Fike FCP-75 User manual

B

P/N LS10147-003FK-E:B • ECN 00003636

Document LS10147-003FK-E

6/20/2022

Addressable Fire Alarm Control Panel

FCP-75

Manual

2FCP-75 Manual — P/N LS10147-003FK-E:B 6/20/2022

Fire Alarm & Emergency Communication System Limitations

While a life safety system may lower insurance rates, it is not a substitute for life and property insurance!

An automatic fire alarm system—typically made up of smoke

detectors, heat detectors, manual pull stations, audible warning

devices, and a fire alarm control panel (FACP) with remote

notification capability—can provide early warning of a developing fire.

Such a system, however, does not assure protection against property

damage or loss of life resulting from a fire.

An emergency communication system—typically made up of an

automatic fire alarm system (as described above) and a life safety

communication system that may include an autonomous control unit

(ACU), local operating console (LOC), voice communication, and

other various interoperable communication methods—can broadcast

a mass notification message. Such a system, however, does not

assure protection against property damage or loss of life resulting

from a fire or life safety event.

The Manufacturer recommends that smoke and/or heat detectors be

located throughout a protected premises following the

recommendations of the current edition of the National Fire

ProtectionAssociation Standard 72 (NFPA 72), manufacturer's

recommendations, State and local codes, and the recommendations

contained in the Guide for Proper Use of System Smoke Detectors,

which is made available at no charge to all installing dealers. This

document can be found at http://www.systemsensor.com/appguides/.

A study by the Federal Emergency Management Agency (an agency

of the United States government) indicated thatsmoke detectors may

not go off in as many as 35% of all fires. While fire alarm systems are

designed to provide early warning against fire, they do not guarantee

warning or protection against fire. A fire alarm system may not

provide timely or adequate warning, or simply may not function, for a

variety of reasons:

Smoke detectors may not sense fire where smoke cannot reach the

detectors such as in chimneys, in or behind walls, on roofs, or on the

other side of closed doors. Smoke detectors also may not sense a

fire on another level or floor of a building.A second-floor detector, for

example, may not sense a first-floor or basement fire.

Particles of combustion or “smoke” from a developing fire may not

reach the sensing chambers of smoke detectors because:

• Barriers such as closed or partially closed doors, walls, chimneys,

even wet or humid areas may inhibit particle or smoke flow.

• Smoke particles may become “cold,” stratify, and not reach the

ceiling or upper walls where detectors are located.

• Smoke particles may be blown away from detectors by air outlets,

such as air conditioning vents.

• Smoke particles may be drawn into air returns before reaching the

detector.

The amount of “smoke” present may be insufficient to alarm smoke

detectors. Smoke detectors are designed to alarm at various levels of

smoke density. If such density levels are not created by a developing

fire at the location of detectors, the detectors will not go into alarm.

Smoke detectors, even when working properly, have sensing

limitations. Detectors that have photoelectronic sensing chambers

tend to detect smoldering fires better than flaming fires, which have

little visible smoke. Detectors that have ionizing-type sensing

chambers tend to detect fast-flaming fires better than smoldering

fires. Because fires develop in different ways and are often

unpredictable in their growth, neither type of detector is necessarily

best and a given type of detector may not provide adequate warning

of a fire.

Smoke detectors cannot be expected to provide adequate warning of

fires caused by arson, children playing with matches (especially in

bedrooms), smoking in bed, and violent explosions (caused by

escaping gas, improper storage of flammable materials, etc.).

Heat detectors do not sense particles of combustion and alarm only

when heat on their sensors increases at a predetermined rate or

reaches a predetermined level. Rate-of-rise heat detectors may be

subject to reduced sensitivity over time. For this reason, the rate-of-

rise feature of each detector should be tested at least once per year

by a qualified fire protection specialist. Heat detectors are designed

to protect property, not life.

IMPORTANT! Smoke detectors must be installed in the same room

as the control panel and in rooms used by the system for the

connection of alarm transmission wiring, communications, signaling,

and/or power. If detectors are not so located, a developing fire may

damage the alarm system, compromising its ability to report a fire.

Audible warning devices such as bells, horns, strobes, speakers

and displays may not alert people ifthese devices are located on the

other side of closed or partly open doors or are located on another

floor of a building. Any warning device may fail to alert people with a

disability or those who have recently consumed drugs, alcohol, or

medication. Please note that:

• An emergency communication system maytake priority over a fire

alarm system in the event of a life safety emergency.

• Voice messaging systems must be designed to meet intelligibility

requirements as defined by NFPA, local codes, andAuthorities

Having Jurisdiction (AHJ).

• Language and instructional requirements must be clearly dissemi-

nated on any local displays.

• Strobes can, under certain circumstances, cause seizures in peo-

ple with conditions such as epilepsy.

• Studies have shown that certain people, even when they hear a

fire alarm signal, do not respond to or comprehend the meaning of

the signal.Audible devices, such as horns and bells, can have dif-

ferent tonal patterns and frequencies. It is the property owner's

responsibility to conduct fire drills and other training exercises to

make people aware of fire alarm signals and instruct them on the

proper reaction to alarm signals.

• In rare instances, the sounding of a warning device can cause

temporary or permanent hearing loss.

A life safety system will not operate without any electrical power. If

AC power fails, the system will operate from standby batteries only

for a specified time and only if the batteries have been properly

maintained and replaced regularly.

Equipment used in the system may not be technically compatible

with the control panel. It is essential to use only equipment listed for

service with your control panel.

Alarm Signaling Communications:

•IP connections rely on available bandwidth, which could be lim-

ited if the network is shared by multiple users or if ISP policies

impose restrictions on the amount of data transmitted. Service

packages must be carefully chosen to ensure that alarm signals

will always have available bandwidth. Outages by the ISP for

maintenance and upgrades may also inhibit alarm signals. For

added protection, a backup cellular connection is recommended.

•Cellular connections rely on a strong signal. Signal strength can

be adversely affected by the network coverage of the cellular car-

rier, objects and structural barriers at the installation location. Uti-

lize a cellular carrier that has reliable network coverage where the

alarm system is installed. For added protection, utilize an external

antenna to boost the signal.

•Telephone lines needed to transmit alarm signals from a premise

to a central monitoringstation may be out of service or temporarily

disabled. For added protection against telephone line failure,

backup alarm signaling connections are recommended.

