Sila EVI Series User manual

Split EVI DC Inverter Series

Installation Manual

AS 9,6 I-EVI AS 16,8 I-EVI, AS 18,8 I-EVI

Air to Water Heat Pump

Heating+Cooling+DHW

Refrigerant: R410A

PC board code:

LCD code:

Safety precaution

a. Toavoid electrical shock, make sure to disconnect power supply

1minute or more before operating the electrical part. Even after

1minute, always measure the voltage at the terminals of main circuit

capacitors or electrical parts and, before touching, make sure that

those voltages are lower than the safety voltage.

b. Power supply wire line size must be selected according to this

manual. And must be grounded.

c. Don’t put in hands or stick to air outlet grill when fan motor are

working.

d. Don’t use wet hand touch wire lines, and don’t pull any wire lines of the

unit.

e. Water or any other kind liquid is forbidden to poured into the unit.

f. Select correct air breaker and leakage protection switch.

g. Don’t touch the fin of source side heat exchanger, it may hurt your

finger.

h. If any wire line is loose or damaged, suggest let qualified person to fix it.

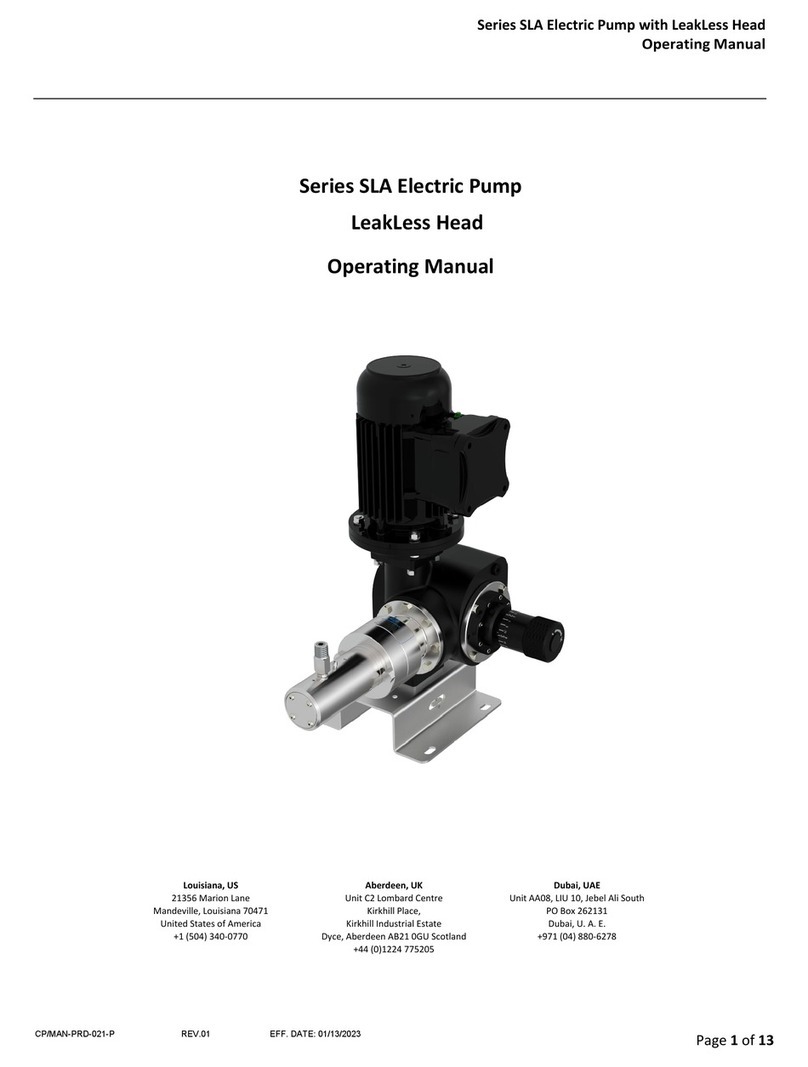

Important parts in heat pump

No.

