SIMON RWA ESM-T/X-EV User manual

for electrical control panels in

modular design, type ESM-T/X-EV

with power supply

(current output 24 A / 48 A / 72 A)

SIMON RWA SYSTEME GmbH

Medienstrasse 8

D-94036 Passau

Phone: +49 851 98870-0

Fax: +49 851 83070

E-mail: [email protected]

Internet: http://www.simon-rwa.de

SIMON RWA Systeme

Installation manual

Edition A: 04/12

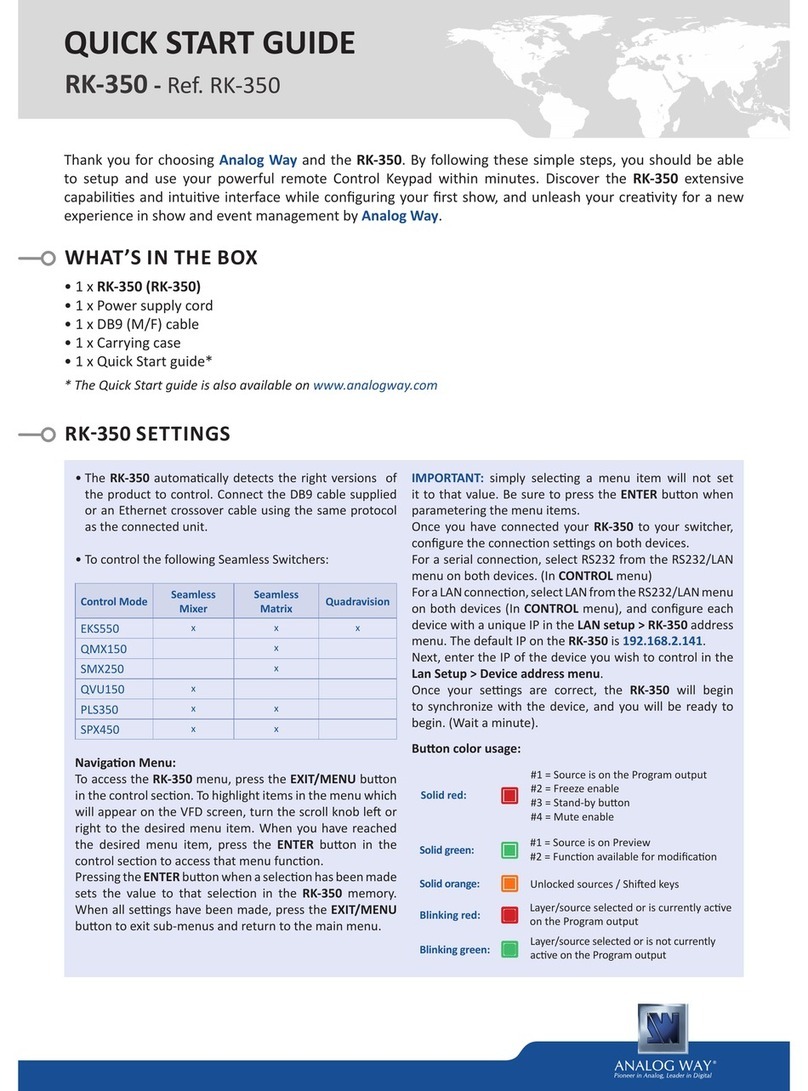

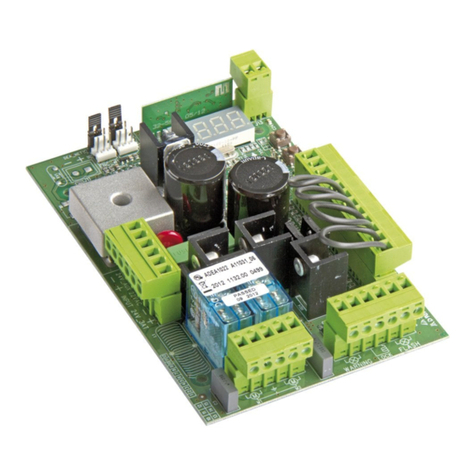

Principle set up of the power supply

Installation manual ESM-T/X-EV (24 A / 48 A / 72 A)

Page 1/20

SIMON RWA SYSTEME GmbH, Passau

ESM-T/X-EV with power supply

Continuous load

Power supply

EV 24

EV 48

EV 72

8 A

16 A

Short-time loading (3 min.)

24 A

24 A

48 A

72 A

Switching

power supply,

SNT-120 Load electronics,

LB-1**

lead-accumulator

Pb-Accu-**

Central relay module

Central ventilation module

Ventilation group module

Power supply, EV-**-(XL)

Universal technical data for the total power supply

Operating temperature range: - 5° to 40° C

Output voltage range (mains operation): 23,8 - 24,3 V

Output voltage range (emergency current mode): 20 - 26,5 V

Dublications, also in extracts, are only legal with express authorisation from SIMON RWA SYSTEME GmbH Passau

®

The electrical control panel is composed of a power supply (switching power supply, load electronics and lead accumulator

system) as well as of the devices central ventilation module, central relay module and ventilation group module. The control

panel is provided with up to three switching power supplies (unit sizes with ED 30%) depending on the particular version. The

accumulator capacity is based upon output (24 V DC, ripple < 500 mV, ripple < 5 %) and internal consumption of the control

panel.

