SILLA DB 3000 Installation and operation manual

GB Operating, maintenance manual

Macchine Edili e Stradali s.r.l.

Via S,Gimignano n°96 Poggibonsi (SI) –Italy

REL. 04 Date Juli 11, 2018

TRUCK MIXER DB 3000/4000/4500 HYDROSTATIC GB

User Manual Rel. 4 of 11/07/18 Page 2 of 20

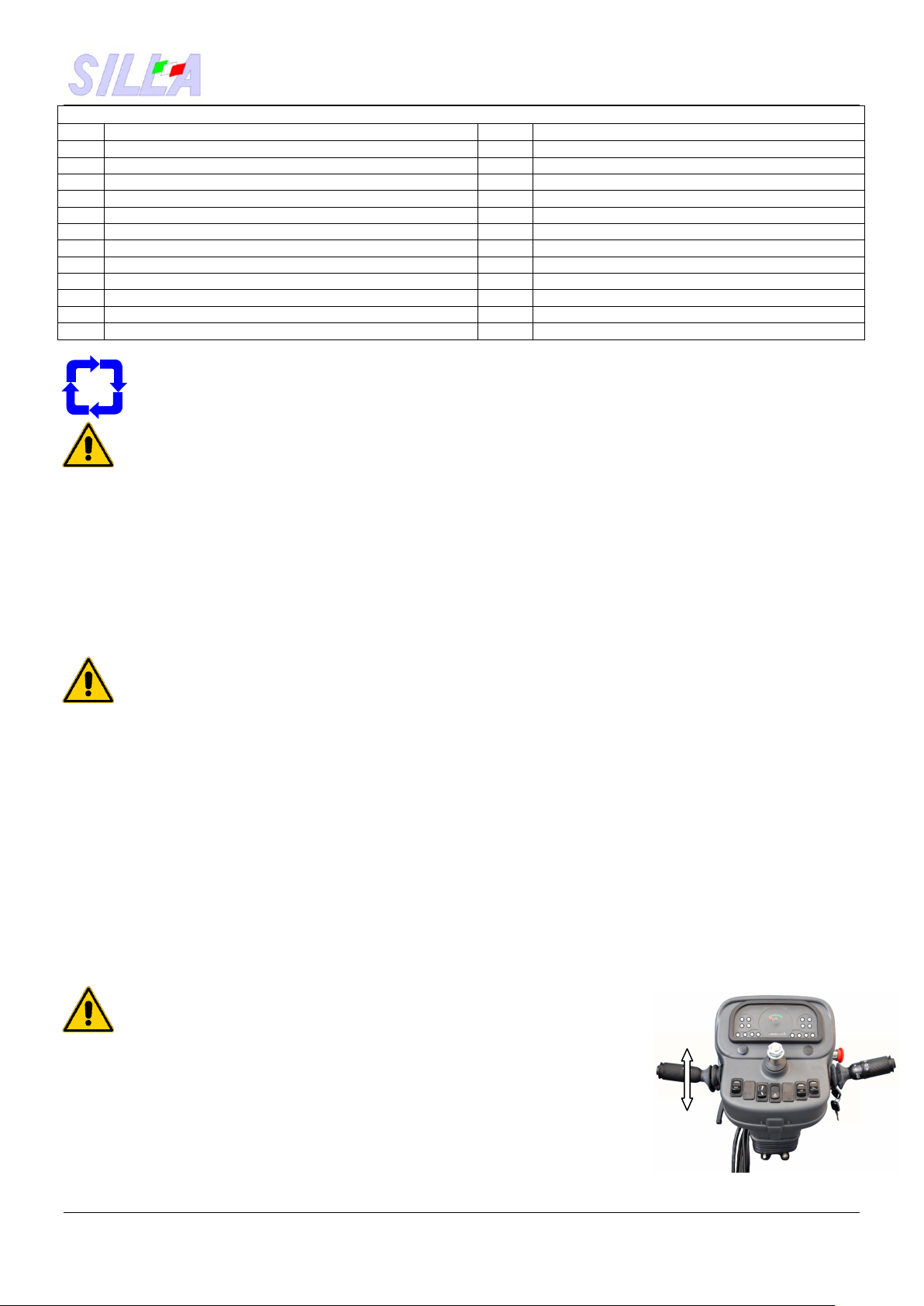

INDEX

Page

7.5.6

Indicators dev.

14

7.5.7

Headlights/Horn switch

14

7.5.8

Accelerator pedal

14

7.5.9

Brake pedal

14

7.5.10

Parking brake lever

14

7.5.11

Direction reversing lever

14

7.5.12

Drum lifting lever

15

7.5.13

Shovel arms drive lever

15

7.5.14

Grab bucket drive lever

15

7.5.15

Water pump lever

15

7.5.16

Drum rotation lever

15

7.5.17

Driver’s seat rotation

15

7.6

Use of the machine

15

7.6.1

Starting the engine

15

7.6.2

Stopping the engine

15

7.6.3

Starting the mixer

15

7.6.4

Auto-loader

16

7.6.5

Water system

16

7.6.6

In action on the construction site

16

8

MAINTENANCE

16

8.1

Routine and extraordinary maintenance

16

8.1.2

Daily maintenance

16

8.1.3

Weekly maintenance

16

8.1.4

Maintenance to be performed every 15 days

16

8.1.5

Maintenance to be performed every 100 hours

17

8.1.6

Maintenance to be performed every 2000 hours

17

8.2

Corrective maintenance

17

8.2.1

Troubleshooting

17

8.3

Maintenance of hydraulic system

18

8.3.1

Check the brake pedal

18

8.3.2

Check the parking brake

18

8.3.3

Check the tires

18

8.3.4

Spare parts

18

9

DISMANTLING

18

9.1

Disassembling and dismantling

18

9.2

Disposal

18

11

WARRANTY REGISTRATION FORM

19

1. INTRODUCTION This manual is directed at the user and operator who will be responsible for the

safe, efficient and trouble free operation of the machine. Read and understand this manual and always follow the safety

precautions stated in the chapters General Precautions and Operation. Keep this manual handy for frequent reference and to

pass on to new operators or owners. The machine is equipped with tested special safety devices and safety systems. SILLA

cannot be held responsible for unauthorized modifications or procedures, replacements and/or all other modifications changing

the use the machine has been designed and manufactured for.

Warranty: The mechanical and electrical products of the machine, which are not normal service items, have a one-year

warranty starting from the date of the sale. The warranty does not cover the normal service items like tools, driving belts, liquids

and oils. The defective or not properly working products will be replaced by the Technical Personnel of the Manufacturer of the

machine, after the defective product has been proven to be defective. The warranty does not cover the products in case of

modification, abuse, misuse, improper use, negligence or improper maintenance (routine and extraordinary maintenance) as

shown by this I.M. This warranty is valid in the territory of the European Community. The consumer is the right holder according

to the applicable national laws governing the sale of consumables and this warranty makes those rights unprejudiced.

2. MARKING A label with the following machine identification data is installed on the machine:

- Name and address of the manufacturer and/or legal representative in Europe; - Machine type; - Serial or part number; - Year

of construction; - Weight of the machine. - Max. rating; - Ready mixed product in litres; - Loading capacity.

For assistance and information or spare parts SILLA Macchine Edili e Stradali

refer to: Via S.Gimignano , 96

53036 –POGGIBONSI (SI) - ITALY

Tel. ++39-0577 - 938051 Fax. ++39-0577 –981609

E-mail: info@sillaitaly.com Web Site: www.sillaitaly.com

This Instruction Manual and all the enclosed documents are freehold property of the Company SILLA.

INDEX

Page

1

INTRODUCTION

2

2

MARKING

2

3

GENERAL PRECAUTIONS

3

4

CHARACTERISTICS

3

4.1

Description of the machine

3

4.2

Dimensions and technical

characteristics

4

4.3

Safety instructions

4

5

INSTALLATION/NEW SITE

5

5.1

Transport

5

5.2

Placing and how to leave the

machine

5

5.3

Areas of respect and overall dimens.

5

5.4

Preparations before use

6

5.5

Safety first

6

5.6

Putting into operation

6

5.7

Training

6

6

ADJUSTMENTS

6

6.1

Adjusting the machine

6

6.2

Adjusting the parking brake

6

6.3

Adjusting the seat

6

7

CONTROL INSTRUMENTS

7

7.1

Warning lights

7

7.2

Controls

7

7.3

Water system

8

7.4

Electrical and hydraulic diagrams

8

7.4.1

Relay/fuse box

8

7.4.2

Gear case wiring

9

7.4.3

Column wiring

10

7.4.4

Service junction box

11

7.4.5

Separate facility for oil coolers

12

7.4.6

Hydraulic diagram

13

7.5

Operation and controls

14

7.5.1

Steering wheel

14

7.5.2

Starting switch

14

7.5.3

Hour meter

14

7.5.4

Rotary lamp switch

14

7.5.5

Warning lights switch

14

TRUCK MIXER DB 3000/4000/4500 HYDROSTATIC GB

User Manual Rel. 4 of 11/07/18 Page 3 of 20

Reproduction (in any form or way inclusive recording and photocopy) in whole and/or part is forbidden without

the written authorisation of the Company SILLA. In case this Instruction Manual should get lost or destroyed ask the

Company SILLA for a complete copy.

Caution! Precautions and instructions to be strictly followed.

3. GENERAL PRECAUTIONS

The operating safety of the machine is only granted for the functions listed in this instruction manual.

