Sim-Lab XP-1 User manual

XP-1 PEDALS

VERSION 1.0

Last updated: 11-09-2023

INSTRUCTION MANUAL

2|2 16

BEFORE YOU START:

Thank you for your purchase. In this manual we will provide you with the means to

get started using your new pedals!

Introducing the Sim-Lab XP-1 200KG Loadcell Pedal Set! Simulate any pedal of any

car with the most complete sim-racing pedal set available. Carefully crafted to satisfy

the needs of serious sim racing enthusiasts, this top-notch and fully customizable

pedal set is designed to take your on-track performance to new heights. Experience

the thrill of absolute control, immerse yourself in the authenticity of sim racing, and

unleash your true racing potential with the Sim-Lab XP-1 200KG Loadcell Pedal Set.

It’s time to elevate your racing experience and leave your competitors in the dust.

XP-1 LC PEDAL SET and CLUTCH

Features:

Aluminum construction

Custom integrated loadcell (Brake)

Hall sensor (Throttle/Clutch)

Multiple elastomers included

Multiple springs included

Plug and play (USB-B)

16-Bit resolution input

3

| |316 16

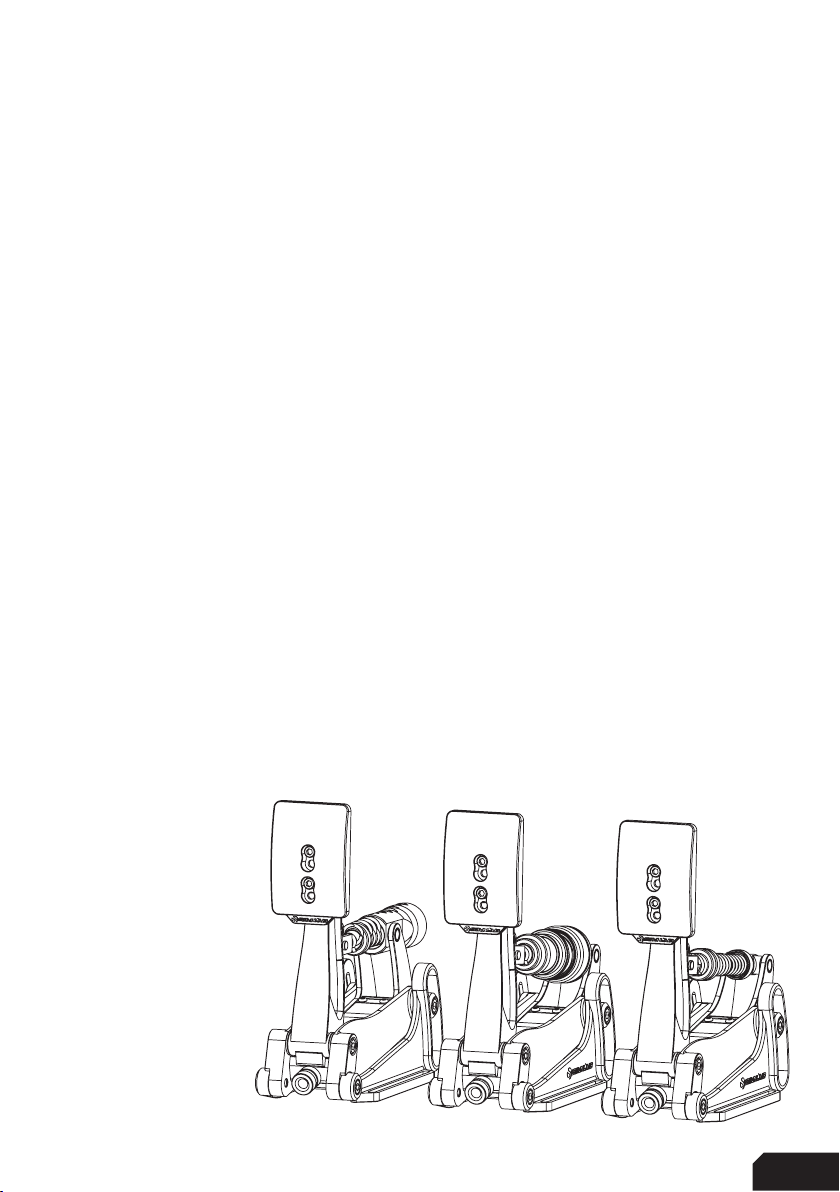

Installation

Depending on your setup, the pedals can be mounted directly to both profile (P1-X) or

pedal decks (like the GT1-EVO). Also the latest universal baseplate is also compatible

with these new pedals so no matter which setup you own, there are ways to mount

this pedal set.

Simply bolt down the set using the 6mm slots (seen from the bottom) shown below.

