SIMAG SV 325 User manual

Page 1

Page 1 SERVICE MANUAL

SV 145

SV 225

SV 325

SV 395

SV 545

R 404 AVERSION

Electronic

modular cubers

MS 1000.78 REV. 04/10

Kälte-Berlin

Am Pfarracker 41

12209 Berlin

Fon: +49 (0) 30 / 74 10 40 22

Fax: +49 (0) 30 / 74 10 40 21

eMail: [email protected]

Internet: http://www.kaelte-berlin.com

Der Link zum Nordcap Eiswürfelbereiter SVN 205 L bei Kälte-Berlin

Page 2

Page 2

TABLE OF

CONTENTS

Table of contents 2

Specifications 3-12

FOR THE INSTALLER

Introduction 13

Storage bin 13

Standard legs 13

Important operating requirements 13

Select location 14

Storage bin 14

Ice machine 14

Stacking instructions 14

Final check list 16

FOR THE PLUMBER

Conform to all applicable codes

Water inlet 15

Drains 15

For the electrician

Electrical connections 15

START-UP

Start-up cycle 15

Freezing cycle 15

Harvest cycle 15

OPERATION

Refrigeration during freeze 19

Water system 20

Refrigeration system during harvest 21

Water system 21

Control sequence 21

Alarm conditions 22

PC Board set up 23

SERVICE SPECIFICATIONS

Component 24

Operating characteristics 24

COMPONENT DESCRIPTION

Component description 25

WIRING DIAGRAM

SV 145-225-325-395-545 air/water cooled 28

SV 395-545 air/water cooled 29

SERVICE DIAGNOSIS

Service diagnosis 30

MAINTENANCE & CLEANING INSTRUCTION

Icemaker 31

Ice storage bin 31

Cabinet erxterior 31

Cleaning (Icemaker) 31-32

Page 3

Page 3

SPECIFICATIONS

MODULAR CUBER SV 145

NOTE.Tokeep your Modular cuber performingat its maximum capacity, itis necessary to perform

periodic maintenance as outlined on page 31 of this manual.

ice making capacity

ICE PRODUCED PER 24 HRS

ICE PRODUCED PER 24 HRS

130

120

110

100

90

Kg.

32 °C

27 15 10

AIR COOLED MODELS

WATER TEMPERATURE

AMBIENT TEMPERATURE

°C

10

21

32

38

WATER COOLED MODELS

AMBIENT TEMPERATURE

Kg.

°C

27 21 15 10

°C

10

21

32

38

21

WATER TEMPERATURE

140

130

110

90

70 32

Page 4

Page 4

SPECIFICATIONS (CONT'D)

Accessoires

KSC 300 - Cube stacking kit

Dimensions:

HEIGHT 575 mm. (22" 1/2)

WIDTH 560 mm. (22")

DEPTH 620 mm. (24" 1/2)

WEIGHT 55 Kgs.

Model Cond. unit Finish Comp. HP

SV 145 - MACHINE SPECIFICATIONS

Water req.

lt/24 HR

Model Basic

electr. amps Start

amps watts Electric power cons.

Kwhx24 HR. N. of wires Amps

Fuse

220-240/50/1

SV 145 - AS

SV 145 - WS 3x1,5 mm210

Cubes per harvest: 132 Full - 264 Half

* With water at 15°C

Stainless Steel 3/4

3,8

3,3 18 780

650 18.7

15.6

AIR COOLED

CORD SET

3/4” GAS WATER INLET

WATER OUTLET

WATER COOLED

3/4” WATER INLET WATER COOLED ONLY

3/4” WATER DRAIN WATER COOLED ONLY

SV 145 - AS Air 300*

SV 145 - WS Water 1500*

EVAPORATOR

ICE DROP AREA

CONDENSER

SV145

Page 5

Page 5

SPECIFICATIONS

MODULAR CUBER SV 225

NOTE. To keep your Modularcuber performing at its maximumcapacity, it is necessary toperform

periodic maintenance as outlined on page 31 of this manual.

ice making capacity

220

200

180

160

140

120

Kg.

32 °C

27 21 15 10

AIR COOLED MODELS

WATER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

°C

10

21

32

38

WATER COOLED MODELS

WATER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

220

200

180

160

140

120

Kg.

