SILICYCLE MiniBlock User manual

www.SiliCycle.com

SiliCycle MiniBlock®

User Guide

SiliCycle MiniBlock® User Guide

2www.SiliCycle.com | inf[email protected]om

1. Usage and Safety Precauons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cleaning .................................................................................................... 6

Maintenance ............................................................................................... 6

Storage ..................................................................................................... 6

Temperature ................................................................................................ 6

Pressure .................................................................................................... 6

Components ................................................................................................ 6

Document Convenons ...................................................................................... 6

2. General .................................................................................... 7

2.1. The SiliCycle MiniBlock Reacon Tubes .................................................................... 8

2.2. SiliCycle MiniBlock Conguraons ....................................................................... 10

2.2.1. Ambient Temperature Conguraons ............................................... 11

2.2.2. Plugs for Unused Pinch-Tube Inserts ................................................ 11

2.2.3. Controlled Temperature Conguraons ............................................. 11

2.2.4. Combining Red and Blue SiliCycle MiniBlocks Into 96-Well Format ....................... 12

2.3. SiliCycleMiniBlock System Materials .................................................................... 12

2.3.1. SiliCycle MiniBlock Metal Components .............................................. 12

2.3.2. Reacon Tube Materials .......................................................... 12

2.3.3. Pinch-Tube Insert Materials ....................................................... 12

2.3.4. Septa Materials ................................................................. 13

2.4. SiliCycleMiniBlock Temperature Control ................................................................. 14

2.5. SiliCycle MiniBlock Reacons Requiring an Inert Atmosphere .............................................. 15

3. SiliCycle MiniBlock Assembly and Reacon Setup ................................................ 16

3.1. Pre-Assembly Checks .................................................................................. 16

3.2. SiliCycle MiniBlock Assembly ........................................................................... 18

3.2.1. Setup for Ambient Temperature Reacon ............................................ 18

3.2.2. Setup for Controlled Temperature Reacon .......................................... 18

3.2.3. Inserng Reacon Tubes .......................................................... 19

3.2.4. Sealing for Reacons Not Requiring Inert Condions .................................. 20

3.2.5. Sealing for Reacons Requiring Inert Condions ...................................... 22

3.2.6. Closing the SiliCycle MiniBlock Valve ................................................ 23

4. Reacon Setup, Mixing and Incubaon ......................................................... 24

4.1. Resin Addion – Solid-Phase Reacons .................................................................. 24

4.1.1. Resin Addion – Serial ........................................................... 24

4.1.2. Resin Addion – Parallel .......................................................... 24

4.1.3. IRORI® Kans™ ................................................................... 24

4.1.4. Resin Swelling .................................................................. 24

4.2. Inert Atmosphere ..................................................................................... 24

4.3. Adding Solvents and Reagents .......................................................................... 25

4.4. Reacon Mixing and Incubaon ........................................................................ 26

4.4.1. Shaking Staons ................................................................ 26

4.4.1.1. Securing SiliCycle MiniBlocks on the Shaking Staon ................................. 26

4.4.1.2. Balancing the Shaking Staon .................................................... 26

4.4.1.3. Pre-Operaonal Shaking Staon Check ............................................ 27

4.4.1.4. Seng Agitaon Speed ......................................................... 28

4.5. Incubaon ............................................................................................ 28

4.5.1. Aaching the Manifold to the Shaker ............................................... 28

4.5.2. Connecng to the Recirculator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.5.3. Tesng the Recirculaon System ................................................... 29

3

5. Washing, Puricaon and Product Collecon .................................................... 30

5.1. Solvent Removal and Resin Washing .................................................................... 30

5.1.1. Removing Solvents to Waste on the Shaking Staon ................................... 30

5.1.2. Accelerang Solvent Drainage ..................................................... 30

5.1.2.1. Air Push Assist Device .......................................................... 31

5.1.2.2. Posive Pressure Manifold ...................................................... 31

5.1.2.3. Inert Atmosphere Manifold ...................................................... 32

5.1.3. Washing ....................................................................... 32

5.2. Puricaon and Clean-Up .............................................................................. 32

5.2.1. Solid-Phase Extracon ( SPE)....................................................... 32

5.2.2. Scavenger Resins ................................................................ 33

5.3. Product Collecon / Cleavage ........................................................................... 33

5.3.1. Collecon Rack Selecon ......................................................... 34

5.3.2. Collecon Vessel Posioning ...................................................... 37

6. Maintenance .............................................................................. 39

6.1. Cleaning Procedure .................................................................................... 39

6.1.1. Post-Collecon Rinse ............................................................. 39

6.1.2. SiliCycle MiniBlock Cleaning ....................................................... 40

6.2. Replacing Consumable Components .................................................................... 40

6.2.1. Replacement of Pinch-Tube Inserts ................................................. 40

6.2.2. Replacement of Compression Cords ................................................ 42

7. Troubleshoong ............................................................................ 43

7.1. Jammed Slide Valve ................................................................................... 43

7.2. Leakage / Solvent Loss ................................................................................. 43

7.3. Prevenve Maintenance ............................................................................... 45

Appendix A: Heat Shrinking Teon® Sleeves Onto Glass Reacon Tubes ................................ 48

A.1. Apparatus ............................................................................................ 48

A.2. Procedure ............................................................................................ 48

A.3. Quality Checks ........................................................................................ 49

A.3.1. Incomplete Heat-Shrinking ........................................................ 49

A.3.2. Defecve Heat-Shrinking ......................................................... 49

Appendix B: Resin Dispenser: Operang Instrucons ............................................... 50

B.1. Overview ............................................................................................. 50

B.2. Operaon Descripon ................................................................................. 50

B.3. Dispensing............................................................................................ 51

B.3.1. Resin Dispenser Setup ( Procedure wrien for the 48-Posions Version )................... 51

B.3.2. Dispensing Procedure ............................................................ 52

B.3.3. Dispensing to Microter / Deep Well Plates .......................................... 53

B.4. Resin Cleaning ........................................................................................ 54

B.5. Resin Dispenser Calibraon ............................................................................ 54

Appendix C: SiliCycle MiniBlock Collecon Rack Conguraons ....................................... 55

C.1. Assembly Diagrams .................................................................................... 56

Appendix D: Determining Correct Collecon Tube Height ............................................ 58

D.1. Instrucons for the Go/No-Go Test ...................................................................... 58

Appendix E: Chemistry Applicaons .............................................................. 59

Procurement ................................................................................ 59