Component

53

Fan

54

DC motor

35

Reservoir

28

Inverter compressor

55

Pressure gauge

31

Filter

46

Small shut-off valve

47

Large shut-off valve

23

Four-way valve

26

Main electronic expansion valve

27

Auxiliary electronic expansion valve

29

Plate heat exchanger economizer

16

Back repair board

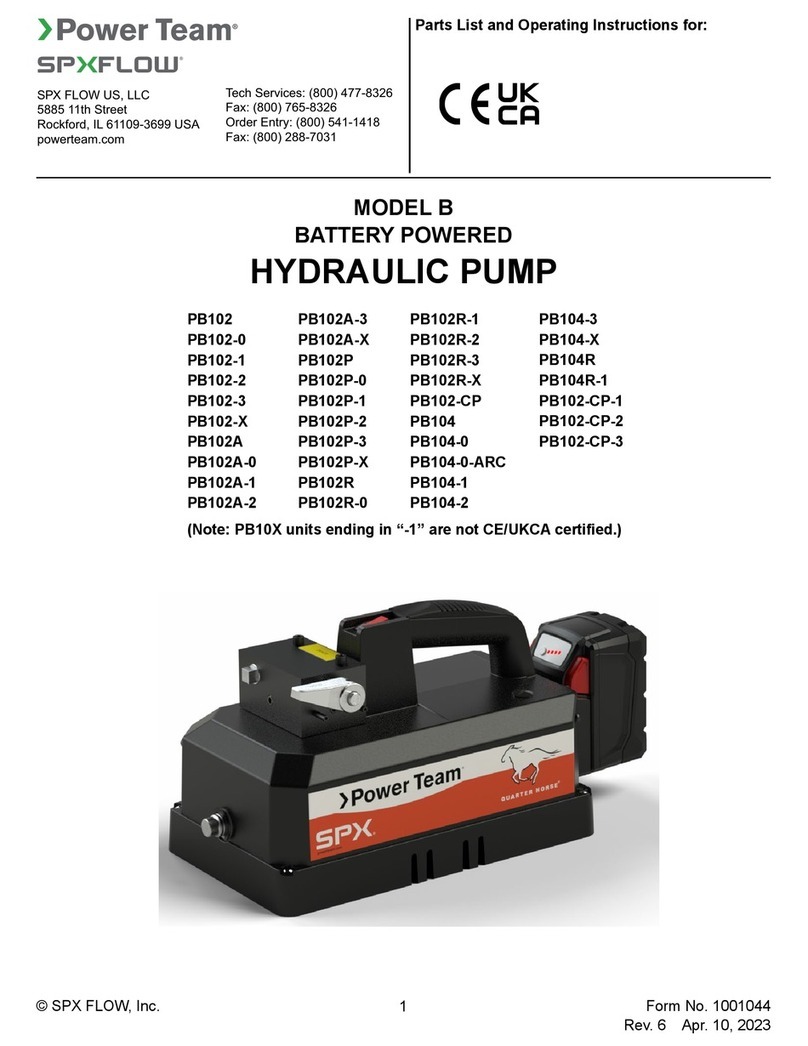

Important parts in heat pump

No.