32 °C

27 21 15 10

°C

10

21

32

38

Page 6

Page 6

SPECIFICATIONS (CONT'D)

Model Cond. unit Finish Comp. HP

SV 225 - MACHINE SPECIFICATIONS

Water req.

lt/24 HR

Model Basic

electr. amps Start

amps watts Electric power cons.

Kwhx24 HR. N. of wires Amps

Fuse

220-240/50/1

SV 215 - AS

SV 215 - WS 3x1,5 mm216

Cubes per harvest: 204 Full - 408 Half

* With water at 15°C

Stainless Steel 7/8

SV 215 - AS Air 340*

SV 215 - WS Water 1900*

6

529 1000

900 24.0

21.6

Accessoires

KSC 450 - Cube stacking kit

Dimensions:

HEIGHT 575 mm. (22" 1/2)

WIDTH 760 mm. (30")

DEPTH 620 mm. (24" 1/2)

WEIGHT 77 Kgs.

AIR COOLED

CORD SET

3/4” GAS WATER INLET

WATER OUTLET

WATER COOLED

3/4” WATER INLET WATER COOLED ONLY

3/4” WATER DRAIN WATER COOLED ONLY

EVAPORATOR

ICE DROP AREA

CONDENSER

SV 225

Page 7

Page 7

SPECIFICATIONS

MODULAR CUBER SV 325

NOTE. To keep your Modularcuber performing at its maximumcapacity, it is necessary toperform

periodic maintenance as outlined on page 31 of this manual.

ice making capacity

320

290

260

230

200

170

Kg.

32 °C

27 21 15 10

AIR COOLED MODELS

WATER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

°C

10

21

32

38

WATER COOLED MODELS

WATER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

300

280

260

240

220

200

Kg.

32 °C

27 21 15 10

°C

10

21

32

38

Page 8

Page 8

SPECIFICATIONS (CONT'D)

Model Cond. unit Finish Comp. HP

SV 325 - MACHINE SPECIFICATIONS

Water req.

lt/24 HR

Model Basic

electr. amps Start

amps watts Electric power cons.

Kwhx24 HR. N. of wires Amps

Fuse

220-240/50/1

SV 325 - AS

SV 325 - WS 3x1,5 mm216

Cubes per harvest: 204 Full - 408 Half

* With water at 15°C

Stainless Steel 1 1/2

10

7.5 31 1600

1300 38.4

31.2

Accessoires

KSC 450 - Cube stacking kit

Dimensions:

HEIGHT 575 mm. (22" 1/2)

WIDTH 760 mm. (30")

DEPTH 620 mm. (24" 1/2)

WEIGHT 77 Kgs.

AIR COOLED

CORD SET

3/4” GAS WATER INLET

WATER OUTLET

WATER COOLED

3/4” WATER INLET WATER COOLED ONLY

3/4” WATER DRAIN WATER COOLED ONLY

SV 325 - AS Air 470*

SV 325 - WS Water 2750*

EVAPORATOR

ICE DROP AREA

CONDENSER

SV 325

Page 9

Page 9

SPECIFICATIONS

MODULAR CUBER SV 395

NOTE. To keep your Modularcuber performing at its maximumcapacity, it is necessary toperform

periodic maintenance as outlined on page 31 of this manual.

ice making capacity

°C

10

21

32

38

°C

10

21

32

38

Kg.

32 °C

27 21 15 10

AIR COOLED MODELS

WATER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

WATER COOLED MODELS

WATER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

Kg.

32 °C

27 21 15 10

450

400

350

300

250

200

450

400

350

300

250

200

Page 10

Page 10

SV 395 - AS Air 650*

SV 395 - WS Water 3300*

SPECIFICATIONS (CONT'D)

Model Cond. unit Finish Comp. HP

SV 395 - MACHINE SPECIFICATIONS

Water req.

lt/24 HR

Model Basic

electr. amps Start

amps watts Electric power cons.

Kwhx24 HR. N. of wires Amps

Fuse

SV 395 - AS

SV 395 - WS 5x1,5 mm210

Cubes per harvest: 289 Full - 578 Half

* With water at 15°C

Stainless Steel 2.5

5.5 26.5 2300

1900 55.2

45.6

Accessoires

KSC 800 - Cube stacking kit

Dimensions:

HEIGHT 725 mm. (28" 1/2)

WIDTH 760 mm. (30")

DEPTH 620 mm. (24" 1/2)

WEIGHT 97 Kgs.

