration work are done on a return to factory basis in

order that our quality standards, product specifications and

safety precautions are not compromised.

The instrument is double insulated

Note: Clean with a moist cloth - USE NO SOLVENTS.

Page 2

Installation

WARNING: Installation should be

conducted by appropriately skilled and

authorised personnel only.

WARNING: Ensure that power to the

instrument is switched off and signal

wiring isolated from hazardous voltages

before carrying out installation.

WARNING: The instrument must be

installed in an enclosure that provides

adequate protection against electric shock.

Location

¨The instrument is designed for

installation in a clean, dry environment

¨Do not install near to switch gear,

motor controllers or other sources of

strong magnetic fields.

¨Avoid exposure to direct sunlight and

ensure the ambient temperature inside

the enclosure that the unit is mounted

in will not exceed our specification.

Fixing

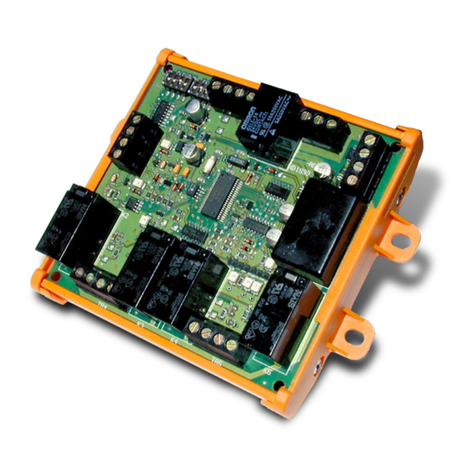

107 Series Modules are designed to be

fitted to any flat dry surface using two

4mm screws. Alternatively, by fitting an

optional DIN clip, they may be clipped to

a rail conforming to BS5584:1978,

EN50 022, DIN46277-3.

Grommets are provided on three sides of

the base section and there are two rear

entry knock outs in the bottom.

Dimensions in mm

Module height 95mm, units with dial 117mm

Plug in Module

Retaining Screws

Optional DIN Clip

Page 3

Wiring and connections

¨Segregate power supply and signal

wiring.

¨Use screened cable for all signal wiring

with the screen earthed at instrument

end only.

¨All connections should be made using

ferrules.

Screw terminals are provided - wire

capacity 2 x 1.5mm2

Access to Terminals

WARNING:Ensure that power to the

instrument is switched off and signal

wiring isolated from hazardous voltages

Loosen the two module securing screws.

Gently pull away the top section of the

module from its base to expose the fixing

points and wiring terminals. To refit the

module, align the module edge

connectors with the socket in the base

and carefully press home. NB do not

over tighten the module securing screws.

Input connections

Inputs are configured during manufacture

to suit the application specified. A change

in the type of input from voltage to current

or vice versa will require a return to factory

for re-configuration.

Voltage and mA

Output connections

Outputs are configured during

manufacture to suit the application

specified. A change in the type of output

will require a return to factory for

re-configuration.

Voltage and current

Current sink

External

voltage

source

Page 4

Power supply connections

This instrument is supplied in one of two

power supply versions.

a.1. AC mains supply: 110, 200, 220 or

240 VAC ±10% 50/60Hz; 5VA

b.2. DC supply: 12, 24 or 48V -10% to

+20%; 3.5W

WARNING: Check that the supply voltage

on the data label (on side of instrument) is

suitable for the application.

WARNING: Ferrules must be used for AC

mains power wiring

Power supply wiring to the instrument

should be protected by a suitable fuse

and double pole switch - see below. The

switch should be clearly marked as the

isolating switch for the instrument.

AC Mains

DC supply

Please note:

The unit cannot be changed by the user

from one type of power supply version to

another. This conversion can only be

done on a return to factory basis.

Fuse replacement and

supply voltage

adjustments

Gaining access to power supply

WARNING: Switch off all supplies and

isolate signal and other wiring from

dangerous voltages before proceeding.

(i) Remove plug-in module as described

in Access to Terminals in the

Installation section.

(ii) The plate with the terminal

connections label can now be

removed by easing apart the longer

sides of the module to release the

interlocking tongue and groove.

(iii) Note the location of the printed circuit

board which must be replaced in the

same position. Slide out the board.

Page 5

Changing AC supply voltage

Mains powered units can be adapted for

operation on 110V, 200V, 220V or 240V

supplies. Fig 1 provides details of the

required link settings which are effected

by soldered tinned copper wire links.

WARNING: Links for 200V operation

must be insulated with silicon rubber

sleeving.

DC powered versions

The operating supply voltage on DC

powered units cannot be changed by the

user. This conversion can only be done

on a return to factory basis.

Fuse replacement

The fuse holder is located at the edge of

the circuit board and above the mains

transformer or DC power unit.

Fuse size: 20mm x 5mm dia.