Profile based pedal deck

In the case of a profile based pedal deck, like found on

the P1-X, mounting is very easy. Sufficient mounting

hardware is included.

The example on the right shows the pedals mounted to

the bigger of the two profiles to allow for a heelplate

to be fitted on the smaller profile. This of course

depends on your preference.

On the next page, you can review our recommended

mounting solutions for pedal decks and baseplates.

A15

A12

A20

4|4 16

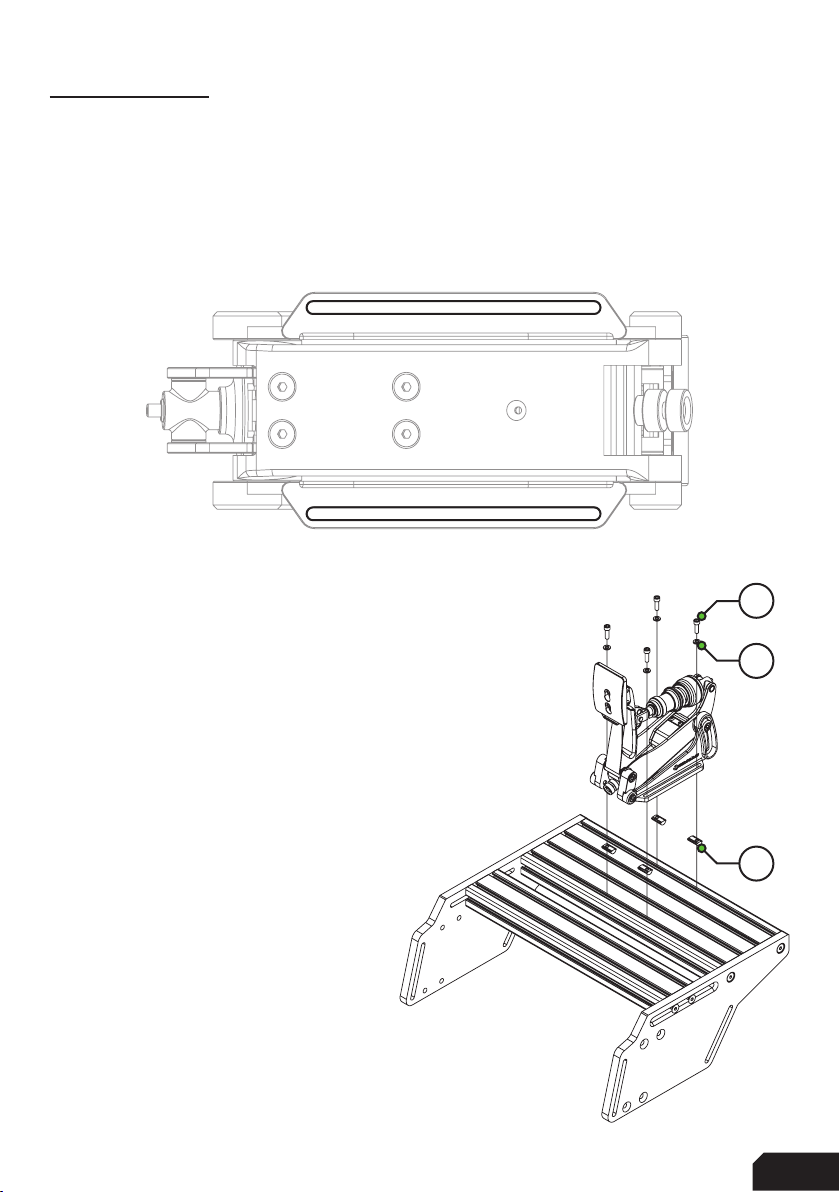

Pedal deck and baseplate

Due to the 6mm slots, you can use almost every slot found on these products and it

all comes down to personal preference.

For baseplates, there still more than enough of possibilities.

The obvious difference here is the lack of slot-nuts, and the inclusion of some

additional washers to help protect your baseplate. As mentioned, the exact slots you

use really don’t matter too much, as almost all slots on our pedal deck based

products match the 6mm slots on the pedal side mounts.

When mounting to a pedal slider

baseplate for example, use the

hardware indicated on the right.

For normal pedal decks, the same

hardware applies. The bolts will

stick out a bit, that is okay.

A18

A15

A11

5

| |516 16

Configuration

Pedal Base

We tried to re-use as many parts throughout the pedals as possible. This means the

configuration and adjustments are virtually the same for all three pedals.

The angle of the pedal arm in relation to your cockpit can be changed by adjusting

the pedal base. Simply loosen four bolts, start with the two (P) where the arm pivots

around. After those are loose, loosen the two (A) in the arcs. Now you should be able

to rotate the entire pedal as a whole while the base remains fixed in place. Tighten all

bolts again after you have found your preferred position and you are good to go.

