SilverBolt 1620-SA User manual

REV 8/2/2021

USER MANUAL

SilverBolt 1620-SA

User Manual

SilverBolt Heat Press

Specifications

Operation Instructions

Control Panel

Troubleshooting

Heat Transfer Application Guidelines

Transfer Material, Cuttable Table

Transfer Material, Printable Table

1

2

3

4

6

7

8

TABLE OF CONTENTS

User Manual SilverBolt Heat Press

Model NO: SilverBolt 1620-CS

Voltage: 110V

Power: 1800W

Control Panel: LCD Control Panel

Time Range: 0~999sec.

Temp. Range: 0~480˚F

Heating Element: 16” by 20”

Packaging: Double-walled Corrugated Paper Carton

Gross Weight: 149 lbs (67.5 kg)

SPECIFICATIONS:

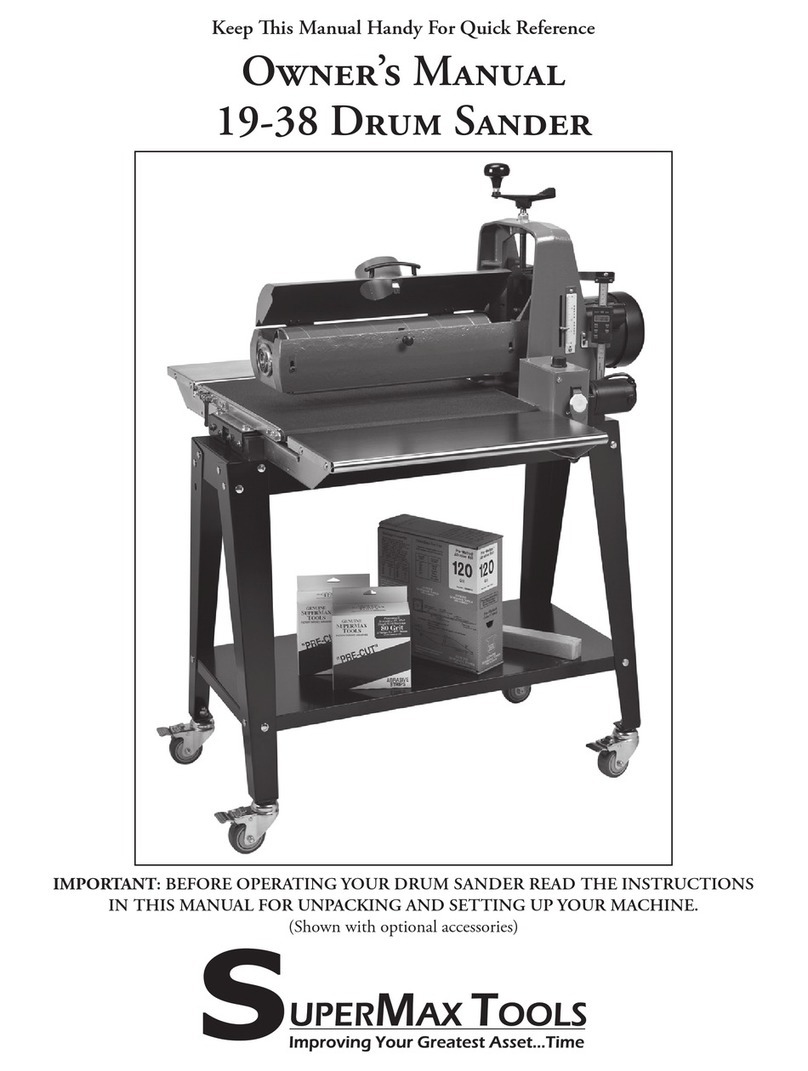

Model No. 1620-SA Pressure Knob

Lower Aluminum Plate

Caddie

Operation Handle

Silicon Pad Heating Element

Control Panel

Power Switch

Circuit Breaker

1

User Manual SilverBolt Heat Press

OPERATION INSTRUCTIONS

READ BEFORE USE

1. Check the voltage before using it. The correct voltage is 110.

2. Turn off the machine when not in use, and remove the power plug from

socket.

3. Grasp the handle firmly when opening.

4. Keep children away from the machine.

5. Do not touch the heating platen and platen cover after pressing whilst

in operation.