Fuse ratings:

AC Supply - 100mA Quick Blow

12V/24V DC - 250mA Anti-surge

48V DC -100mA Anti-surge

Re-assembly

Re-check your link selections.

Replace the printed circuit board into the

case ensuring that it is located in the slot

under the LED indicator window. Replace

the bottom plate by first engaging the

side with the two tongues into the slots in

the case and then press the plate home

to engage the side with the single tongue.

Plug the reassembled module into the

base section and secure with the two

captive screws provided - do not

overtighten.

Fig. 1 AC mains supply links

WARNING!

It is important that this guide is read and fully understood before

attempting installation or commissioning of the instrument.

Instructions appearing in this document, and current safety

legislation, must be observed to ensure personal safety and to

prevent damage to the instrument or equipment connected to it.

The instrument should be installed, commissioned and operated

only by suitably qualified and authorised personnel.

Page 1

Safety and EMC information

Safety: EN61010 -1

Immunity: EN50082-1

Emissions: EN50081-1

CE certified

The specifications for the instrument must not be exceeded. If

the instrument is used in a manner not specified, the

protection provided by the instrument may be compromised.

The instrument must be installed in an enclosure that provides

adequate protection against electric shock.

Ensure that power to the instrument is switched off and signal

wiring isolated from hazardous voltages before carrying out

installation or maintenance.

The instrument is designed for installation in a clean, dry

environment (Pollution degree 1).

Stroud Instruments Ltd strongly recommends that repairs and

re-calibration work are done on a return to factory basis in

order that our quality standards, product specifications and

safety precautions are not compromised.

The instrument is double insulated

Note: Clean with a moist cloth - USE NO SOLVENTS.

Page 6

Continuous development may necessitate changes in these details without notice.

SPECIFICATION

INPUTS

0-10 mA into 100 ohms

0-20 mA into 50 ohms

4-20 mA into 62.5 ohms

0-5v into greater than 1 M ohms

1-5v into greater than 1 M ohms

OUTPUTS

0-10 mA into 2000 (5000) ohms max

0-20 mA into 1000 (2500) ohms max

4-20 mA into 1000 (2500) ohms max

0-5v into 500 ohms min

1-5v into 500 ohms min

Current Sink 4-20mA @ 50 Volts max.

FUNCTION

Output = (A + a) (B + b) x k + c, where A and B

are inputs and a, b, c and k are constants.

CALIBRATED ACCURACY

Set at 100% to be within ± 0.2% FSD.

LINEARITY ERROR

≤± 0.4% FSD.

SUPPRESSION/ELEVATION ERROR

≤± 0.1% FSD.

OUTPUT RIPPLE

≤0.1% (Peak to Peak) of FSD.

LOAD RESISTANCE EFFECT

≤0.001% of span/100 ohms change.

ISOLATION

The inputs and output are not isolated from each

other, but are isolated from the power supply.

STABILITY

Over 24 hrs ± 0.05% FSD.

Over 1 year ± 0.1% FSD.

INTERFERENCE REJECTION

Filtering is incorporated to reject R.F. and

other industrial noise.

SERIES MODE REJECTION

< 0.2% error for 50 Hz RMS

Signal equal to 50% span

INPUT OVER-RANGE PROTECTION

250 volts RMS or DC (voltage inputs only)

TEMPERATURE COEFFICIENTS

Zero: ± 0.02% span/°C

Span: ± 0.02% span/°C

TEMPERATURE RANGE

Operating: -10°C to + 60°C

Storage: -20°C to + 70°C

SUPPLY VOLTAGE REJECTION

Output change < 0.01% span/% supply change.

POWER SUPPLY

AC versions: 110, 220, 240V ±10%

50/60Hz 5VA

Fuse (internal) 100mA quick-blow (20 x 5mm)

DC versions: 12, 24, 48V -10% +20% 3.5W

Fuse (internal) 250mA anti-surge (20 x 5mm)

ENCLOSURE DETAILS

Base: Phenol (black)

Cover: Polystyrol (light grey)

Protection: IP40

SAFETY & EMC

Safety: EN61010-1 Immunity: EN50082-1

Emissions: EN50081-1 CE certified

WEIGHT

Approximately 0.5 kg

figures in

brackets

are options

⎫

⎬

⎭

This manual suits for next models

1

Table of contents

Popular Control Unit manuals by other brands

Trillium

Trillium SARASIN-RSBD STARFLOW V Series Installation, operation & maintenance manual

National Instruments

National Instruments NI 9351 Getting started guide

Siemens

Siemens FS-TRI-M installation instructions

SAMES KREMLIN

SAMES KREMLIN GNM 6080 instruction manual

Motion

Motion Domotica Box RS485 manual

BESA

BESA 130 Series Use and maintenance manual