The most common cause of life safety system malfunction is

inadequate maintenance. To keep the entire life safety system in

excellent working order, ongoing maintenance is required per the

manufacturer's recommendations, and UL and NFPA standards.At a

minimum, the requirements of NFPA 72 shall be followed.

Environments with large amounts of dust, dirt, or high air velocity

require more frequent maintenance. A maintenance agreement

should be arranged through the local manufacturer's representative.

Maintenance should be scheduled as required by National and/or

local fire codes and should be performed by authorized professional

life safety system installers only. Adequate written records of all

inspections should be kept. Limit-F-2020

FCP-75 Manual — P/N LS10147-003FK-E:B 6/20/2022 3

Installation Precautions

Adherence to the following will aid in problem-free installation with long-term reliability:

WARNING - Several different sources of power can be con-

nected to the fire alarm control panel. Disconnect all sources of

power before servicing. Control unit and associated equipment may

be damaged by removing and/or inserting cards, modules, or inter-

connecting cables while the unit is energized. Do not attempt to

install, service, or operate this unit until manuals are read and under-

stood.

CAUTION - System Re-acceptance Test after Software Changes:

To ensure proper system operation, this product must be tested in

accordance with NFPA 72 after any programming operation or

change in site-specific software. Re-acceptance testing is required

after any change, addition or deletion of system components, or after

any modification, repair or adjustment to system hardware or wiring.

All components, circuits, system operations, or software functions

known to be affected by a change must be 100% tested. In addition,

to ensure that other operations are not inadvertently affected, at

least 10% of initiating devices that are not directly affected by the

change, up to a maximum of 50 devices, must also be tested and

proper system operation verified.

This system meets NFPA requirements for operation at 0-49º C/32-

120º F and at a relative humidity 93% ± 2% RH (non-condensing) at

32°C ± 2°C (90°F ± 3°F). However, the useful life of the system's

standby batteries and the electronic components may be adversely

affected by extreme temperature ranges and humidity. Therefore, it

is recommended that this system and its peripherals be installed in

an environment with a normal room temperature of 15-27º C/60-80º

F.

Verify that wire sizes are adequate for all initiating and indicating

device loops. Most devices cannot tolerate more than a 10% I.R.

drop from the specified device voltage.

Like all solid state electronic devices, this system may operate

erratically or can be damaged when subjected to lightning induced

transients.Although no system is completely immune from lightning

transients and interference, proper grounding will reduce susceptibil-

ity. Overhead or outside aerial wiring is not recommended, due to an

increased susceptibility to nearby lightning strikes. Consult with the

Technical Services Department if any problems are anticipated or

encountered.

Disconnect AC power and batteries prior to removing or inserting

circuit boards. Failure to do so can damage circuits.

Remove all electronic assemblies prior to any drilling, filing, ream-

ing, or punching of the enclosure. When possible, make all cable

entries from the sides or rear. Before making modifications, verify

that they will not interfere with battery, transformer, or printed circuit

board location.

Do not tighten screw terminals more than 9 in-lbs. Over-tightening

may damage threads, resulting in reduced terminal contact pressure

and difficulty with screw terminal removal.

This system contains static-sensitive components. Always

ground yourself with a proper wrist strap before handling any circuits

so that static charges are removed from the body. Use static sup-

pressive packaging to protect electronic assemblies removed from

the unit.

Units with a touchscreen display should be cleaned with a dry,

clean, lint free/microfiber cloth. If additional cleaning is required,

apply a small amount of Isopropyl alcohol to the cloth and wipe

clean. Do not use detergents, solvents, or water for cleaning. Do not

spray liquid directly onto the display.

Follow the instructions in the installation, operating, and program-

ming manuals.These instructions must be followed to avoid damage

to the control panel and associated equipment. FACP operation and

reliability depend upon proper installation.

Precau-D2-11-2017

FCC Warning

WARNING: This equipment generates, uses, and can radi-

ate radio frequency energy and if not installed and used in

accordance with the instruction manual may cause interfer-

ence to radio communications. It has been tested and found

to comply with the limits for classA computing devices pur-

suant to Subpart B of Part 15 of FCC Rules, which is

designed to provide reasonable protection against such

interference when devices are operated in a commercial

environment. Operation of this equipment in a residential

area is likely to cause interference, in which case the user

will be required to correct the interference at his or her own

expense.

Canadian Requirements

This digital apparatus does not exceed the ClassA limits for

radiation noise emissions from digital apparatus set out in

the Radio Interference Regulations of the Canadian Depart-

ment of Communications.

Le present appareil numerique n'emet pas de bruits radio-

electriques depassant les limites applicables aux appareils

numeriques de la classeAprescrites dans le Reglement sur

le brouillage radioelectrique edicte par le ministere des

Communications du Canada.

Flexput®, Honeywell®, JumpStart®, and SWIFT® are registered trademarks of Honeywell International Inc.Microsoft® and Windows® are registered trademarks of the

Microsoft Corporation. Chrome™ and Google™ are trademarks of Google Inc. Firefox® is a registered trademark of The Mozilla Foundation.

©2022. All rights reserved. Unauthorized use of this document is strictly prohibited.

4FCP-75 Manual — P/N LS10147-003FK-E:B 6/20/2022

Software Downloads

In order to supply the latest features and functionality in fire alarm and life safety technology to our customers, we make frequent

upgrades to the embedded software in our products. To ensure that you are installing and programming the latest features, we strongly

recommend that you download the most current version of software for each product prior to commissioning any system. Contact

Technical Support with any questions about software and the appropriate version for a specific application.

Documentation Feedback

Your feedback helps us keep our documentation up-to-date and accurate. If you have any comments or suggestions about our online

Help or printed manuals, you can email us.

Please include the following information:

• Product name and version number (if applicable)

• Printed manual or online Help

• Topic Title (for online Help)

• Page number (for printed manual)

• Brief description of content you think should be improved or corrected

• Your suggestion for how to correct/improve documentation

Send email messages to:

or call (800)979-3453, x21 in US or (816)229-3405 international

This symbol (shown left) on the product(s) and / or accompanying documents means that used electrical and electronic products

should not be mixed with general household waste. For proper treatment, recovery and recycling, contact your local authorities or

dealer and ask for the correct method of disposal.

Electrical and electronic equipment contains materials, parts and substances, which can be dangerous to the environment and harmful

to human health if the waste of electrical and electronic equipment (WEEE) is not disposed of correctly.