Installation manual ESM-T/X-EV (24 A / 48 A / 72 A)

Page 2/20

SIMON RWA SYSTEME GmbH, Passau

ESM-T/X-EV with power supply

System set up of the power supply (e. g. EV-72)

Load electronics

Accu

Accu

Mains supply

230V / 1phase

OUT3 OUT2 OUT1

Monitor

Monitor

Monitor

Emergency current supply Control electronics Mains supply

Dublications, also in extracts, are only legal with express authorisation from SIMON RWA SYSTEME GmbH Passau

®

Installation manual ESM-T/X-EV (24 A / 48 A / 72 A)

Page 3/20

SIMON RWA SYSTEME GmbH, Passau

ESM-T/X-EV with power supply

Description Den. Min. Norm al Max Unit

Adjus ted nominal voltage

(IL= 300mA )

Output current (c ontinuous operation)1

EV-24 Iout 8A

EV-48 Iout 16 A

EV-72 Iout 24 A

Voltage stability in s hort ti me

operation2UTol. K -1,50 1,50 %

Output current (s hort ti me operation)

(over load durabilit y t < 3 mi n (ED30%)

EV-24

EV-48 IPeak 48 A

EV-72 IPeak 72 A

VDC

IPeak 24 A

24,25 24,30 24,35

Switching power supply

???

?????'??

N

(+)

L

(+)

PE

Netz / Mains

210 - 250 V AC

Versorgungseinheit

Supply unit

EIN

Power on

Ausgang

Output

SNT - 120

(-) (-)

Monitor

24 V / 20 A (KB 24 A)

+-

Mains input 230 V AC

Mains-

indication

Output for

load electronics

1

( ) This current applies to the complete system in continuous operation.

2

( ) This range of tolerance applies to the adjusted nominal output voltage and to the defined short time current.

The overload detection is provided by an electronic fuse in the SNT

Note! It is not permitted to exceed the

max. total current (e. g. at the power

supply, EV-72=72 A). This would lead

to an automatic regulation by the

switching power supply, SNT (that

means emergency current mode).

The switching power supply, type SNT-120 serves as the main power source and also is responsible for the mains supply of the

control panel. SNT is resistant against permanent short circuit and permanent no-load operation. Cooling occurs exlusively in

a natural way by some louvers at the housing

The mains supply for the switching power

supply has to lie within the nominal voltage

range of 195 - 265 V AC

The mains fuse protection by the customer

occurs with 16 A (fuse characteristic C or

more delayed).

The mains connection cable cross section

must be at least 0,75 mm² for each switching

power supply

Every switching power supply is provided with a monitoring output. This signals a fault in

following cases:

- mains failure (undervoltage detection U < 195 V AC)

- short-circuit resp. overload at the SNT-output

- technical defect of the SNT

- inactivity of the SNT (no energy output possible)

In case of failure the emergency current mode of the system gets triggered by the control

electronics.

Output currents from 24 A can be

realized when connecting several

switching power supplies in parallel

(max. 3 = 72 A).

Dublications, also in extracts, are only legal with express authorisation from SIMON RWA SYSTEME GmbH Passau

®

Installation manual ESM-T/X-EV (24 A / 48 A / 72 A)

Page 4/20

SIMON RWA SYSTEME GmbH, Passau

ESM-T/X-EV with power supply

Control electronics

Output for the ventilation control

of the SHEV system (e. g. for wind/rain detector)

Input SNT (+ / -) for internal supply

Monitoring signals of the individual

switching power supplies

(see page 3/11 “Monitor output”)

(+24)

(H)

Connection lead - accumulators General failure signal for forwarding

to the following control modules

LED - Indication

“fault”:

LED - indication “mains operation”:

LED on = mains operation

LED off = emergency current mode

LED off = emergency current

LED blinks = fault

LED on = normal mode

(no fault)

Charge fuse

3,15 A, delayed

Total discharge

protection (fault)

Temperature sensor

The control electronics, LB-1*0 of the power supply, EV-** is necessary for the following functions:

- Loading of the lead accu (emergency current supply)

- Monitoring of the mains operation resp. the emergency current mode

- Forwarding of status and fault to the connected control modules of the SHEV system.

Output power supply (mains- resp. emergency

current mode) of the individual components:

central ventilation-, central relay- and central

ventilation group modules

Dublications, also in extracts, are only legal with express authorisation from SIMON RWA SYSTEME GmbH Passau

®

Installation manual ESM-T/X-EV (24 A / 48 A / 72 A)

Page 5/20

SIMON RWA SYSTEME GmbH, Passau

ESM-T/X-EV with power supply

Lead accumulator system

Technical data

Output voltage per accu: 12 V DC

Total output voltage (cascade connection): 24 V DC

Nominal capacity: see the following emergency current tables

Possible

accu capacities 12 Ah 17 Ah 24 Ah 38 Ah

Power supply, EV-24

max. closed current in

emergency current

mode / I 72h

70 mA 120 mA 200 mA 340 mA

Possible

accu capacities 17 Ah 24 Ah 38 Ah

Power supply, EV-48

max. closed current in

emergency current

mode / I 72h

80 mA 170 mA 270 mA

Possible

accu capacities 24 Ah 38 Ah

Power supply, EV-72

max. closed current in

emergency current

mode / I 72h

100 mA 250 mA

mA

Closed current

Checking the closed current in the

emergency current mode. No mains

applied!