760 620

AIR COOLED

WATER DRAIN

3/4

GAS POTABLE WATER INLET

CORD SET

725

725

475

69

WATER COOLED

139 451

3/4 WATER INLET - WATER COOLED ONLY

3/4”

WATER DRAIN - WATER COOLED ONL

Y

380-400/50/3

EVAPORATOR

ICE DROP AREA

CONDENSER

SV 395

Page 11

Page 11

SPECIFICATIONS

MODULAR CUBER SV 545

NOTE. To keep your Modularcuber performing at its maximumcapacity, it is necessary toperform

periodic maintenance as outlined on page 31 of this manual.

ice making capacity

500

450

400

350

300

Kg.

32 °C

27 15 10

°C

10

21

32

38

Kg.

°C

27 21 15 10

°C

10

21

32

38

21

500

450

400

350

300 32

AIR COOLED MODELS

WATER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

WATER COOLED MODELS

WATER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

Page 12

Page 12

SV 545 - AS Air 700*

SV 545 - WS Water 3500*

SPECIFICATIONS (CONT'D)

Model Cond. unit Finish Comp. HP

SV 545 - MACHINE SPECIFICATIONS

Water req.

lt/24 HR

Model Basic

electr. amps Start

amps watts Electric power cons.

Kwhx24 HR. N. of wires Amps

Fuse

SV 545 - AS

SV 545 - WS 5x1,5 mm210

Cubes per harvest: 340 Full - 680 Half

* With water at 15°C

Stainless Steel 2.5

5.5 26.5 2500

2100 60.0

50.4

Accessoires

KSC 1000 - Cube stacking kit

Dimensions:

HEIGHT 800 mm. (22" 1/2)

WIDTH 760 mm. (30")

DEPTH 620 mm. (24" 1/2)

WEIGHT 104 Kgs.

AIR COOLED

CORD SET

3/4” GAS WATER INLET

WATER OUTLET

WATER COOLED

3/4” WATER INLET

WATER COOLED ONLY

3/4” WATER DRAIN

WATER COOLED ONLY

380-400/50/3

EVAPORATOR

ICE DROP AREA

CONDENSER

SV 545

Page 13

Page 13

FOR THE INSTALLER

INTRODUCTION

Theseinstructionsprovidethespecificationsand

the step-by-step procedures for the installation,

start up and operation for the SIMAG Model

SV 145-225-325-395-545 Modular Cubers.

The Models SV145-225-325-395-545 Modular

Cubers are quality designed, engineering and

constructed,andarethoroughlytestedicemaking

systems, providing the utmost in flexibility to fit

the needs of a particular user.

INSTALLATION NOTE: Allow 15 cm.

minimum space at sides and back for

ventilation and utility connections.

STORAGE BIN

The SV 145 stack on top of Simag bin model

R85;theSV225-325-395-545stackontoSIMAG

bin model R 155.

Refrigerant R 404 A

Charge per nameplate rating.

STANDARD LEGS: Furnished with storage bin.

Fourlegsscrewintomountingsocketsoncabinet

base. Provide 18.5 cm. (7’’) minimum height

including adjustable leveling foot.

Optional Kit Casters for R 155 (KRB 550) are

available on request.

IMPORTANT OPERATING REQUIREMENTS

MINIMUM MAXIMUM

Air Temperature 10°C(50°F) 40°C(100°F)

Water Temperature 5°C(40°F) 35°C(90°F)0

Water Pressures 1 bar gauge 5 bar gauge

Electrical Voltage

Variations Voltage

rating specified

on nameplate -10% +10%

Extended periods of operation exceeding these

limitations constitues misuse under the terms of

Manufacturer’s Limited Warranty, resulting in a

loss of warranty coverage.

Page 14

Page 14

SELECT LOCATION

The first step in installing the equipment is to

select the location. The purchaser of the unit will

have a desired spot in mind, check out that spot

to insure that it is:

- indoors,inanenvironmentthatdoesnotexceed

theairandwatertemperaturelimitationsforthe

equipment.

- thatthenecessaryutilitiesareavailableincluding

the correct voltage electrical power.

- thattherebespacearoundtheinstalledmachine

forservice, 15cm.minimum left,right,and rear

for air-cooled models.