FCP-75 Manual — P/N LS10147-003FK-E:B 6/20/2022 5

Table of Contents

Section 1: Introduction ..................................................................................................................................................... 9

1.1: Basic System Overview.....................................................................................................................................................................................9

1.1.1: Hardware Features..................................................................................................................................................................................9

1.1.2: Network System Hardware Features ......................................................................................................................................................9

1.1.3: Software Features ...................................................................................................................................................................................9

1.2: About this Manual............................................................................................................................................................................................10

1.2.1: Terms Used in this Manual...................................................................................................................................................................10

1.3: Compatible Products........................................................................................................................................................................................10

1.4: Related Documentation ...................................................................................................................................................................................11

Section 2: Agency Listings, Approvals, and Requirements........................................................................................ 12

2.1: Federal Communications Commission (FCC).................................................................................................................................................12

2.1.1: Electrical Safety Advisory....................................................................................................................................................................12

2.2: Underwriters Laboratories (UL)......................................................................................................................................................................13

2.2.1: Requirements for All Installations........................................................................................................................................................13

2.2.2: UL 864 9th and 10th Edition ................................................................................................................................................................13

2.2.3: Requirements for Central Station Fire Alarm Systems ........................................................................................................................13

2.2.4: Requirements for Local Protected Fire Alarm Systems .......................................................................................................................13

2.2.5: Requirements for Remote Station Protected Fire Alarm Systems........................................................................................................13

2.2.6: Requirements for the Installation of Carbon Monoxide (CO) Detection and Warning Equipment, NFPA 720..................................14

2.2.7: NFPA Requirements.............................................................................................................................................................................14

Section 3: Prerequisites for Installation........................................................................................................................ 15

3.1: Inventory..........................................................................................................................................................................................................15

3.2: Environmental Specifications..........................................................................................................................................................................15

3.3: Software Downloads........................................................................................................................................................................................15

3.4: Electrical Specifications ..................................................................................................................................................................................15

3.5: Calculating Current Draw and Standby Battery..............................................................................................................................................16

3.5.1: Worksheet Requirements......................................................................................................................................................................16

3.5.2: Current Draw Worksheet for SLC Devices..........................................................................................................................................16

Section 4: Control Panel Installation............................................................................................................................. 20

4.1: Mounting the Control Panel Cabinet...............................................................................................................................................................20

4.1.1: Preventing Water Damage....................................................................................................................................................................20

4.1.2: Removing the FCP-75 Assembly from the Housing............................................................................................................................20

4.1.3: Dead Front Installation and Removal...................................................................................................................................................20

4.2: Board Assembly Diagram................................................................................................................................................................................22

4.3: Wiring Specifications.......................................................................................................................................................................................22

4.4: AC Power Connection .....................................................................................................................................................................................23

4.5: Battery Power ..................................................................................................................................................................................................24

4.5.1: Battery Accessory Cabinet ...................................................................................................................................................................25

4.6: Wiring Specifications.......................................................................................................................................................................................26

4.6.1: Length Limitations................................................................................................................................................................................26

4.6.2: Calculating Wiring Distance for SBUS Modules.................................................................................................................................27

4.6.3: Wiring Configurations..........................................................................................................................................................................28

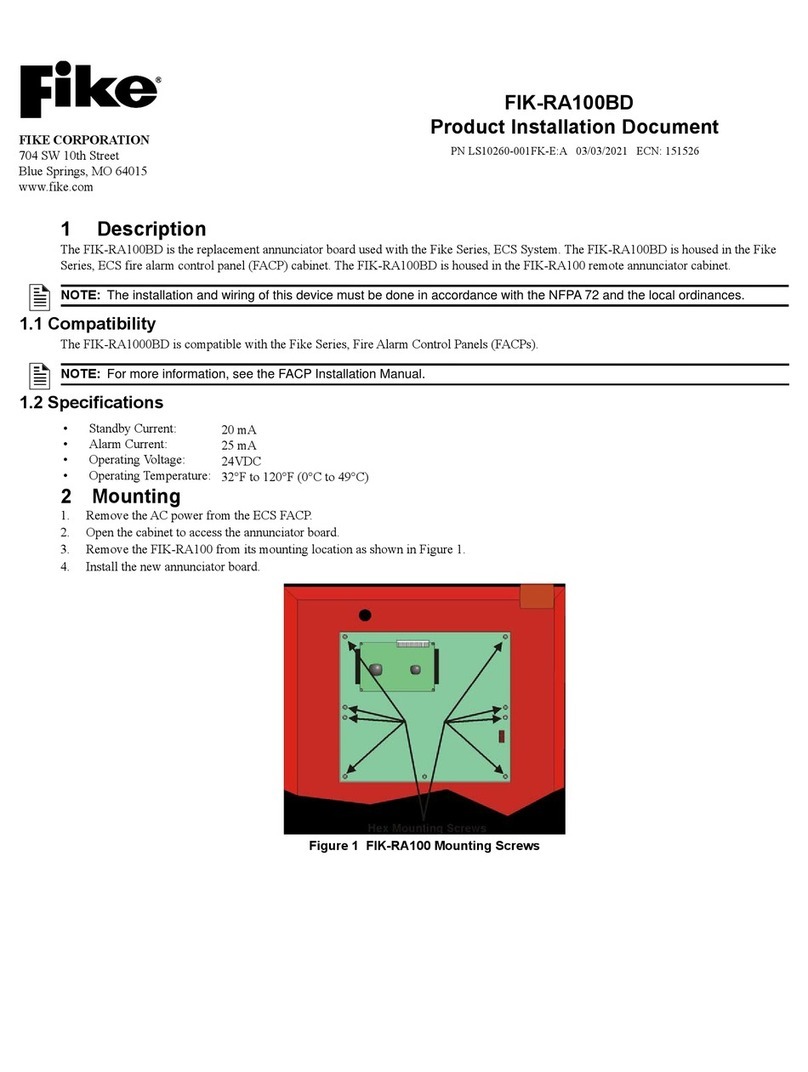

4.7: FIK-RA100 Remote Annunciator Installation.................................................................................................................................................28

4.7.1: Mounting the FIK-RA100 ....................................................................................................................................................................29

4.7.2: FIK-RA100 Connection to the Panel....................................................................................................................................................31