There is quite a large range of adjustment (20 degrees) possible so you can adjust

these pedals to your seating position perfectly.

Note: especially for the brake pedal, make sure all four bolts (A,P) are tight

before using the pedal with higher brake forces.

A

P

6|6 16

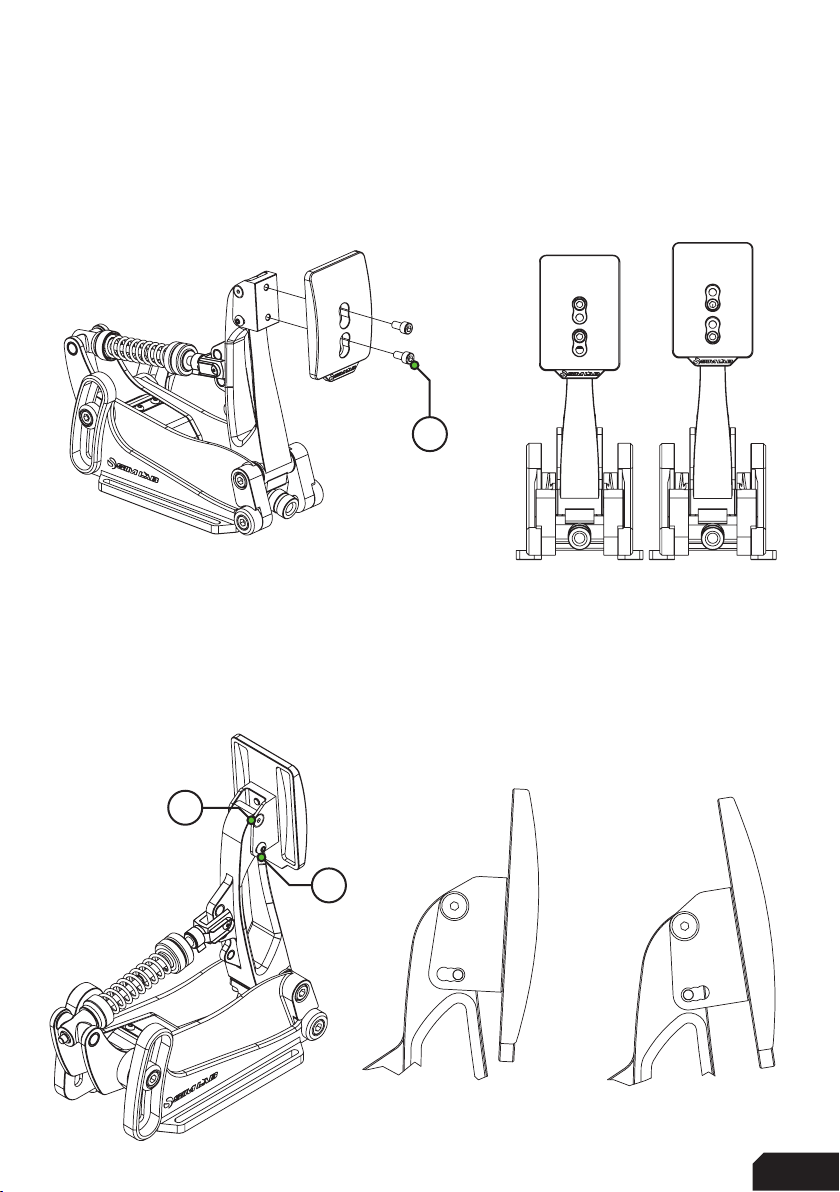

Pedal Face

One of the more simple adjustments is the ability to change the position and angle

of the pedal face. Loosen the two bolts (F) holding the pedal face and you can adjust

the position of the pedal face to your preference.

As mentioned, it is also possible to change the angle of the pedal face. Begin by

loosening the top (T) (countersunk) bolts, but do not remove them. Temporarily

remove the bottom (B) bolts and now the bracket can rotate freely. The bracket

comes with a preset slot for different angles you can choose from. Choose your

angle and fix it in place using the two bottom bolts (B). When happy, tighten the

upper two (T) bolts again as well.