Standard - emergency current

supply

-+

Lead accu, 12V

-+

Lead accu, 12V

Load electronics, LB-1*0

The emergency current mode of the power supply, EV-** is provided by two 12 V lead accus, that are connected in cascade.

The needed capacity is defined by the individual discharging phase. Charging the lead accu is accomplished in the form of an

I/U-charge by an DC/DC-converter. That means that the charging current in the first charging cycle is limited to a constant

charge current. When the accu voltage reaches the charging end voltage, this voltage is limited by regulating the charge

current.

The closed current specified in the table

(e. g. for additional relais) may not be

exceeded. In case of emergency current

mode (max 72 h) the needed power for

operating the actuators (2 x open and 1 x

close within 3 minutes) is thereby

provided.

Dublications, also in extracts, are only legal with express authorisation from SIMON RWA SYSTEME GmbH Passau

®

Installation manual ESM-T/X-EV (24 A / 48 A / 72 A)

Page 6/20

SIMON RWA SYSTEME GmbH, Passau

ESM-T/X-EV with power supply

Measurement readings control electronics

Charge

If no charging current is indicated during

the measurement, after approx. 40

seconds a second measurement has to

be accomplished. The reason therefor is,

that after a charging cycle (8 minutes) a

break- and measure period (approx. 40

seconds) is required for the automatic

accu monitoring.

A

For example a non-connected

accumulator gets detected and

consequently a fault alarm is indicated.

The LED indication “O.K.” at the charging

electronics blinks (= fault). If the lead accu

is defective, this also is signaled by a fault

alarm.

Accu monitoring

Charging electronics, LB-1*0

Charging electronics, LB-1*0

-+

Lead - accu, 12V

-+

Lead accu, 12V

During the measurement mains voltage is applied!!

Dublications, also in extracts, are only legal with express authorisation from SIMON RWA SYSTEME GmbH Passau

®

During mains operation the emergency accu is permanently charged with an I/U-charging. In emergency current mode the

charging gets disconnected. After discharging the load electronics is able to charge 80 % of the nominal capacity within 24 h

and after another 48 h it charges the accu 100%. According to VdS 2593 resp. EN 12101-10 the charging is dependent on

temperature. Thereby the charging voltage is adjusted according to the environmental temperature.

The temperature-operated charging voltage must be within the range of

26,7 V and 28,2 V (e. g. at an environmental temperature of 20° C the

charging voltage is at approx. 27,5 V). This reading can be measured at a

charged accu (without disconnecting the accu from the charging).

In order to check the function of the

charging at a discharged accumulator

anyway, the charging current must be

measured. The reading is approx. 1,5 A.

=V

+-

-+

Lead - Accu, 12V

-+

Lead accu, 12V

Installation manual ESM-T/X-EV (24 A / 48 A / 72 A)

Page 7/20

SIMON RWA SYSTEME GmbH, Passau

ESM-T/X-EV with power supply

Ventilation control panel (connection +24)

The output +24 is required for the ventilation function of the electrical control panel. That means that all relevant ventilation

functions (e. g. wind/rain detector) are provided with power via that output.

Charge electronics, LB-1*0

1. Measurement - Current load + 24

2. Measurement - Proving the output voltage + 24

Attention:

Output voltage

at +24 - connection:

21 - 24,5 V DC

+

=V

-

Measurement readings control electronics

All three status outputs of the power supply, EV-** (+24, H, D) are provided with an overload detection. That means, if the

current exceeds a defined measurement at one of these outputs this particular output gets disconnected. After the

disconnection the control electronics proves whether there is still an overload or not. During this overload phase this fault state

is indicated as a fault indication.

Dublications, also in extracts, are only legal with express authorisation from SIMON RWA SYSTEME GmbH Passau

®

A

max. current capacity: 0,5 A

Charge electronics,

LB-1*0

Central ventilation module,

ES-WS-100

+ 24

Wire disconnected

-+

Lead accu, 12V

-+

Lead accu, 12V

Installation manual ESM-T/X-EV (24 A / 48 A / 72 A)

Page 8/20

SIMON RWA SYSTEME GmbH, Passau

ESM-T/X-EV with power supply

Charging device, mains failure and undervoltage (connection H)

The output H provides a status signal (OK / fault). This output is active in the normal mode (no fault). If the power supply, EV-**

goes into failure mode this signal gets relayed to the electrical control panel via the output H.

1

Fault indication time : 10 min.

Capacity of the

fault indication output: 70 mA

=V

-H

Indication voltage range:

0 V = fault

20 - 24 V = normal mode

Ladeelektronik,

LB-1*0

1

( ) The extended fault indication time results

from the cycle time of the accu monitoring.