4.8: FIK-RA1000R Remote Annunciator Installation............................................................................................................................................31

4.8.1: Mounting the FIK-RA1000R................................................................................................................................................................31

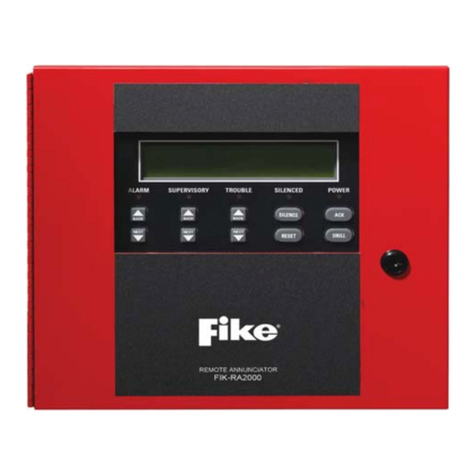

4.9: FIK-RA2000 Remote Annunciator Installation...............................................................................................................................................34

4.9.1: Mounting the FIK-RA2000 ..................................................................................................................................................................34

4.9.2: FIK-RA2000 Connection to the Panel..................................................................................................................................................36

4.10: FIK-5824 Serial/Parallel Printer Interface Module Installation ....................................................................................................................36

4.10.1: Selecting FIK-5824 Options...............................................................................................................................................................36

4.11: FIK-5880 LED Driver Module......................................................................................................................................................................37

4.11.1: FIK-5880 Board Layout .....................................................................................................................................................................37

4.11.2: FACP Connection...............................................................................................................................................................................38

4.11.3: LED Wiring ........................................................................................................................................................................................38

4.11.4: Dry Contact Wiring ............................................................................................................................................................................39

4.12: FIK-5865-3/FIK-5865-4 LED Annunciator Installation ...............................................................................................................................40

4.12.1: FACP Connection...............................................................................................................................................................................40

6FCP-75 Manual — P/N LS10147-003FK-E:B 6/20/2022

Table of Contents

4.12.2: FIK-5865 Mounting............................................................................................................................................................................41

4.13: Configuring Modules.....................................................................................................................................................................................41

4.13.1: Assigning Module IDs........................................................................................................................................................................41

4.14: Telephone Connection ...................................................................................................................................................................................42

4.15: Notification Appliance/Auxiliary Power Circuits .........................................................................................................................................42

4.15.1: Conventional Notification Appliance.................................................................................................................................................43

4.16: Class A Notification Wiring...........................................................................................................................................................................43

4.16.1: Auxiliary Power Installation...............................................................................................................................................................44

4.17: Onboard Relays (Conventional) ....................................................................................................................................................................44

4.17.1: Common Trouble Relay .....................................................................................................................................................................45

4.17.2: Programmable Relays.........................................................................................................................................................................45

4.18: Remote Station Applications .........................................................................................................................................................................45

4.18.1: Keltron Model 3158 Installation.........................................................................................................................................................45

4.18.2: City Box Connection Using the 5220 Module ...................................................................................................................................45

4.18.3: NFPA 72 Polarity Reversal ................................................................................................................................................................46

4.18.4: Using a MR-201/T Control Relay From Air Products .......................................................................................................................47

4.18.5: Transmitter Activated by Dry Contacts..............................................................................................................................................48

Section 5: Networking..................................................................................................................................................... 49

5.1: Network System Hardware Features ...............................................................................................................................................................49

5.1.1: Networked Panels.................................................................................................................................................................................49

5.2: Direct Connect Wiring Option.........................................................................................................................................................................49

5.3: SK-NIC Wiring Options ..................................................................................................................................................................................49

5.3.1: Fiber Loop Modules .............................................................................................................................................................................50

5.3.2: FIK-NIC Mounting Kits .......................................................................................................................................................................50

5.4: SK-NIC Installation.........................................................................................................................................................................................50

5.4.1: Wiring...................................................................................................................................................................................................51

5.5: Setting the Network ID for Each Panel ...........................................................................................................................................................53

Section 6: Network Management................................................................................................................................... 54

6.1: Network Diagnostics .......................................................................................................................................................................................54

6.1.1: Ping Panel.............................................................................................................................................................................................54

6.1.2: Data Network Status.............................................................................................................................................................................54

6.2: Network Programming ....................................................................................................................................................................................54

6.2.1: Learn Network......................................................................................................................................................................................54

6.2.2: Edit Network Names.............................................................................................................................................................................54

6.2.3: Edit Panel ID.........................................................................................................................................................................................54

6.2.4: Computer Access..................................................................................................................................................................................55

6.2.5: Access Codes........................................................................................................................................................................................55

6.2.6: Communicator Options.........................................................................................................................................................................55

6.3: Sync Network Options.....................................................................................................................................................................................56

6.4: Network Management Quick Reference .........................................................................................................................................................57

Section 7: Programming Overview................................................................................................................................ 58

7.1: JumpStart Auto-Programming.........................................................................................................................................................................58

7.1.1: Input Points...........................................................................................................................................................................................58

7.1.2: Output Points ........................................................................................................................................................................................58

7.1.3: Running JumpStart Auto-Programming...............................................................................................................................................58

7.2: Mapping Overview ..........................................................................................................................................................................................59

7.2.1: Input Point Mapping.............................................................................................................................................................................60

7.2.2: Output Circuit Mapping........................................................................................................................................................................60

7.2.3: Event Mapping.....................................................................................................................................................................................60

7.2.4: Mapping LED Points............................................................................................................................................................................62

7.3: Programming Using the HFSS Software Suite................................................................................................................................................62

7.4: Programming Using an Annunciator ...............................................................................................................................................................62

7.4.1: Entering / Exiting the Program Menu..................................................................................................................................................62

7.4.2: Moving through the Menus ..................................................................................................................................................................63

7.4.3: Selecting Options and Entering Data....................................................................................................................................................63

7.5: Programming Menu Quick Reference.............................................................................................................................................................63

Section 8: Programming................................................................................................................................................. 70

8.1: UL 864 Programming Requirements...............................................................................................................................................................70

8.2: Modules ...........................................................................................................................................................................................................70

8.2.1: Edit Modules.........................................................................................................................................................................................70

FCP-75 Manual — P/N LS10147-003FK-E:B 6/20/2022 7

Table of Contents

8.2.2: Adding Modules ...................................................................................................................................................................................71