SILLA cannot accept any responsibility, if the machine should be used for different uses than those listed in this

manual or those, which do not comply with the operating instructions.

SILLA cannot accept any responsibility for safety, liability and performances of the machine, if the precautions and the

instructions of this instruction manual, especially referred to: use, in the construction site and on the road (only for homologated

vehicles), maintenance and dismantling are disregarded.

The operating safety is only guaranteed for the functions listed in this instruction manual.

SILLA cannot accept any responsibility, if the machine is used for other purposes than those stated in this manual and which

do not comply with the operating instructions.

For all repairs, please refer to the After-Sales Service authorised by the supplier of the machine. The user of the machine is the

only responsible for its good and safe operation, if the machine was not repaired or maintained by the specialized or authorised

personnel.

For special maintenance and repairs use only original spare parts.

All these operations must be performed in a suitable location, with the machine turned OFF, taking care to remove the ignition

key from the panel in order to avoid inappropriate starting (by other peopled) and with the parking brake applied.

All the operators using the machine shall be trained on its correct use, the warning devices, the behaviour and actions to

maintain for the proper use of the machine, assuring either their personal or other’s safety.

The machine is delivered with by the operator himself. Check and maintain these protection devices and the machine

according to the maintenance schedule. The operator shall be cautious in using the machine when the drum and the bucket

are moving and when approaching with his hands, and particularly:

DO NEVER TURN ON THE MACHINE WITHOUT THE PROTECTION SHIELDS;

DO NEVER REMOVE AND NEVER OPEN THE PROTECTION SHIELDS WHILE THE MACHINE IS RUNNING.

Ensure good lightening in the work area and around the machine, in order to avoid shady areas, dangerous dazzling and

stroboscopic effects.

Before starting any work, check the work area for any unauthorised persons or obstacles.

The operator shall wear appropriate clothing: work gloves, protective helmet, safety shoes, and respiratory protection. Do not

wear any jewellery or clothing that can get caught or distract from the operation of the machine.

Follow the safety instructions, in particular: Turn off the machine before opening or cleaning it; ensure no one can turn it on by

accident; Use the protective equipment (work gloves, ear muffs, safety shoes, respiratory protection) during use, assembly and

maintenance of the machine;

Be cautious in approaching all the moving parts. - Before starting work and turning on the machine, CHECK: - the work area (5

metres all around the machine) for any persons or obstacles.

Follow the safety instructions shown in chapter SAFETY PRECAUTIONS.

4. CHARACTERISTICS

4.1 Description of the machine The truck mixers for the construction sites are designed,

manufactured, tested and sold by the company Silla. These machines are designed for loading aggregate,

mixing and transporting the concrete on construction sites.

The main feature of these machines is that they are very simple, strong and reliable. The peculiarity of the

articulated frame and the permanent four-wheel drive allow it to operate on all types of terrains ensuring safety and reliability

over time. The auto-loading arm with the grab bucket and the mixing drum, make the machine reliable. A quick check in the

morning will give you a faithful and safe fellow worker all day. The driver’s seat allows excellent visibility in any position, and the

operator has full control of the controls and of the central diagnostic panel.