SiliCycle MiniBlock® User Guide

4www.SiliCycle.com | inf[email protected]om

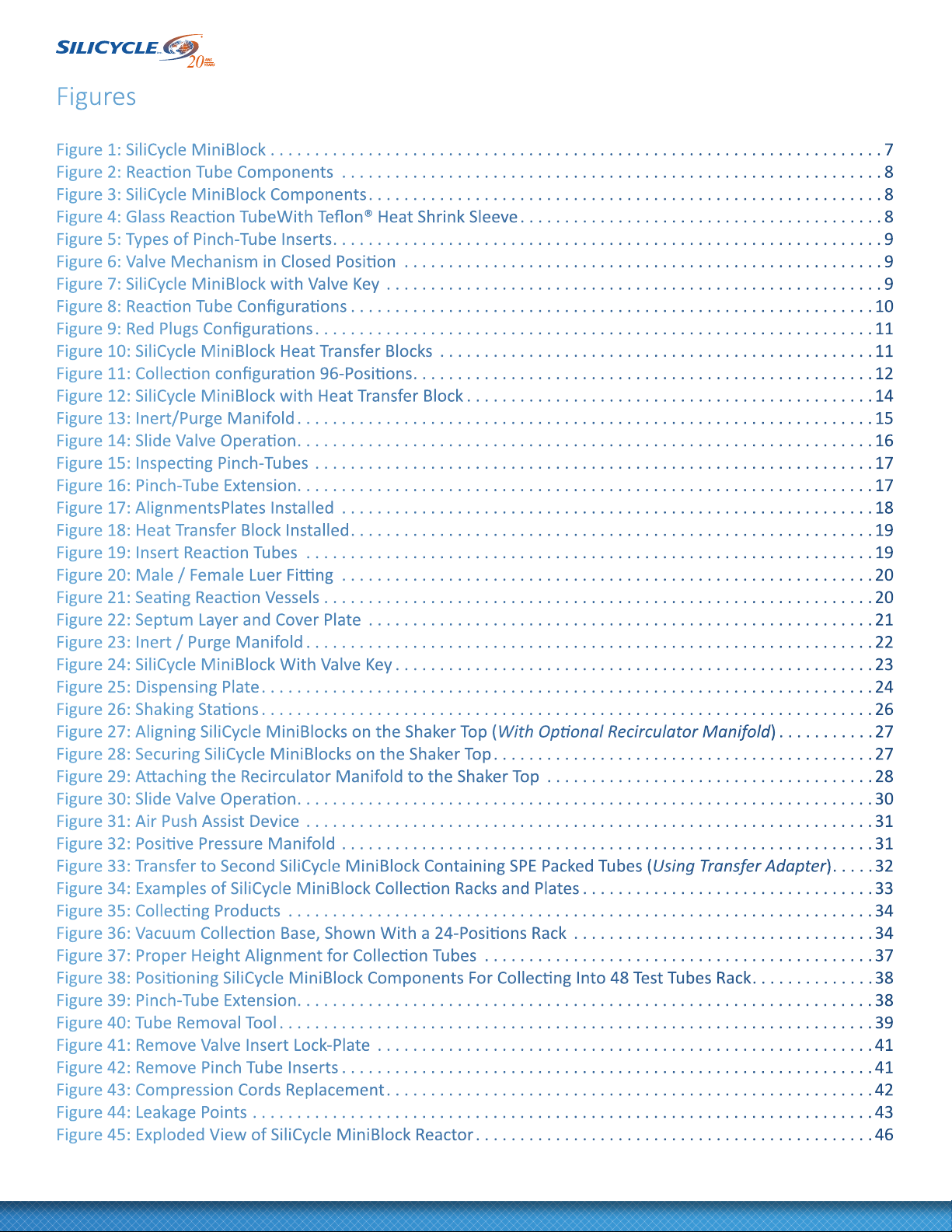

Figures

Figure 1: SiliCycle MiniBlock ..................................................................... 7

Figure 2: Reacon Tube Components ............................................................. 8

Figure 3: SiliCycle MiniBlock Components .......................................................... 8

Figure 4: Glass Reacon TubeWith Teon® Heat Shrink Sleeve ......................................... 8

Figure 5: Types of Pinch-Tube Inserts .............................................................. 9

Figure 6: Valve Mechanism in Closed Posion ...................................................... 9

Figure 7: SiliCycle MiniBlock with Valve Key ........................................................ 9

Figure 8: Reacon Tube Conguraons ........................................................... 10

Figure 9: Red Plugs Conguraons ............................................................... 11

Figure 10: SiliCycle MiniBlock Heat Transfer Blocks ................................................. 11

Figure 11: Collecon conguraon 96-Posions .................................................... 12

Figure 12: SiliCycle MiniBlock with Heat Transfer Block .............................................. 14

Figure 13: Inert/Purge Manifold ................................................................. 15

Figure 14: Slide Valve Operaon ................................................................. 16

Figure 15: Inspecng Pinch-Tubes ............................................................... 17

Figure 16: Pinch-Tube Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 17: AlignmentsPlates Installed ............................................................ 18

Figure 18: Heat Transfer Block Installed ........................................................... 19

Figure 19: Insert Reacon Tubes ................................................................ 19

Figure 20: Male / Female Luer Fing ............................................................ 20

Figure 21: Seang Reacon Vessels .............................................................. 20

