SilverBolt 1620-CSD User manual

REV 10/29/2021

USER MANUAL

SilverBolt 1620-CSD

User Manual

SilverBolt Heat Press

1

2

3

4

5

7

TABLE OF CONTENTS

Specifications

Operation Instructions

Control Panel

Temperature Calibration

Troubleshooting

Heat Transfer Application Guidelines

User Manual SilverBolt Heat Press

Model NO: SilverBolt 1620-CSD

Voltage: 110V*

Power: 1800W

Control Panel: LCD Control Panel

Time Range: 0~999sec.

Temp. Range: 0~480˚F

Heating Element: 16” by 20”

Packaging: Double-walled Corrugated Paper Carton

Gross Weight: 92.6 lbs (42 kg)

SPECIFICATIONS:

Model No. 1620-CSD

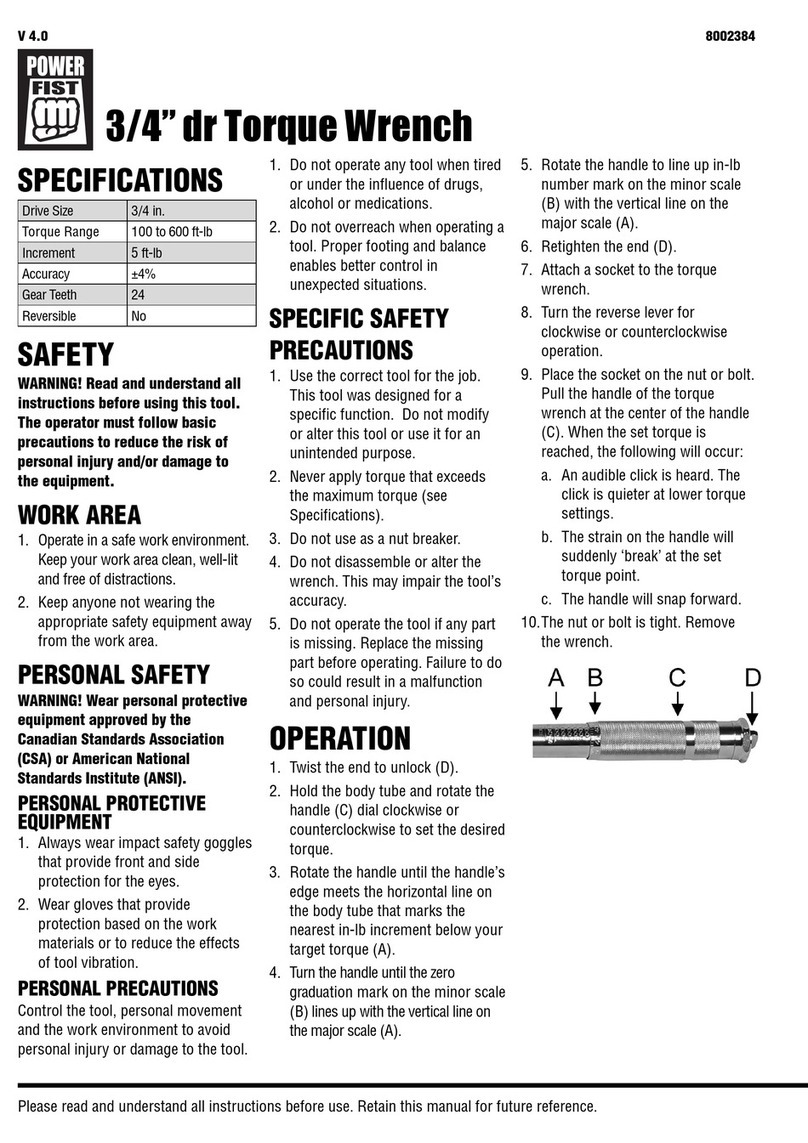

Pressure Knob

Lower Aluminum Plate

Drawer

Operation Handle

Silicon Pad

Heating Element

Control Panel

Emergency Button

Power Switch

1

* For best results, 16” by 20” heat presses should be run on a dedicated 20-amp circuit. This provides sufficent

power to quickly heat the platen, maintains consistent temperature and ensures stedy power supply to the press.

Failure to do so may result in longer heating times, inconsistent platen temperatue and interrupted operation

because of tripped circuit breakers.

User Manual SilverBolt Heat Press

OPERATION INSTRUCTIONS

READ BEFORE USE

1. Check the voltage before using it. The correct voltage is 110.

2. Turn off the machine when not in use, and remove the power plug from

socket.

3. Grasp the handle firmly when opening.

4. Keep children away from the machine.

5. Do not touch the heating platen and platen cover after pressing whilst

in operation.

6. Do not attempt to press products that are not intended for normal heat

transfer.

7. Do not set the temperature any higher than 480F as it may cause over heat

and stop working.

8. The heat press carries a ground line by default, please make sure the socket

gets a ground line protector.