TRUCK MIXER DB 3000/4000/4500 HYDROSTATIC GB

User Manual Rel. 4 of 11/07/18 Page 4 of 20

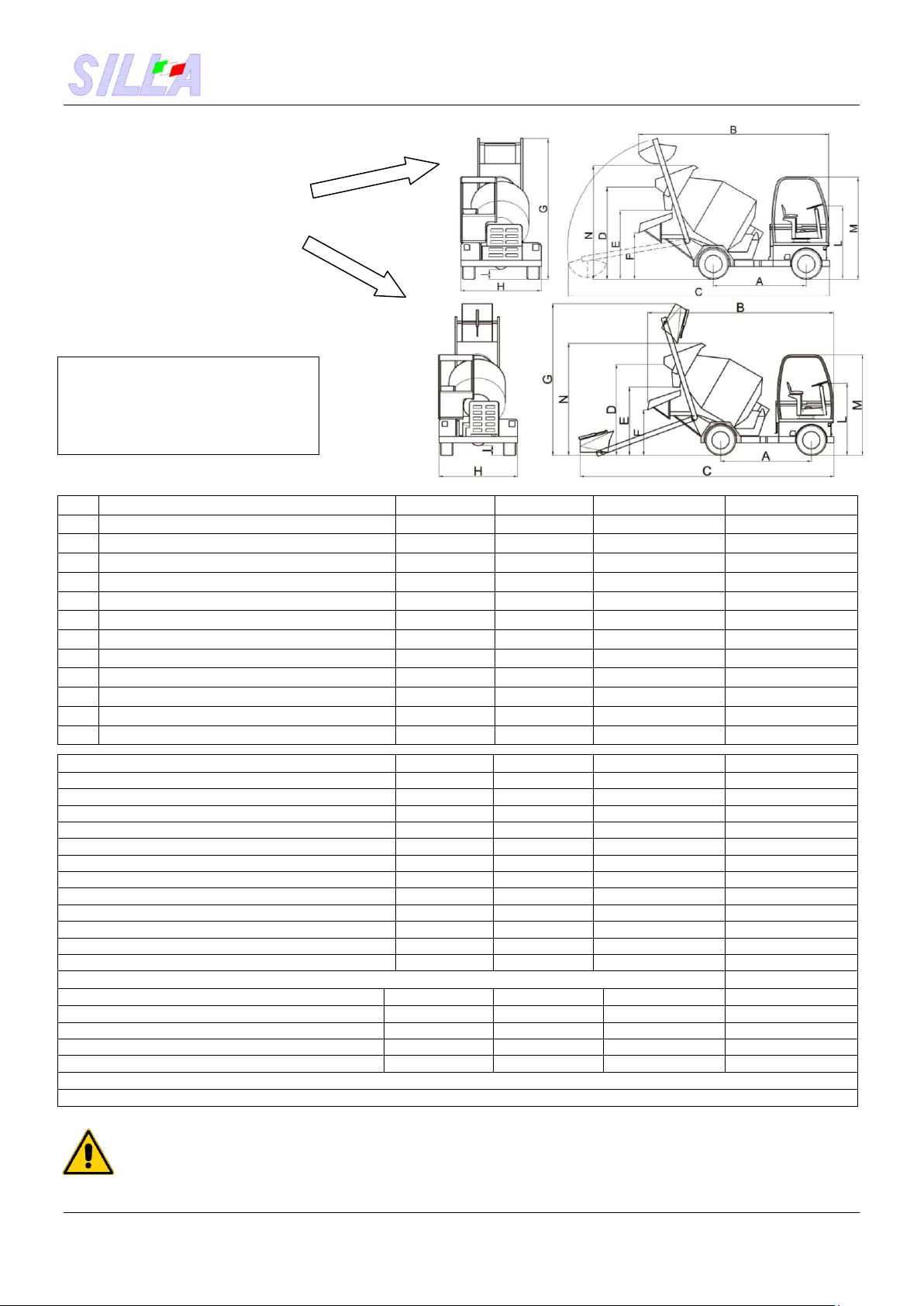

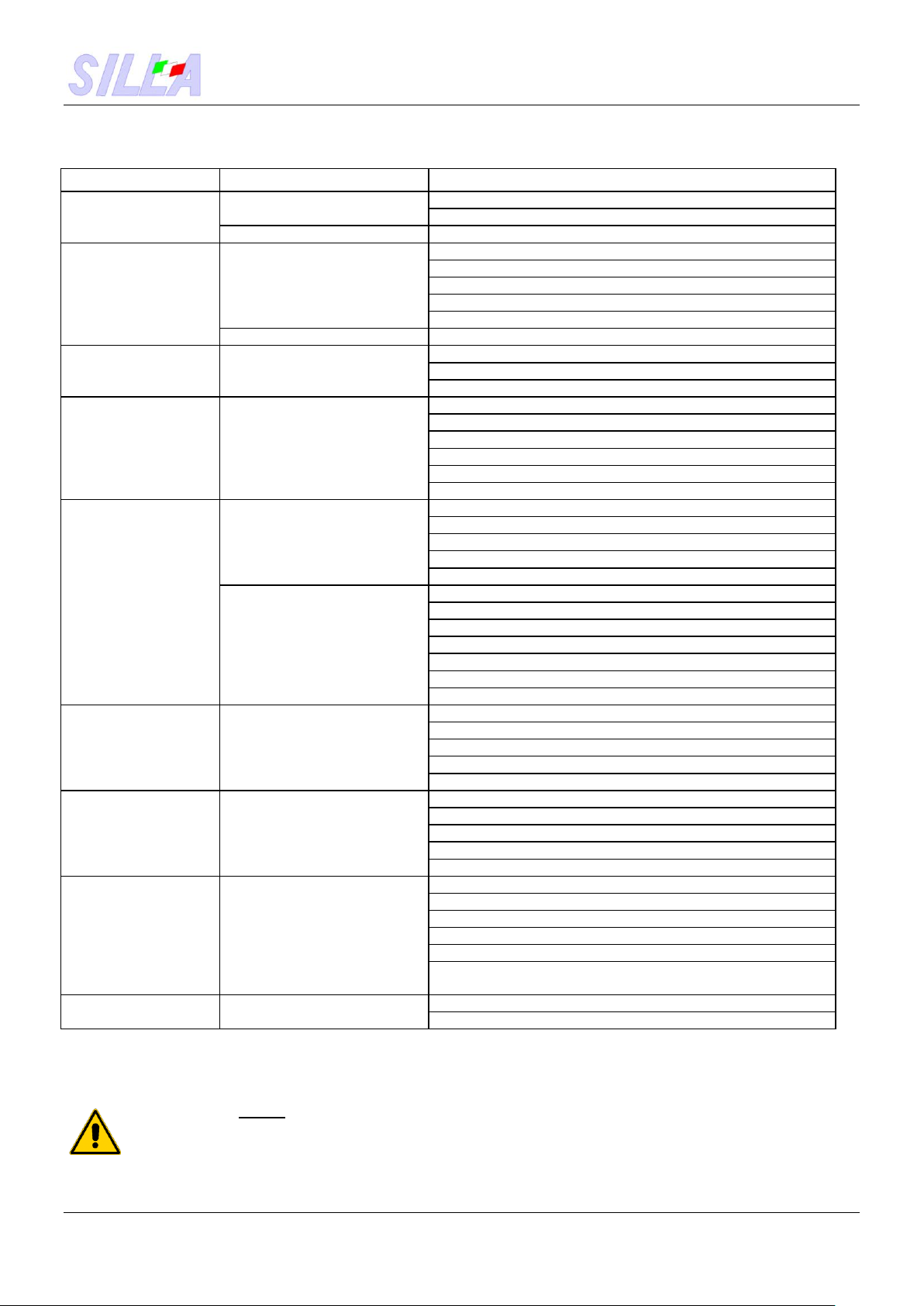

4.2 Overall dimensions:

GRAB SYSTEM

SHOVEL

WARNING |

Approximate measurements,

In particularly those in height,

may vary depending on

wheel mounted.

DIMENSIONS

DB 3000

DB 4000

DB 4500

DB 4500

A

AXLE SPACING

2700mm

2700mm

2700mm

2720mm

B

MINIMUM LENGTH

5300mm

5300mm

5300mm

5500mm

C

MAX. LENGTH (With bucket on the ground)

7150mm

7150mm

7150mm

7800mm

D

HOPPER HEIGHT

2600mm

2600mm

2580mm

2580mm

E

CONVEYOR HEIGHT

2000mm

2000mm

19800mm

2100mm

F

MAX. UNLOADING HEIGHT

1620mm

1620mm

1617mm

1617mm

G

MAXIMUM HEIGHT

3200mm

3750mm

3750mm

4100mm

H

MAXIMUM WIDTH

2270mm

2270mm

2420mm

2420mm

I

MIN. HEIGHT FROM THE GROUND

320mm

320mm

320mm

320mm

L

STEERING WHEEL HEIGHT

2520mm

2520mm

2520mm

2600mm

M

CABIN WHEL

3000mm

3000mm

3050mm

3050mm

M

MAXIMUM HEIGHT HOPPER

3015mm

3015mm

3020mm

3020mm

TECHNICAL CHARACTERISTICS

DB 3000

DB 4000

DB 4500

DB 4500

DRUM CAPACITY

3000Lt

4000Lt

4500Lt

4500Lt

MIX CAPACITY

2400Lt

3000Lt

3500Lt

3500Lt

GRAB BUCKET CAPACITY

270Lt

270Lt

270Lt

500Lt

WATER RESERVOIR CAPACITY

650Lt

650Lt

650Lt

650Lt

UNLADEN WEIGHT

5600Kg

6000Kg

6450Kg

MAXIMUM LOAD

5500Kg

6500Kg

7700Kg

7700Kg

DRIVE

Hydrostatic

Hydrostatic

Hydrostatic

Idrostatica

FORWARD/REVERSE SPEED

2/2

2/2

2/2

2/2

MAXIMUM SPEED

25 Km/h

25 Km/h

25 Km/h

25 Km/h

GRADEABILITY AT FULL LOAD

30%

30%

30%

30%

BRAKES

Disc brakes

Disc brakes

Disc brakes

Freni a disco

TYRES

12,5/80-18

12,5/80-18

405/70 R20”14PR

405/70 R20”14PR

MOTOR

DB 3000

DB 4000

DB 4500

DB 4500

MAX. ENGINE POWER

HP102

HP102

HP102

HP102

NUMBER OF CYLINDERS

4

4

4

4

COOLING SYSTEM

Water

Water

Water

Water

FUEL TANK CAPACITY

55Lt

55Lt

55Lt

55Lt

OPTIONAL

LOADING SYSTEM WITH SHOVEL, HALF CAB, CLOSED CAB, AGGREGATE SCALE

4.3 SAFETY INSTRUCTIONS Limits for use, space, life. The machine has been designed and

built for use on open-air construction sites, according to the climate conditions with reference to the previous para.

(4.2). The machine must never be used in underground excavations, in areas at risk for explosions or fires, in closed

places. The machine is designed and built for transporting concrete, sand, pebble gravel, cement, and water and for use on

Attention !!!! Concrete dosed at

350 kg/m3(plastic consistency S2)

concrete volume can vary according

to the local granulate, grain size,

porosity and percentage and humidity

of sand.

TRUCK MIXER DB 3000/4000/4500 HYDROSTATIC GB

User Manual Rel. 4 of 11/07/18 Page 5 of 20

construction sites only. Ensure the areas of respect of the machine according to the range and the working areas involved. The

machine has an attachment for towing. It’s absolutely necessary for the proper performance of the machine and the security

that the towing weight of 1500kg is not exceeded. Otherwise SILLA is not responsible for any damage that may be caused.

Never carry passengers. The machine is designed and built to carry only the operator / driver.

Working on hilly terrain can be dangerous.

Always operate in the low gears, do not move downhill with the engine off or with the transmission in neutral.

In condition of darkness pay attention to the work area and help yourself with all the lighting devices at your disposal.

It can be dangerous to leave the machine unattended in public places; place barriers around the work area, to keep away

unskilled people.

In case of maintenance, the raised arms of the bucket may fall suddenly; install a safety arm before working under the same.

Diesel fuel is flammable.

Before connecting or disconnecting an electrical component, be sure to be familiar with the electrical system. An incorrect

connection may cause injury and damage.

A battery with frozen electrolyte can explode if used or charged. Do not use the machine with frozen battery and do not

recharge it. To prevent freezing, keep the battery fully charged.

The battery electrolyte is toxic and corrosive. Do not inhale gases from the battery. Keep the electrolyte away from clothing,

skin, mouth and eyes. Wear safety goggles.

The machine is grounded to the negative pole of the battery.

Always ground the negative terminal of the battery. When connecting the battery the ground cable (-) must be connected last.

When disconnecting the battery the ground cable (-) must be disconnected first.

Always remember that the oil is a special waste and shall be disposed of according to the terms of

the law.

CAUTION!!!!!! EVERY USE OF THE MACHINE DIFFERENT THAN THOSE STATED BY THE MANUFACTURER

IN THIS INSTRUCTION MANUAL IS AN IMPROPER USE. THEREFORE, THE COMPANY SILLA CANNOT ACCEPT ANY

RESPONSIBILITY, IF THE MACHINE SHOULD BE USED BY THE OPERATOR FOR DIFFERENT USES THAN THOSE

LISTED IN THIS INSTRUCTION MANUAL OR THOSE NOT COMPLYING WITH THE OPERATING INSTRUCTIONS.

5. INSTALLATION/NEW CONSTRUCTION SITE

5.1 Transport Caution!! The truck mixers are shipped with two wheels off, to unload them from

the container, provide a plane at the same level as the Container, otherwise the machine may be

damaged. The top or cab are disassembled, so you just have to mount them, connect the flashing lamp with

the special connector, turn the battery cut-off switch to the ON position (because it was set to OFF during

transport) and refuel.

The strength of the machines, their shape and size, are such to ensure transport and storage safely and without damage. The

weight of the machines is shown on the CE plate; the weight being relevant, be very careful when loading and unloading. Make

sure that the vehicle, which transports the truck mixer and the loading ramps, has adequate size and capacity. Always stop the

wheels of the truck with wedges before loading or unloading the truck mixer.

Fix the ramps to the truck and drive the truck mixer on it with due caution. Switch off the engine, remove the ignition key, pull

the parking brake and insert the battery cut-off switch. Remove the ramps, fix the wheels of the truck mixer with wedges, and

tie the machine to the means of transport. The truck mixer has no specific points of anchorage; therefore tie the frame with

straps. The machine is delivered with the following accessories:

- 1 Manual for use, maintenance and spare parts; - 1 Instruction manual of Engine Manufacturer;

- 1 Hand pump equipped for greasing; - 1 Socket wrench for wheel assembly;

It is recommended to take all precautions during loading-unloading and transport, in order to avoid danger

and damage to people and machine. The loading and transport devices must be designed and approved in

accordance to the weight to be supported. Never lift the machine, it is too dangerous.

Follow the safety instructions shown in chapter SAFETY PRECAUTIONS.

5.2 Placing and how to leave the machine The machine must be placed / parked in a flat area

of the construction site, where it can be: Covered –Washed –Stored –Upket.

Provide in the area of placement of the machine: -Power supply; -Lighting;

-Water supply. - Ensure an area of respect around the machine of at least 2 meters.

The machine must be placed in areas without gas, explosive materials and/or highly flammable materials.

Follow the safety instructions shown in chapter SAFETY PRECAUTIONS.