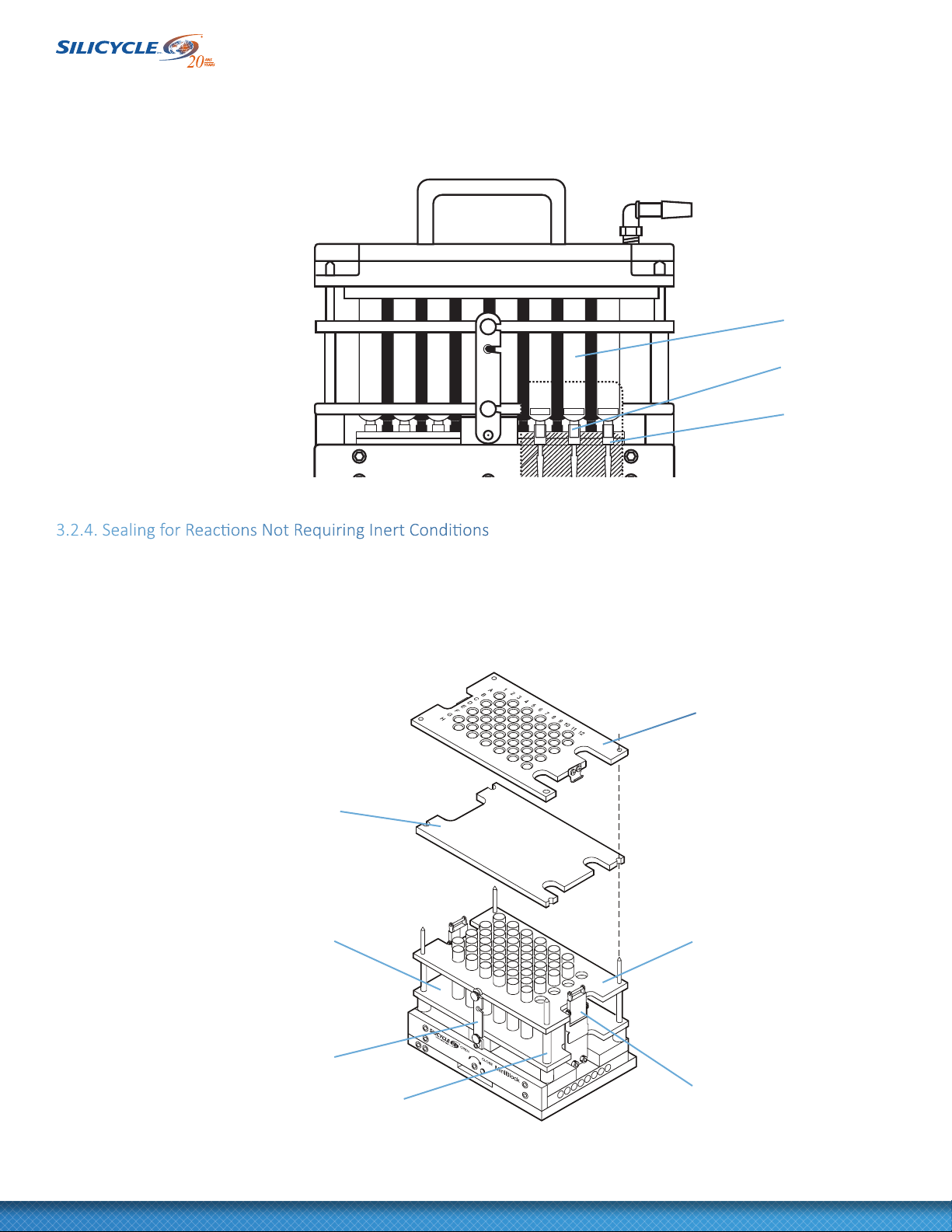

Figure 22: Septum Layer and Cover Plate ......................................................... 21

Figure 23: Inert / Purge Manifold ................................................................ 22

Figure 24: SiliCycle MiniBlock With Valve Key ...................................................... 23

Figure 25: Dispensing Plate ..................................................................... 24

Figure 26: Shaking Staons ..................................................................... 26

Figure 27: Aligning SiliCycle MiniBlocks on the Shaker Top ( With Oponal Recirculator Manifold )........... 27

Figure 28: Securing SiliCycle MiniBlocks on the Shaker Top ........................................... 27

Figure 29: Aaching the Recirculator Manifold to the Shaker Top ..................................... 28

Figure 30: Slide Valve Operaon ................................................................. 30

Figure 31: Air Push Assist Device ................................................................ 31

Figure 32: Posive Pressure Manifold ............................................................ 31

Figure 33: Transfer to Second SiliCycle MiniBlock Containing SPE Packed Tubes ( Using Transfer Adapter ).....32

Figure 34: Examples of SiliCycle MiniBlock Collecon Racks and Plates ................................. 33

Figure 35: Collecng Products .................................................................. 34

Figure 36: Vacuum Collecon Base, Shown With a 24-Posions Rack .................................. 34

Figure 37: Proper Height Alignment for Collecon Tubes ............................................ 37

Figure 38: Posioning SiliCycle MiniBlock Components For Collecng Into 48 Test Tubes Rack .............. 38

Figure 39: Pinch-Tube Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 40: Tube Removal Tool ................................................................... 39

Figure 41: Remove Valve Insert Lock-Plate ........................................................ 41

Figure 42: Remove Pinch Tube Inserts ............................................................ 41

Figure 43: Compression Cords Replacement ....................................................... 42

Figure 44: Leakage Points ...................................................................... 43

Figure 45: Exploded View of SiliCycle MiniBlock Reactor ............................................. 46

5

Figure 46: Glass Reacon Tube with Teon® Sleeve ................................................. 48

Figure 47: Resin Dispensing Plate ................................................................ 50

Figure 48: Resin Dispenser ( 13742086)........................................................... 51

Figure 49: Resin Dispenser Closed Posion ........................................................ 52

Figure 50: Resin Dispensing Spreader ............................................................ 52

Figure 51: Dispensing Powder .................................................................. 53

Figure 52: Replacing the Plate .................................................................. 54

Figure 53: The Vacuum Collecon Base Set ( 13742008)............................................. 55

Figure 54 : 12 x 100 mm Test Tubes ( 8 mL)........................................................ 56

Figure 55 : 12 x 75 mm Test Tubes ( 6 mL)......................................................... 56

Figure 56 : Deep Well Plate ( Various Volumes )..................................................... 56

Figure 57 : Tall Minitube Rack ( 2.5 mL)........................................................... 56

Figure 58 : 16 x 100 mm Test Tubes ( 15 mL)....................................................... 57

Figure 59 : 15 x 45 mm Vials (3.7 mL)............................................................. 57

Figure 60: 17 x 61 mm Vials (7.5 mL) ............................................................ 57

Figure 61 : 21 x 70 mm Vials (15 mL)............................................................. 57

Figure 62 : 28 x 95 mm Vials ( 40 mL)............................................................. 57

Figure 63: Tube Heights are Correct. “GO” ........................................................ 58

Figure 64: Tube Heights are too Low. “NO-GO” .................................................... 58

Figure 65: Tube Heights are too High. “NO-GO” .................................................... 58

Tables

Table 1: MinBlock Physical Descripon ............................................................ 7

Table 2: SiliCycle MiniBlock Conguraons ........................................................ 10

Table 3: SPE Development Kits Available from SiliCycle .............................................. 33

Table 4: Collecon Plates, Racks and Vessels ...................................................... 36

Table 5: SiliCycle MiniBlock Spare Parts .......................................................... 47

Table 6: Standard Conguraons ................................................................ 51

Table 7: High Volume Kit ( Sold Separately )........................................................ 51

Table 8: Collecon Rack Conguraons ........................................................... 55

SiliCycle MiniBlock® User Guide

6www.SiliCycle.com | inf[email protected]om

1. Usage and Safety Precauons

The SiliCycle MiniBlock products for parallel synthesis are intended for use by persons skilled in chemical handling and synthesis. Best results with

the SiliCycle MiniBlock can be achieved by following the usage, maintenance and storage guidelines in this Operaons Manual.

SiliCycle MiniBlock products include a 12 month warranty. This warranty is conngent on proper usage and maintenance as described in this

manual. If instrucons contained in this manual are not followed, the warranty may be invalidated. Some of the common consideraons for opmal

SiliCycle MiniBlock use include:

Cleaning

All chemicals should be cleaned from the SiliCycle MiniBlock as soon as possible. Full cleaning of the SiliCycle MiniBlock is recommended

immediately aer synthesis.

Maintenance

SiliCycle MiniBlocks should be checked and consumable components replaced as part of a scheduled maintenance program.

Storage

SiliCycle MiniBlocks should be stored with the slide (drainage) valve in the open posion and the two side clamps le undone.

Temperature

Reacon temperatures are limited to 80°C unless high temperature components are obtained from SiliCycle. Reacon temperatures must be

achieved using the apparatus described in this manual.

Pressure

SiliCycle MiniBlocks are not designed to withstand pressure build-up. Care should be taken to avoid pressure build-up when designing SiliCycle

MiniBlock synthesis procedures.

Components

Use only SiliCycle MiniBlock components purchased from, or approved by SiliCycle.

Document Convenons

The SiliCycle MiniBlock reactor is the central plaorm in SiliCycle’s advanced system for parallel

synthesis. SiliCycle MiniBlock reactors can be used to yield synthesis products for either high-throughput

or larger volume applicaons.