B

T

F

7

| |716 16

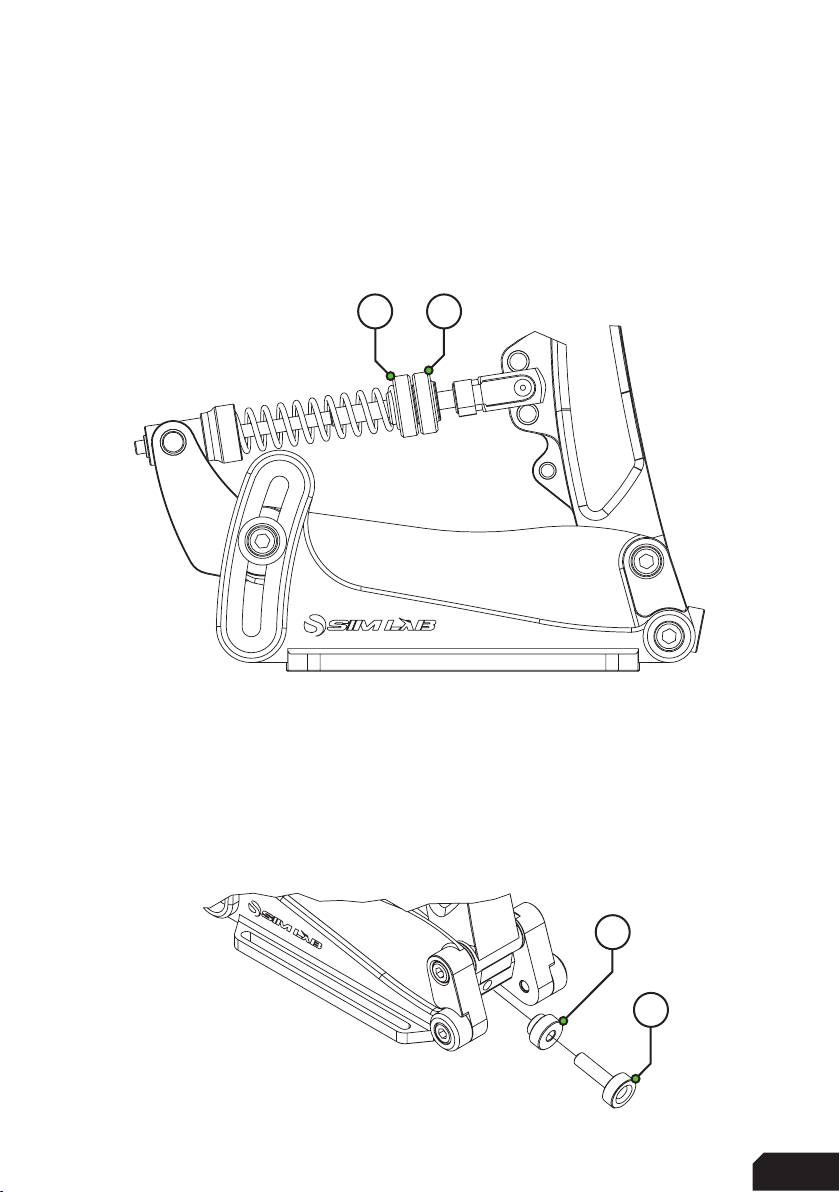

Prepare for changing parts

To get acces to the parts we can change, first we must temporarily remove the

spring bolt (S), which keeps the clevis fork attached to the pedal arm. In this example

we are using the throttle pedal.

Release any tension from the spring by loosening any adjustment knob(s) before

trying to remove the spring bolt.

Unclip the spring bolt (S) from the clevis fork shaft (left drawing) by rotating it up-

wards, then pull it away from the clevis fork altogether. Now the entire shaft holding

parts, can be turned away from the pedal arm and as many parts removed as

desired.

Be careful! The pedal arm is unsupported right now and will be able to fall towards

the front or the rear of the pedal. We recommend to keep holding the pedal arm or

provide support to it by other means, while removing the clevis fork and shaft parts,

to avoid damage.

S

8|8 16

Throttle configuration

This pedal is easy to setup, be it stock or after you have changed the springs. There

are two main options basically. The throttle spring can be adjusted to be more stiff

or soft. Unlock the blue knobs and tighten (clockwise) the adjustment knob (A) for

a stiffer throttle feel. To go softer, do the opposite. When you are happy with the

change, hold the adjustment knob (A) and tighten the locking knob (L) against it, this

locks your change in place.

The same principle applies to the maximum travel of the pedal. On the bottom of the

pedal arm you will find two blue knobs as well. The inner one is the locking knob (L),

the outer one is the adjustment knob (A). Turning the adjustment knob clockwise

results in less travel, turning the adjustment knob anti-clockwise results in more

travel. By default, the pedal has been setup to provide a middle of the road range of

travel but you are free to experiment.

L A

L

A

9

| |916 16

Adjusting spring force isn’t only possible by using the adjustment knobs. Using the

lower of the three adjustment points on the pedal arm gives you a slightly softer (S)

pedal pressure for example. The higher of the three a slightly firmer (F).