Total discharge protection (connection D)

In the emergency current mode the output D is responsible for giving a signal to the electrical control unit when the total

discharging state of the accumulator is reached. Only in emergency current mode this output will cause a fault indication.

During mains operation this already will be indicated via the fault indication output H when reaching the charging end voltage of

the accu.

Fault indication time: 10 sec.

Indication capacity: 70 mA

=V

-

Indication voltage range:

0 V = fault

18 - 26,5 V = normal mode

Charging electronics,

LB-1*0

D

Dublications, also in extracts, are only legal with express authorisation from SIMON RWA SYSTEME GmbH Passau

®

Measurement readings control electronics

During the measurement no mains voltage is applied!!

Installation manual ESM-T/X-EV (24 A / 48 A / 72 A)

Page 9/20

SIMON RWA SYSTEME GmbH, Passau

ESM-T/X-EV with power supply

Fault indications and causes

Besides of the already described monitorings the power supply, EV-** carries out any more checkings, that lead to a fault or

status indication.

Fault status: Emergency current mode (in consequence of mains failure resp. undervoltage at the mains input)

Indication at the control

electronics, LB-1*0 Fault description Possible cause

LED “mains” LED “O.K.”

No accu is connected

off off Check the wiring to the accu.

Procedure

Fault status: Emergency current mode (in consequence of overcharging of a switching power supply, SNT-120)

Indication at the control

electronics, LB-1*0 Fault description Possible cause

LED “mains” LED “O.K.”

off off

Procedure

Fault status: Defective accu fuses

Fault description Possible cause Procedure

One of the accu fuses is defective

Fault status: Defective charging fuse

Fault description Possible causes Procedure

on blinks

Indication at the control

electronics, LB-1*0

LED “mains” LED “O.K.”

on blinks

Indication at the control

electronics, LB-1*0

LED “mains” LED “O.K.”

Dublications, also in extracts, are only legal with express authorisation from SIMON RWA SYSTEME GmbH Passau

®

Disconnect the output wire from the power

supply, EV-**. Afterwards the switching

power supply has to be gradually increased

again immediately (LED-indication at SNT-

120). If the accu fuse is defective the LED

O.K. at the control electronics will start to

blink. => replace the accu fuses. Control the

short circuit source before connecting the

EV-** to the SHEV system.

Check the glass fuse (3,15 A) at the control

electronics, LB-1*0. If that is defective,

replace it by a new fuse (enclosed at the

EV-**).

Emergency current mode - but the

SHEV system doesn’t work

Emergency current mode - but the

SHEV system doesn’t work. Mains

voltage (230 V) is available.

The output of the power supply, EV-

** is short circuited. The switching

power supply, SNT-120

electronically switches off the

power (the accu fuse is defective).

The SHEV system works, but the fault

indication LED ´O.K.´ blinks

Check optically, if one of the accu fuses is

defective and replace it if necessary by a new

fuse (enclosed to the EV-**)

The charging fuse is defective

(glass fuse).

The SHEV system works, but the fault

indication LED ´O.K.´blinks

Installation manual ESM-T/X-EV (24 A / 48 A / 72 A)

Page 10/20

SIMON RWA SYSTEME GmbH, Passau

ESM-T/X-EV with power supply

Fault status: The discharge end voltage can be reached by a longer emergency current mode

Fault description Possible cause

on blinks

Procedure

Fault status: Accu is defective

fault description Possible cause

on blinks

Procedure

Fault status: Overload at the status outputs +24, H and D

Fault description Possible cause

on blinks

Procedure

Indication at the control

electronics, LB-1*0

LED “mains” LED “O.K.”

Fault indications and causes

Indication at the control

electronics, LB-1*0

LED “mains” LED “O.K.”

If the lead accus have been

discharged a short time ago by a

longer emergency current mode,

in mains operation the accu

voltage could still lie below the

discharge end voltage of 21,5 V.

As long as the charging unit fails to

bring the accu voltage over 21,5 V,

the control electronics stays in the

fault indication mode.

Indication at the control

electronics, LB-1*0

LED “mains” LED “O.K.”

Dublications, also in extracts, are only legal with express authorisation from SIMON RWA SYSTEME GmbH Passau

®

In particular time intervals the

control electronics, LB-1*0 cuts off

the charge. During this time the

accu gets proved. If the accu

voltage is below 21,5 V, the control

electronic assumes that the accu is

defective. The accu couple is

charged in mains operation

permanently.

The SHEV system works, but the

fault indicataion ´O.K.´blinks.

Furthermore all the ventilation

functions are disabled.

One of the status outputs ´+24´,

´H´ or ´D´ are overcharged resp.

short circuited.

Disconnect all status outputs from the

control electronics, LB-1*0. If the fault

indication goes out immediately, it must be

proved which wire causes the fault by

connnecting successively every single

status wire. The charge at the output +24

may not be higher than 500mA and at the

outputs H and D it may not exceed 70mA.

In order to distinguish whether the accu is

simply discharged or if it is defective, you just

need to dis- and reconnect the accu couple

(5 s). Then the fault indication should go out

and stay out (wait 10 minutes).

