SIMAG SD 10 User manual

Page 1

Page 1

SERVICE MANUAL

BEDIENUNGSANLEITUNG

SD 10

R 134 a

Home ice cuber

Kegeleisbereiter

090088.41 REV. 05/2001

Page 2

Page 2

INHALTSVERZEICHNIS SEITE

TABLE OF CONTENTS PAGE

TO THE USER 3

USER’S INFORMATIONS

- INTRODUCTION 4

DESCRIPTION

• Sealed Refrigeration System 4

• Self contained Storage Bin 4

• Removable water reservoir 4

SPECIFICATIONS 5

OPERATIONS BEFORE UNIT

START-UP 6

OPERATING INSTRUCTIONS

• Start-up 6

• Cleaning and Care 8

PRINCIPLE OF OPERATIONS

• Freezing cycle 10

• Harvest cycle 10

SERVICEMAN’S INFORMATIONS

- GENERAL 11

• Service Diagnosis 11

• Wiring Diagram 13

• Adjustment & Removal & Replacement

•Procedure 14

PARTS ILLUSTRATIONS AND

PARTS LIST ACCESSORIES 15

COMPRESSOR AND ELECTRIC

COMPONENTS CHART 19

FÜR DEN ANWENDER 20

INFORMATIONEN FÜR DEN ANWENDER

EINFÜHRUNG 21

BESCHREIBUNG

• Kühlsystem 21

• Eisbehälter 21

• Herausnehmbarer Wasserbehälter 21

TECHNISCHE SPEZIFIKATIONEN 22

VORGÄNGE VOR DEM

EINSCHALTEN 23

BETRIEBSANWEISUNGEN

• Einschalten 23

• Reinigung und Wartung 25

FUNKTIONSPRINZIP

• Gefrierzyklus 27

• Abtauzyklus 27

TECHNISCHE INFORMATIONEN

• Vorbemerkung 28

• Hilfe bei der Analyse 28

• Elektroschaltplan 30

• Entfernen und Auswechseln der einzelnen

Komponenten 31

ABBILDUNG UND LISTE DER

ERSATZTEILE 32

SD 10 - KOMPRESSORBAUTEILE UND

ELEKTRISCHE KOMPONENTEN 36

Page 3

Page 3

TO THE USER

YourmodelSD10IceMakerisaproductcarefully

engineered and quality constructed to provide

youwithmanyyearsoffaithfulperformanceand

a minimum of maintenance costs.

Produced by the world’s leading group of

automatic ice making equipments, your ICE

CUBE MAKER incorporates the same reliable

systems already proven over years of actual

operation by thousands of users. Many of you

will have an opportunity to see and use clear,

slow melting CUBERS for the first time.

You will quickly compare the clear, glass-like

quality of your Cubes to the type produced by

your home refrigerator, freezer.

By comparison, cubes made in trays in your

refrigerator are very white or cloudy, they also

melt faster than clear ice.

Takethetimenowtoreviewthismanualandyou

will see why these Cubes are solid and clearer

than ice cubes of your refrigerator.

No installation is required

Easyaccessforserviceisprovidedbytheprompt

removal of the front panel and/or the cabinet.

Page 4

Page 4

USER'S INFORMATIONS

INTRODUCTION

This manual provides the specifications and the

step-by-step procedures for the start-up and

operationand,themaintenanceandcleaningfor

the Model SD 10 Automatic Ice Cube Maker.

The SD 10 Automatic Cubers are quality desi-

gned,engineeredandconstructedandthroughly,

tested ice making and ice storage systems,

providing the utmost in flexibility to fit the needs

of particular users.

Separate sections detail more specifically:

General Informations & Start-up Operation;

PrinciplesofOperation;AdjustmentandRemoval

and Replacement Procedures; Maintenance &

CleaningInstructions;ServiceDiagnosis;Wiring

Diagrams; and the illustrated Assemblies, Parts

List & Accessories.

One of the outstanding features of this series of

cubers is the easy way for starting it up.

Sinceitdoesnotrequireanyplumbingconnection,

it can be placed in any location and put in

operation.

DESCRIPTION

An attractive compact cabinet of textured plastic

with an almond enamel finish, makes the styling

of the SD 10 very handsome allowing it to be in

harmony with many interior decors. The easy

removablefrontpanelprovidesimmediateaccess

to the water reservoir and to the electro-

mechanical components.