Note: by the nature of the position of the clevis fork so low on the pedal arm, travel

might be mechanically limited. Please do check the travel manually (meaning literally,

by hand) to see if you need to decrease travel using the travel adjustment knobs,to

prevent the clevis fork interfering with the flange on the pedal arm. When it does,

please reduce maximum travel until you have about 3-4mm between the flat base

of the clevis fork and the pedal arm flange.

In case you aren’t happy with the overall spring force range, we supply a heavy

throttle spring for ultimate control. Simply follow the steps on page 7, remove the

adjustment knobs and replace the default spring with the heavy one.

F

S

10 |10 16

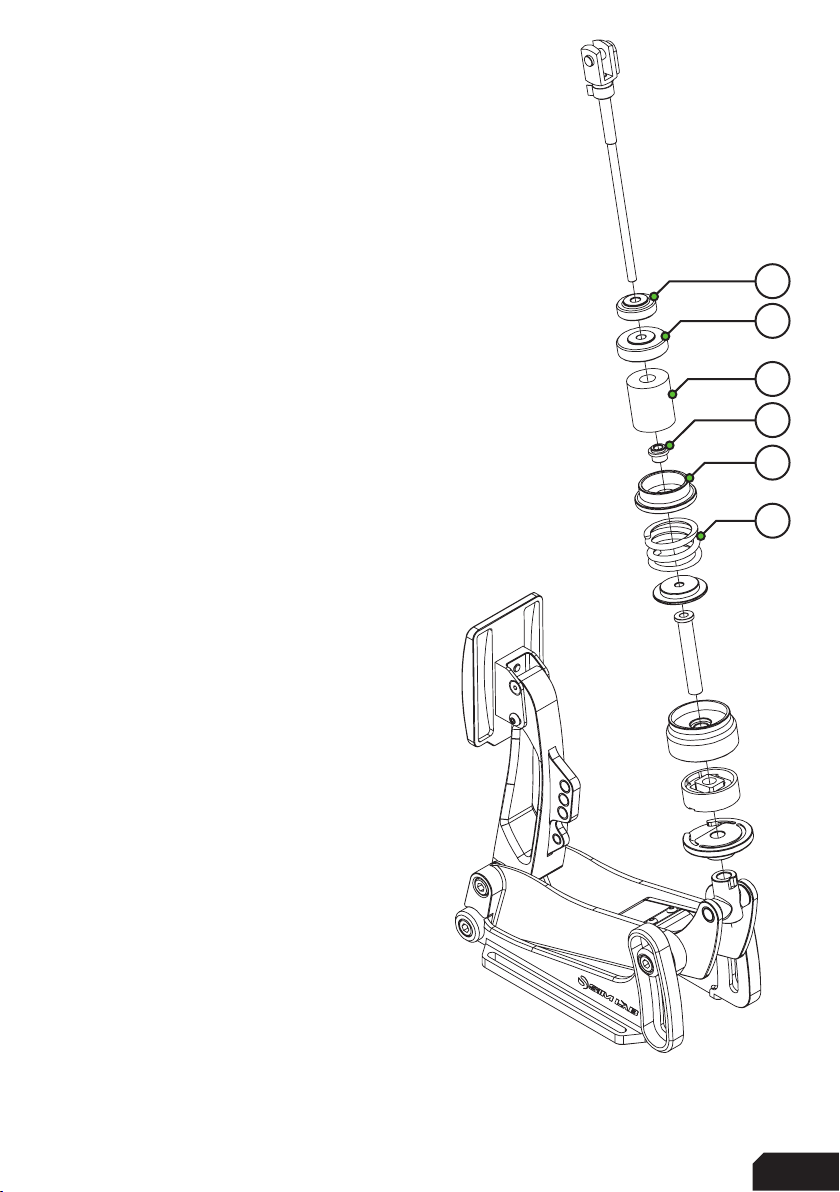

Brake configuration

We will focus just on changing parts in this chapter.

After you have followed the steps on page 7, you

can now remove the clevis fork and shaft. This makes it very

easy to change around parts to suit your preference.

Keep in mind, all parts connected to the shaft are

loose fitting. Make sure to keep parts together

which don’t need to be replaced to avoid

misplacing them.

The parts which we expect to be removed when

changing the brake stack as shown on the right:

Locking Knob (L)

Adjustment Knob (A)

Elastomer (E)

Bushing (B)

Elastomer Washer (W)

Pre-load Spring (P)

Depending on your preference, we have

included four elastomers (E) in different

hardness (Shore A) ratings for you to try.

The medium one is pre-installed.

Included are the following

elastomers, the Shore A ratings are:

Soft - Shore 50A

Medium - Shore 60A

Hard - Shore 70A

We recommend to match your max pressure

to the elastomer rating. We expect you to run lower

pressures with the 50A, this ensures its durability.

We also supply you with different preload springs to

adjust the feel of the preload. The medium strength one is fitted.

