Silvan Selecta SELECTA SQDN100-P1 User manual

Instruction Manual

MANSQDN100 REV E 27/04/20

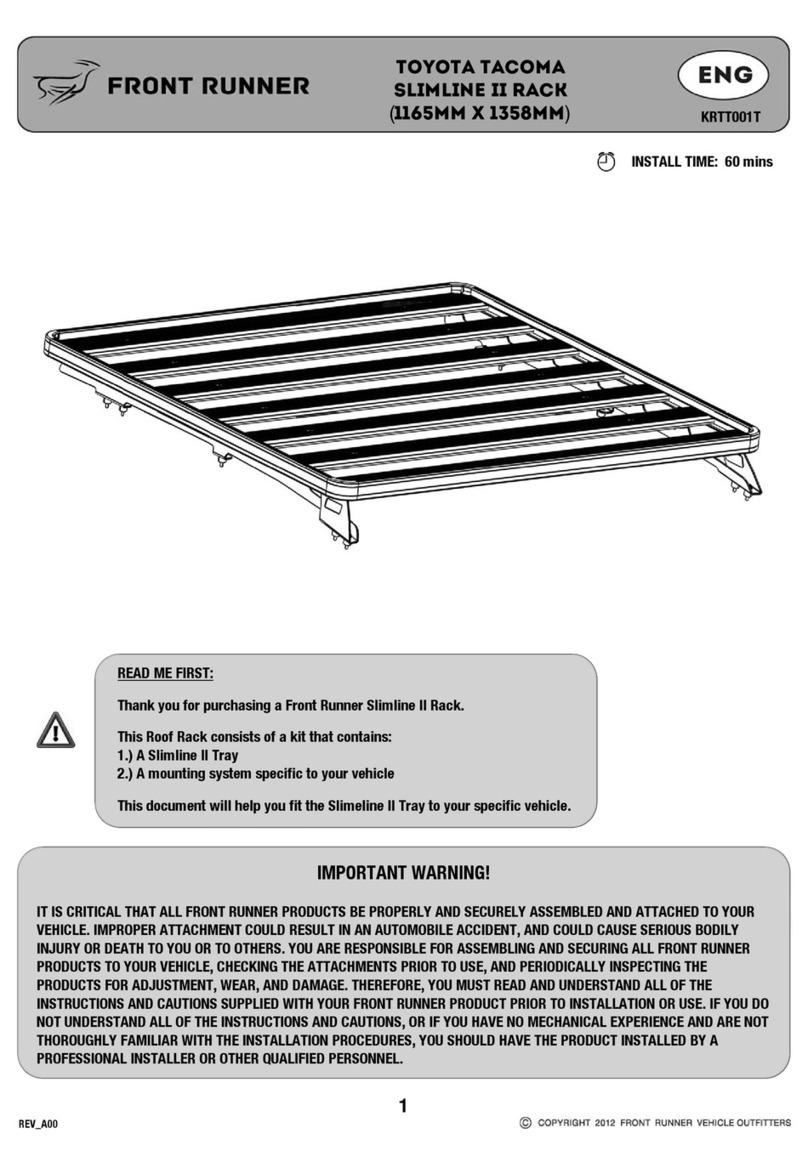

100, 200, 400, 600L DIESEL TRANSFER UNIT

SQDN100-P1, SQDN100-1,

SQDN200L-Z1, SQDN200-7,

SQDN400L-Z1, SQDN400-7,

SQDN600L-X1

VICTORIA (HEAD OFFICE)

Telephone: +61 (03) 9215 2700

Fax: +61 (03) 9215 2701

www.silvan.com.au

NEW ZEALAND

Hamilton, New Zealand

Telephone: +64 (07) 8496 033

Fax: +64 (07) 8496070

www.silvannz.co.nz

SILVAN AUSTRALIA PTY. LTD.

ABN 48 099 851 144

Silvan Warranty

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law.