SEALED REFRIGERATION SYSTEM

Thecompressorisfullyhermeticanditsmotoris

internally spring-mounted to ensure quiet and

efficient operation of the Ice Maker.

Therefrigerantcircuitisentirelysealedtoprevent

mishandling and refrigerant leaks.

SELF CONTAINED STORAGE BIN

TheSD10ICEMAKERstoresitsownicesupply

in a properly insulated ice storage bin.

A sensing bulb of a thermostat keeps automatic

control of the stored ice cubes level.

A sliding (recessing) plastic door located in the

upper front of the cabinet gives ample access to

the storage bin.

REMOVABLE WATER RESERVOIR

ThemostexclusivefeatureoftheSD10consists

in having a removable water sump reservoir. It

can be easily removed at any time to be washed

clean.

A water level indicator is provided on the front of

thereservoirallovingpromptvisualinspectionof

water level into reservoir.

A special funnel in comunication with the water

reservoir allows prompt and easy filling of water

reservoir itself without the need to remove it.

∂

∑

∏

π

∫

bin recessing door

ice storage bin

water vessel

water level indicator

front panel

∂

∑

∏

π

∫

Page 5

Page 5

°C

°F

SPECIFICATIONS

NOTE.

When machine is “built-in” at ambient temperature of 32

°

C (90

°

F) indicated ice capacity

decreases about 10%.

To keep your HOME ICE CUBER performing at its maximum capacity, it is necessary to perform

periodic maintenance as outlined on page 7 of this manual.

• Dimensions =m/m380wide-380deep-640high

• Weight = 29 kg (64 Ibs.)

• Cabinet = Plastic

• Finish = Enamel

• Color = Almond

• Storage bin = ABS

• Door = Sliding (recess)

• Power Requirements = 230 Volts, 50 Hz, 1 Phase

• Power Consumption = 4,5 Kwh x 24 HRS

• Wire Size = 1 m/m

• Fuse Size = 6 Amps

• Compressor = 1/5 HP

• Refrigerant metering

device = Capillary

• Refrigerant Charge = 220 grms FREON, R 134 A

• Harvest Means = Hot gas

• Cubes per harvest = 8

• Storage bin capacity = 3.5 Kgs. (7.7 Ibs.)

• Water reservoir capacity = 4 liters (1.1 gl.)

11

10

9

8

7

6

5

Kg.

35 30 525 20 15 10

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

°C

o

AIR COOLED MODELS

2

Page 6

Page 6

OPERATING INSTRUCTIONS

START-UP

1) Locate on left side, in storage bin

compartment the funnel for pouring the water.

2) Through this funnel pour in unit water

reservoir 4 liters of fresh potable water.

3) Checktoseethroughthewaterlevelglass

the water level obtained. (Must not exceed the

maximumlevellineandnotbelowminimumlevel

line).

OPERATIONS TO PERFORM

BEFORE UNIT START-UP

1) Afterunpackingtheunit,visuallyinspect its

exterior and make sure it does not show any

severe damage.

2) Remove Lower Compartment Panel and

inspect for concealed damage; then check if fan

bladesmovefreely,andifcompressorissnugon

all mounting pads.

3) Open the bin door and remove any

wrappings or adhesive tape that may be inside,

as well as the instruction card attached to the

control knob.

4) Use clean damp cloth or disposable paper

wiper to wipe clean the interior surface of ice

storage bin.

5) Place ice maker in its selected permanent

locationandmakesurethatitisproperlylevelled.

NOTICE:

Priorconsiderationforlocationsite

shall include:

a) Minimum room temperature 10

°

C

(50 degrees F); and maximum room tempe-

rature 40

°

C (100 degrees F)

b) Well ventiled location for efficient air

removalaroundtheunitandmaintainproper

condensing operation.

c) Service Access i.e. adequate space for

prompt service inspections.

6) Check that the location source voltage

corresponds with the voltage specified on the

nameplate of the unit.

WARNING: The location power source

musthaveasolidearthwireconnection.