STORAGE BIN

The Scotsman bins for these units are the R 85

and R 155. Other bins may be available with bin

tops to vary the storage capacity. Lay the bin on

its back, using cardboard from the carton to

support it, screw in the legs.

Stand the bin upright, and correct any possible

small tears in the machine mounting gasket with

food grade silicone sealant.

ICE MACHINE

The use of a mechanical lift is recommended for

lifting the uncrated icemaker onto the bin.

Remove front, top and sides panels.

Place the unit directly onto the bin, align it with

thebackofthebin.Locatethehardwarepackage,

take out two mounting screws, and use them to

secure the Icemaker to the two sides of the bin.

See illustration below.

Removeallshippingmaterialaswellasthemasking

tapes from the ice deflector/evaporator cover.

Remove first the ice deflector/evaporator cover

then the masking tape from the ice thickness

sensor.

AIR BAFFLE

Install on the back side of the machine the air

baffle as per instruction provided with it.

FOR THE PLUMBER

CONFORM TO ALL APPLICABLE CODES

WATER INLET

AIR-COOLED MODELS: The recommended

water supply is cold water connected to

the - 3/4'’ gas - male fitting at the back of the

cabinet.Install ahandvalve nearthemachine to

control the water supply.

1) Switch

2) Plug receptacle

3) Electrical plug

4) Water inlet

5) Shut-off valve

6) Water filter

7) Water outlet line

8) Bin water outlet line

9) Open vented water drain

10) Water outlet from the

condenser: water cooled

version only.

Page 15

Page 15

NOTE: All SIMAG Cubers require a

neutral wire and a solid earth ground wire to

prevent possible severe Electrical Shock

Injury to individuals or extensive damage to

equipments.

FINAL CHECK LIST

1. Is the cabinet/bin level?

2. Is the cuber in a location where ambient

temperatures are a minimum of 10°C (50-de-

grees F.) all year around and to not exceed a

maximum of 40°C. (100°F.).

3. Is there at least a 15 cm. clearance behind

andaroundthecabinetforallconnectionsandfor

proper air circulation?

4. Have all electrical and piping connections

been made?

5. Has the electrical power supply wiring been

properly connected and the voltage tested and

checked against the nameplate rating? Has the

unit properly grounded.

6. Isthewatersupplylineshutoffvalveinstalled

and opened and has the inlet water supply

pressure been checked to insure a minimum of

1 bar without exceeding a maximum of 5 bar.

7. Have the compressor holddown bolts been

checkedtobesurethecompressorissnugonthe

mounting pads.

8. Checkallrefrigerantlinesandconduitlinesto

gard against vibration and possible failure.

9. Has the cuber and the bin been wiped clean

with clean damp cloths?

10. Has the owner/user been given the User

Manual and instructed on how to operate the

icemaker and the importance of periodic

maintenance?

11. Has the owner/user been given the name

and telephone number of the Authorized

SCOTSMAN Distributor or Service Agency

serving him?

12. Has the Manufacturer’s Registration Card

been properly filled out?

Check for correct Model and Serial Numbers

fromnameplate, then mailthe completed cardto

the Manufactured.

When choosing the water supply for the MV

Cuber, consideration should be given to:

A. Length of run.

B. Water clarity and purity.

C. Adequate water supply pressures.

Sincewateristhemostimportantsingleingredient

in producing ice you cannot over emphasize the

three items listed above. Low water pressure,

below 1 bar may cause malfunction, of the

icemaker unit. Water containing excessive

minerals will tend to produce cloudy colored ice

cubes, plus scale build-up on parts in the water

system.

Heavilychlorinatedwatercanbecontrolledusing

charcoal or carbon filters.

DRAINS

AIR-COOLED MODELS: There is one 20 mm.

dia sump drain fitting at the back of the cabinet.

Insulations in high humidity areas is recom-

mended. The ideal drain receptacle would be a

trapped and vented floor drain.

WATER-COOLEDMODELS:Besidestheabove

drain, a separate condenser drain must be run.

Connect it to the - 3/4'’ gas - condenser drain

connection at the back of the cabinet.

STORAGE BIN: A separate gravity type drain

needs to be run, similar to the air-cooled sump

drain. Insulation of this drain line is recom-

mended.