The use of the machine by unauthorized personnel is not allowed.

5.3 Areas of respect and dimensions The working space needed for correct use and proper

maintenance is at least 5 metres, that is the area of respect around the machine, within which you must pay close

attention to both people and things, thus avoiding obstacles while using the machine.

Working debris may make the driver’s seat slippery. Use personal protective equipment such as safety shoes

and provide periodic cleaning of the floor.

Warning: the use of chemicals, shampoos or products to clean the machine can be harmful to a person’s

TRUCK MIXER DB 3000/4000/4500 HYDROSTATIC GB

User Manual Rel. 4 of 11/07/18 Page 6 of 20

health. Carefully read the instructions of the product used. They can also modify the quality of the painting of the truck

mixer and damage its hydraulic parts, then use carefully.

5.4 Preparations before use. Use protective gloves when preparing and putting into use.

Check levels of engine oil, clutch and brake fluid, hydraulic oil. Check refuelling so as to avoid having to stop work.

Check tire pressure and their condition of use.

Clean shoes and steps from mud and grease before getting on the machine. Be sure of perfect visibility from the driver’s seat

and that the warning labels and the various accident prevention devices are clearly visible. Wear ear protections.

5.5 Safety first. All machines can be dangerous. When a truck mixer is properly used and maintained, it is an

extremely safe machine.

If the machine is used incorrectly, it can be rather dangerous. Both in this manual and on the machine you will find the

warnings, indicating all the potential dangers and how to avoid them. If you have any doubts, ask your dealer or your direct

manager for explanations. Do not work with the machine until you are able to control it. Do not start any work until you are

certain of your and other’s safety. You may run into accidents if you perform unfamiliar operations without prior testing, which

must be carried out in free areas, away from other people and on level ground.

Follow the safety instructions shown in chapter 4.3 SAFETY PRECAUTIONS.

5.6 Putting into operation Before putting the machine into operation, especially the very first time, or

when it is installed on a new work place, carry out the following preliminary checks and keep in mind the following

technical warnings and tips: -Check oil level;

-Check tire pressure and condition of use; - Check the area of respect and the workspaces;

-Check that the protections are set correctly; -Check that the indications and warning signs are placed on the

machine and are easily visible. -Carry out a general test of all mechanical and electrical controls of the machine, so

as to check their accuracy, efficiency and operation; - Check levels of engine oil, clutch and brake fluid, and hydraulic fluid; -

Check refuelling so as to avoid having to stop work.

5.7 Training Before using the machine, read carefully this instruction manual and understand how

to use the machine in a safe way.

6. ADJUSTMENTS

6.1 Adjusting the machine At first operation on the construction site, the machine does not need any

adjustments. Verify only the points defined in: 5.4 Preparations before use.

Never carry out adjustments with the machine running/operating. Follow the safety instructions shown in

chapter SAFETY PRECAUTIONS. Every single adjustment and/or modification of the safety/work parameters

set on the machine, which has not been authorised by the technical personnel of the company SILLA or

which is not stated in this instruction manual, may influence the quality of the product and injure the operator’s health.

The company SILLA declines any responsibility for liability, performances and safety of the machine in case of

modification/alteration of the machine and of the relevant operation/safety parameters.

6.2 Adjusting the parking brake

Brake adjustment is carried out directly on the brake lever. By turning the knob of the brake lever you can adjust by loosing or

tightening. To get a proper adjustment, the stress on the brake lever must be of 10Kg.

Avoid “playing” with the brake knob, you may modify it and when necessary it will not work properly.

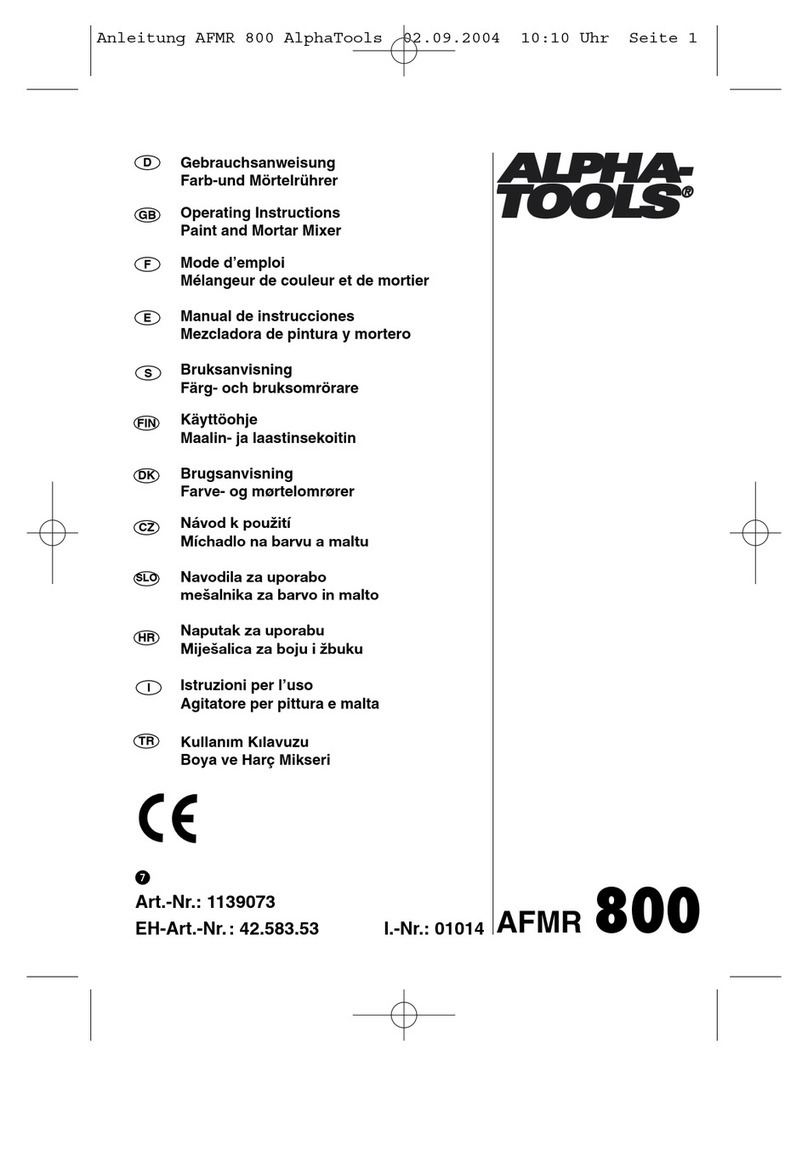

6.3 Adjusting the seat Forward-backward adjustment.

The seat can be moved back and forth to adjust the distance of the pedals: the

operator must be able to press the pedals while keeping his back resting

against the seat. To adjust the seat position, act on the indicated lever and slide

the seat in the ideal position.

Make sure that the seat is locked.

TRUCK MIXER DB 3000/4000/4500 HYDROSTATIC GB

User Manual Rel. 4 of 11/07/18 Page 7 of 20

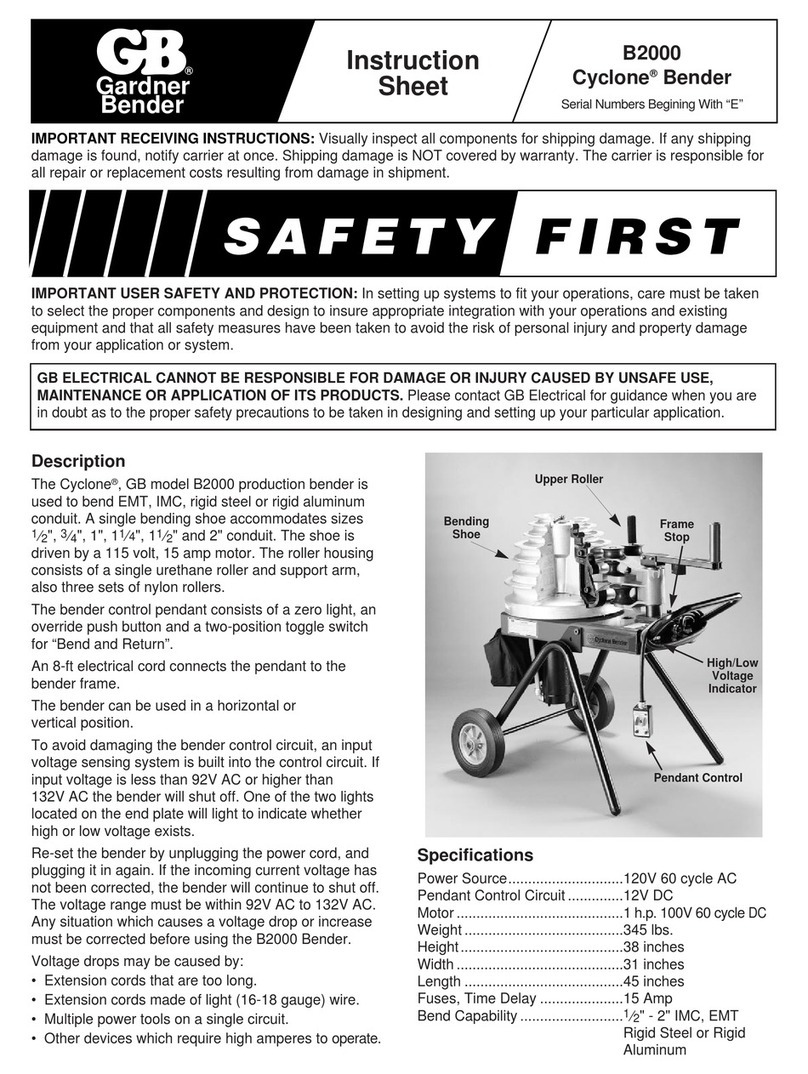

7. CONTROL INSTRUMENTS

7.1 Warning lights 1 2 3 9 10 11 12

1- Belt broken 4 17

2- Low on fuel

3- Hydraulic oil level 5 13

4- Hydraulic contamination filter

5- Air filter 6 14

6- Generator charge

7- Motor oil

8- Water indicator 715

9- Hydraulic oil cooling fan 8 16

10-------------------------

11-Fast running 18

12-Slow running

13-Main headlights

14-Glow plugs preheating

15-Direction indicator lamps

16-Parking

17-Fuel level

18-Hour meter

7.2 Controls

19-Slow/fast running + Forward Reverse

20-Headlights

21-Rotary lamp

22-Working light

23-Ignition switch

24- Commutator switching steering wheel

control to drive position

A/R 25-Warning lights

27 26-Working light

19 20 27- Emergency stop

29

28

21

22 23

24

25 31 26

28------------------------

29- Klaxon

30-Acoustic signal: water temperature,

belt broken and engine heads temperature

31-Negative brake (parking)