Page 7

Page 7

4) Plugtheelectriccableintotheappropriate

socket.Makesurethattheindicatoronthecontrol

knob is pointing to the “white dot”. The machine

is now working and the first cooling cycle can

begin.

5) The first freezing cycle will last about 35

minutes. During this time, make sure that the

plasticcurtainthatcoversthewaterspraysystem

hangs down loose and no excessive water is

passing through, make sure to eliminate

eventually noises and vibration sources.

6) After about 35 minutes of operation, the

first ice cubes harvest takes place.

7) Duringtheharvestcycle,whichlastsabout

3 minutes, the hot gas, circulating through the

evaporatorserpentine,defroststheicecubesup

tothepointthattheyarereleasedfromtheirmold

cups and drop into the storage bin.

8) If the tem-

perature of the

roominwhichthe

machine is place

isbelow20°C,the

cubeswilltendto

be partly hollo-

wed out (see fig.

on right).

If, on the other

hand, the room

temperature is

above 30°C the

cubes produced

willhaveajagged

rim of ice around

the crown.

9) If it is thought necessary, the above

situations can be remedied by, in the first case,

turning the control knob indicator (as little or as

much as is required) to the right of the white

markerand,inthesecondcase,turningtheknob

to the left. It should, however, be remembered

that if the room temperature returns later to the

20 ÷30°C range, the knob indicator must once

againbeturnedtopointtothewhitedot.(seefig.

below).

10) Theicemakerwillautomaticallystopwhen

the ice cubes in this storage bin compartment

cover the sensing bulb of the bin thermostat and

will automatically start when the same sensing

bulb will be cleared from the ice.

11) Remember to fill up the water reservoir

beforethewaterlevelinitgoesbelowtheminimum

level line of the indicator.

Inanycase,ifforsomereasonthemachineisleft

runningforashorttimewithoutwater,noserious

harm will be caused.

Page 8

Page 8

CLEANING AND CARE

WARNING - Before proceeding with

anycleaning operationmakesurethat

the power line of the unit is discon-

nected.

WATER RESERVOIR AND STORAGE

BIN LINER

All commercial units that make or contain edible

produces, require a frequent throught sanitation

of all their parts that are in contact with the

produces.

It is recommendable, therefore, to perform the

cleaninganddisinfectingoperationonceaweek

as per the following indications.

- Remove all ice cubes deposited in ice storage

bin if there are any.

-Remove the front lower panel by pulling it

from its upper edge and locate the water

reservoir.

Place one hand under the reservoir in order to

hold it and with the other grab the hooked front

edge.

- Slightly move the reservoir upward until it is

loose, than lower and tilt it a bit while

drawing out (try to avoid the pump body in

doing this).

- Make this reservoir empty and then place it

back in the unit.

- In a separate plastic pan, prepare a solution

with our rinsing - disinfectant P/N 264000 02.

- Pour the prepared solution into the storage bin

compartment than wipe clean its interior,

meanwhile the solution flows down into the

reservoir.

- Connectthepowerline andputinoperationthe

unitforfewminutes.Thebleachingsolution will

be circulated by the pump through the water

pipes and nozzles.

- Disconnect the power line, remove again the

plasticreservoir,makeitemptythenre-fititinits

place.

-Pourthroughthe funnel the necessary quantity

of new fresh water until the maximum water

level in the water reservoir is reached.

- The until is now sanitized and can resume

normal operations.

PUMP INLET SCREEN

While the water reservoir is removed, it is

recommendable to clean the water pump inlet

screen.

Pull it down with gentle pressure and wash it

clean under a stream of tap water. Once the

screen is properly cleaned reposition it in its

original place on the pump body.

Page 9

Page 9

AIR COOLED CONDENSER

It is very important to clean the condenser

regularly. A dirty or blocked condenser, will

drastically reduce ice production.

Use a vacuum cleaner to remove dust from the

front of the condenser.

CABINET EXTERIOR

Clean with warm water. Do not apply wax.

Note.

When cleaning the floor in the imme-

diate front the unit, try to do not move much

dust that could be easily sucked inside the

units through the panel louvers.

Eventually,forfewseconds,youcanplace

in front of the louvers a piece of paper or

cardboard to prevent that the brushed

dust panetrates into the machine

compartment.