8.2.3: Deleting Modules..................................................................................................................................................................................71

8.2.4: View Module List.................................................................................................................................................................................71

8.3: Zone.................................................................................................................................................................................................................71

8.3.1: Edit Zone ..............................................................................................................................................................................................71

8.3.2: View Zone Points .................................................................................................................................................................................74

8.4: Group...............................................................................................................................................................................................................74

8.4.1: Edit Group ............................................................................................................................................................................................74

8.4.2: View Group Points ...............................................................................................................................................................................75

8.4.3: Edit Output Group Template................................................................................................................................................................75

8.5: Point.................................................................................................................................................................................................................75

8.5.1: Point Programming for SLC.................................................................................................................................................................75

8.5.2: Point Programming for the Internal or External Power Module ..........................................................................................................78

8.5.3: Point Programming for FIK-5880 and FIK-5865 Modules..................................................................................................................79

8.5.4: Point Programming for the FIK-5496...................................................................................................................................................80

8.6: System Options................................................................................................................................................................................................80

8.6.1: Communication Options.......................................................................................................................................................................80

8.6.2: Daytime/Nighttime Sensitivity.............................................................................................................................................................83

8.6.3: Holiday Days ........................................................................................................................................................................................83

8.6.4: Time Options ........................................................................................................................................................................................83

8.6.5: Miscellaneous Options..........................................................................................................................................................................85

8.6.6: Daylight Saving Options.......................................................................................................................................................................85

8.6.7: Edit Banner...........................................................................................................................................................................................85

8.6.8: SLC Family...........................................................................................................................................................................................86

8.7: JumpStart Auto-Programming.........................................................................................................................................................................86

8.8: Restore Defaults...............................................................................................................................................................................................86

Section 9: System Operation.......................................................................................................................................... 87

9.1: Annunciator Description..................................................................................................................................................................................87

9.1.1: LCD Display.........................................................................................................................................................................................87

9.1.2: Banner...................................................................................................................................................................................................87

9.2: Menu System ...................................................................................................................................................................................................87

9.2.1: Panel Login Menu.................................................................................................................................................................................87

9.2.2: Main Menu Overview...........................................................................................................................................................................89

9.2.3: Using the Menus...................................................................................................................................................................................89

9.3: Basic Operation ...............................................................................................................................................................................................89

9.3.1: Setting Time and Date ..........................................................................................................................................................................89

9.3.2: Disable / Enable a Point........................................................................................................................................................................89

9.3.3: View Event History ..............................................................................................................................................................................90

9.3.4: Conduct a Fire Drill..............................................................................................................................................................................90

9.3.5: Conduct an Indicator Test.....................................................................................................................................................................90

9.3.6: Conduct a Walk Test ............................................................................................................................................................................90

9.3.7: Conduct a Communicator Test.............................................................................................................................................................91

9.3.8: Manual AlarmNet Registration.............................................................................................................................................................91

9.3.9: Silence Alarms or Troubles..................................................................................................................................................................91

9.3.10: Reset Alarms.......................................................................................................................................................................................91

9.3.11: Check Detector Sensitivity Through Point Status ..............................................................................................................................91

9.3.12: View Status of a Point ........................................................................................................................................................................92

9.3.13: View Alarms, Supervisories, or Troubles...........................................................................................................................................92

9.3.14: View System Information...................................................................................................................................................................92

9.4: Operation Mode Behavior ...............................................................................................................................................................................93

9.5: Panel Operating Modes....................................................................................................................................................................................94

9.5.1: Multi-Site Annunciator and Multi-Site User Access............................................................................................................................96

9.6: Releasing Operations.......................................................................................................................................................................................96

9.6.1: Single Interlock Zone Releasing...........................................................................................................................................................97

9.6.2: Double Interlock Zone Releasing.........................................................................................................................................................97

9.7: Smoke Alarm Verification ...............................................................................................................................................................................98

9.8: Function Keys.................................................................................................................................................................................................98

9.8.1: Recording an F-Key Macro ..................................................................................................................................................................98

9.8.2: Aborting an F-Key Macro Recording Session......................................................................................................................................98

9.8.3: Erasing an F-Key Macro.......................................................................................................................................................................98

9.8.4: Using a Recorded F-Key Macro...........................................................................................................................................................99

8FCP-75 Manual — P/N LS10147-003FK-E:B 6/20/2022

Table of Contents

9.8.5: F-Key Status Event...............................................................................................................................................................................99

9.8.6: F-Key Map Inhibit................................................................................................................................................................................99

Section 10: Reporting ................................................................................................................................................... 100

10.1: Receivers Compatible with the Control Panel.............................................................................................................................................100

10.2: SIA / FCP-75 Panels PI Modifier Reporting ...............................................................................................................................................109

10.3: SIA– FCP-75 Panel Communicator.............................................................................................................................................................110

Section 11: Testing and Troubleshooting................................................................................................................... 111

11.1: Troubleshooting ...........................................................................................................................................................................................111

11.2: Troubleshooting Common Problems ...........................................................................................................................................................111

11.2.1: Periodic Testing And Maintenance ..................................................................................................................................................111

11.2.2: Event History....................................................................................................................................................................................112

11.3: Built-in Troubleshooting and Testing Tools.................................................................................................................................................112

11.3.1: SLC Device Locater .........................................................................................................................................................................112

11.3.2: SLC Multi Locater............................................................................................................................................................................112

11.3.3: I/O Point Control ..............................................................................................................................................................................113

11.4: Earth Fault Resistance..................................................................................................................................................................................113

Section 12: Installation Records.................................................................................................................................. 114

12.1: SLC Device Point Record............................................................................................................................................................................114

Appendix A: Editing Text Using the Built-In Programmer......................................................................................... 115

A.1: Characters Used for Editing Text..................................................................................................................................................................115

A.2: Edit Name Example......................................................................................................................................................................................115

Appendix B: Expanded Receiver/Panel Relationship................................................................................................ 116

Appendix C: Cadence Patterns....................................................................................................................................117

Appendix D: Panel Security.......................................................................................................................................... 118

Model FCP-75 Basic Operating Instructions............................................................................................................... 119

FCP-75 Manual — P/N LS10147-003FK-E:B 6/20/2022 9

Section 1: Introduction

The FCP-75 Fire Alarm Control / Communicator is an Addressable Fire Alarm Control System that meets the requirements of UL 864

10th Edition Standard.