The SHEV system works, but the

fault indication LED ´O.K.´blinks.

The SHEV system works, but the

fault indication LED ´O.K.´blinks

Disconnect the accu from the control

electronics LB-1*0. Then measure the

voltage at the accu couple for about 1 min. If

the voltage is less than 21,5 V it can be

assumed, that the accu couple is defective.

Installation manual ESM-T/X-EV (24 A / 48 A / 72 A)

Page 11/20

SIMON RWA SYSTEME GmbH, Passau

ESM-T/X-EV with power supply

Fault status: Reaching the total discharge voltage (emergency current mode)

Fault description Possible cause

off off

Procedure

Fault status: Interuption of the accu wire (e. g. fault at the connection of the lead accu)

Fault description Possible cause

on blinks

Procedure

Fault status: Short circuit at the charge output resp. the accu connection

Fault description Possible cause

on blinks

Procedure

Dublications, also in extracts, are only legal with express authorisation from SIMON RWA SYSTEME GmbH Passau

®

Fault indications and causes

Indication at the control

electronics, LB-1*0

LED “mains” LED “O.K.”

Indication at the control

electronics, LB-1*0

LED “mains” LED “O.K.”

Indication at the control

electronics, LB-1*0

LED “mains” LED “O.K.”

The SHEV system is in emergency

current mode

In the emergency current mode the

accu voltage is monitored and

proved. If the accu is totally

discharged (Uaccu < 20 V), the

status output D gets deactivated.

Disconnect the accu from the control

electronics LB-1*0. Measure the voltage at

the accu couple after about 1 min. If the

voltage is less than 20 V the accu couple is

totally discharged. The accu has to be

charged elsewhere by a particular charging

process.

(Please consultate the technical customer

service of SIMON RWA Systeme GmbH)

The SHEV system works, but the fault

indication LED ´O.K.´ blinks

The charging connection of the

power supply, EV-** has a short

circuit protection. If a short circuit at

the charging connection is caused,

the control electronics cuts-off the

charging output.

The charging circuit of the power supply is

therefore not defective. If you now reconnect

the accu the control electronics detects this

and continues charging (fault indication goes

out).

The SHEV system works, but the fault

indication LED ´O.K.´ blinks

In particular time intervals it is proved

whether an accu is connected. This

proving is accomplished at each

connected ciruit. That means that at

an EV-** all accu connection have to

be wired.

Check, if the required accu connections are

available. Consequently should be

checked, if all connections have the right

contact.

Central ventilation module, type ES-WS-100

This device with centric ventilation functioin is an

inherent part of the modular technique and is installed

in electrical control panels as standard.

yellow LED “WTS” for WTS/WS active

fixed ribbon cable

Terminal for maintenance module

green LED “OK” = ready for use

E_

V=

21 - 24,5 V (only at mains)

2

At the terminals a wind/rain combination, a wind or a rain detector can be

connected. The clamp “E” supplies the supply voltage for the heater and the electronics

of the detector. “E” is a plus potential, that is only impressed when the control unit is

supplied with mains voltage. In accu mode this function gets deactivated automatically.

ULZ LA

-ETerminals for Wind-/Rain detector

and central ventilation button

2

Connection ES-WS-100

Terminal for central ventilation button

U_

V=

at least 21 V (only at mains)

(only when “wind/rain detector not triggered”)

LZ _

V=

21 V (only at “wind/rain” or closing demand

via central ventilation button)

ULZ LA

-E

2

Connection ES-WS-100

Installation manual ESM-T/X-EV (24 A / 48 A / 72 A)

Page 12/20

SIMON RWA SYSTEME GmbH, Passau

ESM-T/X-EV with power supply

The plus potential comes back from the detector via the clamp “U” into

the control unit and supplies the connected ventilation button (clamp “T”).

If no detector is connected please bridge between “U” and “E”!

In case of triggering via the SHEV alarm of the particular SHEV group the

clamps “T”, “LZ” and “LA” of all ventilation groups of this SHEV group get

disabled and the detector is without function.

When the detector is triggered the plus potential of the output “E” is connected to the

clamp “LZ” and the clamp “U” is zero potential then. The control unit causes that the

connected actuators close. Connecting has to occur according to the diagram.

Other detectors than the original detectors of Simon RWA Systeme may not be

applied. The lines towards the detector are not monitored.

Dublications, also in extracts, are only legal with express authorisation from SIMON RWA SYSTEME GmbH Passau

®

The terminal for the central ventilation button supplies a plus potential

when the wind/rain detector is not triggered and there is no mains failure. Connecting the

potential to the clamps “LZ” or “LA” cause a central “close” or “open” function of the

connected actuators of every ventilation group. When both clamps are connected with

“U”, the actuators stop and all position indicators go out!

at the clamp “U”

red LED “RWA” = RWA (=SHEV triggered)

green LED “FTZ” = failure free button loop

green LED “RM” = failure free

smoke detector loop

green LED “BMZ” = failure free contact loop

green LED “OK” = this SHEV system and all ventilatilation

groups are ready for use (collective

failure indication)

yellow LED “OPEN” = open command to all vent groups

yellow LED “CLOSE” = close command to all vent groups

2

3

DIP- switches

3

4

5

Terminal ribbon cable

Terminal ribbon cable

WRES

RES

SHEV

CLOSE

OPEN

BMZ

RM

FTZ

ONOFF Adjustment by the customer “ON”. May only be changed at VdS-systems and

only after consultation with the manufactor.