30

TRUCK MIXER DB 3000/4000/4500 HYDROSTATIC GB

User Manual Rel. 4 of 11/07/18 Page 8 of 20

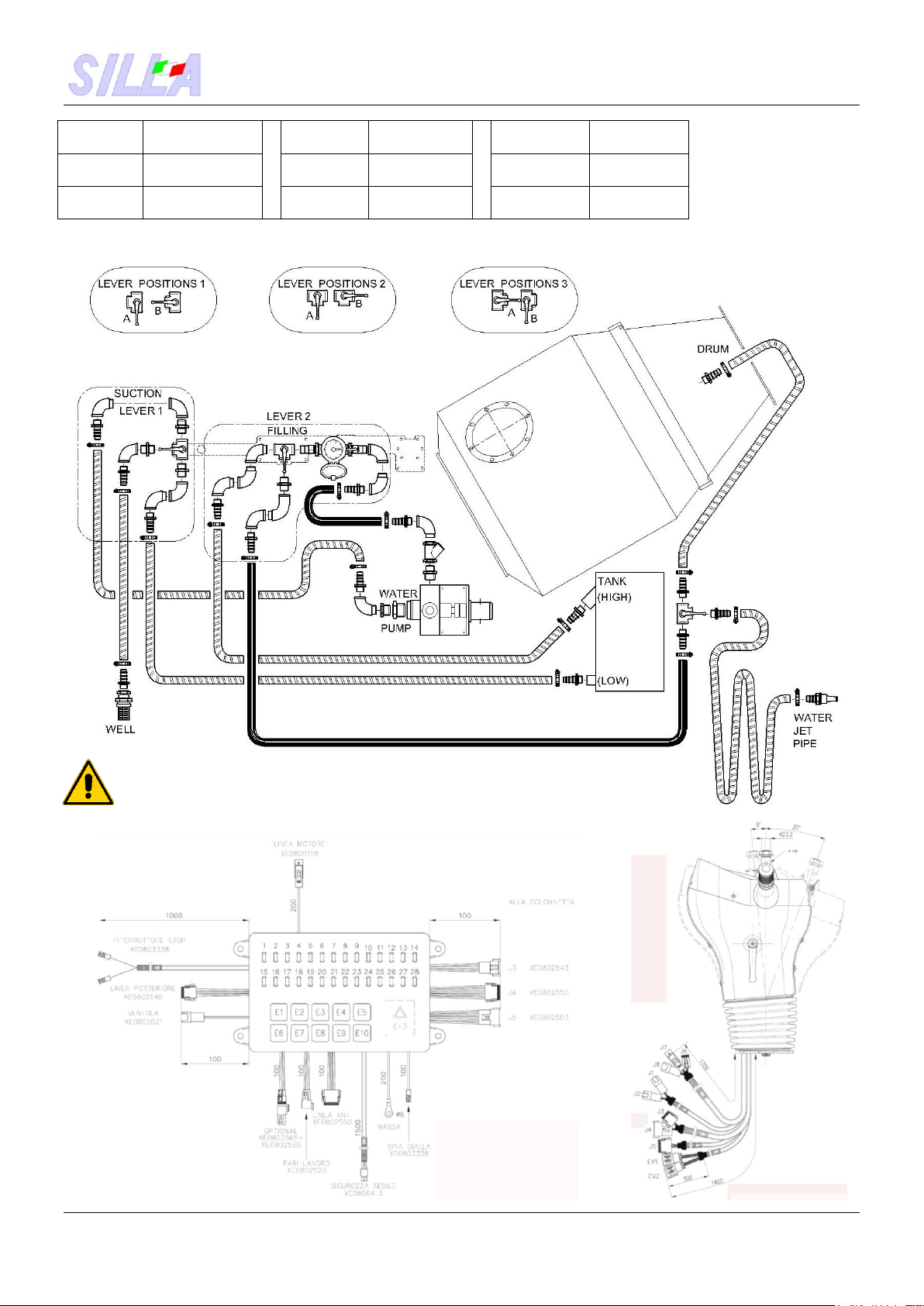

7.3 Water system

On first use you have to

fill the tank: lever 1 in

position “A”

lever 2 in position “A”.

When the tank is full: lever 1 in position “B”, lever 2 in position “B”, lever 3 in position “B”if you want to put water in the drum,

lever 3 in position “A”if you want to wash with the water jet pipe.

Follow while using the system the safety instructions shown

in chapter SAFETY PRECAUTIONS.