Page 10

Page 10

WATER CIRCUIT

∏

π

∫

∂

∑

PRINCIPLE OF OPERATION

IntheSD10,the water to make iceiscontinually

movedorcirculatedbyasmallelectricpumpthat

sprays the water under gentle pressure through

the two spray jets into the eight inverted cube

molds.

Part of the water that hits the cold refrigerated

molds freezes, building gradually into full ice

cubes bell shaped.

FREEZING CYCLE (How it works)

Thehotgasrefrigerant,pumpedanddischarged

bythecompressor,passesthroughthecondenser

wherethefanblowingaircausesthechangingof

it into liquid.

The liquid line takes the refrigerant from the

condensertothecapillarytube.Duringthetravel

intothecapillarytube,theliquidrefrigerantlooses

gradually its temperature and pressure, then it

reaches the evaporator coils.

Because of the water sprayed against the

evaporator molds and coil, the liquid refrigerant

senses the heat of this water and starts boiling,

changing, as a consequence, from liquid into

vapor state.

The vapor refrigerant is sucked back to the

compressor through the suction line.

Thefreezingcycleiscontrolledbyatemperature

controlwhichdeterminesaswellthelengthofthe

cycle and consequently the size of the ice cube.

Duringthisphase,thecontactpointofthetempe-

rature control maintains closed the circuit of the

water pump which constantly sprays the water

under the evaporator mold cups up to the point

that the ice cubes reach their full size.

HARVEST CYCLE (How it works)

As soon as the temperature control senses the

temperature in the evaporator corresponding to

thefullsizecubes,thecontactmovestoclosethe

circuitoftheHotGasValveCoilandconsequently

to open the circuit of the water pump which

momentarily stops.

The hot gas refrigerant discharged by the

compressor is now diverted through the opened

hot gas valve to the evaporator coil.

The hot gas circulares through the evaporator

coil raising the temperature around the cube

cups sufficiently to release the ice cubes.

The released ice cubes drop by gravity into the

storage bin.

The temperature control bulb, due to the warm

temperature in the evaporator moves again the

contact de-energizing the hot gas valve and

energizing the water circulating pump starting a

new freezing cycle.

∑

❼

❾

HARVEST CYCLE

∏

π❻

Ω∫

∂

FREEZING CYCLE

∑

∏

π

∫

❻

∂

❼

Ω

❾

①EVAPORATOR

≠BIN

③SPRAY TUBE

④WATER PUMP

∞WATER RESERVOIR

①EVAPORATOR

≠ACCUMULATOR

③CAPILLARY TUBE

④SUCTION LINE

∞COMPRESSOR

±HOT GAS SOLENOID

±VALVE CLOSED

≤CONDENSER

≥FAN MOTOR

⑨DRIER

①EVAPORATOR

≠ACCUMULATOR

③CAPILLARY TUBE

④SUCTION LINE

∞COMPRESSOR

±HOT GAS SOLENOID

±VALVE OPENED

≤CONDENSER

≥FAN MOTOR

⑨DRIER

Page 11

Page 11

SERVICEMAN’S INFORMATIONS

GENERAL

Models SD 10 Ice Cube Makers have been

designed for little service and maintenance

requirements.

Average head pressure is 10 atm at the start-up

of the freezing cycle at 21°C ambient tem-

perature.

It gradually pulls down to 7 atm at the end of the

cycle.

Suction pressure at the start-up of the freezing

cycle will be around 3 atm then it pulls down

gradually to approximately 0 atm at the end of

freezing cycle.

SERVICE ANALYSIS

The following Service Analysis Section is for use in aiding the serviceman in diagnosing a particular

problem for pin-pointing the area in which the problem lies, thus an ever available reference for proper

corrective action.

SYMPTOM POSSIBLE CAUSE CORRECTION

Machine does not make ice. Fuse in Power Line Blown. Check fuses in the house fuse

box. Other loads on the same

line may have caused fuse

to blow. Use a 10 amp circuit

and fuse.

Water reservoir empty. Re-fill water reservoir.

Temp. control out of setting. Check for proper setting.

Wiring broken or connection off. Check electrical circuitry.

Compressor does not run. Any of the following may be

the cause. Starting relay,

overload, or defective compressor.

Water pump not operating. Clean or replace pump.