The DIP switches are factory-adjusted in a way so that a failure in the

monitoring loops causes an automatic triggering of the SHEV alarm. If

the operator wants to cause simply a failure indication instead of an auto-

matic triggering he has to throw the DIP switches of the particular

loops leftwards.

Central relay module, type ES-ZL-100

* 270 k 12/04)(until manufacture year

Installation manual ESM-T/X-EV (24 A / 48 A / 72 A)

Page 13/20

SIMON RWA SYSTEME GmbH, Passau

ESM-T/X-EV with power supply

For each SHEV group an ES-ZL-100 module is

required. This module controls all commands

relevant for SHEVs like “OPEN” via the break glass

button or the automatic triggers like smoke detector

and also the dry opener contact of the BMZ. These

lines are connected via a 27 k * resistor and closed

current monitored. In case of short circuit or

interruption the SHEV groups get triggered

automatically

Adjustment by the customer “ON”. May only be changed at VdS-systems and

only after consultation with the manufactor.

Adjustment by the customer “ON”. May only be changed at VdS-systems and

only after consultation with the manufactor.

Adjustment by the customer “ON”. May only be changed at VdS-systems and

only after consultation with the manufactor.

Attention! The adjustments by the

customer may only be changed by

authorized qualified personell. False

adjustments of the DIP switches can lead

to a malfunction of the SHEV system!

Dublications, also in extracts, are only legal with express authorisation from SIMON RWA SYSTEME GmbH Passau

®

_

µA=

B1

value to be measured:

0,8 - 1 mA (until date of manufacture 12/04, value 80 - 100 µA)

Button loop

27 kV*

Y_

at least 21 V (Mains)

at least 18 V (Accu)

V=

OK _

V=

21 V

3OK RAYB1

M-RZ Break glass button terminal

M_

V=

at least 20 V (Mains)

at least 18 V (Accu)

Connection central relay module,

type ES-ZL-100

Installation manual ESM-T/X-EV (24 A / 48 A / 72 A)

Page 14/20

SIMON RWA SYSTEME GmbH, Passau

ESM-T/X-EV with power supply

Dublications, also in extracts, are only legal with express authorisation from SIMON RWA SYSTEME GmbH Passau

®

The minus potential of the minus clamp (-) is considered to be a basis for all

terminals for signalizing. The clamp “OK” supplies a plus potential at least 21 V

if there is no failure at the control unit (complete SHEV group). Between these

clamps hangs the green LED of the main station. The clamp “OK” (Y”) is

fused by a PTC (approx. 100 mA - never connect more than 1 main station).

OK

“Y” provides a plus potential for failure indication. This signal is a permanent signal,

that is turned into a blink signal by an electronics at the main station’s circuit board.

Between these clamps hangs a yellow diode of the main station for failure

indicating. Attention!! “Y” is supplied by emergency current.

“M” provides a plus potential at “SHEV OPEN” (HE, RM, TH,

BMZ). Between these clamps hangs the LED-indication

“triggering” of the stations (HE 075/076). These output is also

fused with a PTC and is able to supply max 8 OPEN-indications of the

stations in parallel. If more than 8 break glass buttons are connected the

output “M” breaks down to an undefinable value. Never

connect more than one main and seven slave stations. If some

additional stations are required an auxiliary relay (HR-195) is necessary.

Attention!!

“B1” provides the plus potential for the closed current loop, wherewith the button lines of

the electrical break glass buttons are monitored. The current of this output is limited to 100

mA by a PTC. The closed current tolerance lies between 50 µA and 5 mA. If the closed

current value doesn’t lie within this range, the control unit will be triggering. The end

resistor has to be added to the button line at the last terminal (like shown in the diagrams).

If no buttons shall be connected the resistor needs to be installed directly into the control

unit (delivery state). This loop is monitored for failure and short circuit. If the end

resistor stays in the control unit, triggering via the break glass button (HE 075/076) will be

not possible. Alarm willnot be set.

Attention!!

* 270 k 12/04)(until date of manufacture

When the potential of terminal “B1” is clamped onto the terminal RZ, this will cause a RESET of the system and

consequently a closing of the connected acutators. The plus potential of the terminals “B2” and “B3” thereby get

reseted (= smoke detector - reset). This function is clamped at the button CLOSE/RESET (terminals “8” and “9”) at

the main stations. The “Reset” - button in the control panel has the same function. When a SHEV alarm

has been triggered all other functions are disabled, only by RESETTING other functions like wind and rain detector

or vent button will be reactivated. The terminal RA is not relevant at “normal” operation of the control unit.

Attention!!