You are entitled to a replacement or refund for a major failure and for compensation for any other

reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or

replaced if the goods fail to be of acceptable quality and the failure does not amount to a major

failure.

We warrant our goods to be free from defects in materials and workmanship for the warranty

period of 12 months from the date the product is delivered to the consumer.

Silvan warrants its authorised Dealer, who in turn warrants the original purchaser (consumer) of

each new Silvan product that it will repair or replace the product, or, pay the cost of repair or

replacement, as determined by Silvan without charge for labour or any defective or malfunctioning

parts in accordance with the warranty limitations below.

This Warranty is in addition to any other rights and remedies available to consumers under the law

This Warranty Covers

Only conditions resulting directly from defects in workmanship or material under normal use and

service.

Warranty Exclusions

The Warranty does not cover:

•Conditions resulting from misuse, use of incompatible chemicals, exceeding machine

specifications including overloading, impact damage, negligence, accidental damage or failure to

perform recommended maintenance services as specified in the Owner/Operator Manual

applicable to the product.

•Damage caused by continued use of a product after initial failure

•Any product which has been repaired by other than an authorised Silvan service outlet in a way

which, in the sole and absolute judgment of Silvan, adversely affect its performance or reliability.

•The replacement of maintenance items such as diaphragms, batteries, V belts and ground

engaging components, etc.

How To Claim Warranty

Return the goods to the place of purchase at your cost and within the warranty period along with

evidence of the purchase date. If the original supplier cannot be contacted, then contact Silvan as

below and we can direct you on how to proceed with your warranty claim.

How Your Claim Will Be Managed

The repair of a defective product qualifying under this warranty will be performed by any authorised

Silvan service outlet within a reasonable time following the delivery of the product, at the cost of

the owner, to the service outlet’s place of business. The product will be repaired or replaced

depending on the extent of the problem at the discretion of Silvan and the Silvan dealer.

Warranty

Warning! This Diesel unit is designed and manufactured solely for the purpose of carrying and

pumping Diesel fuel. Under no circumstances may it be used for any other purposes.

Warning! Prior to installing or using the Diesel unit all operators must have read and fully

understand the contents of this instruction manual as well as all other manuals supplied

and the safety decal fitted to the Diesel unit.

Warning! Never allow an inadequately trained person to install or operate the Diesel unit.

Warning! Ensure the capacity of the vehicle is suitable for the loaded mass of the diesel unit. Refer

to the vehicle operator’s manual for safe working loads, correct secure points and relevant

safety instructions.

Warning! Avoid diesel contact with skin and eyes and avoid breathing vapours or mists. Refer to the

Material Data Safety sheet from your Diesel supplier for recommended safety precautions

and any required protective equipment for use when handling. Ensure that all operators

and associated personnel are familiar with the legal regulations and codes of practice that

apply to the safe use, storage and disposal of Diesel.

Warning! This diesel unit should be securely restrained or tied down when being transported on a

vehicle

Warning! This Diesel unit should not be lifted when partially or completely full unless supported by

an appropriate frame or pallet.

Warning! This unit should never be left unattended while dispensing or being filled.

Warning! Before attempting to fill the tank at a service station consult the operator for the correct

procedure.

Warning! Do not store the diesel unit within or next to a dwelling or garage attached to a dwelling.

Warning! Always store the diesel unit in well ventilated open areas.

Warning! Storage of the diesel unit must not be in the proximity of any heating or ignition sources.

Warning! No combustible waste materialor residues shall be permitted to remain in or around areas

in which diesel is stored or decanted

Warning! Any spillage shall be cleaned up immediately and the materials used in the clean-up shall

be disposed of safely and in accordance with any legal regulations and codes of practice

that apply to the safe use, storage and disposal of Diesel.

Warning! Ensure that the electrical lead(s) are always in good condition and the wire is not exposed

through the plastic coating. Do not allow the lead to become tightly knotted, crushed or

pinched.