1.1 Basic System Overview

1.1.1 Hardware Features

• The FCP-75 has one built in signaling line circuit (SLC) that supports 75 detectors and 75 modules.

• The FCP-75 is capable of outputting 2.5A of output power during an alarm activation through 2 sets of terminals for the notification

appliance circuits or an auxiliary application. Each circuit is power-limited and can source up to 2.5A during an alarm activation. The

constant auxiliary power load must not exceed 1A for normal standby.

• Built-in dual phone line, digital alarm communicator/transmitter (DACT), or IP technologies.

•Reports events to central station by point or by zone.

•UL Listed for pre-action and deluge releasing systems.

•Two general purpose Form C programmable relays.

•One FormC Trouble Relay.

•Basic system operation can be performed from the onboard, or any remote annunciator.

• Up to 20 user profiles can be programmed, each having custom Access Code, and Main Menu items.

•Can be used with any combination of up to 8 Model FIK-RA100, FIK-RA1000R, or FIK-RA2000 Remote LCD Annunciators (sold

separately).

•Can be used with Model FIK-5865-3, FIK-5865-4, and FIK-5880 in any combination for a total of eight devices on one control panel.

See Figure 4.34 and Figure 4.30 for additional information on these models.

•Printing of event log available through the Model FIK-5824 serial/parallel printer interface module.

•125 software zones, 125 Output Groups.

•Add four Notification/Auxiliary power circuits with each FIK-5496 NAC Expander. See note below.

1.1.2 Network System Hardware Features

• The default network setup can contain up to 32- FCP-75 panels connected.

• Network support for up to 32 Sites.

• Each building is referred to as a “site”.

• Panels can be interconnected using CLASS B or CLASS A topology.

• Use the FIK-NIC Network Interface Card to create a network. Copper wire or fiber-optic cable panel connectivity can be used within

the same networked System.

• The network architecture provides true peer-to-peer capability allowing network survivability for all hardware that remains operational

in the event of partial system failure.

1.1.3 Software Features

• Advanced smoke detector features:

– Automatic drift compensation

– Maintenance alert region

– Point status meets calibrated smoke test requirements for NFPA 72

• “JumpStart” feature for easy programming

• Non-volatile event history stores 1000 events

• A choice of output patterns available for notification outputs, including Temp 4 along with ANSI 3.41 temporal signal

• Built-in synchronization appliance support forAMSECO, Gentex, Wheelock, or System Sensor

NOTE: Total output power for both circuits must not exceed 2.5A in alarm condition, and total output power for both circuits must not exceed

1.0A for all other activation conditions (i.e. Supervisory, Trouble, etc.).

NOTE: The system can support a maximum of eight intelligent power modules, either the FIK-RPS1000 or FIK-5496, in any combination.

10 FCP-75 Manual — P/N LS10147-003FK-E:B 6/20/2022

Introduction About this Manual

1.2 About this Manual

This manual is intended to be a complete reference for all installation and operation tasks for the FCP-75.

1.2.1 Terms Used in this Manual

The following terminology is used with the FCP-75 system:

1.3 Compatible Products

The chart below lists the products available for use with the FCP-75.

Term Description

SLC Signaling Line Circuit

Module The term module is used for all hardware devices except for SLC addressable devices and notification

appliances. This includes the FCP-75 panel itself.

Input Point An addressable sensing device, such as a smoke or heat detector or a contact monitor device.

Input Zone A protected area made up of input points.

Output Point (or Output Circuit) Anotification point or circuit for notification appliances. Relay circuits and auxiliary power circuits are also

considered output points.

Group (or “Output Group”) A group of output points. Operating characteristics are common to all output points in the group.

Output (or “Cadence”) Pattern The pattern that the output will use, for example, Constant, March Code, ANSI 3.41. Applies to zones

and special system events. See Appendix D for additional information.

Mapping Mapping is the process of specifying which outputs are activated when certain events occur in the

system. Figure 7.2 describes mapping in detail.

Network System Consists of any combination of 32 panels of these model numbers: FCP-75, FCP-300, FCP-300ECS,

FCP-2100, or FCP-2100ECS.

SWIFT Smart Wireless Integrated Fire Technology

Table 1.1 Manual Terminology

Type of Device Model Description

Fike Addressable SLC

Devices For a list of compatible devices, refer to the SLC Wiring Manual, P/N: LS10179-000FK-E.

SWIFT Wireless SLC Devices For a list of compatible devices, refer to the SWIFT Manual, P/N: LS10036-000FK-E.

Other Modules FIK-5824Serial/Parallel

Printer Interface Module Allows a printer to be attached for the on-site event logging. Maximum of four FIK-5824s per

control panel.

FIK-RPS1000 Power

Supply Provides additional power, six Flexput circuits, and two Form C relays. Max 8 per system. See

FIK-RPS1000 Installation Manual (PN LS10259-001FK-E) for more information.

FIK-5496 NAC

Expander Provides 4 additional Notification Appliance Circuits/Auxiliary power. (Up to 8 per FCP-75

System).

FIK-RA100 and FIK-

RA1000R LCD

Annunciator

4 x20 Remote LCD annunciator. Can be used in any combination, up to a total of 8 devices on

one panel.

FIK-RA2000LCD

Annunciator 4 x 40 Remote LCD annunciator can be used in any combination, up to a total of 8 devices on

one panel.

FIK-5865-3 and

FIK-5865-4 LED

Annunciator

LED annunciator can display up to 30 LEDs (15 red and 15 yellow). FIK-5865-4 has key

switches for silence and reset, and a system trouble LED. FIK-5865-3, FIK-5865-4, and FIK-

5880 can be used in any combination, up to a total of eight devices on one panel.

RA-100TR Trim Ring Trim ring kit for surface mounting the FIK-RA2000/FIK-RA100 annunciators.

5860TR Trim Ring Trim ring kits for surface mounting the FIK-RA1000R annunciator.

FIK-5880 LED Driver

Module Driver for up to 40 LEDs. Interfaces with customized annunciator boards. In addition the FIK-

5880 has eight generic switch input points.

FIK-5883 General

Purpose Relay Module Provides 10 Form C relays. Designed to be driven by the FIK-5880. Up to four, FIK-5883s can

be used with each FIK-5880 module.