WARNING : is used to indicate the presence of a hazard which can cause personal

injury or death.

CAUTION : is used to indicate a potenal for damage to equipment

or synthesis results.

TECH TIP : is used to explain a product or operaonal nuance for a more eecve use of

the SiliCycle MiniBlock system.

7

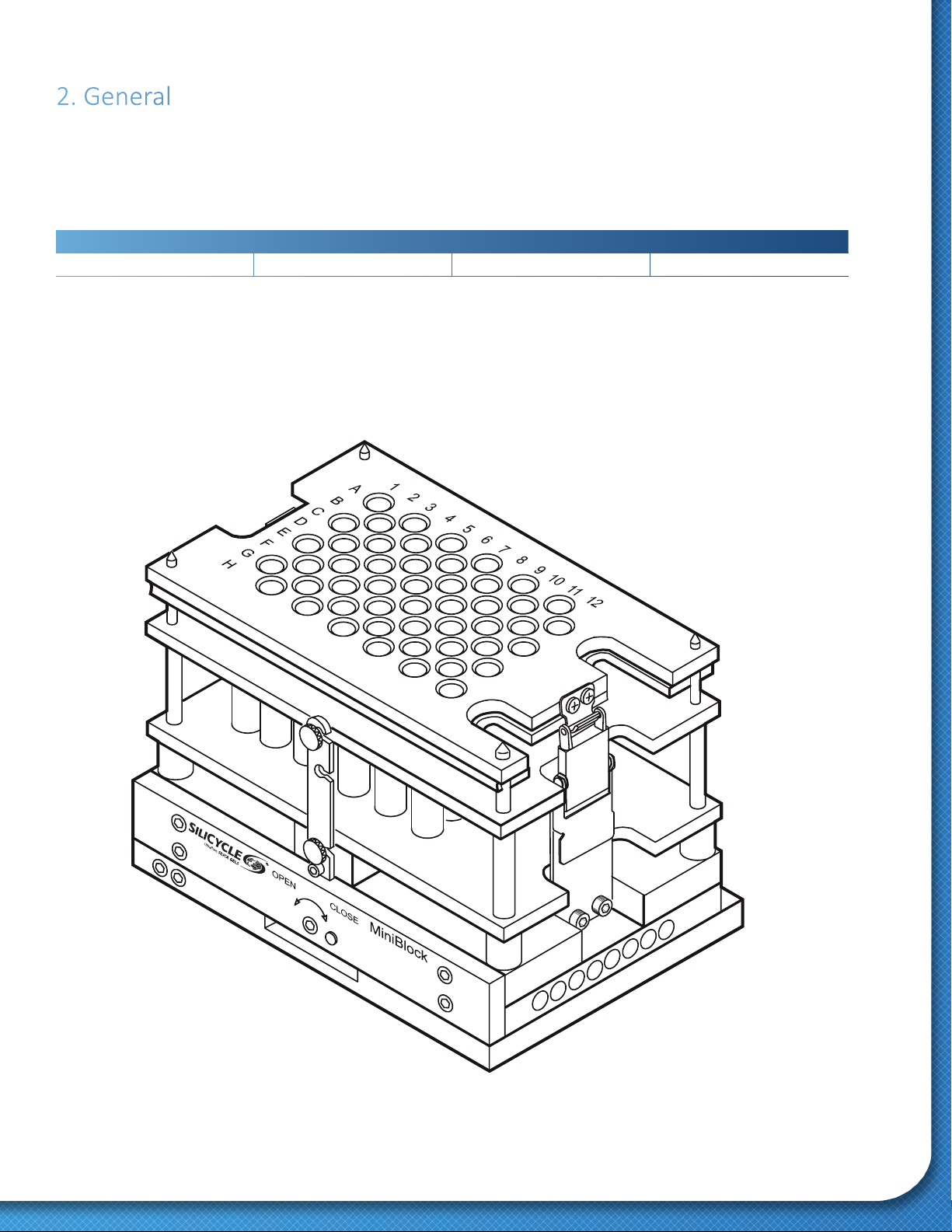

2. General

The SiliCycle MiniBlock is designed to enable the chemist to achieve maximum product yield and purity,

while minimizing the potenal for cross-contaminaon.

The SiliCycle MiniBlock’s patented valve mechanism enables simultaneous boom drainage of all reacon vessels, aided by the use of vacuum

and pressure. Reacon products are then transferred into collecon vessels, or SPE tubes for puricaon.

Ancillary components are used to achieve reacon agitaon and temperature control for the SiliCycle MiniBlock system.

Height Width Depth Weight

5” (13 cm)7” (18 cm)5” (13 cm)6.4 lbs (2.9 kg)

Table 1: MinBlock Physical Descripon

Figure 1: SiliCycle MiniBlock

6

5

4

3

2

1

SiliCycle MiniBlock® User Guide

8www.SiliCycle.com | inf[email protected]om

2.1. The SiliCycle MiniBlock Reacon Tubes

SiliCycle MiniBlock Reacon Tubes are designed as simple yet robust vessels for chemical synthesis. They consist of glass or polypropylene reacon

tubes containing a 20 μm frit for solids ltraon.

Figure 2: Reacon

Tube Components

Figure 3: SiliCycle

MiniBlock Components

Polyethylene

Reacon Tube Cover Plate

Septum Layer

Upper Alignment Plate

Lower Alignment Plate

Blue Teon®

Heat Shrink Sleeve

Large Alignment Pin

Small Alignment Pin

Reacon Tube

20 µm Frit

Pinch Tube

Female Luer Fing

Male Luer Fing

Glass reacon tubes also have a Teon® heat shrink sleeve at the luer p to improve sealing. When using toluene, or other solvents to which

polypropylene is not fully resistant, glass reacon tubes should be used instead.

Figure 4: Glass Reacon Tube

With Teon® Heat Shrink Sleeve

0.5 0.50.5

9

Pinch-Tube Inserts are available in PFA Teon®. PFA Teon® inserts can be used at high temperatures, PFA ngs also provide good chemical

resistance, parcularly to toluene. (Figure 5).

The Reacon Tubes are sealed at the boom by compressing the Pinch-Tubes, which project through the SiliCycle MiniBlock (Figure 6). This closure

is achieved for all Reacon Tubes simultaneously with a single turn of the T-handle valve key (Figure 7).