L

A

E

W

P

B

11

| |1116 16

In case you do not want any preload, we included a preload buffer(BOM) to replace

the spring with. This is basically a spacer which replaces the spring.

As a matter of fact, when you are going to install the preload buffer and do not want

any preload all, remove the spring entirely. This way there is no unnneccesary strain

on the whole assembly and the preload buffer will do its job regardless.

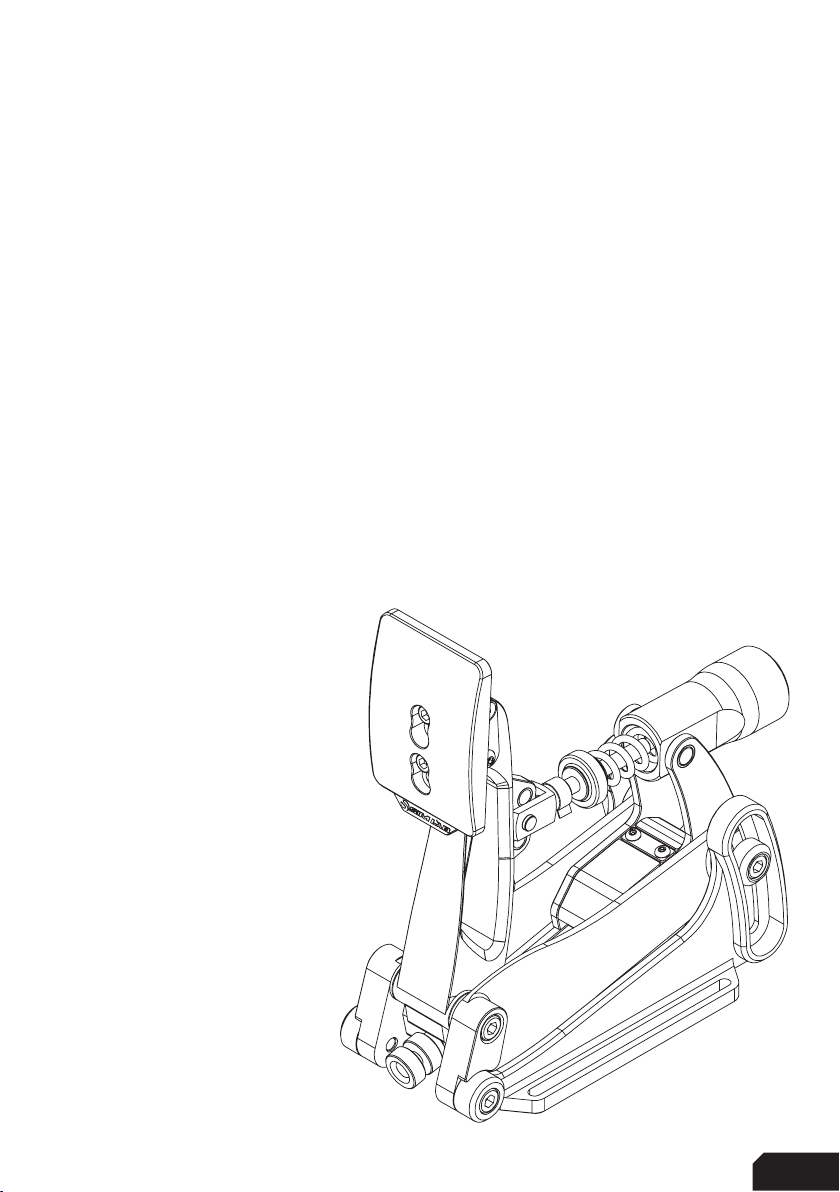

Clutch (sold separately) configuration

We hardly mentioned the clutch in this manual so far. Let’s change that.

The clutch shares all base parts with the brake and mostly the throttle pedal. It does

have an additional (heavy) spring and travel is adjustable to a point.

This is the only pedal which we limit to only using the top adjustment point on the

pedal arm. Because of the swiveling pivot part, we do not support any of the other

adjustment holes.

In the case of the clutch, it

means adjustability is limited,

if only simply by the nature of

the intended feel.

As with the other pedals,

maximum travel can be

adjusted. Please be aware this

does diminish the feel of where

the bitepoint is rather quickly

and might not have the

desired effect.

When adjusting the adjustment

knob for spring tension, please

be mindful that at full travel it

doesn’t collide with the pivot.

We recommend to make

adjustments in small

increments to make sure no

parts collide, possibly causing

damage.