Bin thermostat not operating Check thermostat by warming

correctly. with hand and cooling with ice

cube. Replace if necessary.

Restricted Capillary Tube. Purge and recharge.

Moisture and air in system. Purge - recharge - replace drier.

Shortage of refrigerant. Charge unit properly.

Low ice capacity. High Room Temperature. Provide ventilation to the unit.

Decrease temperature as much

as possible.

High head pressure. Dirty condenser. Clean.

Cubes too large. Cube Size Control set Check and adjust for proper

improperly. operation.

Page 12

Page 12

Cubes cloudy. Spray jets Dirty. Clean.

Shortage of Water. Check water level in water

reservoir and re-fill.

Dirty water supply, accumulator Wipe clean water reservoir

of dirty in water system. and re-fill with new fresh water.

Clean water pump screen.

Cubes too small. Shortage of water. Check water level in reservoir.

Cube size control set Check and adjust for proper

improperly. operation.

Water leaking from pump Check clamp and hoses.

hoses. Replace if necessary.

Compressor cycles Low voltage. Minimum voltasge to be 10%

intermittently. Iess than normal rating.

Air in the system. Purge and recharge.

Poor harvest cycle. Too short defrost time. Check temperature control -

replace if necessary.

Hot gas not passing through Check hot gas valve coil,

valve. replace if necessary.

Shortage of refrigerant. Charge unit properly.

Ice cubes too big. Set control knob correct shape

of ice cubes.

SYMPTOM POSSIBLE CAUSE CORRECTION

Page 13

Page 13

WIRING DIAGRAM

THERMOSTAT

BIN. TEMP. CONTROL

2

4

6

62

4

MOTOR SOLENOID VALVE

FAN MOTOR

MOTOR COMPRESSOR

PUMP MOTOR

FAN MOTOR

A BLUE

M BROWN

N BLACK

G-V YELLOW-GREEN

PUMP MOTOR

BIN. TEMP. CONTROL THERMOSTAT

COMPRESSOR MOTOR

HOT SOLENOID VALVE

Page 14

Page 14

REMOVAL & REPLACEMENT PROCEDURE

WARNING: DISCONNECT THE ELEC-

TRICALSUPPLYBEFOREPERFORMING

ANY OF THE FOLLOWING OPERATIONS

Cabinet Removal

1. Remove lower panel by pulling forwand at

both top corners.

2. Remove water reservoir.

3. Disconnect the electrical cord and pass it

through the rear side of the cabinet into the unit

compartment.

4. Unloose and remove the two screws

secuting the front door trim to the side walls of

cabinet.

5. Through the interior of the compressor

compartment reach the three screws securing

the cabinet to the chassis and unloose them.

(See indicating arrows).

6. Remove the bottom drip tray.

7. Remove the cabinet by pulling it forward

from the rear side.

Temperature control replacement

(Evaporator)

1. Follow step 1 thru 7 for cabinet removal.

2. Removetemperaturecontrolknobbypulling

it.

3. Unloosethescrewsecuringthecontrolbox

panel.

4. Pull forward the control box panel.

5. Unloose and remove the nut securing the

temperature control to the panel.

6. Remove the spade connections from the

control.

7. Locatethethermostatbulbontheevaporator

and push it out from its well.

8. The control is now entirely removed.

9. Re-assemble the new control by

proceeding on reserve.

NOTE:

Seal both the ends of bulb holder

after the introduction of the new evaporator

thermostat capillary tube to avoid that some

water freezes inside.

Bin thermostat replacement

1. Follow step 1 thru 7 for cabinet removal.

2. Followstep1thru4fortemperaturecontrol

replacement.

3. Unloose and remove the nut securing the

bin control to the panel.

4. Remove the end of bin control capillary

tube from the interior of the bin.

5. Remove the spade connection from the

Temp. Control.

6. The control is now completely free.

Proceed to re-assemble acting on reserve.

Water pump Replacement

1. Follow step 1 thru 7 for cabinet removal.

2. Remove the screw which holds the water

pump in place.

3. Remove the two water pump electrical

leads.

4. Remove the hose from pump bottom

housing.

5. Lift out the pump.

6. To small the replacement pump, follow

previous steps in reverse.