Reacon Tube

PFA Teon ©

Grey Fings

Figure 6: Valve Mechanism

in Closed Posion

Figure 7: SiliCycle MiniBlock

with Valve Key

Figure 5: Types of Pinch-Tube Inserts

SiliCycle MiniBlock® User Guide

10 www.SiliCycle.com | inf[email protected]om

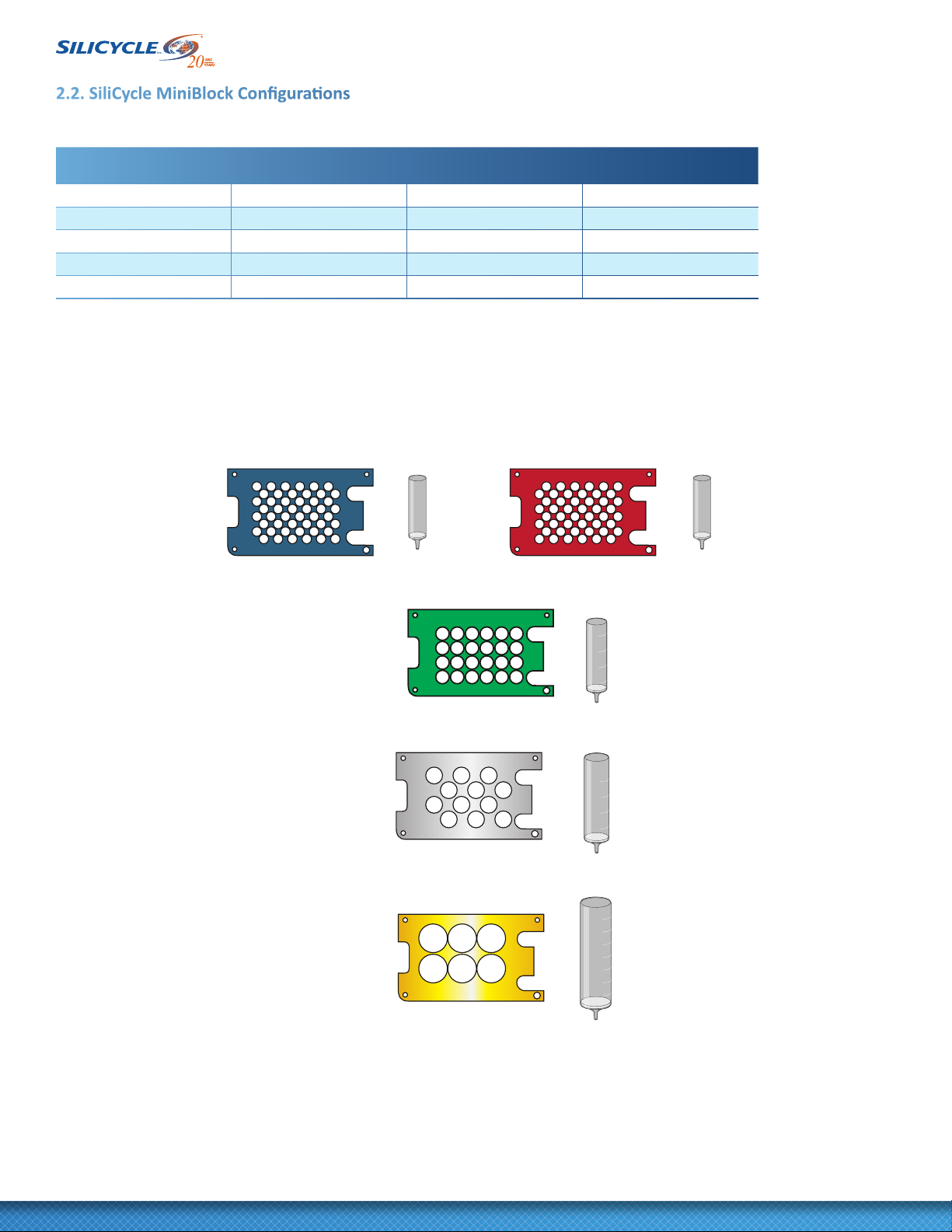

2.2. SiliCycle MiniBlock Conguraons

The base SiliCycle MiniBlock comes as standard with 48 female luer ngs in the base. SiliCycle MiniBlock can be adapted

to any of four basic conguraons:

Reacon Tubes

per SiliCycle MiniBlock

Reacon Tube

Volume (mL)Reacon Tube Material Collecon Format

48 (Blue Block)4Polypropylene or Glass 48 or 96 posions

48 (Red Block)4Polypropylene or Glass 48 or 96 posions

24 (Green Block)10 Glass 24 posions

12 (Silver Block)20 Glass 12 posions

6 (Gold Block)40 Glass 6 posions

Table 2: SiliCycle MiniBlock Conguraons

SiliCycle MiniBlock conguraons, together with the reacon tubes and color-coding are depicted in Figure 8.

Glass reacon tubes are provided with a blue Teon® heat-shrink sleeve at the luer p. This is to improve sealing against the female luer ng:

(Figure 4). Insert glass reacon tubes into Pinch-Tube Inserts gently and carefully to avoid snagging or damaging the Teon® heat-shrink sleeve.

Figure 8: Reacon Tube Conguraons

Blue

Silver

4 mL 4 mL

2

4

6

8

10 mL

4

8

12

16

20 mL

5

10

15

20

25

30

35

40 mL

Red

Gold

Green

11

2.2.1. Ambient Temperature Conguraons

Converng SiliCycle MiniBlock volume conguraons for ambient temperature operaon requires:

• Proper Reacon Tubes

• Corresponding alignment and cover plates

These plates are color-coded (Figure 8) to enable ready idencaon of conguraon components. For 48-Posions SiliCycle MiniBlocks, Black

alignment plates are used for either a Blue or Red SiliCycle MiniBlock.

2.2.2. Plugs for Unused Pinch-Tube Inserts

Red plugs are used to ll unused female luer posions, to hold the vacuum applied beneath the SiliCycle MiniBlock when draining.

Figure 9: Red Plugs Conguraons

2.2.3. Controlled Temperature Conguraons

For temperature controlled reacons, heat transfer blocks are substuted for the alignment plates. The heat transfer blocks are color-coded, as are

the alignment plates, except for the black heat transfer block, which is used with either a Blue or Red 48-Posions SiliCycle MiniBlock. The basic

SiliCycle MiniBlock conguraons with the heat transfer blocks are depicted in Figure 10.

TECH TIP : The two (2) dierent 48-Posions SiliCycle MiniBlocks -

Red and Blue - are actually complementary conguraons.

A Blue block can be collected into half the posions

of a 96 deep well plate; the Red block can then be collected into the

intervening posions of the same 96 well plate (see Figure 11).

Alternavely, either the Red or Blue SiliCycle MiniBlocks

can be transferred into a 48-Posions collecon format.

Use a collecon block of corresponding Blue or Red

to assure proper transfer into the collecon vessels.

Figure 10: SiliCycle MiniBlock Heat Transfer Blocks

Blue block, 6-Posions Blue block, 24-Posions

Blue block, 12-Posions

Red block, 6-Posions Red block, 24-Posions

Red block, 12-Posions

SiliCycle MiniBlock® User Guide

12 www.SiliCycle.com | inf[email protected]om

2.2.4. Combining Red and Blue SiliCycle MiniBlocks Into 96-Well Format

Figure 11: Collecon conguraon 96-Posions

2.3. SiliCycle MiniBlock System Materials

The SiliCycle MiniBlock system is designed and constructed using high quality materials. Understanding of SiliCycle MiniBlock materials is important

when selecng SiliCycle MiniBlock components for a given chemistry.

2.3.1. SiliCycle MiniBlock Metal Components

SiliCycle MiniBlocks are primarily constructed of anodized aluminum and stainless steel. Given proper handling and prompt cleanup of corrosive

or deposit-forming compounds, these materials are very resistant to chemicals and physical wear.