FIK-NIC Network Interface Card

FIK-FML Fiber-Optic Multi Mode

FIK-FSL Fiber-Optic Single Mode

Table 1.2 FCP-75 Compatible Products

FCP-75 Manual — P/N LS10147-003FK-E:B 6/20/2022 11

Related Documentation Introduction

1.4 Related Documentation

Refer to the following documents for more information.

Wireless FIK-W-WGI Wireless Gateway

FIK-W-PHOTO Wireless Photoelectric Smoke Detector

FIK-W-ACCLIMATE Wireless Multi-criteria Smoke Detector

FIK-W-HEAT-ROR Wireless ROR Heat Detector

FIK-W-HEAT Wireless Fixed Heat (135°F) Detector

FIK-W-MONITOR Wireless Addressable Monitor Module

FIK-W-RELAY Wireless Addressable Relay Module

B210W 6" wireless base

Miscellaneous HFSS Programming

Tool For communication and panel programming with a Windows-based computer. Enables

remote viewing of detector status and event history.

7860 Telephone Cord RJ31X cord for connecting phone line to the FCP-75.

7628 UL Listed End-of-line resistor

Type of Device Model Description

Table 1.2 FCP-75 Compatible Products (Continued)

Title Document Number

SLC Wiring Manual LS10179-000FK-E

Device Compatibility Document LS10167-005FK-E

FIK-5824 Printer Interface Module Install Sheet LS10254-002FK-E

FIK-RPS1000 Power Supply Manual LS10259-001FK-E

FIK-5496 NAC Expander Manual LS10253-001FK-E

FIK-RA100 Annunciator Install Sheet LS10260-001FK-E

FIK-RA1000R LCD Annunciator Install Sheet LS10258-001FK-E

FIK-RA2000 LCD Annunciator LS10261-001FK-E

FIK-5865-3 and FIK-5865-4 LED Annunciator LS10255-001FK-E

FIK-5880 LED Driver Module LS10256-001FK-E

FIK-5883 General Purpose Relay Module LS10257-001FK-E

FIK-NIC LS10172-002FK-E

FIK-FML/FSL LS10178-002FK-E

MRD-1 Releasing Disconnect LS10231-000GE-E

Table 1.3 Related Documentation

12 FCP-75 Manual — P/N LS10147-003FK-E:B 6/20/2022

Section 2: Agency Listings, Approvals, and Requirements

Install and maintain this panel in accordance with NFPA72. Detector spacing shall be done in accordance to NFPA 72. End-of -line relays

and resistors shall be placed within the electrical box located at the end of the initiating circuit. Testing and maintenance should be performed

in compliance with NFPA72.

2.1 Federal Communications Commission (FCC)

The following information must be provided to the Telephone Company before the FCP-75can be connected to the phone lines:

1. This device may not be directly connected to the coin telephone or party line services.

2. This device cannot be adjusted or repaired in the field. In case of trouble with the device, notify the installing company or return to:

Fike Corporation

704 SW 10th Street

Blue Springs, MO 61015

1+816-229-3405

3. If the FCP-75 causes harm to the telephone network, the Telephone Company will notify the user in advance that temporary

discontinuance of service may be required. If advance notice is not practical, the Telephone Company will notify the user as soon as

possible. Users have the right to file complaints, if necessary, with the Federal Communications Commission.

4. The Telephone Company may make changes in its facilities, equipment, operations, or procedures that could affect the operation of the

equipment. If this happens, the Telephone Company will provide advance notice to allow you to make the necessary modifications to

maintain uninterrupted service.

5. This equipment complies with Part 68 of the FCC rules and the requirements adopted by theACTA. On the wiring diagram of this

equipment is a label that contains, among other information, a product identifier in the format US: HS9AL10A2100. If requested, this

number must be provided to the Telephone Company.

6. See the manual for phone jack information.

7. A plug and jack used to connect this equipment to the premises wiring and telephone network must comply with the applicable FCC

Part 68 rules and requirements adopted by the ACTA. A compliant telephone cord and modular plug is provided with this product. It is

designed to be connected to a compatible modular jack that is also compliant. See installation instructions for details.

8. The REN (Ringer Equivalence Number) provided on this installation sheet is used to determine the number of devices that may be

connected to the public switched telephone network. This number must not exceed 5.0. Since this product has an REN of 1.0A, the

number of devices is limited. The REN number is embedded in the FCC registration number as 10A.

9. If this equipment FCP-75 causes harm to the telephone network, the Telephone Company will notify you in advance that temporary

discontinuance of service may be required. But if advance notice isn't practical, the Telephone Company will notify the customer as

soon as possible. Also, you will be advised of your right to file a complaint with the FCC if you believe it is necessary.

10. The Telephone Company may make changes in its facilities, equipment, operations or procedures that could affect the operation of the

equipment. If this happens the Telephone Company will provide advance notice in order for you to make necessary modifications to

maintain uninterrupted service.

11. If trouble is experienced with the FCP-75, for repair or warranty information, please contact Technical Support at (800)979-3453 or

www.fike.com. If the equipment is causing harm to the telephone network, the Telephone Company may request that you disconnect the

FCP-75 until the problem has been resolved.

12. See the Manufacturer’s Warranty for repair and replacement information.

13. Connection to party line service is subject to state tariffs. Contact the state public utility commission, public service commission or

corporation commission for information.

14. If your facility has specially wired alarm equipment connected to the telephone line, ensure the installation of this FCP-75 does not

disable your alarm equipment. If you have questions about what will disable alarm equipment, consult your Telephone Company or

qualified installer.

2.1.1 Electrical Safety Advisory

Parties responsible for equipment requiring AC power should consider including an advisory notice in their customer information, suggest-

ing the customer use a surge arrestor. Telephone Companies report that electrical surges, typically lightning transients, are very destructive to

customer terminal equipment connected to AC power sources. This has been identified as a major nationwide problem.

Manufacturer: Fike

Model Number: -75FCP-75

FCC registration number: US: HS9AL10A2100

Ringer equivalence: 1.0A

Type of jack: RJ31X

Facility Interface Codes: Loop Start: 02LS2

Service Order Code: 9.0F

!

WARNING: FCC RULES PART 15

THIS DEVICE HAS BEEN VERIFIED TO COMPLY WITH FCC RULES PART 15. OPERATION IS SUBJECT TO THE

FOLLOWING CONDITIONS: (1) THIS DEVICE MAY NOT CAUSE RADIO INTERFERENCE,AND (2) THIS DEVICE MUST

ACCEPTANY INTERFERENCE RECEIVED, INCLUDING INTERFERENCE THAT MAY CAUSE UNDESIRED OPERATION.