12 |12 16

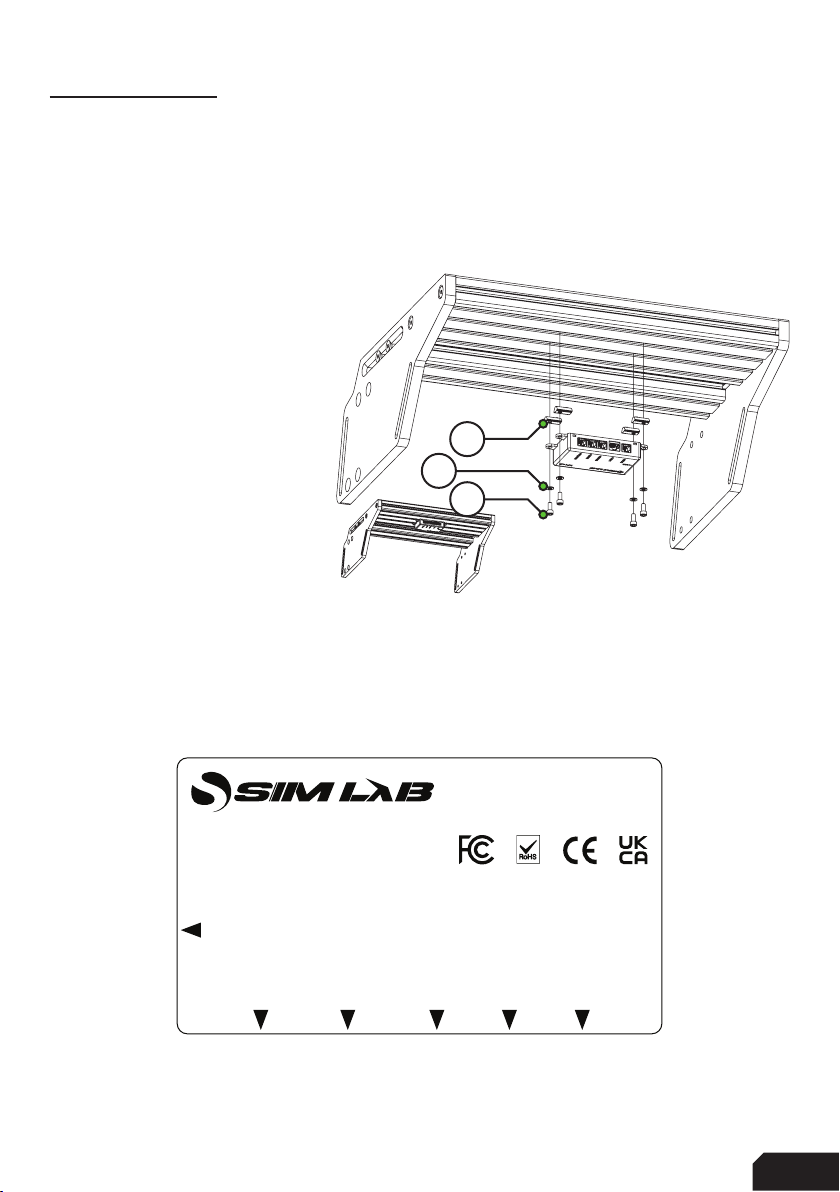

Control box

Installation

The mounting tabs are suited to a 80x40 pattern so they can be mounted almost

everywhere near your pedals. Here we chose to mount the control box underneath a

profile based pedal deck found on our P1-X and X1-Pro cockpits.

Using the hardware provided

the control box won’t go anywhere.

Don’t overtighten the M5 bolts,

the control box doesn’t go

anywhere.

Connected the cables to and

from the pedals as labeled.

We recommend taking some

time for cable management.

Please refer to the included

quick start guide for more

information about mounting

the control box.

Plugging in the pedals

All pedals are plugged into the control box the same way. All inputs are labeled, for

reference, here is top-down drawing with the same information as found on the box.

Every pedal uses the same connector, so you don’t have to worry about mixing up

the cables or anything. They are all identical to each other.

USB

EXT. 2

THROTTLE

BRAKE

CLUTCH

EXT. 1

XP-1 PEDALS

CONTROL BOX

A14

A17

A21

13

| |1316 16

RaceDirector

Download and install the lastest version of RaceDirector from

www.sim-lab.eu/srd-setup

For explanation on how to install and use RaceDirector, please read the manual.

This can be found here: www.sim-lab.eu/srd-manual

We will now go over the very basics to get going using RaceDirector to get you on

track asap. We really urge you to go through the manual for a more in depth

explanation of the possiblities RaceDirector has to offer.

First we need to activate the product, this is done on the ‘Settings’ (1) page.

Tick the ‘Activate’ tickbox next to

‘XP-1 Pedals’ (2) and its icon (3) should appear on the left side of the screen. Selecting

the icon (3) will take us to its device pages.