2.3.2. Reacon Tube Materials

4 mL and 10 mL SiliCycle MiniBlock Reacon Tubes are available in either polypropylene or glass. The polypropylene tubes contain high quality

polyethylene frits (average porosity: 20 μm). All glass Reacon Tubes (4, 10, 20 and 40 mL) have 20 μm average porosity frits. Glass reacon tubes

also have a Teon® heat shrink sleeve at the luer p to improve sealing. When using toluene, or other solvents to which polypropylene is not fully

resistant, glass reacon tubes should be used instead.

2.3.3. Pinch-Tube Insert Materials

Pinch-Tube Inserts are available in PFA Teon®. PFA Inserts can be used at high temperatures, when other high temperature components are used.

PFA ngs also provide best chemical resistance, parcularly to toluene. (Figure 5).

Red Reactor

52-Posions

48 Used

96-Well

Collecon Plate

Blue Reactor

13

2.3.4. Septa Materials

The septa used to cover and seal the tops of SiliCycle MiniBlock reactors serve a number of dierent funcons.

They provide:

• Sealing of the Reacon Tubes to minimize evaporaon.

• Uniform compression of the Reacon Tubes to seal the Pinch-Tube Insert luer ngs.

• Septum piercing for reagent addion.

Septa for MiniBlock Top Plate:

• Mul-layer (13820118) – excellent chemical resistance, reduced solvent evaporave loss, readily pierced by automaon. This is the

recommended septum for most applicaons, except those exceeding 80°C.

• Silicone Mul-Layer Septa (13742080) - for reacons requiring high temperatures, up to 160°C.

TECH TIP: SiliCycle MiniBlocks are not designed for pressurized reacons. Do not

perform synthesis at or above solvent boiling points. Pressure buildup

resultant from synthesis can be avoided using an Inert

Atmosphere Manifold (See Secon 3.2.5 Sealing

For Reacons Requiring Inert Condions).

CAUTION: Hot toluene can damage polypropylene. Hot toluene should be used with

glass reactor tubes and PFA Pinch-Tube Inserts.

WARNING: SiliCycle MiniBlock applicaons are limited to a maximum temperature of

80°C, unless high temperature components are used. Consult SiliCycle for

informaon regarding applicaons over 80°C.

SiliCycle MiniBlock® User Guide

14 www.SiliCycle.com | inf[email protected]om

2.4. SiliCycle MiniBlock Temperature Control

Reacon temperatures are adjusted on the SiliCycle MiniBlock using a Heat Transfer Block, which ts closely around each reacon tube (Figure 12).

Heat transfer uid is recirculated through the anodized aluminum Heat Transfer Block, with heat transmied eciently.

A dierent Heat Transfer Block is required for each of the four basic SiliCycle MiniBlock conguraons (48, 24, 12 and 6-Posions) (Figure 10).

Heat Transfer Block

Locking Arm Large Alignment Pin

Small Alignment Pin

Quick Disconnect Fing

Septum Layer

Cover Plate

Figure 12: SiliCycle MiniBlock with Heat Transfer Block

Outlets Inert/Purge Manifold (48-posions)

15

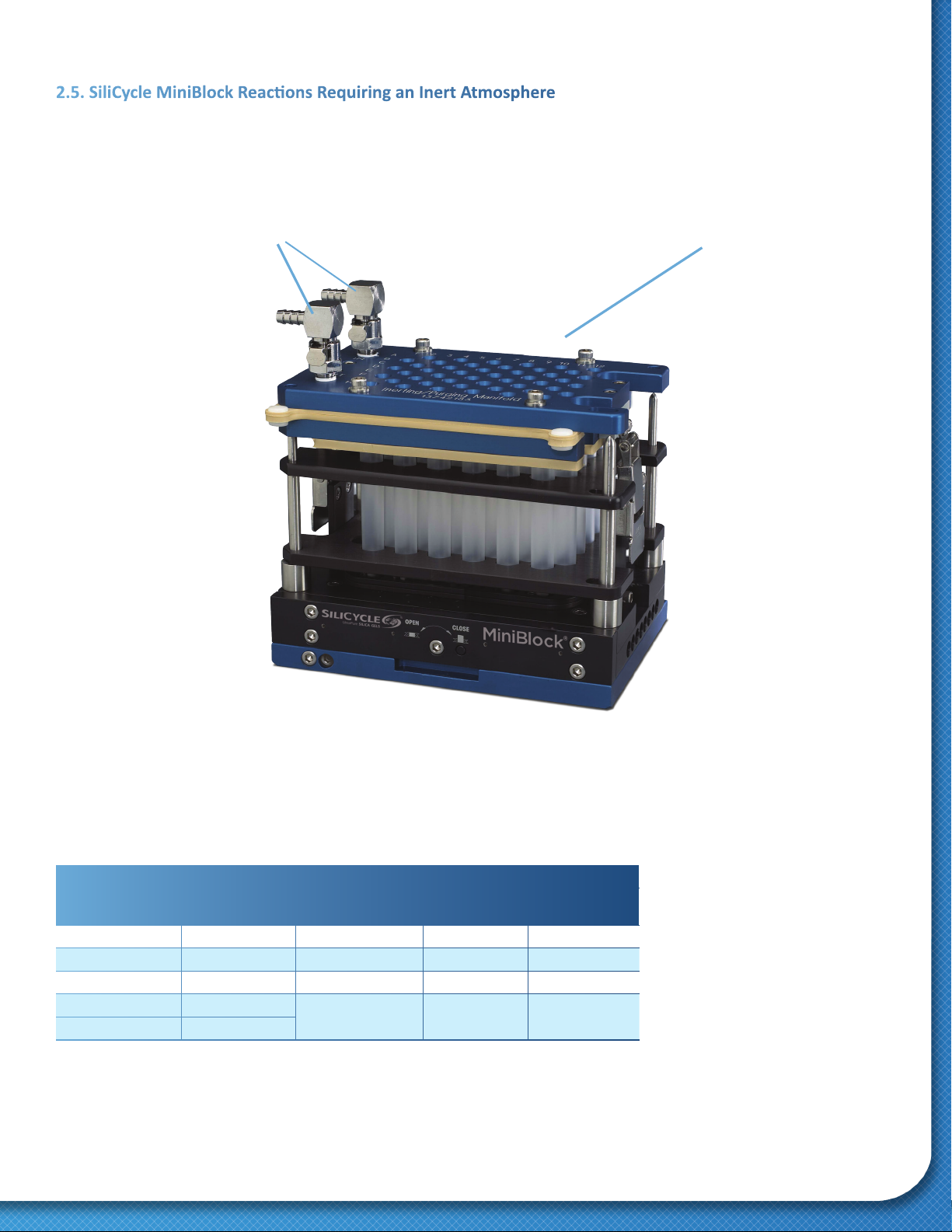

2.5. SiliCycle MiniBlock Reacons Requiring an Inert Atmosphere

For air and / or moisture sensive reacons, the SiliCycle MiniBlock can be ed with an Inert Atmosphere Manifold (Figure 13).