Safety Instructions

Before attempting to operate or install the diesel unit carefully read and take note

of the following safety warnings.

Failure to comply with these warnings may result in serious injury or death.

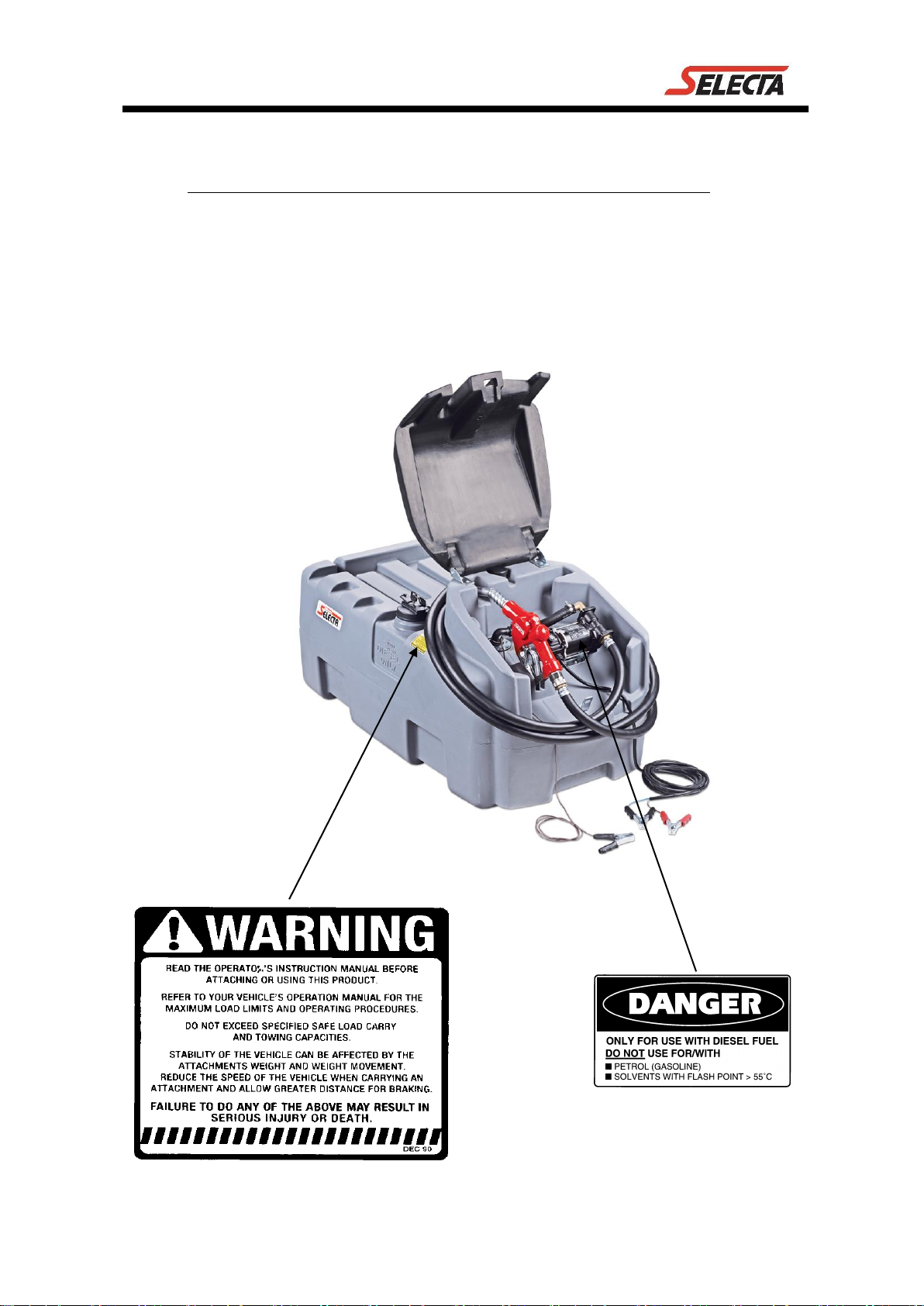

The location and wording of the safety decal fitted to your Silvan Diesel tank is shown below. It is

important that all operators read and follow the information on all safety decals before operating

the unit. Failure to comply with these warnings could result in serious injury or death. Safety decals

should be kept clean and legible at all times. If any decals are missing or unreadable, they should

be replaced by ordering new decals from your Silvan dealer using the part numbers shown.