Connection central relay module,

type ES-ZL-100

4

5

RA

B2 -Smoke detector terminal

RA

B3 -Terminal for an opener contact by the contractor

RESET-button

The electrical control panel, type ESM-T/X has an integrated RESET-

button placed in the central relay module, type ES-ZL-100. Pressing

this button effects the following:

1. the closed current loops at “B2” and “B3” is volt-free during pressing

the button.

2. all connected actuators close and

3. if no failures or triggerings are setted, the system stays closed until

the next open command.

4. In accu mode the reset button holds deadman function,

after pressing all outputs are volt-free again (actuators) and the

closed current consumption is minimized except the monitoring loop

In contrast to the reset button in the HE 075 this one can not be passed (independent from switch adjustment “WRES”).

The RESET command is active as long as the button is pressed.

Installation manual ESM-T/X-EV (24 A / 48 A / 72 A)

Page 15/20

SIMON RWA SYSTEME GmbH, Passau

ESM-T/X-EV with power supply

Dublications, also in extracts, are only legal with express authorisation from SIMON RWA SYSTEME GmbH Passau

®

The terminal “B2” provides as well as the terminal “B1” a plus potential, that with end resistor connected between

“B2” and minus results a defined closed current loop. The end resistor closes the circuit loop at the last smoke

detector (see diagram). Don’t connect more than max. 8 smoke detectors type RM-521 or RM 2860. If no smoke

detectors are connected the resistor is connected directly into the control unit (delivery state!). RA is without function

at a standard connection. Closed current tolerance see at “B1”.

The terminal for a contact (opener) by the contractor is realized by the terminals “B3” and “-”. The principle of

monitoring is identical with the other monitoring loops of the terminals “B1” and “B2”. At the terminal “B3” also for

example a thermo detector with dry contact can be connected (see diagram). If no contacts are connected the end

resistor stays connected in the control unit (delivery state!) RA is not connected.

Ventilation group module, type ES-MR-100

LZ

LA

Z PAR

A PAR

Z TOT

A TOT

END

DIP-switches (adjustment samples)

ON

OFF

Central vent command in closing direction is active for this vent group.

Parallel connection of this vent group module in closing direction to the

foregoing vent group

Dead man operation for vent function in “close” switched off.

Switch not used

Closes the monitoring loop and consequently the collective failure indication

of the SHEV group (must be in “EIN” position at the last vent module). All

groups between must be switched off.

For each ventilation group a ES-MR-100 module is

necessary. This module supplies the connected actuators

with voltage in pole changing technique. The max. output

current is 12 A per module.

16

7

6

green LED “OK” = ready for use

yellow LED “OPEN” = actuators openyellow LED “CLOSE” = actuators close

(LED “OPEN/CLOSE” at the same time =

actuators stopped, e.g. by vent switch)

Connection ribbon cable

Connection ribbon cable

5A 10A

Installation manual ESM-T/X-EV (24 A / 48 A / 72 A)

Page 16/20

SIMON RWA SYSTEME GmbH, Passau

ESM-T/X-EV with power supply

Dublications, also in extracts, are only legal with express authorisation from SIMON RWA SYSTEME GmbH Passau

®

The actuator line is monitored for interruption by an end of

the line diode unit. The maximum cable cross section is

2,5 mm² when connected directly at the terminals. For

bigger cross sections a block terminal can be installed.

The output is fused by a delay micro fuse with 5 A resp.

10 A.

Central vent command in opening direction is active for this vent group.

Parallel connection of this vent group module in opening direction to the

foregoing vent group

Dead man operation for vent function in “open” switched off.

Connection Ventilation group module,

type ES-MR-100

Actuator output, 24 Volt DC, max. 12 A

per ES-MR-100 Short time operation. Please don’t forget to install the fuses!

Triggered or not installed fuses are indicated as failure!

Only delayed-action fuses may be applied.Attention !!

OS

V=

0,5

24 V (Mains)

6

21,5 V - 26 V (Accu)

SSGOO

6

7

The terminal for the vent switch supplies a plus potential at “T” when wind/rain detector and SHEV have not been

triggered and if there has been no mains failure. Switching the potential at “Z” or “A” causes a “close” or “open” function

of the connected actuators. If both terminals were connected with “T” the actuators would stop and all position indications

would go out!

ATZ Terminal for vent switch

The enclosed diodeblock must be installed at the last connection point as shown in

the connection diagram. If there is a failure at the line, in the main station will appear

a failure indication! If the diode block is installed in the control panel there

will be no failure indication but the actuator lines will not be monitored!

Attention!!

SO

G

µA=

M

24V

40 - 100µA

= Connection for monitoring loop -

actuator line

6

7

Notice: Do not connect contact “F” of the

actuator with “G” in the control panel. This

would cause a short circuit at the actuator

lines.

Connection for actuators

Fuses

Fuse actuator: 5 or 10 A delayed-action (at vent group module)

Only use delayed-action fuses.Attention!!

Triggering resp. a lack of this fuse is indicated as a failure

(at the specific modules of the electrical control panel and in the main station.)