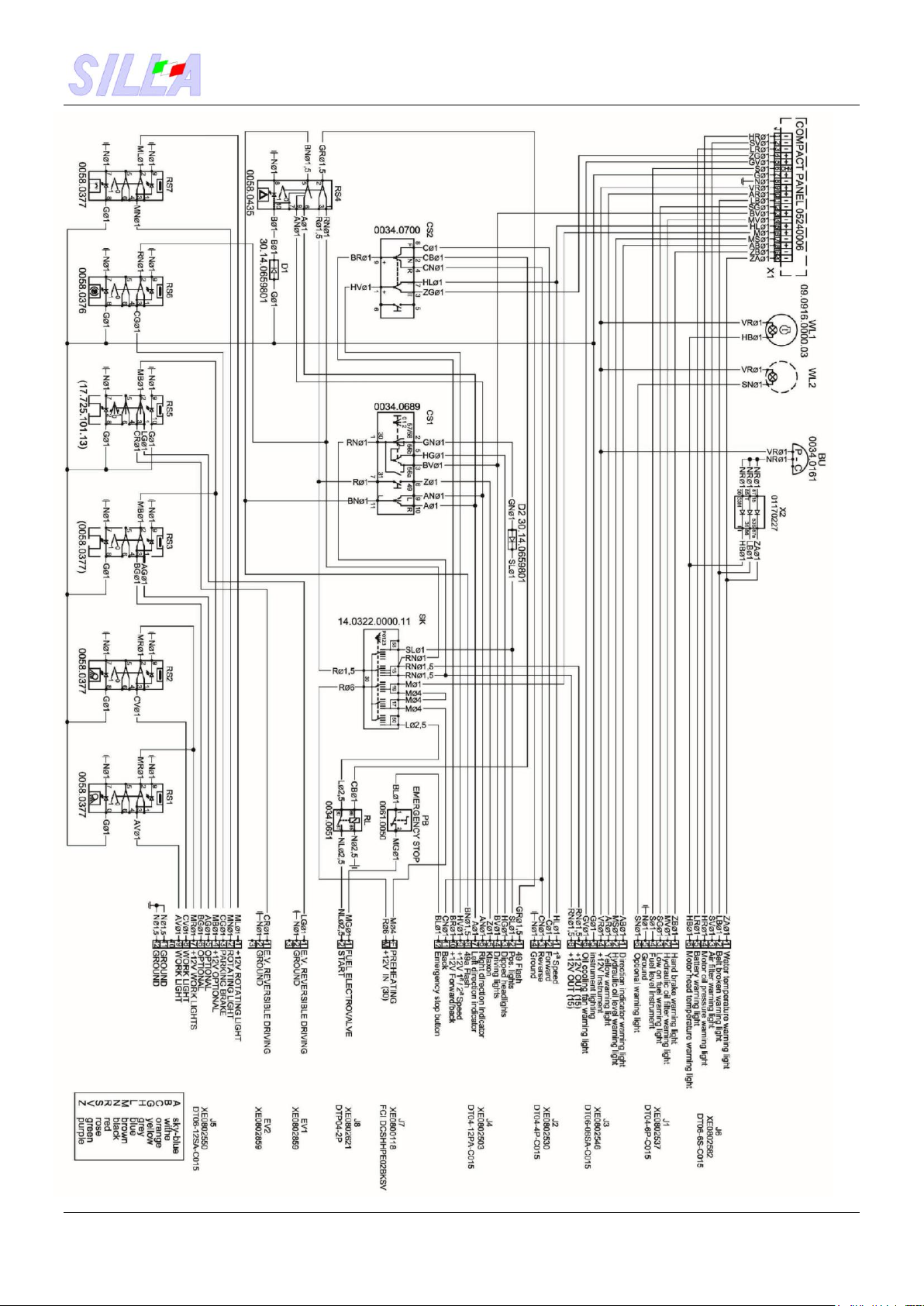

7.4 Electrical and hydraulic diagrams

7.4.1 Relay/fuse box

Lever 1

Position

Function

Lever 2

Position

Function

Lever 3

Position

Function

A

Suction from the

well

A

Flow to the

tank

A

Water jet

pipe

B

Suction from the

tank

B

Flow to the

drum

B

Drum

TRUCK MIXER DB 3000/4000/4500 HYDROSTATIC GB

User Manual Rel. 4 of 11/07/18 Page 9 of 20

7.4.2 Gear case wiring

TRUCK MIXER DB 3000/4000/4500 HYDROSTATIC GB

User Manual Rel. 4 of 11/07/18 Page 10 of 20

7.4.3 Column wiring

TRUCK MIXER DB 3000/4000/4500 HYDROSTATIC GB

User Manual Rel. 4 of 11/07/18 Page 11 of 20

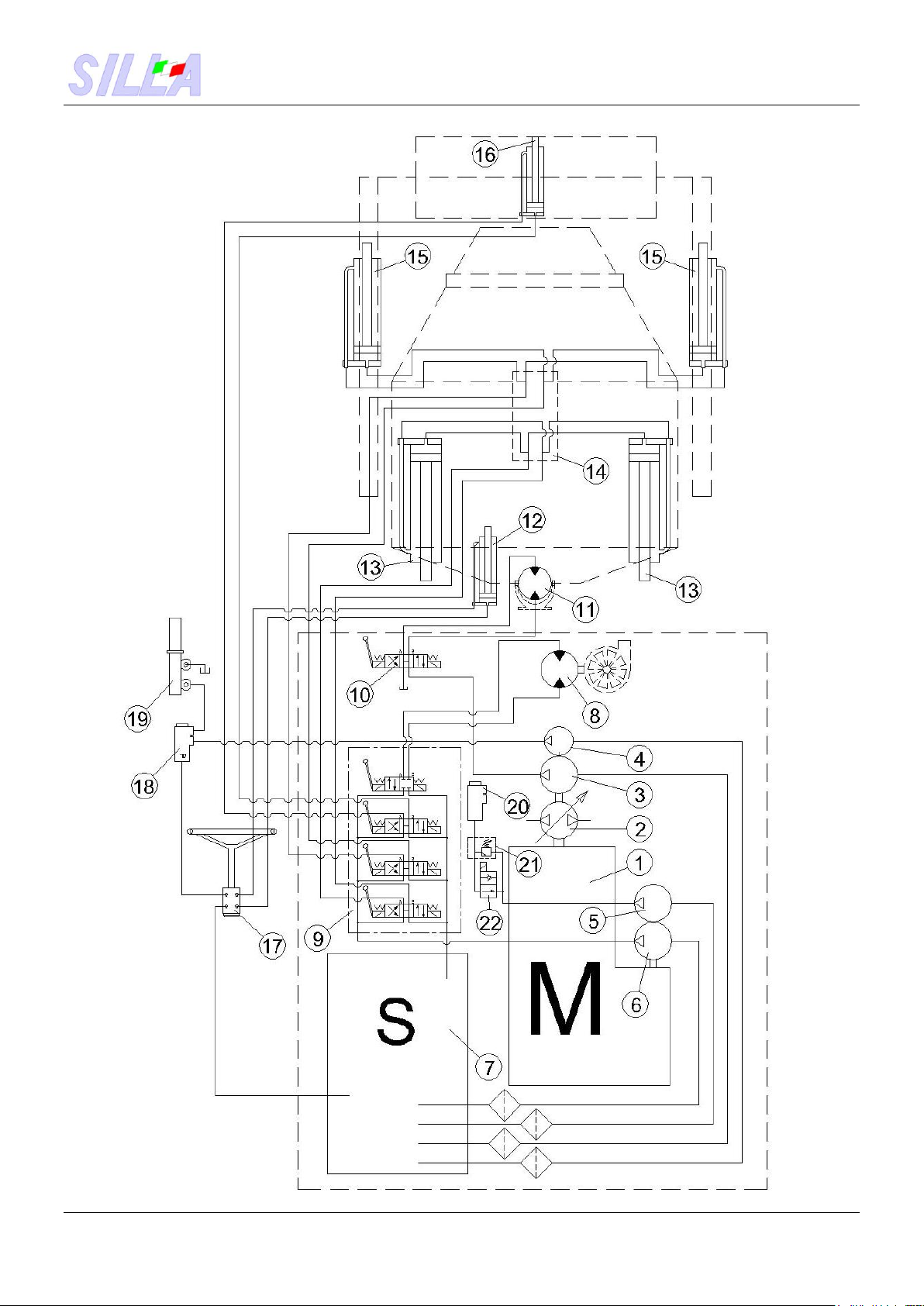

7.4.6 Hydraulic scheme Grab system version

TRUCK MIXER DB 3000/4000/4500 HYDROSTATIC GB

User Manual Rel. 4 of 11/07/18 Page 12 of 20

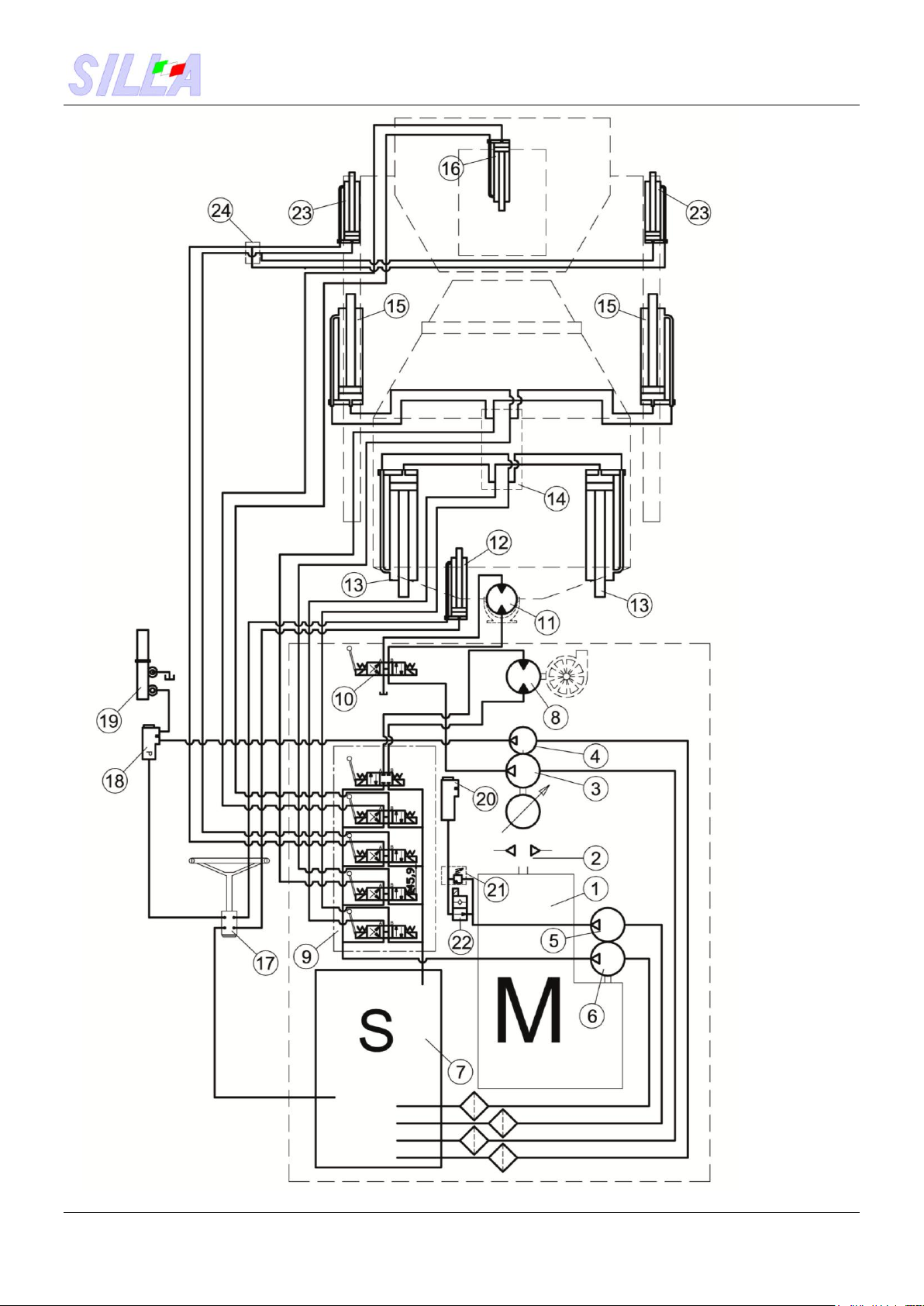

7.4.7 Hydraulic scheme Shovel version

TRUCK MIXER DB 3000/4000/4500 HYDROSTATIC GB

User Manual Rel. 4 of 11/07/18 Page 13 of 20

LEGEND - HYDRAULIC DIAGRAM

Item

Description

Item

Description

1

Diesel engine

13

Hydraulic cylinders (drum lifting)

2

Hydrostatic pump

14

Distribution block

3

Gear pump (drum)

15

Hydraulic cylinders (arm)

4

Gear pump (hydr. steering gear/servo brake)

16

Hydraulic cylinder (grab bucket)

5

Gear pump (Brake release)

17

Hydraulic steering gear

6

Gear pump (facilities)

18

Brake pump

7

Oil tank

19

Servo brake

8

Hydraulic motor (water pump)

20

Brake pump

9

Distributor (facilities)

21

Valve

10

Distributor (drum rotation)

22

Solenoid valve (brake release)

11

Hydraulic motor (drum geared motor)

23

12

Hydraulic cylinder (hydr. steering gear)

24

7.5 Operation and controls

7.5.1 Steering wheel

Turn the steering wheel in the desired direction. Power-assisted steering system powered by means of hydraulic

pump and acting with hydraulic jack on the front half-frame.