Page 15

Page 15

THE PARTS ILLUSTRATIONS AND PARTS LIST

CONTROL PANEL ASSY

④

±

≤

≥

Pos. Part. N. Description

6 620264.10 Evaporator thermostat

7 660321.01 Panel

8 620263.00 Bin control

Page 16

Page 16

FRONT - VIEW

Pos. Part. N. Description

3 620433.00 Water pump assy

18 650330.00 Plug

22 660321.00 Control panel

24 784169.03 Curtain

25 660330.00 Funnel cover

Page 17

Page 17

SIDE - VIEW

Pos. Part. N. Description

44 784378.02 Evaporator cover

46 650361.05 Insulation

47 660326.05 Cabinet assy

49 660340.02 Evap. bulb holder

660386.00 Clip

50 783130.00 Evap housing

51 640093.00 Seal ring

52 660320.00 Water spray tray

53 610139.00 Plastic hose

(pump to spray system)

54 660336.00 Cover

57 660325.00 Water drip tray

58 781284.03 Bin door assy

59 782053.00 Ice storage bin

60 660339.00 Bulb holder

* Not shown

Pos. Part. N. Description

61 781285.04 Front lower panel assy

62 793114.00 Water reservoir assy

63 781335.00 Reservoir holder

65 784234.00 Evaporator platen assy

66 784252.02 Suction accumulator

67* 660359.00 Funnel insert

68 660335.00 Upper separator

69 660343.00 Lower separator

70 660338.00 Rubber fitting

71 660337.00 Sight glass

72* 783141.00 Reservoir cover

660424.00 Reservoir cover - Pump

73 660341.00 Rubber plug

Page 18

Page 18

Pos. Part. N. Description

8 620057.35 Relay for Cubigel

23 630003.05 Dryer

35 620285.00 Condenser

36 781283.00 Chassis assy

COMPRESSOR&CONDENSINGUNIT

Pos. Part. N. Description

1 670097.08 Compressor cpl. Cubigel

2 620306.48 Hot gas valve coil

620306.14 Hot gas valve body

3 620419.00 Fan motor only

7 620058.65 Protector for Cubigel

Page 19

Page 19

Compr. Compr. Start

relay protector Capacitor

SD 10-2 220/60/1 U.H. AE Z4425Y 670066.08 620057.40 620058.74 620167.45

SD 10-6 220/50/1 Cubigel GL 80PB 670097.08 620057.35 620058.65 –

Hot gas valve Hot gas valve Fan motor

coil body only

SD 10-2 620306.48 620306.14 620433.01 620419.00

SD 10-6 620306.48 620306.14 620433.00 620419.00

SD 10 - COMPRESSOR AND ELECTRIC COMPONENTS CHART

Model Volts Compr. Model Compr. Cpl.

Model Water pump

Page 20

Page 20

FÜR DEN ANWENDER

IhrEisbereiterModellSD10isteindurchdachtes

undsorgfältighergestelltesErzeugnis,dasIhnen

jahrelang beste Ergebnisse bei gleichzeitig

minimalen Betriebs- und Unterhaltskosten

garantieren wird.

Dieses Gerät wurde von einem der

bedeutendstenUnternehmensgruppenindiesem

Sektor,nachdemselbenPrinziphergestellt,das

bereits seit Jahrzehnten in Tausenden von

Geräten in der ganzen Welt erfolgreich zum

Einsatz kommt.

Viele von Ihnen werden wohl zum ersten Male

die Gelegenheit haben, Eiswürfel zu sehen und

anzuwenden, die sich durch außergewöhnliche

Festigkeit und Transparenz auszeichnen, und

die, was besonders wichtig ist, in einem

langsamen Prozess entstehen.

AlldieskönnenSiesonstvonherkömmlichen,im

HaushaltsgefrierschrankproduziertenEiswürfeln

nichterwarten,dieinderRegeltrübsindundsich

sehr schnell bilden

Wir möchten Ihnen vorschlagen, ein wenig Ihrer

Zeit der Lektüre dieses Handbuchs zu widmen.

So können Sie sich selbst davon überzeugen,

dass diese Eiswürfel sehr viel klarer und fester

sind als die Ihres Gefrierschranks.

Ein Wasseranschluss ist nicht erforderlich.