Installation manual ESM-T/X-EV (24 A / 48 A / 72 A)

Page 17/20

SIMON RWA SYSTEME GmbH, Passau

ESM-T/X-EV with power supply

Dublications, also in extracts, are only legal with express authorisation from SIMON RWA SYSTEME GmbH Passau

®

Polarity changes between “S” and “O” in case of open or close. At switching

position “OPEN” “S” has plus and “O” has minus potential. At “G” the monitoring

loop is connected. If the actuator lines are without failure you can measure a

closed current in the line “G” of 40 - 100µA

Additional slots

Ready for use only for this vent group

resp. if not failure indication (supply, fuses, line monitoring).

Slot 2 and/or 3:

(at the central relay module, type ES-ZL-100)

Slot 3:

(at the central relay module, type ES-ZL-100)

Slot 1:

(at the vent group module,

type ES-MR-100)

Install the repeat module at slot 3.

Connection or adjustment is not necessary.

=

=

=

=

=

Smoke exhaust triggered

Command “OPEN” for daily vent and

smoke exhaust

Command “CLOSE” for daily vent, wind/rain active

and smoke exhaust reset

“Mains OK” or if not “Mains failure”

Control panel ready for use or if not:

“collective failure indication” (complete SHEV group,

central vent + all vent groups as well as all appropriate supplies)

wind/rain detector active or central vent switch active

=

SHEV

OPEN

CLOSE

MAINS

OK

WTS

1 2 3 4 5 6

ON

OFF Auxiliary relay module, type HR-195

Repeat module

Auxiliary relay module, type HR-195

=Smoke exhaust triggered

SHEV

1

ON

OFF

=

=

=

=

Command “OPEN”, for daily vent and

smoke exhaust

Command “CLOSE”, for daily vent, wind/rain active

and smoke exhaust reset

“Mains OK”, or if not “Mains failure” only for supply of this group)

Wind/rain detector or central vent switch active

=

OPEN

CLOSE

MAINS

OK

WTS

2 3 4 5 6

DIP-Switch (ES-ZL-100)

WRES

RES

SHEV

CLOSE

OPEN

BMZ

RM

FTZ

ONOFF

When the repeat module is used adjust the DIP switch to “OFF”

Installation manual ESM-T/X-EV (24 A / 48 A / 72 A)

Page 18/20

SIMON RWA SYSTEME GmbH, Passau

ESM-T/X-EV with power supply

Dublications, also in extracts, are only legal with express authorisation from SIMON RWA SYSTEME GmbH Passau

®

Debugging

Please check voltage in the following sequence:

Check voltage!

L1 N

230 V~

Only with “mains”

1.

If the voltage value now complies with the datas at the data sheet, the power consumption of one of the consuming devices

connected to the outputs “E” , is too high. Reconnect and recheck the particular output

voltage. Check the consuming devices for quantity and faultless function. If the voltage values even after disconnecting

still differ from the declared values, the control panel has to be checked in the factory.

“U”, “B1”, “B2”, “Y”, “OK”, “M” or “B3”

E-

V=

2.

only with “mains”

at least 21 V

only at “mains”

at least 21 V

SO

V=

3.

only at “OPEN” or “CLOSE”

24 V (Mains)

60,5

21,5 - 26 V (Accu)

B1 _

V=

4.

B2 _

V=

5.

B3 _

V=

6.

at “mains” and “Accu”

at least 20 V (Mains)

at least 18 V (Accu)

7.

OK _

V=

Please check the fuses if the voltage differed from the

datas of this manual. Disconnect all power consuming

devices and close all closed circuit loops in the control

panel with resistors and diode block.

Attention!! Mains failure causes a failure indication!

The failure causes an activation of the SHEV system!

SSG

OO

Example:

Output actuators

8. 9.

at “mains” and “accu”

at least 21 V (Mains)

at least 18 V (Accu)

in case of failure only only when SHEV triggered

Y_

V=

M_

V=

at “mains” and “akku”

at least 20 V (Mains)

at least 18 V (Accu)

Installation manual ESM-T/X-EV (24 A / 48 A / 72 A)

Page 19/20

SIMON RWA SYSTEME GmbH, Passau

ESM-T/X-EV with power supply

Dublications, also in extracts, are only legal with express authorisation from SIMON RWA SYSTEME GmbH Passau

®

Table of contents

Other SIMON RWA Control Panel manuals

Popular Control Panel manuals by other brands

Johnson Controls

Johnson Controls IFC-200 Installation procedures

VTS Medical Systems

VTS Medical Systems HMI WING HY manual

CWSI

CWSI CP-3500D Operating and installation instruction manual

Kingspan

Kingspan SHE TRZ Plus 2A Technical information and operating instruction

LEGRAND

LEGRAND Wattstopper LP8 quick start guide

ETC

ETC SmartFade user manual

ILLUMINO IGNIS

ILLUMINO IGNIS SMARTWIRE quick start guide

DynaGen

DynaGen Tough Series user manual

Lofa

Lofa CANplus 750 Operation and Troubleshooting

Dea

Dea NET24N Operating instructions and warnings

Intermatic

Intermatic P40000 Series Installation, operation & service manual

FlameStop

FlameStop PFS200-2 Installation and operation manual