FOR THE ELECTRICIAN

ELECTRICAL CONNECTIONS

The unit come equipped with an electrical cord

for power supply. The lead wires must be

connectedto an electrical plug that corresponds

to the local electrical codes and requirements or

to a separate two poles disconnect box with

opening to the contacts of about 3 millimeters.

The disconnect box shoulds be placed close to

the selected ice maker location to be easily and

prompt reached.

Undersized wiring or unproperly installed

electricalcircuit willresult inmajorproblems and

malfunctions.

Voltagevariationsshoudnotexceedtenpercent.

IMPORTANT- Allplumbing and electrical

connections must be made by licensed

plumbers and electricians, this one must

followtheelectricalspecificationsprinted

on the ice maker nameplate.

This manual suits for next models

14

Table of contents

Other SIMAG Ice Maker manuals

Popular Ice Maker manuals by other brands

Follett

Follett D17617 Installation, operation and service manual

EdgeStar

EdgeStar IB450SSP Service manual

Hoshizaki

Hoshizaki F-1000MAF-C Service manual

Modena

Modena IM 1020B User manual book

Follett

Follett R425A/W Installation, operation and service manual

Rotel

Rotel ICECUBEMAKER9902CH Instructions for use

Klarstein

Klarstein On-The-Rocks manual

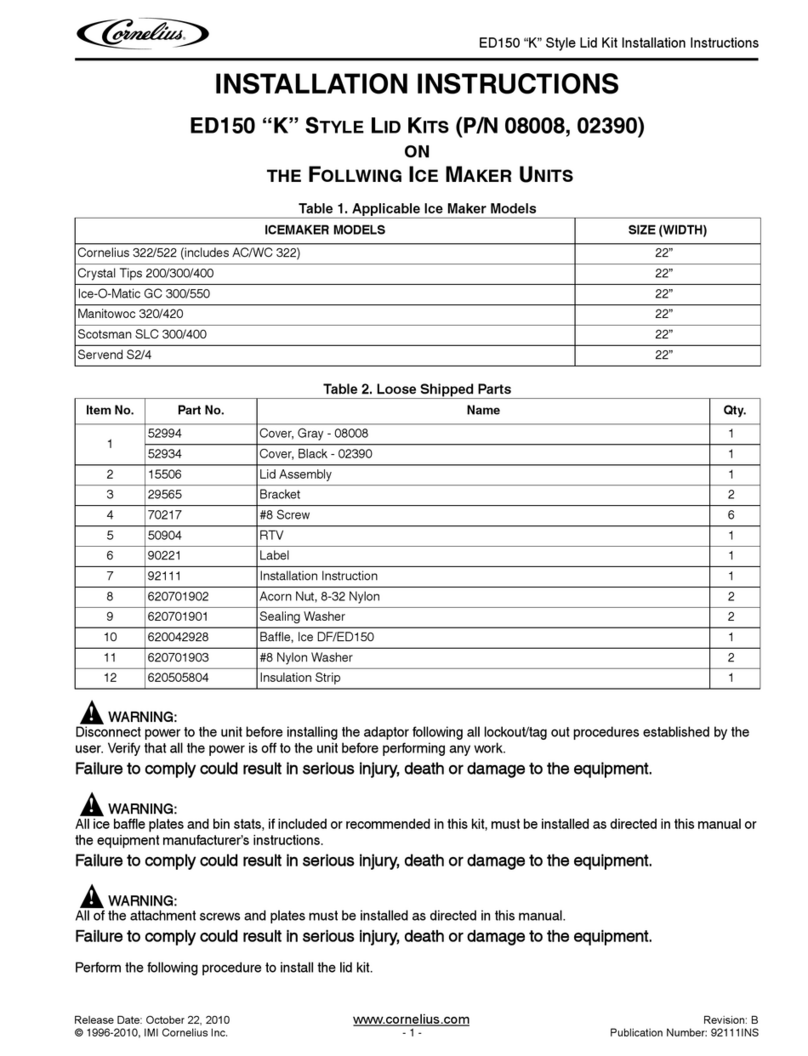

Cornelius

Cornelius ED150 "K" Style Lid Kit installation instructions

Perlick

Perlick H80CIMS-AD product manual

Chard

Chard HZB-15/BF user manual

Manitowoc

Manitowoc NEO UR0310AE Installation, operation and maintanance manual

Cornelius

Cornelius Xtreme 322 Series Pocket guide