All duties are hydraulic: transmission, steering, braking and all movements, therefore: Do not use the

machine with the engine off !!!!

7.5.2 Starting switch

Position “0” OFF engine stop: Engine stop position.

Before stopping the machine, make sure that it is stopped and the parking brake set.

Position “I”ON.In this position the switch connects the battery to all the electric circuits with the exception of the headlights

and the warning lights. The lights and the emergency circuit are always live. The ignition key automatically returns to that

position when it is released from the position “II” and “III”.

Position “II” Preheating.

When starting the machine in cold climates, keep the key in this position to heat the glow pugs. The preheating position should

not be maintained for more than 15 seconds.

Position “III”Starting. Activates the engine starter and the engine runs.

Do not activate the engine starter for more than 20 seconds at a time. After each starting attempt, let cool for

at least 2 minutes then repeat the operations from position “II”. Do not use the starter with voltages greater

than 14Volt.

Do not use the starter to move the vehicle.

7.5.3 Hour meter Indicates the working hours of the machine with the key inserted, check it to

determine the lubrication and maintenance program.

7.5.4 Rotation lamp switch Enables/Disables rotating lamp.

7.5.5 Warning lights switch Enables/Disables warning lights.

7.5.6 Indicators device Activates the direction indicators.

7.5.7 Headlights/Horn switch Activates the headlights, low beams at first click and high beams at the second

click. By pressing it in any position (zero, first click or second click) it activates the klaxon.

7.5.8 Accelerator pedal Press the accelerator pedal to increase the motor speed, release it to decrease.

Use the accelerator pedal with the upmost attention. It’s not a racing car!!!

7.5.9 Brake pedal Press the brake pedal to slow down or stop the vehicle.

The service brake acts hydraulically by means of pump on the brakes.

The stop lights must light up when the brakes are used.

Use the machine only if both stop lights are working properly.

7.5.10 Parking brake lever To set the parking brake, pull the lever upwards. To release push it downwards.

Operate the lever to set the parking brake whenever you leave the driver’s seat.

Never start with the parking brake set.

7.5.11 Direction reversing lever Used to reverse the direction of travel of the machine.

Use it only when the machine stops and at a speed

as low as possible.

TRUCK MIXER DB 3000/4000/4500 HYDROSTATIC GB

User Manual Rel. 4 of 11/07/18 Page 14 of 20

Grab system controls

7.5.12 Drum lifting lever

Push forward to lift the drum, pull to reposition.

7.5.13 Grab bucket arms drive lever

Push to lower the arms, pull to lift.

7.5.14 Grab bucket drive lever

Push to open the bucket, pull to close it.

7.5.15 Water pump lever

Pushing the lever it starts the water pump that stays

in place until switching off by pulling the lever.

(see diagram 7.3 Water system).

7.5.16 Drum rotation lever

Pushing the lever the drum turns in the “discharge”

direction, pulling the lever the drum turns in the “mixing”

direction.

Shovel commands

7.5.17 Drum lifting lever

Push forward to lift the drum, pull to reposition.

7.5.18 Grab bucket arms drive lever

Push to lower the arms, pull to lift.

7.5.19 Door shovel operate lever.

Push to lower, pull to lift up.

TRUCK MIXER DB 3000/4000/4500 HYDROSTATIC GB

User Manual Rel. 4 of 11/07/18 Page 15 of 20

7.5.20 Open/Close lever.

Push to open, Pull to close.

7.5.21 Water pump operate lever.

Pulling yhe lever, operating the water pump.

Push the lever for stop..

7.5.22 Drum rotation lever.

Pushing the lever the drum turms in the “discharge”

Direction, pulling the lever the drum turns in the

“mixing” direction.

ALL THE MAINTENANCE OPERATIONS AND CHECKS MUST

BE CARRIED OUT WITH THE MACHINE TURNED OFF, PARKING BRAKE SET.

Always keep the machine switched off when it is not in use.

Always perform a test of all the controls and check that everything works properly .

Make sure that in the area of respect and work there are no people or objects

large enough to compromise the security.

7.5.17 Driver’s seat rotation The driver’s seat is turned in the direction of work, in order to

check the drum operations, the arms and the grab bucket, by using the lever under

the seat. When pushing it downwards and turning the driver’s seat by hand up to the

180° click, you get the position you want, but be careful when using button n. 24 “driving

switch”, press it whenever you change the direction of the driver’s seat, otherwise the

steering will work in reverse. Repeat the same operations for driving the vehicle on the site.

7.6 Use of the machine

7.6.1 Starting the engine - Make sure that the parking brake is set. -

Check the level of oil in the pan. –Make sure that there is sufficient fuel in the tank for

the work to be performed - Check level of hydraulic oil -Accelerate to about 3/4 of

the run and engage the starter

Caution! When the engine is running do not disconnect the contacts of the

battery, to avoid burning of the capacitor. B A

SPEED VARIATOR:

SLOW (Lever in direction of the snail symbol)

CENTRAL POSITION = NEUTRAL

FAST (Lever in direction of the hare symbol)

To change the speed move the “A” lever in

the desired position (low speed symbol snail)-(fast speed symbol hare). Never change

the speed with machine in movement. The speed variation must always be with

machine stopped and passing from the central neutral position, giving small shots to

the accelerator “B” that facilities the sliding of the lever. Do not force only on the lever

without acting also on the accelerator.

7.6.2 Stopping the engine Reset the throttle control by hand. Activate the stopping device.

7.6.3 Starting the mixer For mixing, the drum seen from the driver’s seat, must rotate counter-clockwise.

- When you want to unload, stop the mixing operation, lift the drum and start clockwise rotation of the drum;

- The starting operations and reverse rotation of the drum must be performed with the engine idling.

CAUTION! At the end of each working cycle, wash the inside of the drum entering a shovelful of gravel, in order to avoid the

formation of incrustations of concrete.

7.6.4 Auto-loader -Open the grab bucket, place the bucket on the heap with the machine stopped, close the bucket and

lift the arms to unload the material inside the hopper.

- Move the machine only when the bucket is lifted from the ground

TRUCK MIXER DB 3000/4000/4500 HYDROSTATIC GB

User Manual Rel. 4 of 11/07/18 Page 16 of 20

7.6.5 Water system -When there is danger of frost, drain all water from the system, including the pump

-For the various manoeuvres see “Operating scheme - water system” (7.3) -Do not run the water pump dry.

The machine is the exclusive responsibility of the operator, which is the only one authorized to manoeuvre it.

Special precautions: Do not carry people;Do not turn the drum with hardened concrete;

Do not drive with the drum raised or with the seat turned towards the drum; Do not abruptly reverse the direction of

rotation of the drum; Do not lower the shovel when the extension is inserted; Do not insist on the control levers when their

cylinders have attained the end of the stroke; Do not abruptly brake or swerve at high speed; Do not tolerate the presence of

others within the range of the machine;

7.6.6 In action on the construction site. Lift the drum (for unloading) only on firm level ground.

On sloping terrain, do not place the machine next to the slope and do not unload in that position, because you are likely to tip

over. Maintain, on steep slopes, the opening of the full-loaded drum always facing upstream. Start the inversion of the rotation

of the drum only with the engine idling. Every time you leave always leave the machine safely, that is with the bucket on the

ground, the drum lowered, the motor stopped and the ignition key removed, the handbrake set. Drive always with the drum

behind the driver’s seat.

SAFETY STANDARDS The driver of public works vehicles, in order to work profitably and safely, must have experience of

mechanical means, know the various commands, the operational characteristics as well as the stability of the machine

entrusted to him and possess an adequate sense of prudence and skill. A risky manoeuvre, out of laziness or to save a few

minutes, could also result in a serious accident with subsequent stopping of the whole construction site.

Never tow the truck mixer on the road. Use appropriate means of transport.

8. MAINTENANCE The machine does not require any particular maintenance work.

The technical solutions and the components installed on the machine reduce the maintenance works at the

minimum. However, we recommend to carry out a series of operations, which aim at ensuring safety, liability

and efficiency of the machine for a long period of time.

During maintenance Work on the machine only after having placed/parked it in the area defined in point 5.2

Placing and how to leave the machine. In the event of mechanical or electrical problems, contact the authorized

personnel. If the machine is out of service due to equipment failure, maintenance or repair, place a special sign to

highlight this status and remove the ignition key.

Always use personal protective equipment during repair and replacement of the machine parts.

Electrical work must be performer only by authorized personnel.

Works on the engine must be performed only by authorized and skilled personnel.

Do not place hands, arms or body parts near the handling and transmission area. Use a suitable device to remove debris

(brush, wooden piece, etc.): never use your hands!