3

1

2

14 |14 16

Device page

The device page for the pedals allow you to calibrate (1), adjust the input curves (2)

and adjust deadzones (3). We will focus on the middle colum in this example, as their

functionality is identical:

Calibration

- Press ‘Calibrate’ (1) for the device to enter calibration mode.

- Press the pedal to the maximum travel or force, press ‘Finish calibration’ when

done.

- We advise to dial some deadzone (3) on both sides of the spectrum. This way

when you’re not touching a pedal, it can’t provide an unwanted input.

- The percentages are using the calibrated range. We advise to keep these in the

single digits.

Input curve adjustment

Adjusting the input curves (2) is as easy as moving points on a line. You can

manipulate a maximum of 5 points per graph. By manually moving/overriding the

‘input slider’ (4) you can see how the curve affects your input.

By pressing ‘save profile’ (5) you can save all settings.

By pressing ‘load profile’(6) you can load a settings file you previously configured.

We supply some presets (7), which come with RaceDirector by default.

6

2

4

1

3

7

5

15

| |1516 16

Maintenance

Although the pedal set has bronze bushings and teflon parts, we do recommend to

take care of your pedal set. Every now and then some cleaning and oiling will benefit

performance and condition of your pedal set.

As for lubrication ( ), we generally recommend WD-40 Specialist White Lithium

Grease to lubricate moving parts. Also, do not forget the spring bolt which also sits in

a bushing on the pedal arm.

This doesn’t take much time and effort at all but goes a long into enjoying your pedal

set for many hours on the virtual track to come.

16 |16 16

Bill of materials

More information

If you still have some questions regarding assembly of this product or about the

manual itself, please refer to our support department. They can be reached at:

Alternatively, we now have Discord servers where you can hang out or ask for help.

www.sim-lab.eu/discord

Product page on the

Sim-Lab website:

THROTTLE AND BRAKE SET

#Part QTY Note

A1 Brake pedal 1

A2 Throttle pedal 1

A3 Control box 1

A4 Pedal cable short 2 30cm.

A5 Pedal cable long 2 75cm.

A6 USB-A cable 1

A7 Elastomer set 2 50A, 70A.

A8 Brake preload spring set 2 Light, Heavy.

A9 Brake preload buffer 1

A10 Throttle spring heavy 1

A11 Bolt M6 X 30 DIN 912 10

A12 Bolt M6 X 20 DIN 912 10

A13 Bolt M5 X 25 DIN 912 2

A14 Bolt M5 X 12 DIN 912 4

A15 Washer M6 DIN 125-A 20

A16 Washer M5 DIN 9021 2

A17 Washer M5 DIN 125-A 4

CLUTCH

#Part QTY Note

B1 Clutch pedal 1

B2 Clutch spring heavy 1

B3 Bolt M6 X 30 DIN 912 4

B4 Bolt M6 X 20 DIN 912 4

B5 Washer M6 DIN 125-A 8

B6 Lock-Nut M6 4

B7 Slot-Nut M6 4

#Part QTY Note

A18 Lock-Nut M6 20

A19 Lock-Nut M5 2

A20 Slot-Nut M6 10

A21 Slot-Nut M5 4

Table of contents

Popular Music Pedal manuals by other brands

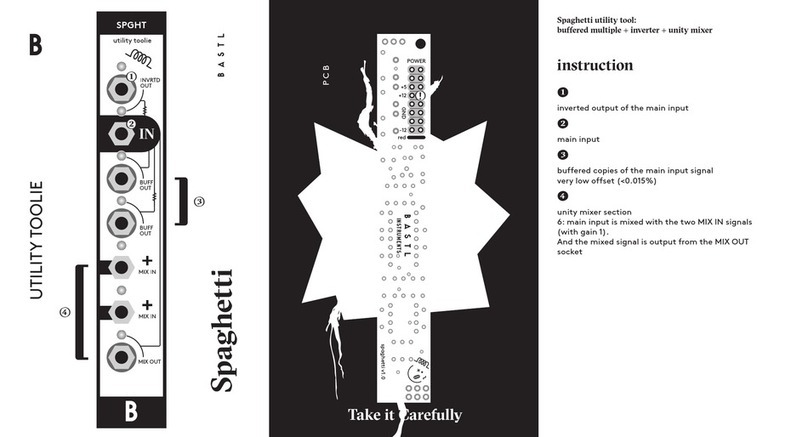

Bastl Instruments

Bastl Instruments Spaghetti Utility Toolie quick start guide

Dunlop

Dunlop MC404 CAE WAH manual

thomann

thomann Harley Benton Dynamic Compressor user manual

Electro-Harmonix

Electro-Harmonix CHILLSWITCH manual

Mooer

Mooer Micro Series owner's manual

Alexander Pedals

Alexander Pedals Leap Series user manual