6. Do not attempt to press products that are not intended for normal heat

transfer.

7. Do not set the temperature any higher than 480F as it may cause over heat

and stop working.

8. The heat press carries a ground line by default, please make sure the socket

gets a ground line protector.

2

User Manual SilverBolt Heat Press

Control Panel Display Home Screen

Press the Setting Button

to access the control setting.

This is how your screen will look

when you turn on your heat press

Present Settings

Name: Custom Name for Presents

Temperature: Can set

temperature for the Present

Pressure: How much pressure that is

used for the Present

Time: Can set time for the Present

Setting Screen

Home Button

Unit: °C/°F

Calibration: Temperature

Compensation Adjustment

Sound: On/Off

Standby: On/Off Standby Mode

and to set the Standby Time

Reset: Reset all Settings

This button will take

you back to the

home screen

This button will take

you to the settings

of the heat press

This can lock or unlock

the settings. Can adjust and

save over the preset

Go to preset the

Temperature, pressure,

and time

Use the arrows to

change the pressure,

time or temperature

This will put the press

in stnadby mode.

To turn back on,

hit this button again

Use the arrows to

change the pressure,

time or temperature

CONTROL PANEL

Settings Button

Program Button

Lock Button

Left Arrow

Right Arrow

Power Button

3

User Manual

SilverBolt Heat Press

TROUBLE-SHOOTING TIPS

Q. Why isn’t my heat transfer vinyl sticking to the fabric?

A. This can be caused by three things. Insufficient pressure, or temperature, or time.

Time: Some heat transfer films need a few seconds to cool before you remove the

liner. Try a warm or cold peel first.

Temperature: If that doesn’t work, check to make sure you are using the

recommended time and temperature settings. If you are, your press may not be

putting out the correct amount of heat. Use a Geo Knight IR thermometer to check

the actual temperature of the platen. If it is more than 5° different from the LCD

display (PV), adjust it using step four in the control panel (see page 4).

Pressure: If the temperature is correct, adjust the pressure. Some films require more

pressure to bond the adhesive to the fabric. There should be some resistance

when you close the press. If you have verified all of these and the film doesn’t

stick, contact SIGNWarehouse customer service or Technical Support for further

assistance.

Q. Why does my sublimated transfer look washed out?

A. This is usually caused by insufficient temperature. Sublimation works best at or

near 400°F. If your transfer is faded, check the output of the heat platen with a

contact thermometer and make sure the output matches the displayed

temperature. If not, adjust as directed above. Then repress at 390 - 400°F.

4

User Manual

SilverBolt Heat Press

TROUBLE-SHOOTING TIPS: CONT’D

Q. Why are my transfers are sticking to the heating element of the upper platen?

A. If T-shirt vinyl is sticking to the heating element, you have it upside down. Remove

any adhesive residue, flip it over and try again. If an inkjet or laser transfer is

sticking to the heating element, it’s because the heat is affecting the ink. Cover it

with a Teflon sheet or sheet of silicone Kraft paper to prevent this. Using a Teflon

sheet or Kraft paper is recommended for almost all heat transfer applications.

Q. Why is it so hard to peel the liner when I’m done pressing the paper?

A. A hot or warm peel film may become hard to peel if allowed to cool. Always peel

the film or transfer paper in accordance with the product’s recommendations.

5

User Manual

SilverBolt Heat Press

HEAT TRANSFER APPLICATION GUIDELINES

These are general guidelines. For specific time and temperature settings for specific films

and/or transfer papers, please refer to the instructions for that particular product.

TRANSFERS Device Fabric TEMP. TIME PRESSURE

Sublimation Paper Ricoh, Epson Polyester 400°F 25 - 30 sec. 30Psi

Ink Tran. Paper Inkjet Printer Light Color 365°F 15 sec. 30Psi

Dark Color 330°F 25 sec. 30Psi

Laser Transfer Paper** Laser Printer Light Color 345°F 30 sec. 30Psi

Laser Printer Dark Color 260 - 320°F 35 - 120 sec. 25Psi

Transfer Vinyls Cutting Plotter / 300 - 320°F 8 -10 sec. 30Psi

Plastisol Transfer / / 335°F 12 sec. 50Psi

** The SilverBolt 1620CSD and 1620-CSM are not recommended for use with two-step laser

transfer papers. For these demanding applications, we recommend the SilverBolt 1620

Premium Auto or 1620A Premium.