FCP-75 Manual — P/N LS10147-003FK-E:B 6/20/2022 13

Underwriters Laboratories (UL) Agency Listings, Approvals, and Requirements

2.2 Underwriters Laboratories (UL)

2.2.1 Requirements for All Installations

General requirements are described in this section. When installing an individual device, refer to the specific section of the manual for addi-

tional requirements. The following subsections list specific requirements for each type of installation (for example, Central Station Fire

Alarm Systems, Local Protected Fire Alarm Systems, and so on). See Section 9.6 for information on releasing operation.

1. All field wiring must be installed in accordance with the NFPA 70 National Electric Code.

2. Use addressable smoke detectors specified in the SLC Wiring Manual, P/N: LS10179-000FK-E.

3. Use UL listed notification appliances compatible with the FCP-75 from those specified in the Device Compatibility Document, P/N:

LS10167-005FK-E.

4. A full System checkout must be performed any time the panel is programmed.

Restricted Options

• The loss ofAC signal is defaulted to 3 hours. However, the System allows settings from 0 - 30 hours. For UL-certified installations, this

number must be set from 1 to 3 hours.

• The system allows the use of non-latching spot type smoke detectors.This feature may not be used in commercial applications whereby

a general alarm is sounded. It is intended for elevator recall, door holding applications, and hotel/motel room applications.

• The system allows the Alarm Verification time to be set from 60 to 250 seconds. For UL-certified installations, the setting must be a

maximum of 60 seconds.

• The system allows the Auto-resound time to be set to 4 or 24 hours. For UL certified installations that are using SWIFT devices, the

value must be set to 4 hours.

• Call forwarding shall not be used.

• When two-count is used, detector spacing shall be cut in half, you shall not use the alarm verification feature, and no delay shall be

used.

• P.A.S (Positive Alarm Sequence) feature shall be used only with automatic detectors.

2.2.2 UL 864 9th and 10th Edition

• Per the UL Continuing Certification Program, UL 864 9th edition fire alarm control equipment will retain certification after the rollout

of UL 10th edition (12/2/2018).

• Installations of UL 864 10th Edition certified equipment are permitted to use UL864 9th Edition certified equipment when approved by

the local Authority Having Jurisdiction (AHJ).

For product compliance, refer to the UL/ULC listing cards located on the UL online certification directory. https://iq.ulprospector.com

2.2.3 Requirements for Central Station Fire Alarm Systems

1. Use both phone lines. Enable phone line monitors for both lines.

2. You must program a phone number and a test time so that the FCP-75 shall automatically initiate and complete a test signal

transmission sequence to its associated receiver at least once every 6-hours, using two phones or one phone line with Ethernet backup.

The AC Loss Hours option must be set from 1-3 hours.

3. If you use wired Ethernet or cellular, you must program the correspondingAccount/Subscriber ID and a test time so that the FACP shall

automatically initiate a test signal transmission sequence to its associated receiver at least once every 6-hours.

The automatic 6-hour test signal transmission only applies if secondary communication paths are used. If no secondary communication

paths are used, the FACP shall automatically initiate a test signal transmission sequence to its associated receiver at least once every 60

minutes.

2.2.4 Requirements for Local Protected Fire Alarm Systems

At least one UL listed supervised notification appliance must be used.

2.2.5 Requirements for Remote Station Protected Fire Alarm Systems

1. Do not exceed the current load restrictions shown in Section 3.5.

2. The AC Loss Hours option must be set from 1-3 hours.

!

CAUTION: INSTALLATION AND TEST

TO ENSURE PROPER OPERATION, THIS EQUIPMENT MUST BE INSTALLED ACCORDING TO THE ENCLOSED

INSTALLATION INSTRUCTIONS. TO VERIFY THAT THE EQUIPMENT IS OPERATING PROPERLYAND CAN

SUCCESSFULLY REPORTAN ALARM, THIS EQUIPMENT MUST BE TESTED IMMEDIATELY AFTER INSTALLATION,

AND PERIODICALLY THEREAFTER, ACCORDING TO THE ENCLOSED TEST INSTRUCTIONS.

!

CAUTION: LINE IN USE

IN ORDER FOR “ALARM DIALING EQUIPMENT” TO BE ABLE TO SEIZE THE PHONE LINE TO REPORTAN ALARM OR

OTHER EVENT WHEN OTHER CUSTOMER EQUIPMENT (TELEPHONE,ANSWERING SYSTEM, COMPUTER MODEM,

ETC.) CONNECTED TO THE SAME LINE IS IN USE, “ALARM DIALING EQUIPMENT” MUST BE CONNECTED TO A

PROPERLY INSTALLED RJ31X JACK. THE RJ31X JACK MUST BE CONNECTED IN SERIES WITH, AND AHEAD OF,ALL

OTHER EQUIPMENTATTACHED TO THE SAME PHONE LINE. SERIES INSTALLATION OF AN RJ31X JACK IS DEPICTED

IN THE FIGURE BELOW. IF YOU HAVE ANY QUESTIONS CONCERNING THESE INSTRUCTIONS, CONSULT YOUR

TELEPHONE COMPANY OR A QUALIFIED INSTALLER ABOUT INSTALLING THE NECESSARY JACK AND ALARM

DIALING EQUIPMENT.

14 FCP-75 Manual — P/N LS10147-003FK-E:B 6/20/2022

Agency Listings, Approvals, and Requirements Underwriters Laboratories (UL)

2.2.6 Requirements for the Installation of Carbon Monoxide (CO) Detection and Warning

Equipment, NFPA 720

When using carbon monoxide detection the system must be monitored by a Supervising Station with emergency response, both aspects meet-

ing the Standard for the Installation of Carbon Monoxide (CO) Detection and Warning Equipment, NFPA 720.

2.2.7 NFPA Requirements

The following is the minimum configuration necessary to comply with the NFPA requirements.

Model/Module Description Local Releasing Remote

Station Auxiliary Central

Station Emergency

Signaling

FCP-75 Control Unit Y Y Y Y Y Y

5220 Direct Connect Module N N N Y N O

FIK-5496 NAC Expander O Y* O O O O