Warning decal part number: DEC48.

Safety Instructions (cont.)

GENERAL:

All transfer units come standard with an Auto shut-off gun and all pumps feature a duty cycle for 30

minutes of continues dispensing, all pumps also contain an internal bypass that allows for the pump

to operate for up to a maximum of three minutes when the filling nozzle shuts off without damaging

the pump or motor.

SPECIFICATIONS:

TANKS:

Made from impact resistant polyethylene, UV stabilized, coloured grey and fitted with lid and

breather with a 100L, 200L,400L or 600L capacity in a Low-Profile free-standing design (which allows

for minimal interruption to visibility when mounted to the tray of a Utility).

GUN:

Trigger filling nozzle with automatic shut-off and hose swivel.

FILTRATION:

Suction foot screen filter.

PUMPS AND DELIVERY HOSE:

All Selecta Diesel transfer units are fitted with an electric self-priming vane pump with a 4-meter

power lead and alligator clips, details are provided below.

PUMP:

For pump details refer to the last page.

IMPORTANT OPERATIONAL NOTE- The internal Bypass fitted in all diesel pump models is designed

to protect the pump and motor from damage when the trigger is shut off for a time no greater the

2-3 minutes.

This is enough time for the operator to switch off the pump or recommence pumping. When the

nozzle is off and the pump is running the pump pressure increases and the electric motor load

increased using more power (amps) which in turn generates more heat within both the pump and

motor, risking increased wear or possible if the pump is not switched off.