Component

60

Fan

61

DC motor

31

Plate heat exchanger economizer

28

Auxiliary electronic expansion valve

30

Main electronic expansion valve

53

Large shut-off valve

52

Small shut-off valve

23

Four-way valve

64

Pressure gauge

29

Filter

50

Reservoir

24

Gas-liquid separator

41

Inverter compressor

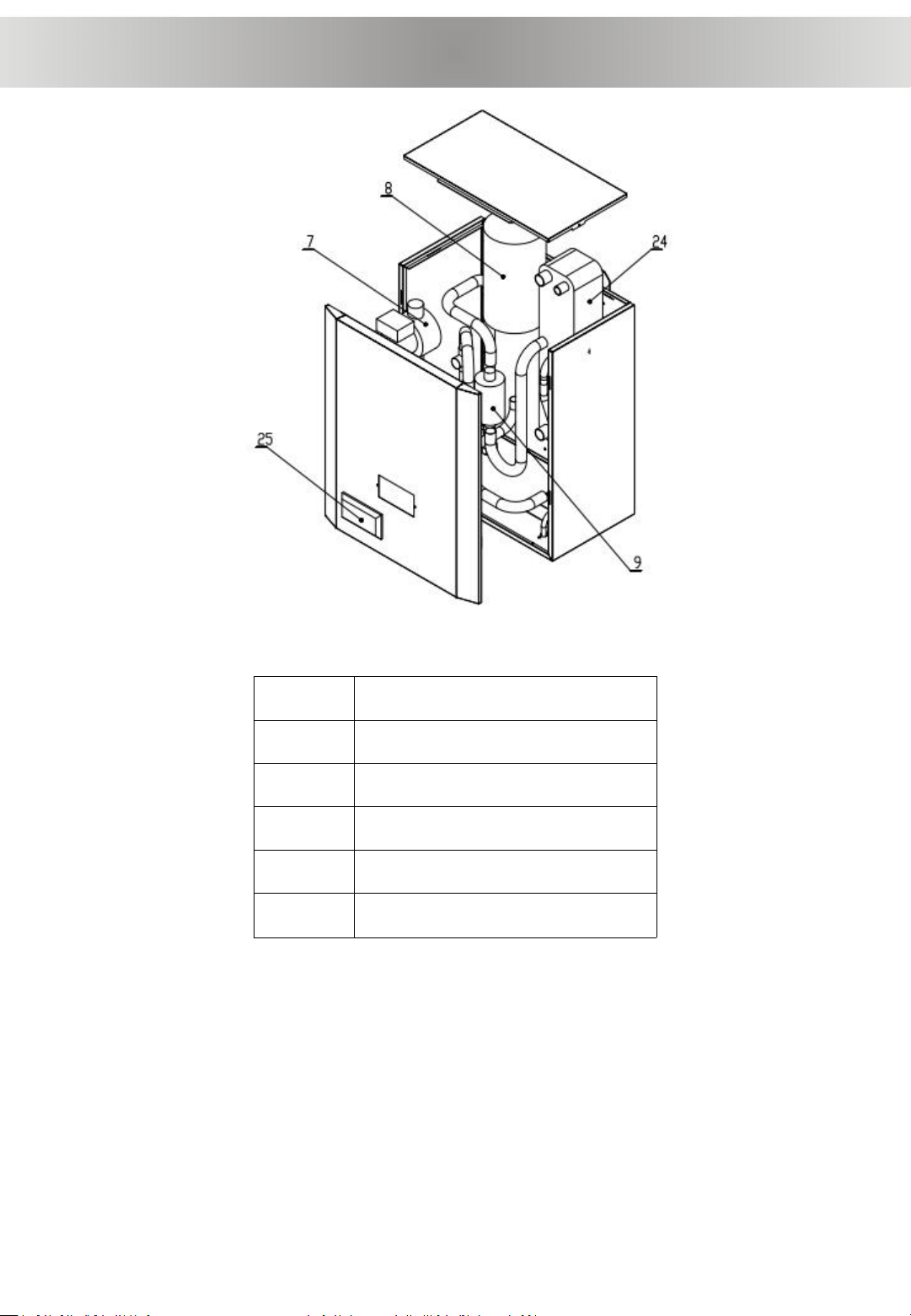

Important parts in heat pump

No.