Wenn Sie die Vorderplatte und/oder das ganze

Gehäuse abnehmen, haben Sie leicht Zugang

zudeneinzelnenBestandteilendesEisbereiters

SD10.

Seite

This manual suits for next models

2

Table of contents

Languages:

Other SIMAG Ice Maker manuals

Popular Ice Maker manuals by other brands

Monogram

Monogram ZDI15 installation instructions

Aquila

Aquila Pelletizer PE50 Original instruction manual

MicroLux

MicroLux ML450SL user manual

Marvel

Marvel MA15CRS1XS Installation, operation and maintenance instructions

Cornelius

Cornelius CCM0330 Service and maintenance manual

Follett

Follett Maestro Plus MCD425WBS installation instructions

Manitowoc

Manitowoc UG Series Technician's handbook

Hoshizaki

Hoshizaki KML-250MAH Cleaning & Sanitizing

Scotsman

Scotsman DCE33 Series user manual

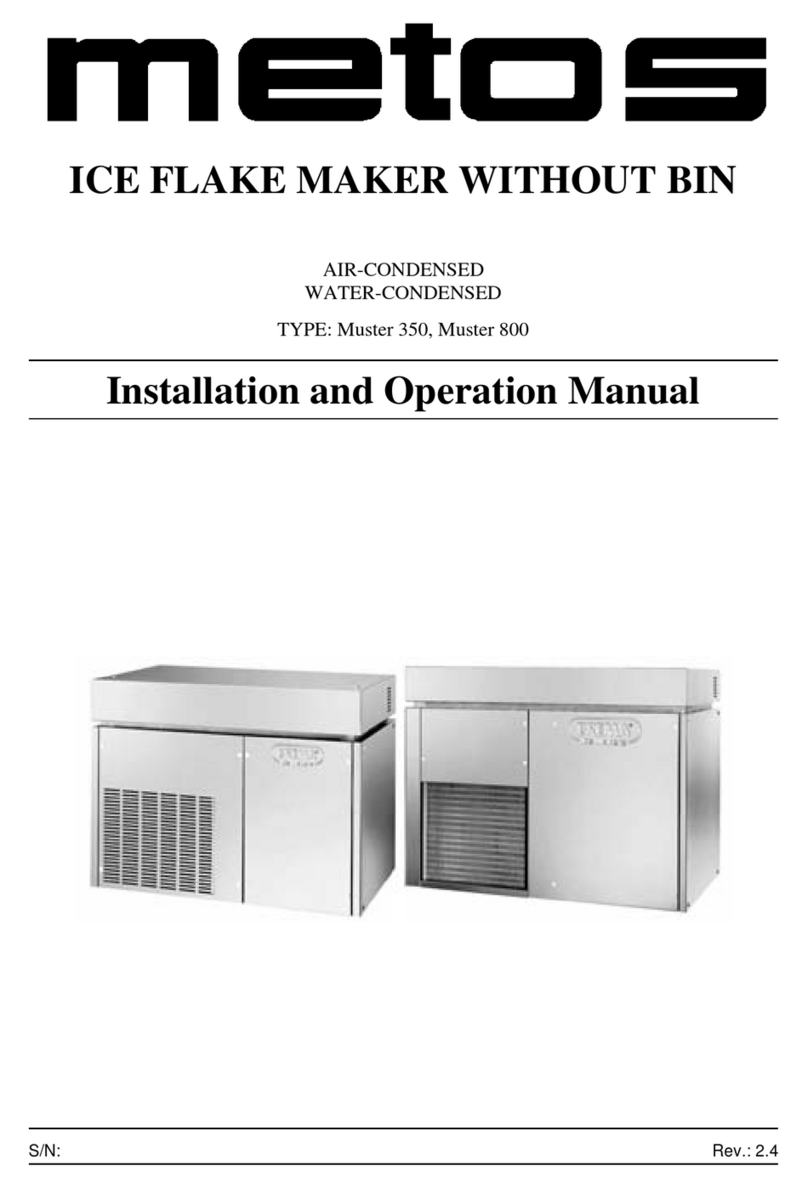

Metos

Metos Muster 350 User's installation and operation manual

Orien

Orien FS260IM user manual

Manitowoc

Manitowoc GUARDIAN GSI200 Installation use and care manual