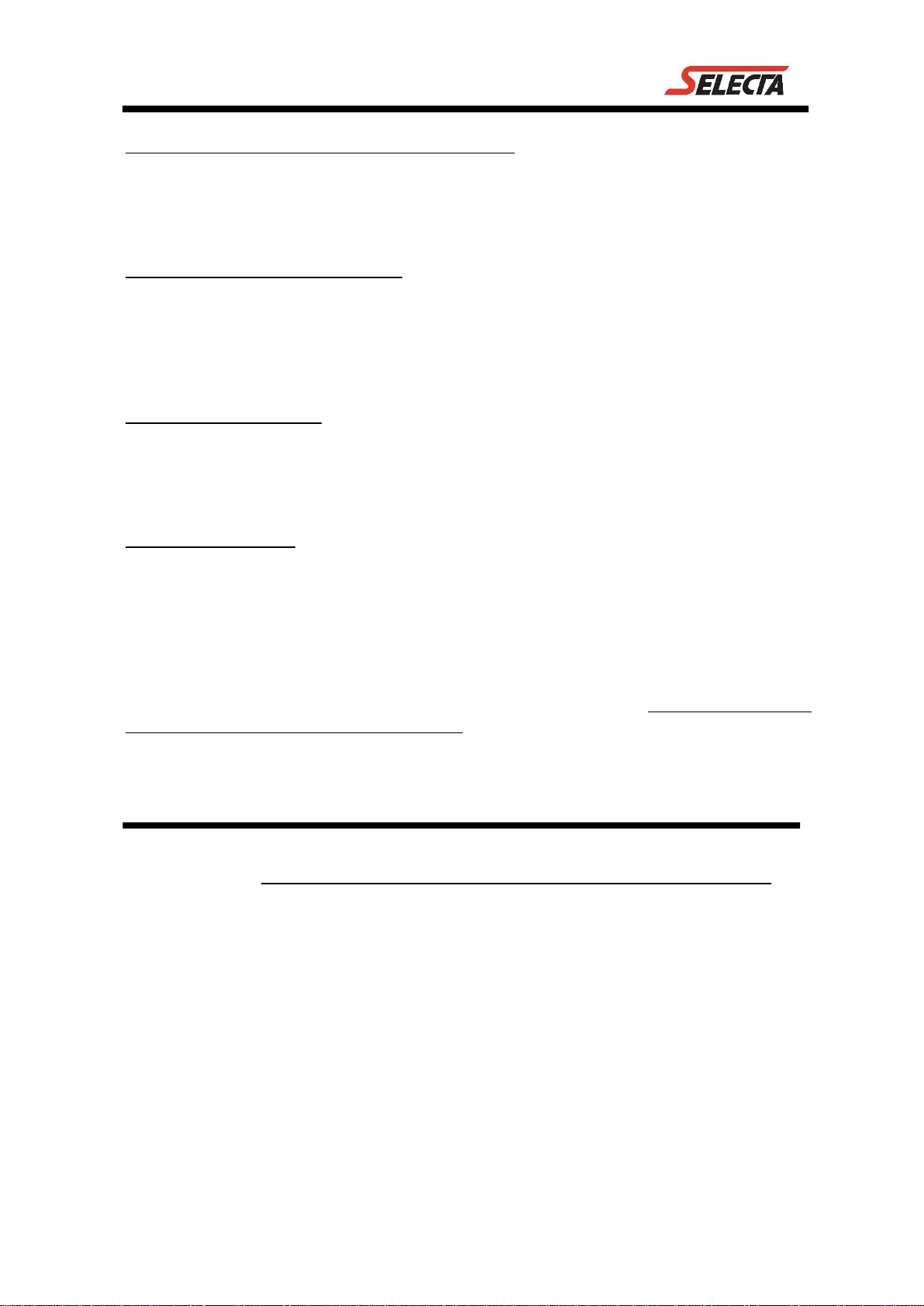

DIMENSIONS AND WEIGHTS:

Mass is specified with tank empty. To roughly calculate gross mass, add 1 kg/liter capacity. (e.g. 200L

=200Kg). All dimensions are in mm, Mass in Kg, the mass of each tank may vary according to the

type of pump fitted and other accessories.

Tank

Capacity

Length

Width

Height

Mass

100L

800

620

440

18

200L

1100

640

550

24

400L

1700

820

590

48

600L

1664

840

810

55

Specifications

PREPARING THE TRANSFER UNIT FOR OPERATION:

For transport purposes some transfer units will be supplied with the Delivery hose and Automatic

Shut-off gun disconnected from the pump. Before attempting to pump any Diesel ensure that the

delivery hose is securely fitted to the pump’s outlet, and that the Automatic Shut-off gun (with

swivel) is fitted to the other end of the delivery hose.

CONNECTING TO A POWER SUPPLY:

All the diesel transfer units are fitted with DC electric motors are supplied with alligator clips that

can be connected directly to a 12-volt DC battery. Connect the Red alligator clip to the positive

terminal and the black alligator clip to the negative terminal. If the pump runs backwards, simply

swap the clips on the battery. If you intend to extend the cable or add a plug, make sure it is of

sufficient capacity 25Amps

FILLING THE DIESEL UNIT:

Ensure that the tank is supported on an even base capable of taking the weight. No Special

equipment is required for filling the tank, however when the lid has been removed from the tank

take care not to introduce contaminants into the tank via the filler neck and ensure that the lid is

kept free of contaminating particles while filling.

TRANSFERING DIESEL:

The pump will need to prime itself upon first use. Turn the pump on and depress the trigger to allow

air to bleed from the hoses, after a short time the pump will have primed and delivery will

commence. We recommend for this first priming that the lid is removed from the tank and the

nozzle is directed back into the tank while pumping to avoid spillage or loss of Diesel, with this done

the unit is now ready to operate.