This manifold has a natural rubber septum inside, providing inert gas to individual reactor tubes.

The Inert Gas Manifold septum can also be pierced at each reactor posion with a syringe, without compromising the inert condions

in the reactors.

Figure 13: Inert/Purge Manifold

MiniBlock Format Inert Manifold PN Internal Septum PN

Sealing Gaskets (Bottom Gasket)

Rubber PN Mul-Layer PN

6-posions 13200957 13742152 13200992 13201040

12-posions 13200951 13742169 13200993 13201041

24-posions 13200950 13742170 13200994 13201042

48-posions Red 13742182 13200080 13200079 13200081

48-posions Blue 13742183

SiliCycle MiniBlock® User Guide

16 www.SiliCycle.com | inf[email protected]om

3. SiliCycle MiniBlock Assembly and Reacon Setup

3.1. Pre-Assembly Checks

1. With no reactor tubes inserted, make sure the SiliCycle MiniBlock is clean and that plugs are inserted in Pinch-Tube Inserts for unused posions.

The Pinch-Tube Inserts should be inserted uniformly ush to the base of the SiliCycle MiniBlock. The «keyhole» alignment plate should be secured

to x the posion of all Pinch-Tube Inserts. See secon 6.2.1 Replacement of Pinch-Tube Inserts for detailed instrucons.

2. Use the T-handle Valve Key (5/32’’ hex key) to check that the valve mechanism slides freely (Figure 14). Be certain that the SiliCycle MiniBlock has

been stored with the valve in the «open» posion. If the valve was closed, see secon 6 Maintenance before proceeding.

3. Inspect the Pinch-Tubes (the part of the Pinch-Tube Inserts which projects through the base of the SiliCycle MiniBlock) on the boom of the SiliCycle

MiniBlock (Figure 15). All Pinch-Tubes should be extending through the boom of the SiliCycle MiniBlock by 3-5 mm. (Figure 16.) This extension is

important to prevent cross-contaminaon in later transfer steps. Reinsert or replace any Pinch-Tubes that do not extend through the base properly.

See secon 6.2.1 Replacement of Pinch-Tube Inserts for detailed instrucons.

Figure 14: Slide Valve Operaon

17

Figure 15: Inspecng Pinch-Tubes

Figure 16: Pinch-Tube Extension

Tall Tube Extender

Spacer

3-5 mm

Collecon Base

SiliCycle MiniBlock® User Guide

18 www.SiliCycle.com | inf[email protected]om

3.2. SiliCycle MiniBlock Assembly

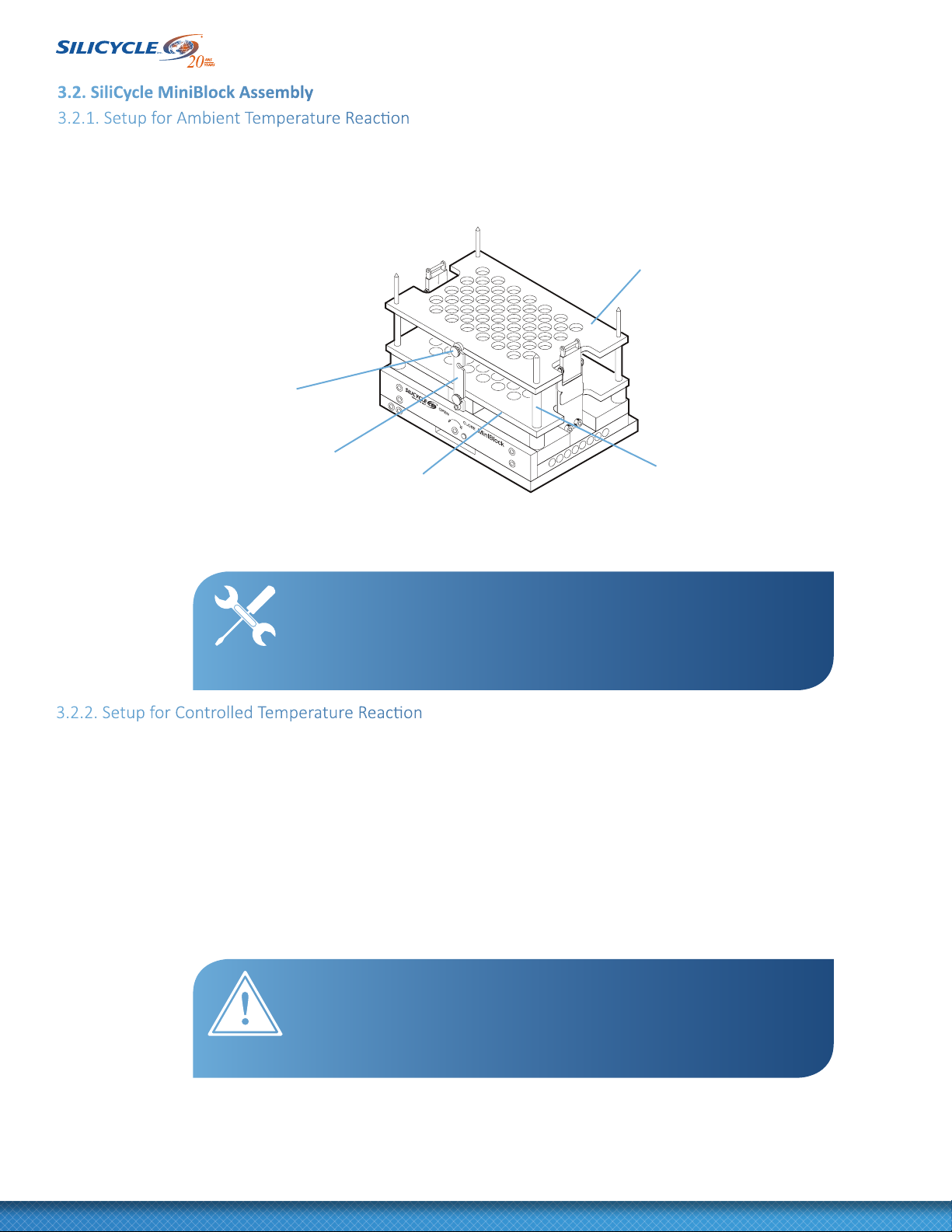

3.2.1. Setup for Ambient Temperature Reacon

1. Place the corresponding colored lower Alignment Plate on the SiliCycle MiniBlock, followed by the upper alignment plate (Figure 17). Note that

these plates have hole sizes corresponding to SiliCycle MiniBlock alignment pins, which make it possible to only posion the lower plate at the

boom and the upper Alignment Plate at the top.

2. Secure the Alignment Plates on either side of the SiliCycle MiniBlock, by turning front and back locking arms into posion and ghtening

thumbscrews.

Figure 17: Alignment Plates Installed

3.2.2. Setup for Controlled Temperature Reacon

1. With no alignment plates on the SiliCycle MiniBlock, place a Heat Transfer Block of the corresponding color over the Alignment Pins. Be sure to

orient the large alignment hole of the Heat Transfer Block with the large alignment pin on the SiliCycle MiniBlock.

