4

GENERAL

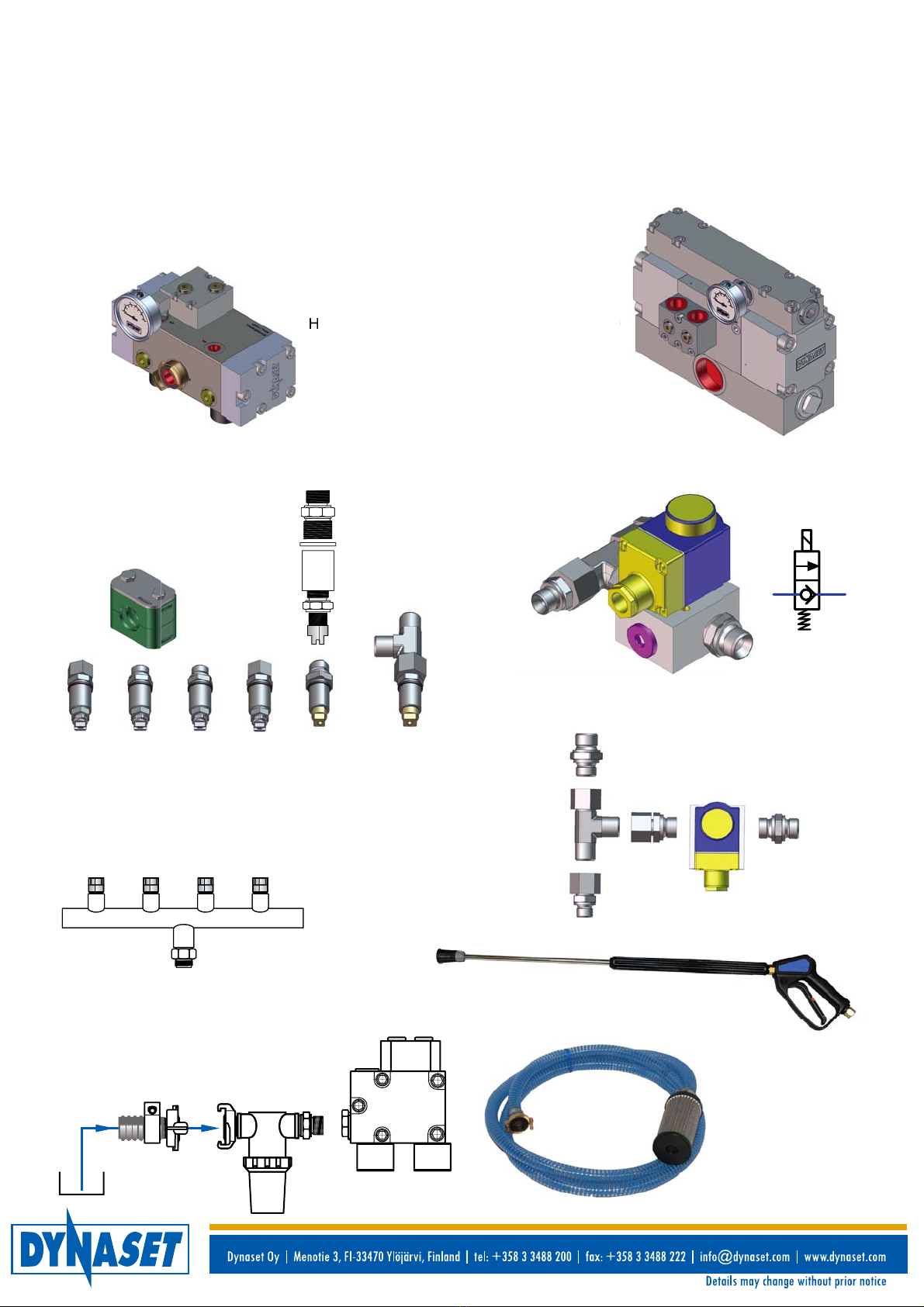

HWP High Pressure Dust Suppression system forms microscopic water

mist which means low water consumption and low costs. Mist-like

atomized water binds even the smallest dust particles and makes them

heavier to falling down in a controlled manner. Dust suppression system

avoid soiling of surroundings, inhibits mud sagging keeping the working

area almost dry.

The compact hydraulic operated high pressure pump is easily mounted

onto the machine.

HPW pump is controlled by electric ON/OFF valve on machinery cabin.

Hydraulic valve kit controls the water pressure with pressure reducer

and the oil flow limiter. Pressure reducer and solenoid valve to

appropriate application control nozzles water flow. Pressure compensated

oil flow-limiter controls the biggest running speed of the HPW-pump.