2

User Manual SilverBolt Heat Press

Control Panel Display P-1: Temperature Setting

Mode

Hit SET & use the up and down

arrows to set temperature

P-3: ºC or ºF Read Out

Auto Shut Off Mode

Hit SET three times & use the up

and down arrows to select

Celsius or Fahrenheit

The screen will read OFF and

start to cool down if heat press

is inactive to reheat the press,

hit any button

P-3: ºC or ºF Read Out P-4: Auto Shut Off Mode

Hit SET three times & use the up

and down arrows to select

Celsius or Fahrenheit

P-2: Time Setting Mode

Hit SET twice & use the up and

down arrows to set amount of

time for pressing

Hit SET four times & use the up and

down arrows to set auto shut off

when inactive 0-120 minutes range

Clear Counter Number

Long hold the CLEAR button to clear

your counter on the panel.

Other Functions

If you need to calibrate your press,

hold the up and down arrow

together for a few seconds.

If you need to clear your counter,

hold your clear button for

a few seconds.

CONTROL PANEL

3

User Manual SilverBolt Heat Press

Touch the up and down arrow for a

few seconds together.

Touch the SET key till you find a

window like the picture above.

Gauge enters into a window like

above picture

Touch the up and down arrow to

determine the temperature will

be modified. Say -30 (i.e. heating

platen 30°F cooler than the

gauge read-out)

Touch the SET key back to the

temperature, and it will read out

200°F, and the press will continue

to heat up to 230°F

Touch the up and down arrow to

determine the temperature will

be modified. Say 30 (i.e. heating

platen 30°F hotter than the

gauge read-out)

Touch the SET key back to the

temperature, and it will read out

260°F, and the press will cool down

to 230°F

Touch the up arrow till you hit 88.

TEMPERATURE CALIBRATION

4

User Manual

SilverBolt Heat Press

TROUBLE-SHOOTING TIPS

Q. Why isn’t my heat transfer vinyl sticking to the fabric?

A. This can be caused by three things. Insufficient pressure, or temperature, or time.

Time: Some heat transfer films need a few seconds to cool before you remove the

liner. Try a warm or cold peel first.

Temperature: If that doesn’t work, check to make sure you are using the

recommended time and temperature settings. If you are, your press may not be

putting out the correct amount of heat. Use a Geo Knight IR thermometer to check

the actual temperature of the platen. If it is more than 5° different from the LCD

display (PV), adjust it using step four in the control panel (see page 4).

Pressure: If the temperature is correct, adjust the pressure. Some films require more

pressure to bond the adhesive to the fabric. There should be some resistance

when you close the press. If you have verified all of these and the film doesn’t

stick, contact SIGNWarehouse customer service or Technical Support for further

assistance.

Q. Why does my sublimated transfer look washed out?

A. This is usually caused by insufficient temperature. Sublimation works best at or

near 400°F. If your transfer is faded, check the output of the heat platen with a

contact thermometer and make sure the output matches the displayed

temperature. If not, adjust as directed above. Then repress at 390 - 400°F.

5

User Manual

SilverBolt Heat Press

TROUBLE-SHOOTING TIPS: CONT’D

Q. Why are my transfers are sticking to the heating element of the upper platen?

A. If T-shirt vinyl is sticking to the heating element, you have it upside down. Remove

any adhesive residue, flip it over and try again. If an inkjet or laser transfer is

sticking to the heating element, it’s because the heat is affecting the ink. Cover it

with a Teflon sheet or sheet of silicone Kraft paper to prevent this. Using a Teflon

sheet or Kraft paper is recommended for almost all heat transfer applications.

Q. Why is it so hard to peel the liner when I’m done pressing the paper?

A. A hot or warm peel film may become hard to peel if allowed to cool. Always peel

the film or transfer paper in accordance with the product’s recommendations.

6

User Manual

SilverBolt Heat Press

HEAT TRANSFER APPLICATION GUIDELINES

These are general guidelines. For specific time and temperature settings for specific films

and/or transfer papers, please refer to the instructions for that particular product.

TRANSFERS Device Fabric TEMP. TIME PRESSURE

Sublimation Paper Ricoh, Epson Polyester 400°F 25 - 30 sec. 30Psi

Ink Tran. Paper Inkjet Printer Light Color 365°F 15 sec. 30Psi

Dark Color 330°F 25 sec. 30Psi

Laser Transfer Paper** Laser Printer Light Color 345°F 30 sec. 30Psi

Laser Printer Dark Color 260 - 320°F 35 - 120 sec. 25Psi

Transfer Vinyls Cutting Plotter / 300 - 320°F 8 -10 sec. 30Psi

Plastisol Transfer / / 335°F 12 sec. 50Psi

** The SilverBolt 1620CSD and 1620-CSM are not recommended for use with two-step laser

transfer papers. For these demanding applications, we recommend the SilverBolt 1620

Premium Auto or 1620A Premium.

7

Table of contents

Other SilverBolt Power Tools manuals