Component

25

Controller

7

Inverter pump

8

Expension tank

24

Plate heat exchanger

9

Electric heater

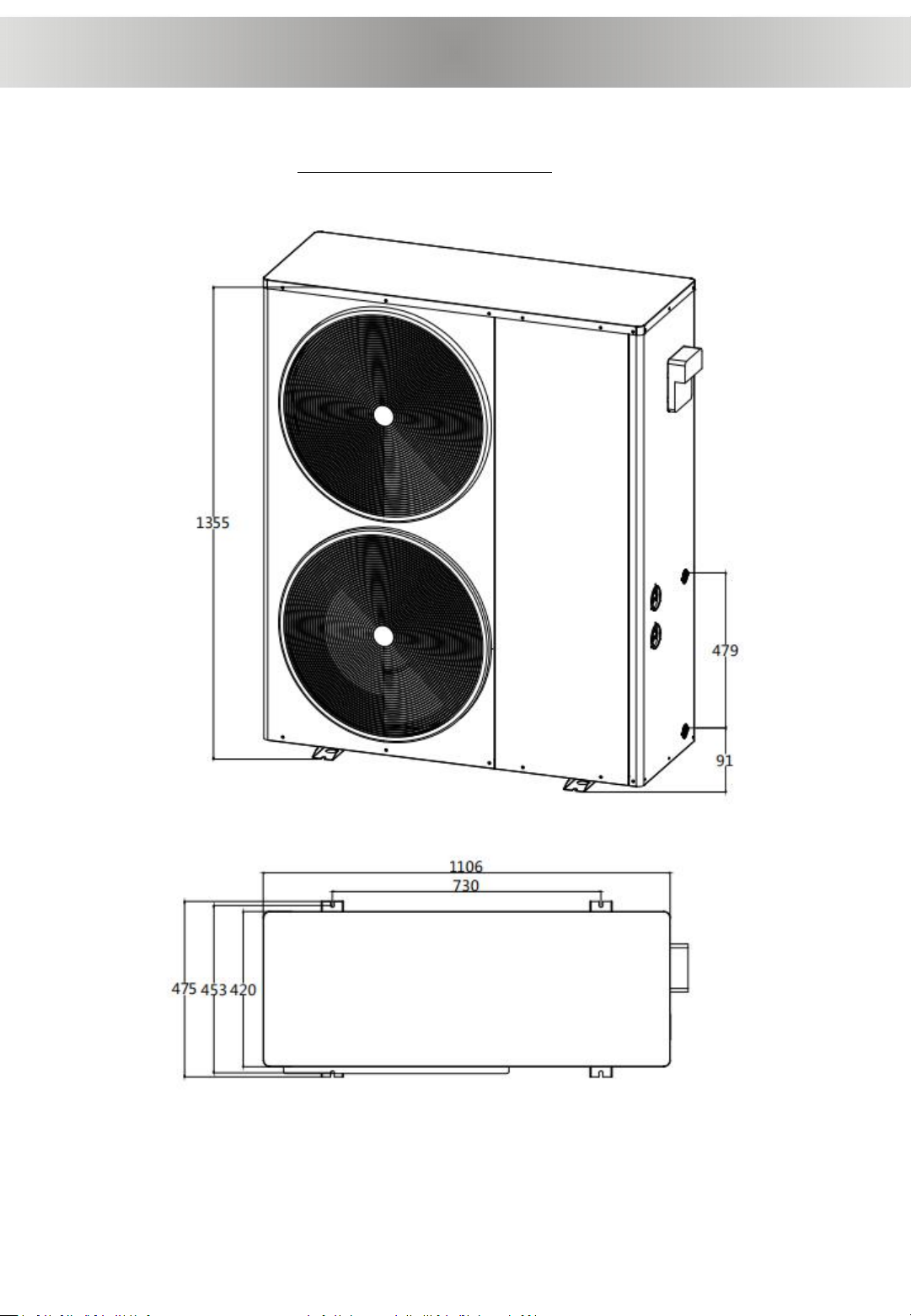

Heat pump size

AS 9,6 I-EVI

Heat pump size

AS 16,8 I-EVI, AS 18,8 I-EVI

Heat pump size

Indoor unit

Installation diagram

Primary circulation system

Installation diagram

Secondary circulation system

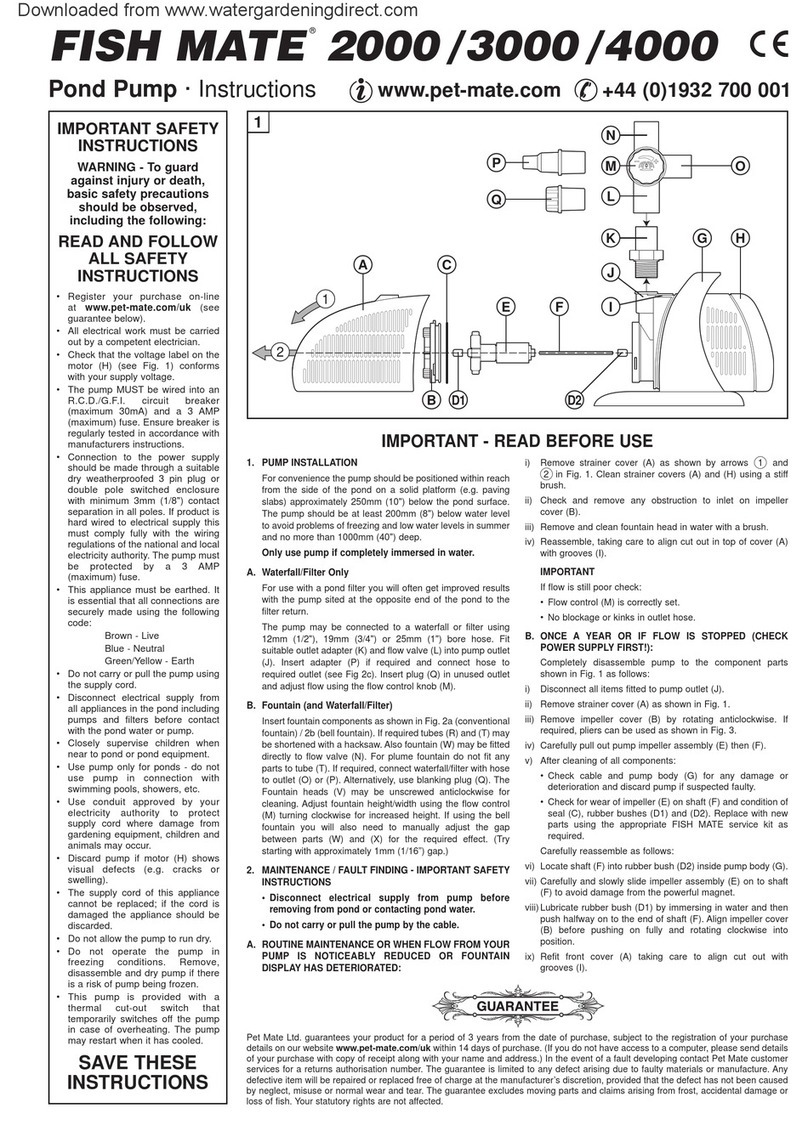

Distances to barrier and ground

1) The heat pump must be installed in open space. Normally is installedon the

roof of house.

2) The unit should be placed in dry and well-ventilated environment. If the

environment is humid, electronic components may get corroded orshort

circuit.

3) Heat pump mustn’t be installed in the environment wherecorrosive,

volatile, or flammable liquid or gas exists.

4) Because of the noise is a little loud, please don’t install the heatpump near

bedroom or living room or meeting room.

5) Please install a shed for the heat pump, otherwise, rain water can reduce the

lifetime of the shell, and snow may cover the air outlet.

6) Water drainage ditch should be set around the heat pump, whenheat

pump is working, there is condensing water flow down, or when defrosting,

there are plenty of water flow down too.

7) Heat pump should far away from kitchen exhaust, because thefinned tube

is not easy to clean if there is oil on it.

8) Heat pump must be installed on flat concrete blocks or a raised concrete

platform, or steel bracket. The bottom of the heat pump should be at least

50cm higher than ground, because rain water, snow may enter inside if the

installation is on ground.