6

7

Transfer Material, Cuttable TEMP. TIME PRESSURE

Logical Color WarmPEEL CP 320°F 15 sec. 4-6

Logical Color Universal

• 100% Cotton

• Cotton/Polyster Blends

PEEL

Warm

320°F 15 sec. 4-6Logical Color GlitterSOFT

Logical Color Flock

320°F 3 sec. 6-8

Warm

320°F 15 sec. 4-6

Warm

Warm

300°F 4 sec. 4-6Warm

• Polyster and Acrylic 300°F 5 sec. 2-4Warm

Siser EasyWeed 305°F 10-15 sec. 4-6

Siser EasyWeed Glow

Siser EasyWeed Stretch

Hot or Cold

Siser EasyPatterns 305°F 10-15 sec. 4-6Hot or Cold

Siser EasyReflective 305°F 15 sec. 4-6Warm

Siser Blackboard 275°F 15 sec. 4-6Warm

Siser Glitter 320°F 15-20 sec. 4-6Warm

320°F 15-20 sec. 4-6Warm

305°F 10-15 sec. 4-6Siser EasyWeed Extra

305°F 10-15 sec. 4-6

Hot or Cold

305°F 10-15 sec. 4-6Siser EasyWeed Fluorscent Hot or Cold

305°F 10-15 sec. 4-6Siser EasyWeed Electric Hot or Cold

Hot or Cold

320°F 20 sec. 6-8Hot or Cold

Siser EasyWeed Adhesive 275°F 5-10 sec. 4-6Hot

Siser Twinkle

Siser Holographic 320°F 15-20 sec. 4-6Cold

Siser EasySubli 311°F 15 sec. 4-6Hot

HEAT TRANSFERS FOR TEXTILES

Chemica Hotmark 320°F 20 sec. 4-6Cold

Chemica Hotmark Revolution

285°F 5 sec. 5-7

285°F 5 sec. 5-7Warm

250°F 20 sec. 5-7Warm

Hot or Cold

285°F 15 sec. 5-7Hot or Cold

Chemica Metallic

Chemica Fashion

Chemica Galaxy

300°F 10-15 sec. 4-6Warm or Cold

293°F 15 sec. 4-6Cold

320°F 20 sec. 4-6Cold

320°F 20 sec. 4-6Cold

320°F 20 sec. 4-6Cold

Chemica FirstMark

Chemica UpperFlock

• Quick Mode

• Low Temp Mode

• Nylon, 1st Press

• Nylon, 2nd Press

SilverBolt 1620-SA

8

Transfer Material, Printable TEMP. TIME PRESSUREPEEL

Logical Color WarmPEEL CP PRINT 320°F 15 sec. 4-6Warm

Logical Color CozyPRINT 320°F 15 sec. 4-6Warm

Logical Color DarkJET 350°F 20 sec. 4-6Cold

Logical Color RGP 375°F 20 sec. 4-6Warm

Logical Color Universal PRINT

• 100% Cotton

• Sublimated Polyster

320°F 3 sec. 6-8Warm

267°F 5 sec. 4-6Warm

• Nylon 302°F 5 sec. 4-6Warm

Siser ColorPrint PU 295°F 15-20 sec. 4-6Hot

Siser ColorPrint Easy 300°F 15 sec. 4-6Warm

Siser ColorPrint Extra 320°F 10-15 sec. 4-6Hot

Siser ColorPrint Soft Opaque 311°F 15 sec. 5-7Hot

320°F 20 sec. 4-6HotChemica BestPrint

Chemica HotMark

Chemica HotMark Revolution

320°F 20 sec. 4-6Hot

• Quick Mode 285°F 5 sec. 5-7Warm

• Low Temp Mode 250°F 20 sec. 5-7Warm

HEAT TRANSFERS FOR TEXTILES

285°F 5 sec. 5-7Hot or Cold

285°F 15 sec. 5-7Hot or Cold

• Nylon, 1st Press

• Nylon, 2nd Press

* These settings are from our testing and recommended starting point.

Always perform a test press before going nto production.*

SilverBolt 1620-SA

Other manuals for 1620-SA

1

Table of contents

Other SilverBolt Power Tools manuals