Red and Blue SiliCycle MiniBlocks require a Black (48-Posions) Heat Transfer Block. The 24, 12 and 6-Posions SiliCycle MiniBlocks have color-coded

Heat Transfer Blocks (Green for 24-Posions, Silver for 12-Posions, Gold for 6-Posions).

2. Secure the Heat Transfer Blocks on either side of the SiliCycle MiniBlock, using front and back locking arms and thumbscrews (Figure 18).

TECH TIP: The SiliCycle MiniBlock has one large alignment pin, which prevents

installaon of the alignment plates in any way other than the intended

orientaon. Do not force the alignment plates or other SiliCycle MiniBlock

components onto the SiliCycle MiniBlock. Proper orientaon with respect to

the large alignment pin permits all components to slide on easily.

Upper Alignment Plate

Lower Alignment Plate

Thumb Screw

Front Locking Arm

Large Alignment Pin

WARNING: Keeping alignment plates or heat transfer blocks secured with the front

and back locking arms is important to safe operaon. Liing an unsecured

SiliCycle MiniBlock by the plates or heat transfer block could result in block

slippage and potenal chemical spillage or contact, as well as physical injury.

19

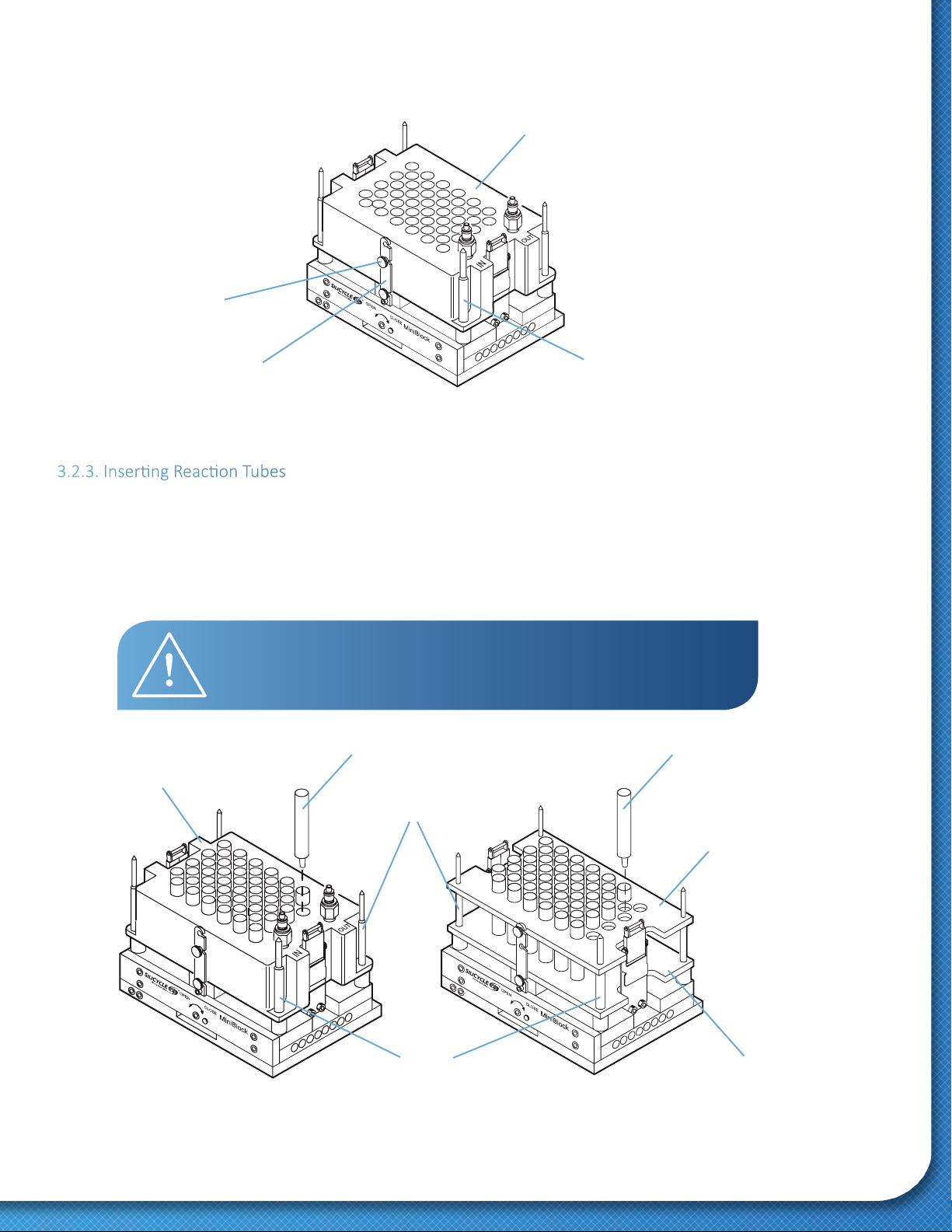

3.2.3. Inserng Reacon Tubes

1. Insert the appropriate Reacon Tubes into the available posions on the SiliCycle MiniBlock (Figure 19). A full complement of Reacon Tubes is

required; all posions must be occupied to assure uniform sealing.

2. Ensure the luer ps of the Reacon Tubes are fully and evenly posioned in the female luer ngs of the Pinch-Tube Inserts (Figure 20).

The luer ngs are compressed together by installaon of the septum and cover plate, or inert atmosphere manifold.

Upper Alignment Plate

Heat Transfer Block

Reacon TubeReacon Tube

Small Alignment Pin

Heat Transfer Block

Lower Alignment Plate

Thumb Screw

Front Locking Arm Large Alignment Pin

Large Alignment Pin

Figure 18: Heat Transfer Block Installed

CAUTION: Take care inserng glass reacon tubes, so the Teon®

heat shrink sleeves are not snagged or damaged.

Figure 19: Insert Reacon Tubes

SiliCycle MiniBlock® User Guide

20 www.SiliCycle.com | inf[email protected]om

Figure 20: Male / Female Luer Fing

3.2.4. Sealing for Reacons Not Requiring Inert Condions

1. Select the appropriate septum for your applicaon (see secon 2.3 SiliCycle MiniBlock System Materials). Mul-layer or laminated septa

should be placed over Reacon Tubes with the Teon® side down and the largest end notch ed to the large alignment pin.

2. Place the appropriately colored cover plate over the Reacon Tubes, being careful to correctly orient the plate

on the large alignment pin (Figure 21).

Reacon Tube

Female Luer Fing

Valve Insert

Spring Clamp

Lower Alignment Plate Upper Alignment Plate

Figure 21: Seang Reacon Vessels

Cover Plate

Septum Layer

Large Alignment Pin

Locking Arm

Table of contents

Popular Laboratory Equipment manuals by other brands

Smeg

Smeg GW0160 Technical manual

Seiler

Seiler Coolscope 985 LED owner's manual

Markes International

Markes International HiSorb Agitator U-HSAG-20 Instructions for use

DDS Calorimeters

DDS Calorimeters CAL3K-F installation guide

Azure Biosystems

Azure Biosystems Cielo AIQ030 user manual

Nikon

Nikon NWL860 Series manual