9) Between heat pump and basic or bracket, at leas 4pcs anti-shock pads

should be placed.

10) Before make basic or bracket, please check heat pump dimension.

11) Before fix heat pump on basic, please confirm heat pump direction

according to project design.

12) Normally use expansion bolt to fix heat pump on concrete basic.

13) Make sure circulating water pipe must be ≥DN25 (or PPR32), and pipes

must be insulated.

14) When install water temp sensor on pipe or in water tank, make sure temp

sensor will not touch water directly, best through a sensor tube. Like below

picture.

≥0.5

m

Basic of installation

1. Installation site

1.1 The outdoor unit should be installed in a sunny and ventilated place to prevent the formation

of a cold field due to poor ventilation or in a dark place, which affects the use of the unit;

1.2 The outdoor unit should not be installed in a place with too much dust to prevent the dust

from adhering to the fin heat exchanger and affecting the heat exchange effect;

1.3 The outdoor unit should not be installed in places with corrosive gas to prevent the unit heat

exchanger from being corroded and affecting the service life;

1.4 The outdoor unit should be equipped with anti-vibration pads and fixed firmly with expansion

screws to prevent vibration, noise and displacement;

1.5 The outdoor unit should be installed in a place where it can be drained to prevent

condensation and ice formation;

1.6 The outdoor unit should be placed according to the installation distance diagram, and there

should be a bracket to prevent the short drainage distance from causing ice formation;

1.7 The indoor unit must be well-supported, installed on a wall, and the wall must be able to bear

the weight;

1.8 The indoor unit should not be installed outdoors in direct sunlight or rain.

2. Installation considerations

2.1 The copper pipe connecting the internal and external machines is 5 meters, and it cannot be

lengthened without permission. If you need to lengthen, you need to contact the manufacturer;

2.2 When the connecting copper pipe is bent, do not crush the copper pipe, otherwise it will

affect the normal operation of the unit;

2.3 After installation, use soapy water to detect leaks.

Installation details

Installation details

3. Outdoor unit installation

3.1 Outdoor unit installation distance requirements

3.2 The outdoor unit installation needs to be fixed on the bottom frame with expansion screws,

and the bottom corner of the main unit needs to be installed with a cushion

Anti-shock pad

Concrete basic

Expansion bolt

4. Indoor unit installation:

4.1 Indoor unit installation requires three expansion screws to fix the internal unit to the wall.

Installation details

5. Fix the connecting pipe

5.1 After the outdoor door unit and indoor unit are fixed, look for the nearest connection route,

punch a hole of 50-100mm at the location of the wall, pay attention to waterproof when drilling

5.2 Pass the two connecting pipes through the wall, and place the two ends at the connection

between the indoor and outdoor units

6. Fluorine copper tube connection

6.1 Indoor unit and connection location

Outdoor unit gas connector

Pipes connection

Indoor unit gas connector

6.2 Fluorine connection pipe specification:

CGK030V2LS connection pipe specification φ15.88 / φ12.7

CGK050V2LS connecting pipe specification φ19 / φ12.7

CGK060V2LS connecting pipe specification φ19 / φ12.7

7. Fluorine system pipeline connection steps

7.1 Remove the plastic cover of the globe valve, directly align the bell mouth of the connecting pipe

with the connection port on the heat pump, and then tighten the nut, paying attention to alignment,

otherwise it will cause air leakage

Remove cover Bell mouth

Pipes connection

7.2 After connecting the connecting pipes of the indoor and outdoor units, use a vacuum

pump to evacuate the air in the pipeline and the indoor unit to ensure the evacuation time

and ensure that the air in the pipeline is cleaned.

7.3 After evacuation, close the refrigerant meter valve, use a φ5 hex nut to open the shut-

off valve switch, close the shut-off valve switch after a little refrigerant enters the

connection pipe, then unscrew the connection pipe for evacuation, and then reopen all the

shut-off valve switches, Complete the connection.