Regular maintenance of the mechanical and electrical machine parts extends the live of the machine, ensures best

performances and is an important safety factor.

8.1 Routine and extraordinary maintenance In the run-in period (50 hours).

Do not force the engine and avoid intensely exploiting the machine performances.

Clean the hydraulic oil drain filter after the first 20 hours.

Check for leaks of hydraulic oil, brake oil, clutch oil, lubricants of various mechanical assemblies. Check tightness of all the

bolts, in particular the fixing of the wheel rims, after the first 20 hours.

Change the motor oil and perform the other operations provided by the manufacturer (see motor instruction booklet provided in

the annex to this manual).

Perform all daily, weekly, fortnightly and successive maintenance operations, a listed below.

8.1.2Daily maintenance at the end of the work Eliminate any anomaly that had occurred.

Thoroughly clean the inside of the drum in order to avoid the formation of incrustations. With a strong jet of water wash the

outside of the machine, to remove any residue. Grease all lubrication points, with the engine stopped and the drum in home

position. Carefully check the tire condition. Check the condition of the brakes. Remove any debris from the driver’s

seat.

DO NOT wash with high pressure jets electrical parts and control elements.

8.1.3Weekly maintenance

Check the oil level of the brakes, clutch oil, hydraulic oil with the engine stopped and the booms down.

Always remember that the oil is a special waste and must be disposed of in accordance with the law.

Check the fluid level of the battery. Check the belt tension of the blower fan.

Wash the engine air filter and fill the pan up to level with oil. Check the condition of the drive belts.

8.1.4Maintenance to be performed every 15 days Check free travel of the brake pedal, normal value is 20/25mm.

Check the travel of the handbrake lever, it must block with an effort not less than 10Kg.

Clean the hydraulic oil drain filter and the tank breather cap.

8.1.5Maintenance to be performed every 100 hours of work

Replace the motor oil, see the instructions of the manufacturer. Replace the fuel filter cartridge.

Replace the suction filter cartridges inside the hydraulic oil tank.

8.1.6Maintenance to be performed every 2000 hours of work Replace the two suction filter cartridges inside the tank.

Replace hydraulic oil after cleaning the magnetic drain plug. Replace the oil exhaust filter.

Always remember that the oil is a special waste and must be disposed of in accordance with the law.

TRUCK MIXER DB 3000/4000/4500 HYDROSTATIC GB

User Manual Rel. 4 of 11/07/18 Page 17 of 20

8.2 Corrective maintenance Other corrective maintenance operations (extraordinary/repairs) must be

performed by authorized service personnel.

8.2.1 Troubleshooting

PART

PROBLEM

CAUSE

Clutch

Does not disengage

Screw on release lever has to be adjusted

Lack or loss of oil in the control device

Slips during engagement

Pump or control cylinder hardened

Hydraulic brake

Insufficient

Lack or insufficient oil

Air bubbles in the circuit

Brake pump with worn seals

Hose which swells under pressure

Worn brake discs

They jam

Pump or cylinders jammed

Handbrake

Insufficient

Hand lever has to be adjusted

Control linkage has to be adjusted

Worn brake discs

Hydr. steering gear

Steering wheel is hardened

Pressure relief valve has to be adjusted

Suction filter cartridge is clogged

Low oil level

Oil leaks or air bubbles in the circuit

Obstructions in the suction pipe

Worn pump

Drum

Rotates slowly if full

Pressure relief valve has to be adjusted

Suction filter cartridge is clogged

Low oil level

Obstructions in the suction pipe

Worn pump

Rotates unevenly

Pressure relief valve has to be adjusted

Suction filter cartridge is clogged

Low oil level

Obstructions in the suction pipe

Worn pump

Concrete is hardening, if drum full

Heavy internal fouling, if drum empty

Autoloader

Rises jerky or with difficulty

Pressure relief valve has to be adjusted

Suction filter cartridge is clogged

Low oil level

Obstructions in the suction pipe

Worn pump

Bucket

Closes without force

Pressure relief valve has to be adjusted

Suction filter cartridge is clogged

Low oil level

Obstructions in the suction pipe

Worn pump

Hydraulic oil

Overheats

Unsuitable oil quality

Low oil level

Pressure relief valves jammed

Worn pumps

Automatic return failure of distributor levers

Excessive insistence on the levers by the operator, with the

cylinders already at the stroke end

Water system

Does not pump water

Suction strainer clogged

Entrained air in the suction pipe

For all other kinds of troubles, please refer to the After-Sales Dept. of the Company SILLA.

CAUTION !!!!! SILLA decline any responsibility in case the machine does not undergo maintenance as

prescribed in this instruction manual and in case of use of spare parts and accessories other than original

and not appropriate.

TRUCK MIXER DB 3000/4000/4500 HYDROSTATIC GB

User Manual Rel. 4 of 11/07/18 Page 18 of 20

8.3 Maintenance of hydraulic system

Protected against dust and infiltration, no special maintenance is required, unless verification of the level, but it requires a

thorough cleaning of the oil. If you have to replace the two filter cartridges inside the tank, you need to drain the oil and remove

the cover. Use only clean containers and fill the oil through funnel fitted with a filter. Any other work on the system must only be

performed by qualified personnel and with appropriate equipment.

8.3.1 Check the brake pedal The travel of the pedal must be between 20 and 25mm.

8.3.2 Check the parking brake The control lever must block with an effort not less than 10 kg.

8.3.3 Check the tires Normal operating pressure 3,5Atm. When working on rough terrains it can be useful to

ballast the tires by introducing the appropriate antifreeze liquid.

8.3.4 Spare parts When ordering spare parts, order the component from the supplier and/or

manufacturer of the machine. Always mention the model of the machine, part number, type of machine, description of the

desired component, quantity and the main features.

9. DISMANTLING

Should the machine not be used for a long time (e.g. holidays), carry out the following operations:

Carefully clean the whole machine, remove dust, deposits and dirt.

Wash the inner part of the drum.

Remove the concrete deposits, but do not hurt the drum with hard objects like hammers, shovels, etc.

Oil all the moving parts exposed to seizure and the mechanical components exposed to oxidation.

Store the machine in a dry and ventilated place, or use a nylon covering.

9.1 Disassembling / dismantling

Before carrying out any dismantling or disassembling operation, disconnect the battery.

Disconnect all the electric and mechanical components;

Disassemble the driving parts, bridges, engine, and brakes.

Disassemble the hydraulic parts of distributor, hoses, cylinders, pump, and hydraulic steering gear.

Disconnect and disassemble all the other mechanical components and the wheels.

9.2 Disposal

The following are the materials the machine is made of:

Painted steel, aluminium and other metallic components.

Plastic materials.

Oil-hydraulic materials

Cables, motors, battery and electric components.

Please dispose of these materials through specialised companies, in accordance with the laws in force.

TRUCK MIXER DB 3000/4000/4500 HYDROSTATIC GB

User Manual Rel. 4 of 11/07/18 Page 19 of 20

11. WARRANTY REGISTRATION FORM

Machine type

Part number

IMPORTANT

This form must be filled out and stamped by the Dealer at the time of purchase of the machine.

The Dealer or the buyer must send this form by registered mail to the After-Sales Dept. of the

Company SILLA within 3 days from the purchase, attaching a copy of the delivery note or

invoice.

The mailing of this form, with attached copy of the transport document or copy of the invoice, is

an essential requirement to start warranty period.

The company SILLA does not recognize any warranty in case of failure to submit the required

documents.

Date . . . . . . . . . . . . . . . . .

Stamp and Signature of the Dealer

Messrs

SILLA Macchine Edili e Stradali

Via S.Gimignano , 96 - 53036 –POGGIBONSI (SI) –ITALY

11.1 WARRANTY CONDITIONS

Warranty means the repair and/or the replacement of those parts, which are proven to be defective in

manufacture. The replacement of the whole machine is excluded.

The warranty is for the period of 1 year from the date of delivery to the user, that is to say the date written in

the Warranty Registration Form.

The defective materials must be sent, free delivered, to our factory. After technical approval the material will

be replaced and sent carriage forward.

The warranty expires in case of:

modifications, repairs, alterations of the machine carried out by the buyer and not expressly authorised by

SILLA.

improper assembling or failure to use the machine according to the instructions of the instruction manual.

The electric components are not covered by this warranty, because a wrong connection done by the user

and/or line problems cause damage to these components.

Any repair under warranty will not interrupt the warranty period.

The dealers shall enter the serial number of the truck mixer, both in the delivery

note and in the invoice.

This manual suits for next models

4

Table of contents

Other SILLA Construction Equipment manuals

Popular Construction Equipment manuals by other brands

Epiroc

Epiroc EC Series Safety and operating instructions

Altrad

Altrad BELLE EASY SCREED PRO Operator's manual

nokka

nokka 2051P Installation, operation and maintenance manual

KRAUSE

KRAUSE MONTO ProTec 1000 Assembly instructions and user's manual

Case

Case 821G Service manual

Dynaset

Dynaset HPW-DUST operating instructions

Discount Equipment

Discount Equipment MULTIQUIP Mikasa Series Operation manual

Lievers

Lievers LHF user manual

Northern Industrial Tools

Northern Industrial Tools 426282 owner's manual

Alpha tools

Alpha tools AFMR 800 operating instructions

APW Wyott

APW Wyott GB Cyclone B2000 instruction sheet

Husqvarna

Husqvarna Blastrac 1-8DM Operator's manual