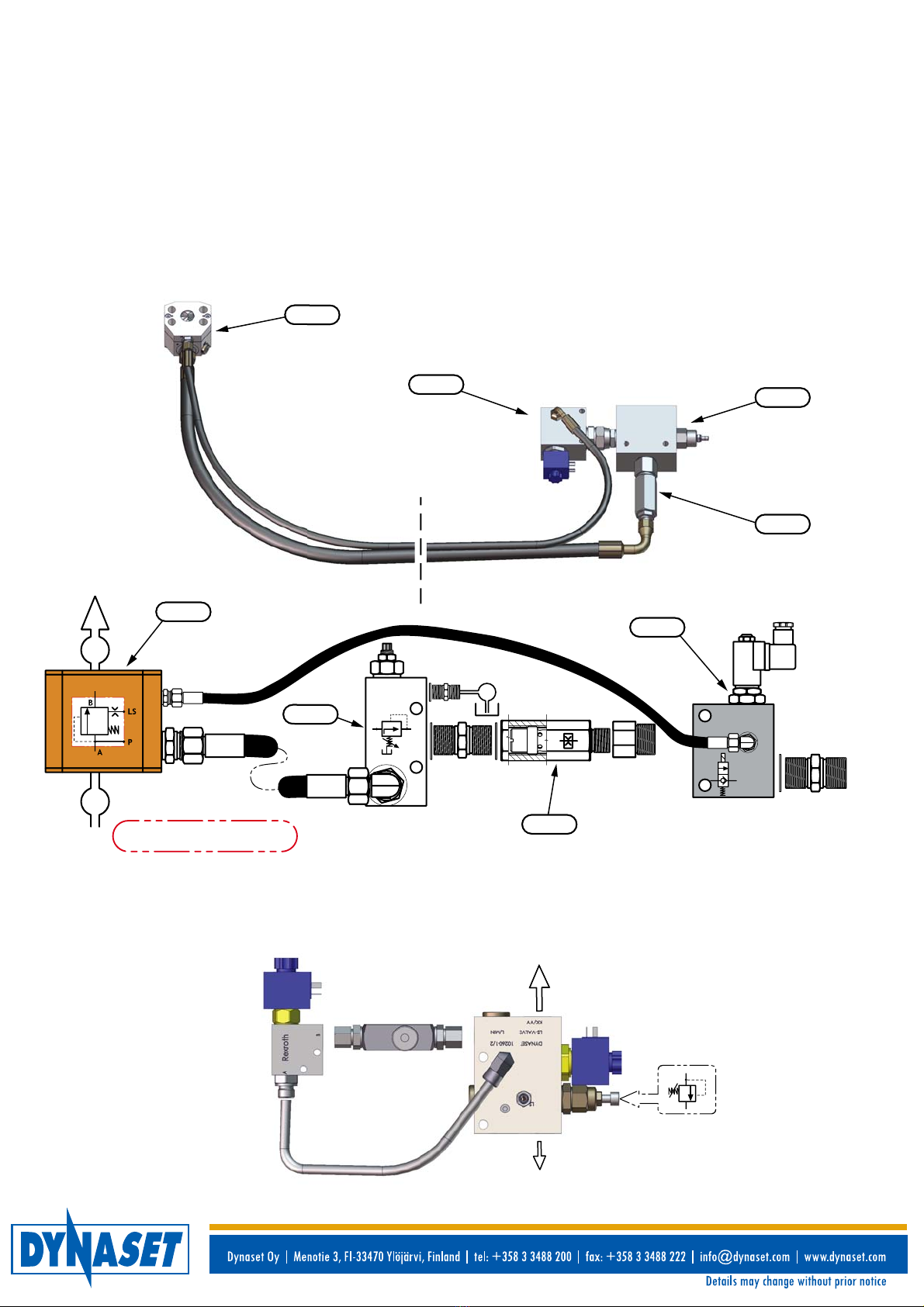

Excavator fitted Dynaset HPW-Dust suppression system are dual power

stage type. Continuous basic dust suppression is supplement with a

high power mode, which is used as frequently as necessary to suppress

dust created during demolition by fallen debris by bulk-loaded dump on

a truck’s platform etc.

Technically dual stage power output is implemented in two different

ways:

1. In a Dual Water Circuit (DWC), both basic and high power

levels use individual high-pressure nozzle pairs. The high power

dust suppression is switched on by activating separate water

solenoid valve.

High power suppression nozzles can be the first time coarsely

pre-aimed to an assumed dust source according to task demand

and conditions. Exact aiming is done after the experiment.

2. In a Single Water Circuit (SWC), the same nozzle pair is for

both basic and high power dust suppression, using two separate

hydraulic flows – one for each power level of dust suppression.

Prior to switching on the dust suppression, operator have to aim the

attachment with dust suppression nozzles to a dust source.

Front loader’s bucket or mobile crusher’s feed hopper and conveyors

can be equipped with dust suppression-nozzle pipe(s) of a single

water circuit mode continuous mode, dust suppression system

HPW200 Dust.

Nozzles: 8 x

(1,6 lpm 120°)

April 2014 JLe

HPW-DUST HIGH PRESSURE SUPPRESSION SYSTEMS