Tool

Remove cover Switch

8. Leak detection

Fill an empty bottle with the right amount of detergent solution and water, shake it, and pour it into

all the connection ports to check whether there are bubbles emerging. If there are bubbles, it can

be judged that the refrigerant is leaking. It needs to be tightened immediately until no bubbles

come out.

9. Water system pipeline connection

9.1 Use pipe connections with specifications greater than or equal to DN25, and the connection

should be tightened to prevent water leakage;

9.2 If used for three functions of floor heating, cooling and hot water, a three-way valve needs to be

installed;

9.3 Automatic exhaust valve shall be installed at the highest part of the water system and the top of

the water tank.

Pipes connection

Wire line

10. Line connection

10.1 When connecting the main power supply, please note that the wire diameter of the power cord

must be greater than or equal to the recommended wire diameter, and must be reliably

grounded.

10.2 The connection terminal of the water pump can be used as the power supply of the water

pump. The water pump with the PWM signal needs to be connected to the signal line. Pay

attention to distinguish the power line and the signal line of the pump, which can be

distinguished according to the number of the connection line

10.3 Models with inside electric heater can be directly wired according to the mark.

10.4 Models with external electric heater need to select a suitable wire diameter according to the

electric heating power. The electric heating terminal cannot be used directly as an electric

heating power supply, but only as a control line. The main power supply needs to be equipped

with an AC contactor according to the power size

10.5 The connection of the three-way valve is 2 live wire and 1 neutral wire, and the switching

direction of the three-way valve must be accurately judged when wiring, otherwise it will

damage the unit and render it unusable

10.6 The user hot water probe using the three functions of floor heating, cooling and hot water

needs to be installed in the hot water tank.

10.7 Corresponding numbers of the inlet and outlet probe lines and the water flow switch

connection line can be directly connected

11. Power wire diameter selection

Voltage: 220V~240V/50Hz or 60 Hz/1Ph Electric heater: 3KW

N

L

12. Wiring terminal diagram with self water pump and electric heater

AS 9.6 I-EVI AS 16.8 I-EVI AS 18.8 I-EVI

Line(mm)

6

10

10

Max.

Current(A)

15

26

30

Terminal

13.Wiring terminal diagram of externally electric heater and water pump

Terminal

This manual suits for next models

3

Table of contents

Popular Water Pump manuals by other brands

Blumfeldt

Blumfeldt 10031255 manual

FLOWTECH

FLOWTECH flowpac compact SE Operation and maintenance manual

Pentair Pool Products

Pentair Pool Products Delta D2CX20-21 Installation & Service Manual with Parts List

Hayward

Hayward VS Omni How-to guide

Tsurumi Pump

Tsurumi Pump C series Operation manual

All Pond Solutions

All Pond Solutions ACP-500 instruction manual

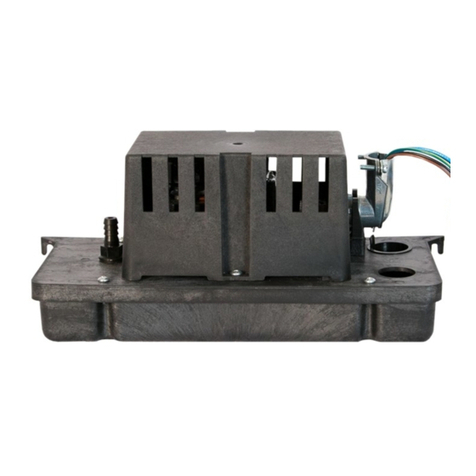

Little Giant

Little Giant HRK-360S instruction sheet

Aqua Medic

Aqua Medic EcoDrift 4.1 Operation manual

Little Giant

Little Giant 1-EAYS Installation instructions manual

red lion

red lion RL-SWJ Series owner's manual

Little Giant

Little Giant VCCA-20-P owner's manual

Little Giant

Little Giant 1-EA Series quick start guide