To dispense the pump must be turned on and the nozzles trigger depressed, the nozzle features an

automatic shut-off which operates when fluid contacts the outer nozzle. Once the auto shut off

operates turn off the pump within 2 or 3 minutes so as not to allow the motor to run for longer than

its specified duty cycle.

The pumps have been designed and built to require minimal maintenance however it is still

important that you Always remove the pump from the power source before any inspection.

The Vanes in the head of the pump will wear over time and require replacement. To extend the life

of the Vanes, ensure that the filters are kept clean and the tank free of contaminants. If a reduced

flow rate is noticeable, or a screeching sound is heard from the pump, dirt or debris may have

entered the pumps and requires immediate cleaning before parts are permanently damaged.

Periodically check the suction foot filter to ensure that is clean and free of debris. This should be

done if there is a noticeable decrease in diesel flow rate. There is also a coarse screen mesh at the

inlet of the red “Selecta” Auto shut-off gun and can be checked by removing the gun from the swivel.

Operation and Installation

Maintenance

TROUBLE SHOOTING GUIDE

Problem

Solution

Pump does not operate

•Ensure battery wires are connected to battery properly. Red

Clip to +ve

•Check Fuse (25A) under plastic pump switch cover is intact.

To Test & Repair if Pump does

not

operate

•Remove pump end cover, connect power to White & Black

wires to test

•If motor still does not operate, remove 3 x head cover bolts &

check for rust or obstruction, do not over tighten the screws

when replacing the cover as this will jam the rotor against the

cover and also prevent the electric motor from turning and

blow the fuse.

Pump Wiring Overheating

•This can happen when pump is operated in bypass mode for

longer than 3 minutes or if low voltage/amps. Ensure that

pump is not left running for longer than 3 minutes without

depressing Transfer Gun trigger.

•The wiring loom has been extended using wire of insufficient

gauge. 25A wire is required and a matching connector

Pump makes a

squealing/scratching sound

while running.

•This can be caused by dirt or debris entering the pump and

becoming caught in the working parts. Remove the end cover

of the pump by first unscrewing the three Socket Head

screws and lifting off the cover. Clean the impeller vanes

ensuring you remove any dirt particles caught between the

ends of the vanes and the impeller housing. Do not over-

tighten head screws when reassembling.

Pump stalls when Transfer

Gun trigger is released, and

pump is running.

•The non-return valve in the outlet of the pump may be

jammed shut. Remove the outlet hose from the pump.

Operate the white plastic valve in the outlet port of the pump

manually (by pushing it in and out), to ensure it moves freely.

To Test & Repair if the Pump

is running but low or nil flow

from nozzle

•Remove gun from hose & re-test, Run the hose into the tank

filling neck while checking.

•If flow improves, check hole in the end of the nozzle for

blockage

•Replace gun as required

Pump runs but does not

pump

•Check red alligator clip fitted to positive terminal, black to

negative. If it is the wrong way around the pump runs

backwards.

•Check suction hose and foot filter are immersed in diesel.

The suction hose may be bent up out of the diesel.

•If pump is brand new or has not been used in a long period of

time unscrew automatic gun from hose and put hose in filler

neck to prime pump

Troubleshoot

Pump Model Type

Pump

Name

Volts

(DC)

Amps

Open

Flow

Motor Duty

Cycle

Internal

Bypass

Delivery

Hose

DIESEL

POWER

2000

12

22

40L/min

30 minutes

Yes

4

meters

(20mm

I.D.)

PUISI

BP3000

12

22

45L/min

30 minutes

Yes

5

meters

(20mm

I.D.)

PUISI

BP3000

INLINE

12

22

45L/min

30 minutes

Yes

5

meters

(20mm

I.D.)

12V

DIESEL

PUMP

POLY

382-081

12

22

40L/min

20 minutes

Yes

4

meters

(20mm

I.D)

Pump Specifications

This manual suits for next models

6

Table of contents