23833A596 3

PUMP

1. Pumpbuildsupheat and pressure during opera-

tion, allow time for pump to cool before handling or

servicing.

2. Onlyqualifiedpersonnelshouldinstall,operateor

repairpump.

3. Keep clear of suction and discharge openings. DO

NOT insert fingers in pump with powerconnected.

4. DO NOT pumphazardousmaterialnotrecom-

mended for pump (flammable, caustic, etc.).

5. Make sure lifting devices are securely fastened

each time before lifting pump.

6. DO NOT LIFT PUMP BYTHE POWER CORD.

7. DO NOT exceedmanufacturer’srecommendation

for maximum performance, as this could cause the

motortooverheat.

8. Secure the pump in its operating position so it

cannot tip over, fall or slide.

9. Keep hands andfeetaway from impellerwhen

powerisconnected.

10. Submersiblegrinderpumpsare notapproved for

useinswimmingpools,recreationalwaterinstalla-

tions, decorative fountains or any installation where

human contact with the pumped fluid is common.

11. DO NOT pump without safety devices in place.

12. For hazardous locations, use pumps that are listed

and classified for such locations.

13. DO NOT usenon-explosionproofratedpumpsin

locationsconsideredhazardousinaccordance with

theNationalElectrical Code,ANSI/NFPA70-1993.

14. Basin must be vented in accordance with the local

plumbingcodes.

IMPORTANT: Manufacturer is not responsible for

losses, injury or death resulting from failure to observe

these safety precautions, misuse or abuse of pumps

orequipment.

CONTROLPANELS

All control panels used on these grinders are UL listed

and CSA certified. Control panels mounted directly to

the basin used outdoors are UL listed and CSA

certifiedwaterproof.

If intrinsically safe controls used in hazardous loca-

tionsarerequired,manufacturercanfurnish a UL listed

or CSA certified panel. Otherwise the installer must

obtainasourceforthepanelrequired.

LEVEL SENSING CONTROLS

Intrinsically-safetypefloatcontrolsarerecommended

forallapplicationsand required for explosion-proof

service. An intrinsically safe control panel relay will

limit the current and voltage to the level controls. A

Delta control panel can be supplied with this type

circuitry.

The float level controls maintain the basin sewage water

levelbycontrolling pump turn-on and turn-off level.

1. The lower turn-off control should be set so that the

pump stops at approximately the top of the pump.

2. Theupperturn-oncontrolshouldbesetabovethe

lower turn-off control. The exact height between the

two controls is determined by the number of pump

starts desired and the depth of the basin. A maxi-

mum of 10 starts per hour should not be exceeded.

3. The override control is set at a specified height

abovetheupperturn-on control.

4. The alarm control is set about 6” to 12” above the

overridecontrol.

5. No control should be set above the inlet invert.

JUNCTIONBOXES

If a junction box is used in a hazardous location, it must

beanexplosion-proof approved type withexplosion-proof

cord connectors. Wires from the junction box must pass

throughanexplosion-proofsealconnector.

CAUTION: No persons should be in the basin when

pump is lowered into position! DO NOT lift pump in a

manner where any failure could result in loss of life.

AIRVENTING

Air tends to trap in the pump volute when water raises in

the sump or when the pump is lowered into water after

service. To vent off this air, a small hole is drilled into

the pump volute. Be sure this vent hole is clean after

any service work on pump.

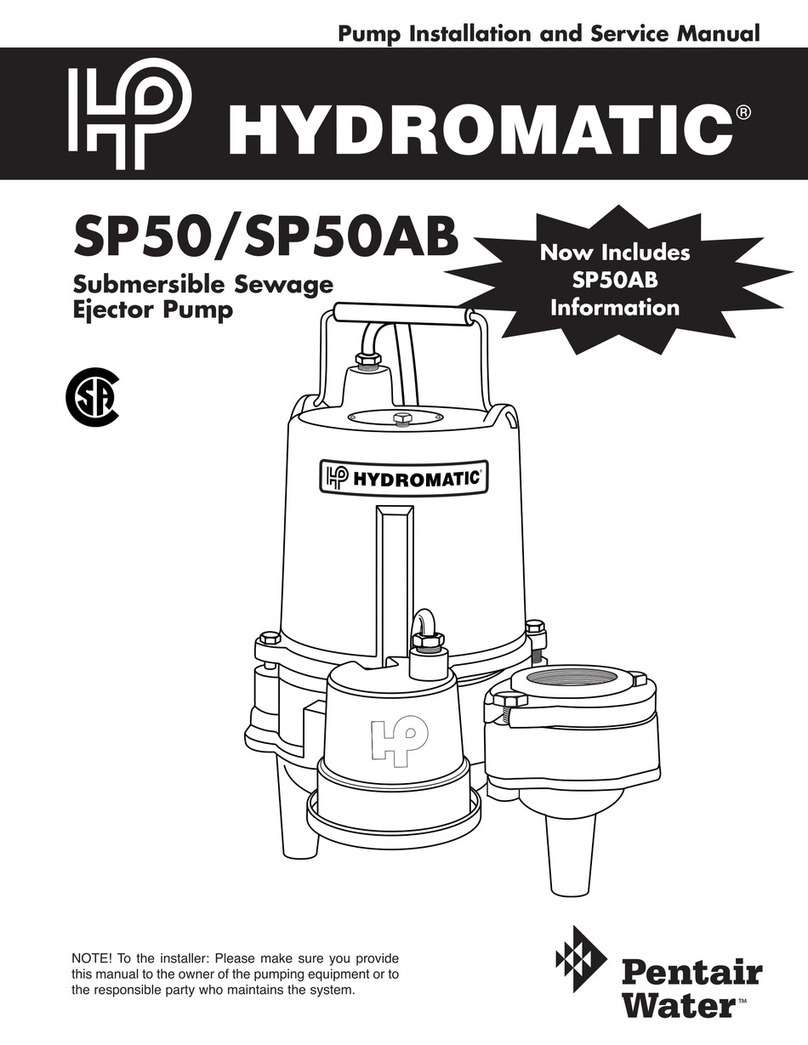

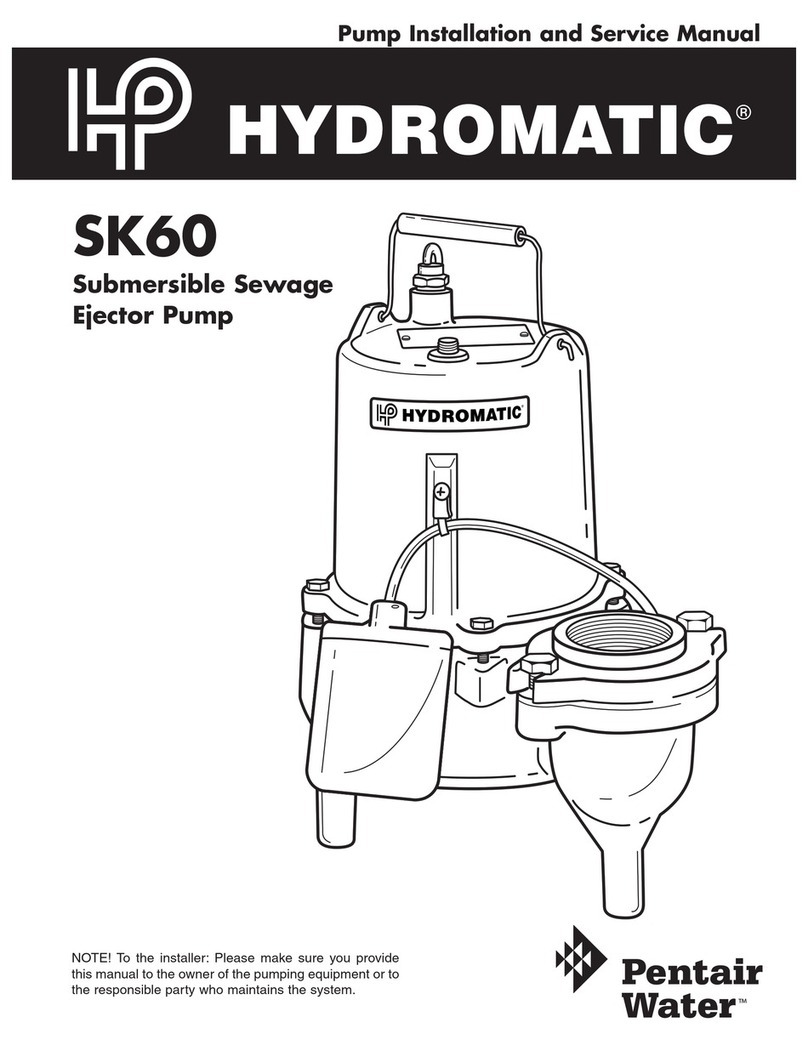

PUMP MODELS —This grinder pump is made in one

model only for use with single phase and three phase

power. Motor rating is 2 HP, 3540 RPM, 60 Hz. Also

can be used for 50 Hz. operation. Single phase is for

230 volt.

PACKAGING — Each pump is packaged with 15 feet of

power cord in a carton that is marked with Model

NumberandEngineeringNumber. Longer cordsare

available for special jobs.

INSTRUCTIONS — Instructions cover only the pump

unit. Separate instructions for the electrical control panel

and basin packaged system are included with these

items.

CAUTION: PUMP IS NOTTO BE DISASSEMBLED IN

THE FIELD EXCEPT AT CERTIFIED SERVICE STA-

TIONS OR AT FACTORY. WARRANTY ISVOID IF

PUMP IS TAKEN APART FOR ANY REASON EXCEPT

TOREPLACEGRINDERIMPELLERAND GRINDER

RINGWHICHIS COVEREDINTHESEINSTRUCTIONS.

PUMP CAUTIONS AND WARNINGS